Evaluate Polymer Coatings in Microfluidics for Enhanced Stability

SEP 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer Coating Technology Background and Objectives

Polymer coatings in microfluidic systems have evolved significantly over the past three decades, transitioning from simple surface treatments to sophisticated multi-functional interfaces. The development trajectory began in the early 1990s with rudimentary hydrophilic and hydrophobic modifications, progressing through various generations of increasingly complex and application-specific coating technologies. This evolution has been driven by the growing demands of microfluidic applications in diagnostics, drug delivery, and analytical chemistry, where surface properties critically influence device performance.

The current technological landscape encompasses a diverse range of polymer coating approaches, including covalent grafting, layer-by-layer assembly, plasma treatment, and in-situ polymerization. Each method offers distinct advantages in terms of stability, functionality, and compatibility with different substrate materials. Recent advancements have focused on stimuli-responsive coatings that can dynamically alter their properties in response to environmental changes, representing a significant leap forward in coating sophistication.

A persistent challenge in microfluidic applications has been the stability of polymer coatings under operational conditions. Conventional coatings often degrade when exposed to various solvents, pH extremes, or mechanical stress from fluid flow, leading to compromised device performance and reliability. This instability manifests as delamination, swelling, chemical degradation, or loss of functional properties, ultimately limiting the lifespan and application scope of microfluidic devices.

The primary technical objective of current research is to develop polymer coating technologies that maintain structural integrity and functional performance under diverse operational conditions. This includes resistance to organic solvents, compatibility with biological samples, stability across wide pH ranges, and durability under continuous flow conditions. Additionally, there is a growing emphasis on coatings that can withstand sterilization processes without degradation, enabling reusable microfluidic platforms for clinical applications.

Beyond stability, secondary objectives include enhancing specific surface functionalities such as anti-fouling properties, controlled wettability, and selective molecular interactions. The ideal coating system would combine robust stability with tailored surface chemistry, enabling precise control over fluid behavior and molecular interactions within microchannels. This dual focus on stability and functionality represents the frontier of polymer coating technology in microfluidics.

The technological trajectory points toward integrated coating systems that combine multiple polymers or incorporate hybrid organic-inorganic materials to achieve unprecedented stability profiles. Emerging approaches include self-healing coatings that can autonomously repair damage, gradient coatings with spatially varying properties, and biomimetic surfaces inspired by natural systems with exceptional stability characteristics.

The current technological landscape encompasses a diverse range of polymer coating approaches, including covalent grafting, layer-by-layer assembly, plasma treatment, and in-situ polymerization. Each method offers distinct advantages in terms of stability, functionality, and compatibility with different substrate materials. Recent advancements have focused on stimuli-responsive coatings that can dynamically alter their properties in response to environmental changes, representing a significant leap forward in coating sophistication.

A persistent challenge in microfluidic applications has been the stability of polymer coatings under operational conditions. Conventional coatings often degrade when exposed to various solvents, pH extremes, or mechanical stress from fluid flow, leading to compromised device performance and reliability. This instability manifests as delamination, swelling, chemical degradation, or loss of functional properties, ultimately limiting the lifespan and application scope of microfluidic devices.

The primary technical objective of current research is to develop polymer coating technologies that maintain structural integrity and functional performance under diverse operational conditions. This includes resistance to organic solvents, compatibility with biological samples, stability across wide pH ranges, and durability under continuous flow conditions. Additionally, there is a growing emphasis on coatings that can withstand sterilization processes without degradation, enabling reusable microfluidic platforms for clinical applications.

Beyond stability, secondary objectives include enhancing specific surface functionalities such as anti-fouling properties, controlled wettability, and selective molecular interactions. The ideal coating system would combine robust stability with tailored surface chemistry, enabling precise control over fluid behavior and molecular interactions within microchannels. This dual focus on stability and functionality represents the frontier of polymer coating technology in microfluidics.

The technological trajectory points toward integrated coating systems that combine multiple polymers or incorporate hybrid organic-inorganic materials to achieve unprecedented stability profiles. Emerging approaches include self-healing coatings that can autonomously repair damage, gradient coatings with spatially varying properties, and biomimetic surfaces inspired by natural systems with exceptional stability characteristics.

