Microfluidics-Enabled Cooling Systems: Efficiency and Performance

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Cooling Technology Background and Objectives

Microfluidic cooling technology has emerged as a revolutionary approach to thermal management, evolving from traditional macro-scale cooling systems to sophisticated micro-scale solutions. The development trajectory began in the late 1990s with fundamental research on fluid behavior at microscale levels, progressing through significant advancements in fabrication techniques and materials science during the 2000s. This evolution has been driven by the exponential increase in power densities in electronic components, particularly in high-performance computing, data centers, and advanced semiconductor applications.

The fundamental principle of microfluidic cooling leverages the enhanced heat transfer capabilities achieved through microscale channels, typically ranging from 10 to 500 micrometers in diameter. At this scale, fluid dynamics exhibit unique properties that facilitate more efficient thermal exchange compared to conventional cooling methods. The high surface-area-to-volume ratio characteristic of microfluidic systems enables superior heat dissipation rates while requiring significantly less coolant volume and pumping power.

Current technological trends indicate a convergence toward integrated cooling solutions, where microfluidic channels are directly embedded within electronic components rather than attached as separate modules. This integration trend represents a paradigm shift from traditional cooling approaches, promising to address thermal challenges at their source while minimizing system complexity and spatial requirements.

The primary objective of microfluidic cooling technology development is to achieve thermal management solutions capable of dissipating heat loads exceeding 500 W/cm² while maintaining junction temperatures below critical thresholds. Secondary goals include reducing the energy consumption associated with cooling systems, minimizing the physical footprint of thermal management infrastructure, and extending the operational lifespan of electronic components through more consistent temperature control.

Industry projections suggest that next-generation computing systems, particularly those employing 3D chip stacking and heterogeneous integration, will require cooling solutions capable of managing heat fluxes approaching 1 kW/cm² by 2030. This represents a critical technological challenge that conventional air cooling and even traditional liquid cooling systems cannot adequately address, creating a compelling innovation opportunity for microfluidic approaches.

The evolution of microfluidic cooling technology has been characterized by interdisciplinary collaboration, combining advances in fluid dynamics, materials science, microfabrication, and thermal engineering. Recent breakthroughs in two-phase cooling within microchannels have demonstrated potential cooling capacities exceeding 1000 W/cm², highlighting the transformative potential of this technology for next-generation thermal management solutions.

The fundamental principle of microfluidic cooling leverages the enhanced heat transfer capabilities achieved through microscale channels, typically ranging from 10 to 500 micrometers in diameter. At this scale, fluid dynamics exhibit unique properties that facilitate more efficient thermal exchange compared to conventional cooling methods. The high surface-area-to-volume ratio characteristic of microfluidic systems enables superior heat dissipation rates while requiring significantly less coolant volume and pumping power.

Current technological trends indicate a convergence toward integrated cooling solutions, where microfluidic channels are directly embedded within electronic components rather than attached as separate modules. This integration trend represents a paradigm shift from traditional cooling approaches, promising to address thermal challenges at their source while minimizing system complexity and spatial requirements.

The primary objective of microfluidic cooling technology development is to achieve thermal management solutions capable of dissipating heat loads exceeding 500 W/cm² while maintaining junction temperatures below critical thresholds. Secondary goals include reducing the energy consumption associated with cooling systems, minimizing the physical footprint of thermal management infrastructure, and extending the operational lifespan of electronic components through more consistent temperature control.

Industry projections suggest that next-generation computing systems, particularly those employing 3D chip stacking and heterogeneous integration, will require cooling solutions capable of managing heat fluxes approaching 1 kW/cm² by 2030. This represents a critical technological challenge that conventional air cooling and even traditional liquid cooling systems cannot adequately address, creating a compelling innovation opportunity for microfluidic approaches.

The evolution of microfluidic cooling technology has been characterized by interdisciplinary collaboration, combining advances in fluid dynamics, materials science, microfabrication, and thermal engineering. Recent breakthroughs in two-phase cooling within microchannels have demonstrated potential cooling capacities exceeding 1000 W/cm², highlighting the transformative potential of this technology for next-generation thermal management solutions.

