How to Reduce Evaporation in Open-Channel Microfluidic Systems

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Evaporation Control Background and Objectives

Microfluidic systems have revolutionized numerous fields including biomedical diagnostics, chemical synthesis, and biological research by enabling precise manipulation of fluids at microscale levels. Since their emergence in the early 1990s, these systems have evolved from simple channel networks to sophisticated platforms capable of performing complex analytical and synthetic functions. Open-channel microfluidic systems, in particular, have gained prominence due to their accessibility, ease of operation, and direct sample interaction capabilities.

Evaporation in open-channel microfluidic systems represents a significant technical challenge that has persisted throughout the technology's development. This phenomenon occurs when liquid in microchannels is exposed to ambient conditions, leading to fluid loss, concentration changes, and flow disruptions. The microscale dimensions of these channels (typically 1-1000 μm) exacerbate evaporation effects due to high surface-area-to-volume ratios, making evaporation control a critical factor in system reliability.

The evolution of evaporation control strategies has progressed from rudimentary approaches such as environmental chambers to more sophisticated integrated solutions. Early techniques focused primarily on external environmental control, while recent advances have explored material science innovations, channel geometry optimizations, and active control mechanisms to mitigate evaporation effects.

The primary objective of evaporation control research is to develop robust, scalable, and cost-effective solutions that maintain stable fluid conditions in open-channel microfluidic systems without compromising their inherent advantages. Specific goals include extending operational time windows, ensuring consistent analyte concentrations, maintaining predictable flow dynamics, and preserving sample integrity throughout experimental or diagnostic procedures.

Current technological trajectories indicate growing interest in hybrid approaches that combine physical barriers, chemical modifications, and environmental controls. The field is increasingly moving toward solutions that can be seamlessly integrated into existing microfluidic platforms without adding significant complexity or cost. Additionally, there is a push toward environmentally sustainable approaches that minimize resource consumption while maximizing evaporation control efficiency.

The significance of addressing evaporation challenges extends beyond technical performance to enabling new applications in point-of-care diagnostics, long-term cell culture studies, and continuous monitoring systems. As microfluidic technologies continue to penetrate diverse markets including healthcare, environmental monitoring, and food safety, effective evaporation control will become increasingly critical to their widespread adoption and practical utility.

Evaporation in open-channel microfluidic systems represents a significant technical challenge that has persisted throughout the technology's development. This phenomenon occurs when liquid in microchannels is exposed to ambient conditions, leading to fluid loss, concentration changes, and flow disruptions. The microscale dimensions of these channels (typically 1-1000 μm) exacerbate evaporation effects due to high surface-area-to-volume ratios, making evaporation control a critical factor in system reliability.

The evolution of evaporation control strategies has progressed from rudimentary approaches such as environmental chambers to more sophisticated integrated solutions. Early techniques focused primarily on external environmental control, while recent advances have explored material science innovations, channel geometry optimizations, and active control mechanisms to mitigate evaporation effects.

The primary objective of evaporation control research is to develop robust, scalable, and cost-effective solutions that maintain stable fluid conditions in open-channel microfluidic systems without compromising their inherent advantages. Specific goals include extending operational time windows, ensuring consistent analyte concentrations, maintaining predictable flow dynamics, and preserving sample integrity throughout experimental or diagnostic procedures.

Current technological trajectories indicate growing interest in hybrid approaches that combine physical barriers, chemical modifications, and environmental controls. The field is increasingly moving toward solutions that can be seamlessly integrated into existing microfluidic platforms without adding significant complexity or cost. Additionally, there is a push toward environmentally sustainable approaches that minimize resource consumption while maximizing evaporation control efficiency.

The significance of addressing evaporation challenges extends beyond technical performance to enabling new applications in point-of-care diagnostics, long-term cell culture studies, and continuous monitoring systems. As microfluidic technologies continue to penetrate diverse markets including healthcare, environmental monitoring, and food safety, effective evaporation control will become increasingly critical to their widespread adoption and practical utility.

Market Applications for Evaporation-Resistant Microfluidics

Evaporation-resistant microfluidic technologies have significant market potential across multiple industries where precise fluid handling at microscale is critical. The healthcare and pharmaceutical sectors represent the largest market opportunity, with applications in drug discovery, diagnostics, and personalized medicine. These industries require stable microenvironments for cell cultures, enzymatic reactions, and high-throughput screening, where evaporation control directly impacts result reliability and reproducibility.

The life sciences research market presents another substantial opportunity, particularly in genomics and proteomics. Advanced sequencing technologies rely on microfluidic platforms where sample integrity must be maintained throughout multi-step protocols. Evaporation-resistant systems enable longer experimental durations and improved data quality, addressing a critical pain point for researchers working with limited or precious biological samples.

Point-of-care diagnostics represents a rapidly growing application area, especially in resource-limited settings. Devices that can operate reliably without sophisticated environmental controls depend on inherent evaporation resistance. The global point-of-care testing market, valued at approximately $29 billion in 2021, is projected to grow significantly, with microfluidic technologies playing a central role in this expansion.