Market Demand Analysis for Stable Microfluidic Coatings

The microfluidics market has experienced substantial growth in recent years, with polymer coatings emerging as a critical component for ensuring device stability and performance. Current market analysis indicates that the global microfluidics market is valued at approximately 23 billion USD in 2023, with projections suggesting a compound annual growth rate of 11.5% through 2030. Within this expanding market, the demand for stable and reliable polymer coatings has become increasingly pronounced.

Healthcare applications represent the largest segment driving demand for stable microfluidic coatings, accounting for nearly 40% of the market share. Point-of-care diagnostics, drug delivery systems, and lab-on-a-chip devices all require coatings that maintain stability under various biological conditions. The COVID-19 pandemic significantly accelerated this trend, as rapid diagnostic testing platforms utilizing microfluidic technology saw unprecedented adoption rates.

Pharmaceutical research and development constitutes another substantial market segment, where high-throughput screening and drug discovery platforms depend on consistent surface properties provided by advanced polymer coatings. Industry reports indicate that pharmaceutical companies are increasingly investing in microfluidic technologies to reduce development costs and accelerate time-to-market for new therapeutics.

Academic and research institutions represent a growing market segment, particularly as microfluidics becomes more integrated into fundamental scientific research across disciplines. These institutions typically seek cost-effective coating solutions that offer reliability for experimental reproducibility while accommodating diverse research applications.

Consumer demand trends show increasing preference for coatings that demonstrate long-term stability under various environmental conditions, resistance to biofouling, and compatibility with a wide range of sample types. Market surveys reveal that end-users prioritize coatings that maintain consistent surface properties over extended periods without requiring frequent recalibration or replacement.

Regional market analysis indicates that North America currently leads in adoption of advanced microfluidic coating technologies, followed closely by Europe. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding healthcare infrastructure and increasing investment in biotechnology research in countries like China, Japan, and South Korea.

Industry challenges creating market opportunities include the need for coatings that can withstand sterilization processes without degradation, maintain stability across wide pH ranges, and resist protein adsorption in biological applications. Additionally, there is growing demand for environmentally friendly coating materials that comply with increasingly stringent regulatory requirements while maintaining performance characteristics.

Healthcare applications represent the largest segment driving demand for stable microfluidic coatings, accounting for nearly 40% of the market share. Point-of-care diagnostics, drug delivery systems, and lab-on-a-chip devices all require coatings that maintain stability under various biological conditions. The COVID-19 pandemic significantly accelerated this trend, as rapid diagnostic testing platforms utilizing microfluidic technology saw unprecedented adoption rates.

Pharmaceutical research and development constitutes another substantial market segment, where high-throughput screening and drug discovery platforms depend on consistent surface properties provided by advanced polymer coatings. Industry reports indicate that pharmaceutical companies are increasingly investing in microfluidic technologies to reduce development costs and accelerate time-to-market for new therapeutics.

Academic and research institutions represent a growing market segment, particularly as microfluidics becomes more integrated into fundamental scientific research across disciplines. These institutions typically seek cost-effective coating solutions that offer reliability for experimental reproducibility while accommodating diverse research applications.

Consumer demand trends show increasing preference for coatings that demonstrate long-term stability under various environmental conditions, resistance to biofouling, and compatibility with a wide range of sample types. Market surveys reveal that end-users prioritize coatings that maintain consistent surface properties over extended periods without requiring frequent recalibration or replacement.

Regional market analysis indicates that North America currently leads in adoption of advanced microfluidic coating technologies, followed closely by Europe. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding healthcare infrastructure and increasing investment in biotechnology research in countries like China, Japan, and South Korea.

Industry challenges creating market opportunities include the need for coatings that can withstand sterilization processes without degradation, maintain stability across wide pH ranges, and resist protein adsorption in biological applications. Additionally, there is growing demand for environmentally friendly coating materials that comply with increasingly stringent regulatory requirements while maintaining performance characteristics.

Current Challenges in Microfluidic Surface Modification

Despite significant advancements in microfluidic technologies, surface modification remains a critical challenge that limits broader application and commercialization. The primary issue stems from the inherent surface properties of commonly used microfluidic materials such as polydimethylsiloxane (PDMS), polymethyl methacrylate (PMMA), and cyclic olefin copolymer (COC), which often exhibit undesirable characteristics including hydrophobicity, non-specific adsorption, and chemical instability.