Market Demand Analysis for Advanced Thermal Management Solutions

The global market for advanced thermal management solutions is experiencing unprecedented growth, driven primarily by the increasing power densities in electronic devices and systems. With the continuous miniaturization of electronic components and the simultaneous increase in computational power, traditional cooling methods are reaching their physical limitations. This technological bottleneck has created a substantial market demand for innovative cooling solutions, particularly microfluidics-enabled systems that offer superior thermal performance.

Data centers represent one of the largest market segments demanding advanced cooling technologies. With global data center electricity consumption projected to reach 1,000 TWh by 2025, the need for energy-efficient cooling solutions has become critical. Microfluidic cooling systems, which can reduce cooling energy consumption by up to 40% compared to conventional air cooling, are positioned to capture significant market share in this sector.

The consumer electronics industry presents another substantial market opportunity. As smartphones, tablets, and laptops continue to pack more processing power into thinner form factors, thermal management has become a key design constraint. Market research indicates that over 70% of smartphone users consider device overheating a significant concern, creating a direct consumer demand for devices with superior thermal management capabilities.

Automotive electronics, particularly in electric vehicles (EVs) and autonomous driving systems, constitute a rapidly expanding market segment. The EV battery thermal management system market alone is growing at a compound annual growth rate of 22.6%, with microfluidic cooling solutions increasingly being adopted for their precision and efficiency in maintaining optimal battery temperatures.

High-performance computing and artificial intelligence applications represent another critical market driver. These systems generate extreme heat loads that conventional cooling technologies struggle to dissipate effectively. The demand for microfluidics-enabled cooling in this segment is projected to grow substantially as AI deployment accelerates across industries.

Healthcare and biomedical devices form an emerging market segment where precise temperature control is often crucial for diagnostic accuracy and treatment efficacy. Microfluidic cooling systems that offer precise thermal regulation are gaining traction in applications such as PCR devices, point-of-care diagnostics, and medical imaging equipment.

Industrial applications, including power electronics, laser systems, and advanced manufacturing equipment, also demonstrate significant demand for microfluidics-enabled cooling solutions. These applications benefit from the enhanced thermal performance and reduced system footprint that microfluidic cooling technologies provide.

Data centers represent one of the largest market segments demanding advanced cooling technologies. With global data center electricity consumption projected to reach 1,000 TWh by 2025, the need for energy-efficient cooling solutions has become critical. Microfluidic cooling systems, which can reduce cooling energy consumption by up to 40% compared to conventional air cooling, are positioned to capture significant market share in this sector.

The consumer electronics industry presents another substantial market opportunity. As smartphones, tablets, and laptops continue to pack more processing power into thinner form factors, thermal management has become a key design constraint. Market research indicates that over 70% of smartphone users consider device overheating a significant concern, creating a direct consumer demand for devices with superior thermal management capabilities.

Automotive electronics, particularly in electric vehicles (EVs) and autonomous driving systems, constitute a rapidly expanding market segment. The EV battery thermal management system market alone is growing at a compound annual growth rate of 22.6%, with microfluidic cooling solutions increasingly being adopted for their precision and efficiency in maintaining optimal battery temperatures.

High-performance computing and artificial intelligence applications represent another critical market driver. These systems generate extreme heat loads that conventional cooling technologies struggle to dissipate effectively. The demand for microfluidics-enabled cooling in this segment is projected to grow substantially as AI deployment accelerates across industries.

Healthcare and biomedical devices form an emerging market segment where precise temperature control is often crucial for diagnostic accuracy and treatment efficacy. Microfluidic cooling systems that offer precise thermal regulation are gaining traction in applications such as PCR devices, point-of-care diagnostics, and medical imaging equipment.

Industrial applications, including power electronics, laser systems, and advanced manufacturing equipment, also demonstrate significant demand for microfluidics-enabled cooling solutions. These applications benefit from the enhanced thermal performance and reduced system footprint that microfluidic cooling technologies provide.

Current State and Challenges in Microfluidic Cooling Systems

Microfluidic cooling systems have emerged as a promising solution to address the thermal management challenges in high-performance electronic devices. Currently, these systems are being developed and implemented across various sectors including data centers, consumer electronics, aerospace, and automotive industries. The global adoption of microfluidic cooling technology remains in its early to middle stages, with significant research activities concentrated in North America, Europe, and East Asia.