Environmental monitoring applications benefit from evaporation-resistant microfluidics for field-deployable water quality testing, pollutant detection, and environmental sample analysis. These applications often require devices to function in variable ambient conditions where traditional laboratory-based evaporation control methods are impractical.

The food and beverage industry utilizes microfluidic platforms for quality control, pathogen detection, and composition analysis. Evaporation resistance extends the operational window for these tests and improves reliability in production environments where temperature and humidity may fluctuate.

Cosmetics and personal care product development represents an emerging market, with microfluidic platforms enabling rapid formulation testing and stability assessment. Evaporation-resistant systems allow for more accurate simulation of product performance under various conditions.

Industrial applications in chemical synthesis and process monitoring benefit from microfluidic systems that maintain consistent fluid volumes during extended operations. The ability to precisely control reactions at microscale offers significant advantages in catalyst screening, reaction optimization, and process development.

The agricultural sector is adopting microfluidic technologies for soil analysis, plant pathogen detection, and pesticide screening, where field-deployable systems must function reliably despite environmental variations. Evaporation resistance is particularly valuable for applications requiring extended incubation periods or multi-step analytical procedures.

The life sciences research market presents another substantial opportunity, particularly in genomics and proteomics. Advanced sequencing technologies rely on microfluidic platforms where sample integrity must be maintained throughout multi-step protocols. Evaporation-resistant systems enable longer experimental durations and improved data quality, addressing a critical pain point for researchers working with limited or precious biological samples.

Point-of-care diagnostics represents a rapidly growing application area, especially in resource-limited settings. Devices that can operate reliably without sophisticated environmental controls depend on inherent evaporation resistance. The global point-of-care testing market, valued at approximately $29 billion in 2021, is projected to grow significantly, with microfluidic technologies playing a central role in this expansion.

Environmental monitoring applications benefit from evaporation-resistant microfluidics for field-deployable water quality testing, pollutant detection, and environmental sample analysis. These applications often require devices to function in variable ambient conditions where traditional laboratory-based evaporation control methods are impractical.

The food and beverage industry utilizes microfluidic platforms for quality control, pathogen detection, and composition analysis. Evaporation resistance extends the operational window for these tests and improves reliability in production environments where temperature and humidity may fluctuate.

Cosmetics and personal care product development represents an emerging market, with microfluidic platforms enabling rapid formulation testing and stability assessment. Evaporation-resistant systems allow for more accurate simulation of product performance under various conditions.

Industrial applications in chemical synthesis and process monitoring benefit from microfluidic systems that maintain consistent fluid volumes during extended operations. The ability to precisely control reactions at microscale offers significant advantages in catalyst screening, reaction optimization, and process development.

The agricultural sector is adopting microfluidic technologies for soil analysis, plant pathogen detection, and pesticide screening, where field-deployable systems must function reliably despite environmental variations. Evaporation resistance is particularly valuable for applications requiring extended incubation periods or multi-step analytical procedures.

Current Challenges in Open-Channel Microfluidic Evaporation

Open-channel microfluidic systems face significant evaporation challenges that fundamentally limit their practical applications in various fields. Unlike closed-channel systems, these open configurations expose liquid samples to ambient conditions, resulting in rapid evaporation that can dramatically alter fluid properties and experimental outcomes. The evaporation rate in these systems is influenced by multiple factors including temperature, humidity, air flow velocity, and the surface area-to-volume ratio of the exposed liquid.

One of the primary technical challenges is the concentration effect, where evaporation leads to increased concentration of solutes, potentially altering reaction kinetics, cellular environments, or analytical results. This is particularly problematic in applications requiring precise concentration control, such as enzymatic assays or cell culture systems, where even minor changes can significantly impact experimental validity.

Flow instability represents another critical challenge, as evaporation creates surface tension gradients that induce Marangoni flows. These unintended flows can disrupt carefully designed laminar flow patterns, compromising the spatial control that makes microfluidic systems valuable in the first place. Additionally, evaporation-induced pressure changes can create unpredictable fluid movement, further complicating experimental design and reproducibility.

Temperature fluctuations resulting from evaporative cooling present yet another obstacle. The latent heat of vaporization removes thermal energy from the system, creating temperature gradients that can affect reaction rates, molecular diffusion, and even the viability of biological samples. These thermal variations are often difficult to predict or control precisely in open-channel configurations.

The time-dependent nature of evaporation poses significant challenges for extended experiments. As evaporation progresses, system parameters continuously change, making it difficult to maintain stable conditions over time. This temporal instability severely limits the application of open-channel microfluidics in long-term monitoring or continuous processing applications.

Miniaturization efforts are also hampered by evaporation challenges. As device dimensions decrease, the surface area-to-volume ratio increases dramatically, accelerating evaporation effects. This fundamental physical constraint creates a practical lower limit for channel dimensions in open systems, restricting the benefits of further miniaturization that closed-channel systems can achieve.