Surface fouling represents one of the most persistent challenges, where biomolecules, cells, or other analytes adhere to channel walls, compromising device performance and analytical accuracy. This phenomenon is particularly problematic in diagnostic applications where protein adsorption can lead to false positives or negatives, and in long-term cell culture systems where surface conditioning affects cellular behavior.

Chemical compatibility presents another significant hurdle. Many polymer-based microfluidic devices demonstrate poor resistance to organic solvents, which severely restricts their application in chemical synthesis and analysis. PDMS, despite its popularity, is particularly susceptible to swelling and deformation when exposed to nonpolar solvents, leading to altered channel geometries and compromised flow dynamics.

Temporal stability of surface modifications represents a third major challenge. Current surface treatment methods often produce transient effects, with modified surfaces reverting to their original properties over time. This "aging effect" necessitates either immediate use after modification or frequent retreatment, significantly limiting shelf life and practical utility of microfluidic devices in commercial and clinical settings.

Reproducibility and scalability of surface modification techniques pose additional challenges for industrial implementation. Many laboratory-scale modification methods prove difficult to standardize across production batches, creating inconsistencies in device performance. This variability becomes particularly problematic when transitioning from prototype to mass production.

The integration of multiple functionalities on a single microfluidic platform often requires spatially controlled surface modifications, where different regions possess distinct surface properties. Current techniques struggle to achieve precise spatial control without complex and costly multi-step processes, limiting the development of sophisticated integrated systems.

Environmental and biocompatibility concerns further complicate surface modification strategies. Many effective chemical treatments involve potentially toxic reagents that may leach into samples or create disposal issues. This is particularly problematic for biomedical applications where material cytotoxicity and biocompatibility are paramount considerations.

Surface fouling represents one of the most persistent challenges, where biomolecules, cells, or other analytes adhere to channel walls, compromising device performance and analytical accuracy. This phenomenon is particularly problematic in diagnostic applications where protein adsorption can lead to false positives or negatives, and in long-term cell culture systems where surface conditioning affects cellular behavior.

Chemical compatibility presents another significant hurdle. Many polymer-based microfluidic devices demonstrate poor resistance to organic solvents, which severely restricts their application in chemical synthesis and analysis. PDMS, despite its popularity, is particularly susceptible to swelling and deformation when exposed to nonpolar solvents, leading to altered channel geometries and compromised flow dynamics.

Temporal stability of surface modifications represents a third major challenge. Current surface treatment methods often produce transient effects, with modified surfaces reverting to their original properties over time. This "aging effect" necessitates either immediate use after modification or frequent retreatment, significantly limiting shelf life and practical utility of microfluidic devices in commercial and clinical settings.

Reproducibility and scalability of surface modification techniques pose additional challenges for industrial implementation. Many laboratory-scale modification methods prove difficult to standardize across production batches, creating inconsistencies in device performance. This variability becomes particularly problematic when transitioning from prototype to mass production.

The integration of multiple functionalities on a single microfluidic platform often requires spatially controlled surface modifications, where different regions possess distinct surface properties. Current techniques struggle to achieve precise spatial control without complex and costly multi-step processes, limiting the development of sophisticated integrated systems.

Environmental and biocompatibility concerns further complicate surface modification strategies. Many effective chemical treatments involve potentially toxic reagents that may leach into samples or create disposal issues. This is particularly problematic for biomedical applications where material cytotoxicity and biocompatibility are paramount considerations.

Current Polymer Coating Solutions for Microfluidic Stability

01 Environmental resistance of polymer coatings

Polymer coatings can be formulated to resist environmental factors such as UV radiation, moisture, and temperature fluctuations. These coatings incorporate specific additives and stabilizers that prevent degradation when exposed to harsh conditions. The formulations often include UV absorbers, antioxidants, and cross-linking agents that work synergistically to maintain coating integrity over extended periods, even in challenging outdoor environments.- Environmental stability of polymer coatings: Polymer coatings can be formulated to withstand various environmental factors such as UV radiation, temperature fluctuations, and chemical exposure. Specific additives and stabilizers can be incorporated into the polymer matrix to prevent degradation and maintain coating integrity over time. These formulations often include UV absorbers, antioxidants, and radical scavengers that work synergistically to protect the polymer backbone from chain scission and oxidation, thereby extending the service life of the coating in harsh environments.