The fundamental working principle of microfluidic cooling involves the circulation of coolants through microscale channels to efficiently remove heat from electronic components. Current implementations typically utilize channel dimensions ranging from 10 to 500 micrometers, with various geometrical configurations including straight channels, serpentine structures, and tree-like branching networks. The most commonly employed coolants include deionized water, dielectric fluids, nanofluids, and phase-change materials.

Despite promising advancements, microfluidic cooling systems face several critical challenges. Fabrication complexity represents a significant hurdle, as manufacturing precise microchannels with consistent dimensions requires sophisticated techniques such as photolithography, etching, and micro-machining. These processes often involve high costs and specialized equipment, limiting widespread commercial adoption.

Integration challenges also persist, particularly regarding the interface between microfluidic cooling systems and electronic components. Creating reliable fluidic connections, preventing leakage, and ensuring uniform thermal contact remain problematic. Additionally, the long-term reliability of these systems is concerning due to potential issues like channel clogging, corrosion, and material degradation under thermal cycling conditions.

Performance optimization presents another challenge, as achieving uniform cooling across large chip areas with varying heat generation rates requires complex flow distribution designs. The trade-off between pressure drop and thermal performance necessitates careful engineering of channel geometries and flow parameters.

From a geographical perspective, research leadership in microfluidic cooling is distributed across several regions. The United States leads in fundamental research and patent filings, with significant contributions from institutions like Stanford University, MIT, and companies such as IBM and Intel. European research centers in Switzerland, Germany, and the Netherlands focus on novel materials and fabrication techniques. Meanwhile, East Asian countries, particularly Japan, South Korea, and China, are rapidly advancing in commercialization efforts and manufacturing innovations.

The economic barriers to widespread adoption include high initial costs, complex manufacturing requirements, and the need for specialized expertise in system design and maintenance. These factors currently limit microfluidic cooling systems to high-value applications where conventional cooling methods are inadequate.

The fundamental working principle of microfluidic cooling involves the circulation of coolants through microscale channels to efficiently remove heat from electronic components. Current implementations typically utilize channel dimensions ranging from 10 to 500 micrometers, with various geometrical configurations including straight channels, serpentine structures, and tree-like branching networks. The most commonly employed coolants include deionized water, dielectric fluids, nanofluids, and phase-change materials.

Despite promising advancements, microfluidic cooling systems face several critical challenges. Fabrication complexity represents a significant hurdle, as manufacturing precise microchannels with consistent dimensions requires sophisticated techniques such as photolithography, etching, and micro-machining. These processes often involve high costs and specialized equipment, limiting widespread commercial adoption.

Integration challenges also persist, particularly regarding the interface between microfluidic cooling systems and electronic components. Creating reliable fluidic connections, preventing leakage, and ensuring uniform thermal contact remain problematic. Additionally, the long-term reliability of these systems is concerning due to potential issues like channel clogging, corrosion, and material degradation under thermal cycling conditions.

Performance optimization presents another challenge, as achieving uniform cooling across large chip areas with varying heat generation rates requires complex flow distribution designs. The trade-off between pressure drop and thermal performance necessitates careful engineering of channel geometries and flow parameters.

From a geographical perspective, research leadership in microfluidic cooling is distributed across several regions. The United States leads in fundamental research and patent filings, with significant contributions from institutions like Stanford University, MIT, and companies such as IBM and Intel. European research centers in Switzerland, Germany, and the Netherlands focus on novel materials and fabrication techniques. Meanwhile, East Asian countries, particularly Japan, South Korea, and China, are rapidly advancing in commercialization efforts and manufacturing innovations.

The economic barriers to widespread adoption include high initial costs, complex manufacturing requirements, and the need for specialized expertise in system design and maintenance. These factors currently limit microfluidic cooling systems to high-value applications where conventional cooling methods are inadequate.

Current Technical Solutions for Microfluidic-Based Cooling

01 Microfluidic channel design optimization for cooling efficiency

Optimized design of microfluidic channels can significantly enhance cooling system performance. This includes specific geometries, dimensions, and flow patterns that maximize heat transfer while minimizing pressure drop. Advanced channel designs incorporate features such as varying cross-sections, engineered surface textures, and strategic flow distributors to ensure uniform cooling across heat-generating components. These design optimizations enable more efficient thermal management in compact electronic systems.- Microfluidic channel design for enhanced heat transfer: Advanced microfluidic channel designs can significantly improve cooling system efficiency. These designs include optimized geometries, flow patterns, and surface treatments that maximize heat transfer rates while minimizing pressure drops. By engineering precise microchannels with specific dimensions and configurations, cooling systems can achieve higher thermal performance with lower pumping power requirements. These innovations enable more efficient heat dissipation in compact electronic devices and high-performance computing systems.