- Cross-linking mechanisms for enhanced stability: Cross-linking between polymer chains significantly improves the mechanical and chemical stability of coatings. Various cross-linking agents and mechanisms can be employed, including thermal curing, UV-initiated cross-linking, and chemical cross-linkers that form covalent bonds between polymer chains. These techniques create a three-dimensional network structure that enhances resistance to solvents, chemicals, and physical abrasion. The degree of cross-linking can be controlled to achieve the desired balance between flexibility and durability in the final coating.

- Nanocomposite polymer coatings for improved stability: Incorporating nanoparticles into polymer matrices creates nanocomposite coatings with superior stability properties. Nanomaterials such as silica, clay, carbon nanotubes, and metal oxides can significantly enhance the mechanical strength, thermal stability, and barrier properties of polymer coatings. These nanofillers create tortuous paths for diffusing molecules, reducing permeability to gases and liquids. Additionally, the large interfacial area between nanoparticles and the polymer matrix improves stress distribution and crack resistance, resulting in coatings with extended service life and improved performance under demanding conditions.

- Water-resistant and hydrophobic polymer formulations: Specialized polymer formulations can be developed to create highly water-resistant and hydrophobic coatings. These formulations often incorporate fluoropolymers, silicones, or modified acrylics with hydrophobic side chains. The resulting coatings exhibit excellent water repellency, reduced water absorption, and enhanced stability in humid or aqueous environments. Surface modification techniques can also be employed to increase the contact angle and reduce surface energy, further improving water resistance and preventing coating degradation due to moisture ingress.

- Self-healing and adaptive polymer coating systems: Advanced polymer coating systems can incorporate self-healing mechanisms to repair damage and maintain stability over time. These systems may include microcapsules containing healing agents that are released upon damage, reversible chemical bonds that can reform after breaking, or shape memory polymers that return to their original configuration after deformation. Some formulations also feature stimuli-responsive components that adapt to environmental changes, providing dynamic protection against various stressors. These innovative approaches significantly extend coating lifespan by addressing the root causes of coating failure before they lead to catastrophic degradation.

02 Chemical modification for enhanced stability

Chemical modifications to polymer structures can significantly improve coating stability. These modifications include introducing functional groups that promote better adhesion to substrates, incorporating silane coupling agents, or adding reactive end groups that facilitate cross-linking. Such chemical alterations can enhance resistance to hydrolysis, oxidation, and other degradation mechanisms, resulting in coatings with superior long-term performance and durability.Expand Specific Solutions03 Advanced polymer blends and composites

Blending different polymers or incorporating nanoparticles and other reinforcing materials can create composite coatings with enhanced stability properties. These formulations combine the beneficial properties of multiple components to overcome the limitations of single-polymer systems. For example, adding nanosilica or carbon nanotubes to polymer matrices can improve mechanical strength, thermal stability, and barrier properties, resulting in more durable and resilient coatings.Expand Specific Solutions04 Thermal and oxidative stability enhancements

Specific formulation techniques can improve the thermal and oxidative stability of polymer coatings. These include incorporating heat-resistant monomers, using specialized curing agents, and adding thermal stabilizers. Such formulations maintain their structural integrity and functional properties even when exposed to elevated temperatures or oxidizing conditions, making them suitable for high-temperature applications in industrial settings.Expand Specific Solutions05 Novel curing and cross-linking methods

Advanced curing and cross-linking methods can significantly enhance polymer coating stability. These include dual-cure systems, photo-initiated cross-linking, and controlled radical polymerization techniques. By optimizing the cross-link density and network structure, these methods create more robust polymer films with improved resistance to chemical attack, mechanical stress, and environmental degradation, resulting in coatings with extended service life.Expand Specific Solutions

Leading Companies and Research Institutions in Microfluidic Coatings

The polymer coatings in microfluidics market is currently in a growth phase, with increasing adoption across biomedical and analytical applications. The global market size is expanding rapidly, projected to reach significant value as microfluidic technologies become more mainstream in diagnostics and research. Technologically, the field shows moderate maturity with established players like Bio-Rad Laboratories, BASF Coatings, and Henkel AG offering commercial solutions, while research institutions such as National University of Singapore and University of California continue advancing fundamental innovations. Companies like Wacker Chemie, Lubrizol Advanced Materials, and PPG Industries are developing specialized polymer formulations that address key challenges in surface stability and biocompatibility. The competitive landscape features both chemical industry giants and specialized materials science companies working to overcome remaining technical barriers in long-term coating stability.