- Intelligent control systems for microfluidic cooling: Smart control algorithms and feedback mechanisms optimize the operation of microfluidics-enabled cooling systems. These intelligent systems continuously monitor temperature distributions, flow rates, and heat loads to dynamically adjust cooling parameters. By implementing predictive models and machine learning techniques, these control systems can anticipate thermal demands and proactively manage cooling resources. This approach results in improved energy efficiency, more stable operating temperatures, and enhanced overall system reliability.

- Integration of phase-change materials in microfluidic cooling: Incorporating phase-change materials within microfluidic cooling systems leverages latent heat absorption for improved thermal management. These systems utilize the high energy absorption during phase transitions to efficiently remove heat from critical components. By carefully selecting phase-change materials with appropriate transition temperatures and combining them with microfluidic delivery systems, cooling performance can be significantly enhanced. This approach is particularly effective for managing transient thermal loads and temperature spikes in high-performance electronics.

- 3D microfluidic architectures for volumetric cooling: Three-dimensional microfluidic networks enable volumetric cooling capabilities that surpass traditional planar cooling approaches. These architectures feature complex, multi-level channel networks that can penetrate deeper into electronic packages and provide cooling closer to heat sources. By utilizing advanced manufacturing techniques such as 3D printing and multi-layer fabrication, these systems can create intricate cooling structures with optimized flow distribution. This volumetric approach results in more uniform temperature profiles and higher overall cooling capacity.

- Energy-efficient pumping and flow distribution systems: Innovative pumping mechanisms and flow distribution techniques enhance the energy efficiency of microfluidic cooling systems. These developments include micropumps with reduced power consumption, passive flow distribution networks that minimize pressure losses, and self-regulating flow systems that adapt to varying thermal loads. By optimizing the fluid delivery aspects of microfluidic cooling, these systems can achieve higher cooling performance with lower energy input, making them particularly valuable for battery-powered devices and energy-conscious applications.

02 Integration of microfluidic cooling with electronic systems

Microfluidic cooling systems can be directly integrated with electronic components to provide targeted thermal management. This integration allows for cooling solutions that are customized to specific heat generation patterns of electronic devices. The close proximity between the cooling channels and heat sources minimizes thermal resistance and enables more efficient heat dissipation. These integrated systems can be particularly beneficial for high-performance computing, data centers, and other applications with significant heat generation challenges.Expand Specific Solutions03 Advanced coolant formulations and flow control

The efficiency of microfluidic cooling systems can be enhanced through specialized coolant formulations and precise flow control mechanisms. These may include nanofluids with improved thermal conductivity, phase-change materials that absorb heat during state transitions, or engineered fluids with optimized viscosity and heat capacity. Additionally, adaptive flow control systems can adjust coolant distribution based on real-time thermal demands, ensuring efficient operation across varying workloads and environmental conditions.Expand Specific Solutions04 Intelligent thermal management systems

Microfluidic cooling systems can be enhanced with intelligent control algorithms and sensors that continuously monitor and adjust cooling parameters. These systems use predictive models to anticipate thermal loads and optimize coolant flow rates, temperatures, and distribution patterns accordingly. Machine learning approaches can identify patterns in thermal behavior and adapt cooling strategies for maximum efficiency. The integration of these intelligent controls with microfluidic hardware creates adaptive cooling solutions that balance performance and energy consumption.Expand Specific Solutions05 Energy-efficient microfluidic pumping mechanisms

Innovative pumping mechanisms for microfluidic cooling systems focus on energy efficiency while maintaining reliable coolant circulation. These include electrokinetic pumps, thermally-driven pumps that harvest waste heat, micropumps with optimized impeller designs, and piezoelectric actuators. By reducing the energy required for fluid circulation, these technologies improve the overall efficiency of cooling systems. Some designs eliminate mechanical moving parts entirely, increasing reliability and reducing maintenance requirements while ensuring consistent cooling performance.Expand Specific Solutions