Lubrizol Advanced Materials, Inc.

Technical Solution: Lubrizol has developed innovative thermoplastic polyurethane (TPU) coating technologies specifically engineered for microfluidic applications. Their approach utilizes water-dispersible polyurethanes with carefully controlled molecular weight distributions that enable uniform coating of complex microfluidic channels. The technology incorporates hydrophilic segments that reduce non-specific protein adsorption while maintaining mechanical integrity under flow conditions. Lubrizol's coatings feature self-healing properties through reversible hydrogen bonding networks, allowing recovery from minor surface damage. Their formulations include proprietary additives that enhance resistance to hydrolytic degradation, critical for long-term stability in aqueous environments. The coatings demonstrate excellent adhesion to various substrate materials including PDMS, PMMA, and COC through tailored interfacial chemistry, with coating thicknesses precisely controlled between 50-500nm depending on application requirements.

Strengths: Excellent mechanical properties with good abrasion resistance; tunable hydrophilicity/hydrophobicity for specific applications; environmentally friendly water-based formulations. Weaknesses: Lower temperature stability compared to some alternatives; potential for mechanical deformation under high pressure; more complex application process requiring precise control.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed specialized UV-curable polymer coating systems optimized for microfluidic applications requiring enhanced chemical and mechanical stability. Their technology utilizes acrylate-based formulations with precisely controlled viscosity profiles that enable uniform coating of high-aspect-ratio microchannels. The coatings incorporate silane coupling agents that form strong covalent bonds with glass and silicon substrates, ensuring exceptional adhesion even under harsh conditions. Henkel's proprietary photoinitiator systems allow rapid curing (under 30 seconds) with minimal shrinkage, preserving the critical dimensions of microfluidic features. Their formulations include fluorinated components that provide both hydrophobicity and oleophobicity, reducing fouling from both aqueous and organic samples. The coatings demonstrate excellent chemical resistance to acids, bases, and common solvents used in analytical applications, with stability verified through accelerated aging tests equivalent to over 2 years of continuous operation.

Strengths: Rapid processing through UV curing; excellent dimensional stability; superior adhesion to multiple substrate materials including glass, silicon, and polymers. Weaknesses: Limited gas permeability may restrict certain biological applications; requires specialized UV curing equipment; some formulations may have biocompatibility limitations.

Key Patents and Innovations in Microfluidic Surface Treatments

Coatings for capillaries capable of capturing analytes

PatentInactiveEP2713158A1

Innovation

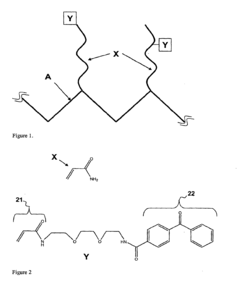

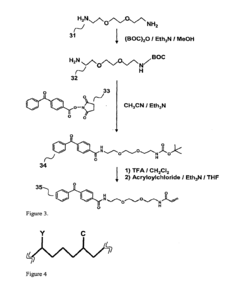

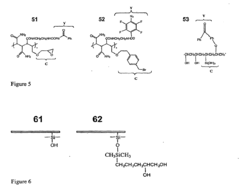

- Development of microfluidic devices with polymer coatings that contain triggerable analyte capture moieties, allowing for one-step application and effective immobilization of analytes through adsorbed or covalent attachments, which can be triggered photochemically or thermally, providing improved electroosmotic flow suppression and separation characteristics.

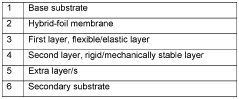

Method for sealing microfluidic structures by means of a hybridfoil membrane

PatentWO2023025502A1

Innovation

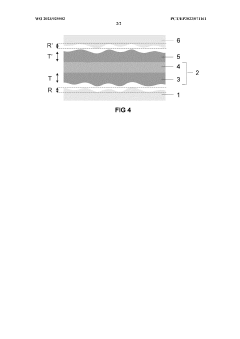

- A hybrid-foil membrane is formed by combining a flexible elastic layer with a rigid mechanically stable layer, where the flexible layer's thickness matches the substrate roughness, enabling effective bonding and mechanical stability through physical and/or chemical treatment.

Biocompatibility and Safety Considerations

Biocompatibility remains a critical concern when evaluating polymer coatings for microfluidic applications, particularly in biological and medical contexts. The direct contact between polymer surfaces and biological samples necessitates rigorous assessment of potential cytotoxicity, immunogenicity, and long-term biocompatibility effects. Recent studies indicate that even trace leaching of monomers, additives, or degradation products from polymer coatings can significantly impact cell viability and analytical outcomes in microfluidic devices.

Standard biocompatibility testing protocols for polymer coatings typically include ISO 10993 compliance testing, which encompasses cytotoxicity assays, sensitization tests, and hemocompatibility evaluations. For microfluidic applications specifically, dynamic flow-based biocompatibility assessments provide more relevant data than static tests, as they better simulate actual operating conditions. Research by Jang et al. (2020) demonstrated that polyethylene glycol (PEG)-based coatings exhibited superior biocompatibility metrics compared to traditional polydimethylsiloxane (PDMS) surfaces, with significantly reduced protein adsorption and cellular adhesion.

Safety considerations extend beyond biocompatibility to include chemical stability under various operational conditions. Polymer coatings must maintain structural integrity without releasing harmful compounds when exposed to different pH environments, temperature fluctuations, and common sterilization methods. The degradation kinetics of biodegradable polymer coatings require particular attention, as breakdown products must remain non-toxic throughout the device's intended lifetime.

Regulatory compliance represents another crucial dimension of safety assessment. FDA guidelines for medical devices incorporating polymer coatings in microfluidics have become increasingly stringent, requiring comprehensive documentation of material composition, manufacturing processes, and quality control measures. The European Union's Medical Device Regulation (MDR) similarly emphasizes thorough risk assessment of materials used in diagnostic and therapeutic applications.

Emerging research focuses on developing inherently biocompatible polymer coatings that eliminate the need for additional surface modifications. Zwitterionic polymers, biomimetic phosphorylcholine-based coatings, and hydrogel-based surface treatments have shown promising results in minimizing biological interactions while maintaining functional stability. These advanced materials aim to address both biocompatibility and performance requirements simultaneously.

Environmental considerations are increasingly important in polymer coating selection, with growing emphasis on reducing potentially harmful substances. PFAS-free formulations and environmentally degradable alternatives are gaining attention as sustainable options that maintain performance while reducing long-term environmental and biological risks.

Standard biocompatibility testing protocols for polymer coatings typically include ISO 10993 compliance testing, which encompasses cytotoxicity assays, sensitization tests, and hemocompatibility evaluations. For microfluidic applications specifically, dynamic flow-based biocompatibility assessments provide more relevant data than static tests, as they better simulate actual operating conditions. Research by Jang et al. (2020) demonstrated that polyethylene glycol (PEG)-based coatings exhibited superior biocompatibility metrics compared to traditional polydimethylsiloxane (PDMS) surfaces, with significantly reduced protein adsorption and cellular adhesion.

Safety considerations extend beyond biocompatibility to include chemical stability under various operational conditions. Polymer coatings must maintain structural integrity without releasing harmful compounds when exposed to different pH environments, temperature fluctuations, and common sterilization methods. The degradation kinetics of biodegradable polymer coatings require particular attention, as breakdown products must remain non-toxic throughout the device's intended lifetime.

Regulatory compliance represents another crucial dimension of safety assessment. FDA guidelines for medical devices incorporating polymer coatings in microfluidics have become increasingly stringent, requiring comprehensive documentation of material composition, manufacturing processes, and quality control measures. The European Union's Medical Device Regulation (MDR) similarly emphasizes thorough risk assessment of materials used in diagnostic and therapeutic applications.

Emerging research focuses on developing inherently biocompatible polymer coatings that eliminate the need for additional surface modifications. Zwitterionic polymers, biomimetic phosphorylcholine-based coatings, and hydrogel-based surface treatments have shown promising results in minimizing biological interactions while maintaining functional stability. These advanced materials aim to address both biocompatibility and performance requirements simultaneously.