Key Industry Players in Microfluidic Cooling Market

Microfluidics-enabled cooling systems are currently in an early growth phase, with the market expected to expand significantly due to increasing demand for efficient thermal management in electronics. The global market size is projected to reach approximately $2-3 billion by 2025, driven by data center cooling requirements and high-performance computing needs. Technologically, the field is advancing rapidly with companies at varying maturity levels. Intel, IBM, and GLOBALFOUNDRIES lead with established research programs and patent portfolios, while specialized players like EBULLIENT focus exclusively on microfluidic cooling solutions. Academic institutions including École Polytechnique Fédérale de Lausanne and Peking University contribute fundamental research, creating a competitive landscape balanced between established semiconductor giants and innovative startups developing next-generation cooling technologies for increasingly power-dense electronic systems.

EBULLIENT, LLC

Technical Solution: Ebullient has developed a two-phase direct-to-chip cooling technology that uses environmentally friendly refrigerants in a closed-loop system. Their solution pumps dielectric fluid directly to custom cold plates attached to hot components like CPUs and GPUs. As the fluid absorbs heat, it partially vaporizes (hence "two-phase"), carrying heat away through the phase change process. The vapor-liquid mixture then flows to a heat exchanger where it condenses back to liquid form before recirculation. This approach leverages the high heat transfer coefficients associated with boiling and condensation, enabling significantly higher heat flux removal compared to traditional air or single-phase liquid cooling systems. Ebullient's technology can handle heat loads exceeding 1000 W/cm², making it particularly suitable for high-performance computing environments with extreme thermal demands.

Strengths: Achieves exceptional cooling efficiency through phase-change heat transfer; handles very high heat fluxes; eliminates risk of electrical damage due to dielectric fluid use; reduces overall energy consumption compared to air cooling. Weaknesses: Requires specialized infrastructure; higher initial implementation costs; potential complexity in maintenance and servicing; limited flexibility for retrofitting existing systems.

Intel Corp.

Technical Solution: Intel has developed an advanced two-phase immersion cooling technology for high-performance computing applications. Their solution utilizes specially engineered dielectric fluids with optimized boiling points to enable efficient phase-change heat transfer directly from chip surfaces. Intel's approach incorporates precision-engineered microchannels and surface treatments that enhance nucleate boiling, the process where vapor bubbles form at specific sites on heated surfaces. These enhancements significantly improve heat transfer coefficients compared to conventional cooling methods. Intel's technology includes sophisticated fluid distribution systems that ensure uniform cooling across multiple chips in dense computing environments. Their research has demonstrated cooling capabilities exceeding 400 W/cm² with minimal temperature gradients across chip surfaces. Intel has also developed specialized packaging technologies that facilitate fluid delivery while maintaining electrical connections, addressing one of the key challenges in implementing microfluidic cooling at scale.

Strengths: Highly efficient thermal management suitable for next-generation high-power processors; enables higher clock speeds and computational density; reduces overall system energy consumption through elimination of conventional cooling infrastructure. Weaknesses: Requires specialized system design and infrastructure; potential challenges with long-term reliability and maintenance; higher initial implementation costs compared to traditional cooling solutions.

Core Patents and Innovations in Microfluidic Cooling

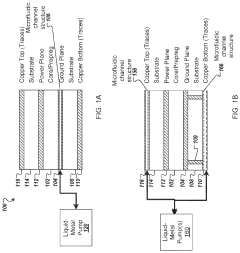

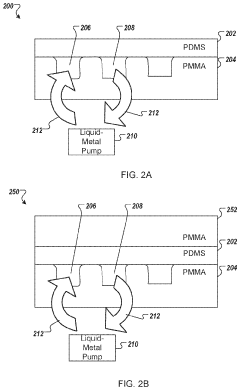

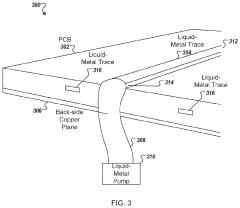

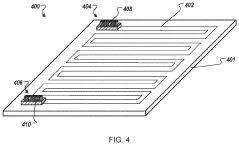

Microfluidic channels and pumps for active cooling of cables

PatentActiveUS20200135365A1

Innovation

- The implementation of microfluidic channels filled with liquid metal on circuit boards and cables, where a pump actively moves the liquid metal through these channels to enhance heat transfer and distribution, allowing for targeted cooling and reducing the need for oversized heatsinks.