Environmental considerations are increasingly important in polymer coating selection, with growing emphasis on reducing potentially harmful substances. PFAS-free formulations and environmentally degradable alternatives are gaining attention as sustainable options that maintain performance while reducing long-term environmental and biological risks.

Scalability and Manufacturing Challenges

The scaling of polymer coating technologies from laboratory prototypes to industrial-scale microfluidic device production presents significant challenges that must be addressed for commercial viability. Current manufacturing processes often struggle with maintaining coating uniformity across large production batches, resulting in performance variability that undermines reliability in critical applications such as medical diagnostics and pharmaceutical development.

Surface preparation protocols that work effectively at small scales frequently encounter complications when implemented in high-throughput manufacturing environments. The precise control of environmental parameters—including temperature, humidity, and dust levels—becomes increasingly difficult yet remains essential for consistent polymer adhesion and performance characteristics. This challenge is particularly pronounced for complex microfluidic geometries featuring high aspect ratios or intricate channel networks.

Material compatibility issues emerge more prominently at scale, as industrial manufacturing equipment may introduce contaminants or create unexpected interactions with coating precursors. The selection of coating application methods must balance precision with throughput capabilities, with techniques like vapor deposition offering excellent uniformity but limited scalability compared to solution-based approaches that may sacrifice some precision for higher production rates.

Quality control represents another significant hurdle, requiring the development of high-throughput, non-destructive testing methodologies to verify coating integrity across production volumes. Current analytical techniques often prove too time-consuming or costly for implementation in manufacturing settings, creating a technological gap that impedes industrial adoption.

Cost considerations become increasingly dominant as production scales increase. While specialized polymer formulations may deliver superior performance characteristics, their economic viability must be evaluated against manufacturing volumes and target applications. The development of cost-effective alternatives to premium materials without compromising essential stability properties remains an active area of research and development.

Regulatory compliance adds another layer of complexity, particularly for biomedical applications where material biocompatibility and leaching characteristics must be thoroughly documented across manufacturing batches. Establishing robust quality management systems that can track coating performance from raw materials through finished devices becomes essential for market approval in regulated industries.

Addressing these manufacturing challenges requires interdisciplinary collaboration between materials scientists, process engineers, and equipment manufacturers to develop integrated solutions that maintain coating performance while enabling commercial-scale production. Recent advances in automated quality inspection systems and computational modeling of coating processes offer promising pathways toward resolving these scalability limitations.

Surface preparation protocols that work effectively at small scales frequently encounter complications when implemented in high-throughput manufacturing environments. The precise control of environmental parameters—including temperature, humidity, and dust levels—becomes increasingly difficult yet remains essential for consistent polymer adhesion and performance characteristics. This challenge is particularly pronounced for complex microfluidic geometries featuring high aspect ratios or intricate channel networks.

Material compatibility issues emerge more prominently at scale, as industrial manufacturing equipment may introduce contaminants or create unexpected interactions with coating precursors. The selection of coating application methods must balance precision with throughput capabilities, with techniques like vapor deposition offering excellent uniformity but limited scalability compared to solution-based approaches that may sacrifice some precision for higher production rates.

Quality control represents another significant hurdle, requiring the development of high-throughput, non-destructive testing methodologies to verify coating integrity across production volumes. Current analytical techniques often prove too time-consuming or costly for implementation in manufacturing settings, creating a technological gap that impedes industrial adoption.

Cost considerations become increasingly dominant as production scales increase. While specialized polymer formulations may deliver superior performance characteristics, their economic viability must be evaluated against manufacturing volumes and target applications. The development of cost-effective alternatives to premium materials without compromising essential stability properties remains an active area of research and development.

Regulatory compliance adds another layer of complexity, particularly for biomedical applications where material biocompatibility and leaching characteristics must be thoroughly documented across manufacturing batches. Establishing robust quality management systems that can track coating performance from raw materials through finished devices becomes essential for market approval in regulated industries.

Addressing these manufacturing challenges requires interdisciplinary collaboration between materials scientists, process engineers, and equipment manufacturers to develop integrated solutions that maintain coating performance while enabling commercial-scale production. Recent advances in automated quality inspection systems and computational modeling of coating processes offer promising pathways toward resolving these scalability limitations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!