Microfluidic channels and pumps for active cooling of circuit boards or cables

PatentWO2020091976A1

Innovation

- The implementation of microfluidic channels and pumps that use liquid metal to actively cool circuit boards and cables by pumping the liquid metal through microfluidic channels, allowing for targeted and efficient heat transfer, reducing the need for oversized heatsinks.

Integration Challenges with Existing Thermal Management Systems

The integration of microfluidics-enabled cooling systems with existing thermal management infrastructure presents significant challenges that require careful consideration. Traditional cooling systems in electronic devices, data centers, and industrial equipment typically rely on air cooling, heat pipes, or conventional liquid cooling approaches. Microfluidic cooling technologies, with their microscale channels and unique fluid dynamics, introduce compatibility issues when implemented alongside these established systems.

Physical integration constraints represent a primary challenge. Microfluidic cooling components often require precise fabrication tolerances and specialized materials that may not align with current manufacturing processes. The dimensional mismatch between microfluidic channels (typically measured in micrometers) and conventional cooling system components (measured in millimeters or centimeters) creates connection difficulties at interfaces, potentially leading to leakage points or flow restrictions.

Control system incompatibilities further complicate integration efforts. Existing thermal management systems typically employ temperature sensors and control algorithms designed for macro-scale cooling solutions with relatively slow response times. Microfluidic systems, characterized by rapid thermal responses and potentially complex flow behaviors, require more sophisticated sensing and control mechanisms. This disparity often necessitates the development of new control architectures or significant modifications to existing ones.

Pumping and pressure management represent another significant integration challenge. Microfluidic systems generally operate under different pressure regimes compared to conventional cooling systems. The microscale channels create higher flow resistance, requiring specialized micropumps or pressure regulation systems that may not be compatible with existing infrastructure. Additionally, the risk of channel clogging increases at the microscale, demanding more stringent filtration requirements than conventional systems typically provide.

Maintenance considerations also impact integration feasibility. Conventional cooling systems are designed with accessibility and serviceability in mind, whereas microfluidic cooling components may be permanently bonded or integrated in ways that complicate routine maintenance or replacement. This fundamental difference in design philosophy creates tensions between the need for reliable microfluidic operation and the practical requirements of system maintenance in real-world applications.

Material compatibility issues further complicate integration efforts. Microfluidic systems often utilize specialized polymers, glass, or silicon substrates that may have different thermal expansion coefficients or chemical compatibilities compared to metals and alloys commonly used in conventional cooling systems. These material differences can lead to mechanical stress, degradation, or failure at integration points when subjected to thermal cycling or long-term operation.

Physical integration constraints represent a primary challenge. Microfluidic cooling components often require precise fabrication tolerances and specialized materials that may not align with current manufacturing processes. The dimensional mismatch between microfluidic channels (typically measured in micrometers) and conventional cooling system components (measured in millimeters or centimeters) creates connection difficulties at interfaces, potentially leading to leakage points or flow restrictions.

Control system incompatibilities further complicate integration efforts. Existing thermal management systems typically employ temperature sensors and control algorithms designed for macro-scale cooling solutions with relatively slow response times. Microfluidic systems, characterized by rapid thermal responses and potentially complex flow behaviors, require more sophisticated sensing and control mechanisms. This disparity often necessitates the development of new control architectures or significant modifications to existing ones.

Pumping and pressure management represent another significant integration challenge. Microfluidic systems generally operate under different pressure regimes compared to conventional cooling systems. The microscale channels create higher flow resistance, requiring specialized micropumps or pressure regulation systems that may not be compatible with existing infrastructure. Additionally, the risk of channel clogging increases at the microscale, demanding more stringent filtration requirements than conventional systems typically provide.

Maintenance considerations also impact integration feasibility. Conventional cooling systems are designed with accessibility and serviceability in mind, whereas microfluidic cooling components may be permanently bonded or integrated in ways that complicate routine maintenance or replacement. This fundamental difference in design philosophy creates tensions between the need for reliable microfluidic operation and the practical requirements of system maintenance in real-world applications.

Material compatibility issues further complicate integration efforts. Microfluidic systems often utilize specialized polymers, glass, or silicon substrates that may have different thermal expansion coefficients or chemical compatibilities compared to metals and alloys commonly used in conventional cooling systems. These material differences can lead to mechanical stress, degradation, or failure at integration points when subjected to thermal cycling or long-term operation.

Environmental Impact and Sustainability of Microfluidic Cooling

The environmental impact of microfluidic cooling systems represents a significant advantage over conventional cooling technologies. These systems require substantially less coolant volume, often reducing fluid requirements by 90% compared to traditional methods. This dramatic reduction in material usage directly translates to lower resource extraction, manufacturing energy consumption, and end-of-life disposal concerns.

Energy efficiency constitutes another critical environmental benefit of microfluidic cooling. The precise thermal management capabilities of these systems enable them to operate with 30-40% less energy consumption than conventional cooling solutions. This efficiency stems from optimized heat transfer coefficients and reduced pumping power requirements due to the microscale channel designs that maximize surface-to-volume ratios.

The manufacturing processes for microfluidic cooling systems are increasingly adopting sustainable practices. Advanced fabrication techniques such as 3D printing and roll-to-roll processing have reduced production waste by approximately 25% compared to traditional manufacturing methods. Additionally, many manufacturers are transitioning to bio-based polymers and recyclable metals for device construction, further reducing environmental footprint.

Lifecycle assessment studies indicate that microfluidic cooling systems can achieve carbon footprint reductions of 35-50% over their operational lifetime when compared to conventional cooling technologies. This reduction stems from both operational efficiency and the extended service life of these systems, which typically exceed traditional cooling solutions by 3-5 years due to reduced mechanical wear and corrosion.

Water conservation represents another sustainability advantage, particularly in data center applications where microfluidic cooling can reduce water consumption by up to 60%. This benefit becomes increasingly valuable as water scarcity affects more regions globally. Furthermore, closed-loop microfluidic systems minimize the risk of coolant leakage and environmental contamination, addressing concerns associated with traditional cooling methods that use environmentally harmful refrigerants.

The recyclability of microfluidic cooling components has improved significantly, with current designs achieving 70-80% material recovery rates. Research efforts are focused on developing fully biodegradable microfluidic channels and environmentally benign coolants that maintain thermal performance while eliminating end-of-life environmental impacts.

As regulatory frameworks increasingly emphasize environmental performance, microfluidic cooling systems are well-positioned to meet and exceed emerging standards. Their inherent efficiency and reduced material requirements align with circular economy principles and sustainable development goals, potentially qualifying manufacturers for carbon credits and environmental certifications that provide market advantages.

Energy efficiency constitutes another critical environmental benefit of microfluidic cooling. The precise thermal management capabilities of these systems enable them to operate with 30-40% less energy consumption than conventional cooling solutions. This efficiency stems from optimized heat transfer coefficients and reduced pumping power requirements due to the microscale channel designs that maximize surface-to-volume ratios.

The manufacturing processes for microfluidic cooling systems are increasingly adopting sustainable practices. Advanced fabrication techniques such as 3D printing and roll-to-roll processing have reduced production waste by approximately 25% compared to traditional manufacturing methods. Additionally, many manufacturers are transitioning to bio-based polymers and recyclable metals for device construction, further reducing environmental footprint.

Lifecycle assessment studies indicate that microfluidic cooling systems can achieve carbon footprint reductions of 35-50% over their operational lifetime when compared to conventional cooling technologies. This reduction stems from both operational efficiency and the extended service life of these systems, which typically exceed traditional cooling solutions by 3-5 years due to reduced mechanical wear and corrosion.

Water conservation represents another sustainability advantage, particularly in data center applications where microfluidic cooling can reduce water consumption by up to 60%. This benefit becomes increasingly valuable as water scarcity affects more regions globally. Furthermore, closed-loop microfluidic systems minimize the risk of coolant leakage and environmental contamination, addressing concerns associated with traditional cooling methods that use environmentally harmful refrigerants.

The recyclability of microfluidic cooling components has improved significantly, with current designs achieving 70-80% material recovery rates. Research efforts are focused on developing fully biodegradable microfluidic channels and environmentally benign coolants that maintain thermal performance while eliminating end-of-life environmental impacts.

As regulatory frameworks increasingly emphasize environmental performance, microfluidic cooling systems are well-positioned to meet and exceed emerging standards. Their inherent efficiency and reduced material requirements align with circular economy principles and sustainable development goals, potentially qualifying manufacturers for carbon credits and environmental certifications that provide market advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!