Current mitigation strategies such as humidity chambers, oil overlays, or continuous fluid replenishment each introduce their own complications, including reduced accessibility, potential contamination, or increased system complexity. The lack of standardized approaches for quantifying and controlling evaporation further complicates the development of effective solutions across different application domains.

One of the primary technical challenges is the concentration effect, where evaporation leads to increased concentration of solutes, potentially altering reaction kinetics, cellular environments, or analytical results. This is particularly problematic in applications requiring precise concentration control, such as enzymatic assays or cell culture systems, where even minor changes can significantly impact experimental validity.

Flow instability represents another critical challenge, as evaporation creates surface tension gradients that induce Marangoni flows. These unintended flows can disrupt carefully designed laminar flow patterns, compromising the spatial control that makes microfluidic systems valuable in the first place. Additionally, evaporation-induced pressure changes can create unpredictable fluid movement, further complicating experimental design and reproducibility.

Temperature fluctuations resulting from evaporative cooling present yet another obstacle. The latent heat of vaporization removes thermal energy from the system, creating temperature gradients that can affect reaction rates, molecular diffusion, and even the viability of biological samples. These thermal variations are often difficult to predict or control precisely in open-channel configurations.

The time-dependent nature of evaporation poses significant challenges for extended experiments. As evaporation progresses, system parameters continuously change, making it difficult to maintain stable conditions over time. This temporal instability severely limits the application of open-channel microfluidics in long-term monitoring or continuous processing applications.

Miniaturization efforts are also hampered by evaporation challenges. As device dimensions decrease, the surface area-to-volume ratio increases dramatically, accelerating evaporation effects. This fundamental physical constraint creates a practical lower limit for channel dimensions in open systems, restricting the benefits of further miniaturization that closed-channel systems can achieve.

Current mitigation strategies such as humidity chambers, oil overlays, or continuous fluid replenishment each introduce their own complications, including reduced accessibility, potential contamination, or increased system complexity. The lack of standardized approaches for quantifying and controlling evaporation further complicates the development of effective solutions across different application domains.

Existing Evaporation Reduction Methods for Open Microchannels

01 Evaporation control mechanisms in open-channel microfluidics

Various mechanisms can be implemented to control evaporation in open-channel microfluidic systems. These include specialized channel designs, surface treatments, and environmental control systems that regulate the rate of fluid evaporation. By controlling evaporation rates, these systems can maintain consistent fluid properties and flow characteristics, which is crucial for applications requiring precise fluid handling and analysis.- Evaporation control mechanisms in open-channel microfluidics: Various mechanisms can be implemented to control evaporation in open-channel microfluidic systems. These include specialized channel designs, surface treatments, and environmental control systems that regulate the rate of fluid evaporation. Such control is crucial for maintaining consistent fluid properties and preventing sample concentration changes during analysis or processing in open microfluidic platforms.

- Evaporation-driven fluid transport in microfluidic channels: Evaporation can be harnessed as a driving force for fluid transport in open-channel microfluidic systems. By creating controlled evaporation gradients, passive pumping mechanisms can be established that move fluids through microchannels without external power sources. This approach enables simplified device designs for point-of-care diagnostics and resource-limited settings where powered pumping may not be feasible.

- Microfluidic system designs for enhanced evaporation efficiency: Specific geometric configurations and material selections can enhance evaporation efficiency in open-channel microfluidic systems. These designs include optimized channel widths, depths, and patterns that maximize surface area exposure while maintaining fluid control. Enhanced evaporation efficiency is particularly valuable for applications requiring rapid sample concentration, crystallization processes, or heat transfer operations.

- Evaporation-resistant coatings and materials for microfluidics: Specialized coatings and materials can be applied to open-channel microfluidic systems to resist unwanted evaporation. These include hydrophobic barriers, vapor-impermeable films, and composite materials that maintain fluid integrity over extended periods. Such evaporation-resistant technologies are essential for long-duration experiments, stable reagent storage, and applications requiring precise fluid volume control.

- Sensing and monitoring evaporation in open microfluidic systems: Integrated sensing technologies can monitor evaporation rates in real-time within open-channel microfluidic systems. These include optical, electrical, and mechanical sensors that detect changes in fluid volume, concentration, or flow characteristics resulting from evaporation. Monitoring capabilities enable automated feedback control systems that adjust operating parameters to compensate for evaporative effects, ensuring consistent experimental conditions.

02 Evaporation-driven fluid transport in microfluidic channels

Evaporation can be harnessed as a driving force for fluid transport in open-channel microfluidic systems. By creating controlled evaporation gradients along microchannels, passive pumping mechanisms can be established without the need for external power sources. This approach utilizes surface tension and capillary effects combined with evaporation to achieve directional fluid flow, which is particularly useful for point-of-care diagnostic devices and environmental monitoring systems.Expand Specific Solutions03 Thermal management in evaporative microfluidic systems

Thermal management is critical in open-channel microfluidic systems where evaporation occurs. Heat transfer mechanisms can be integrated to either promote or restrict evaporation depending on the application requirements. These systems may incorporate heating elements, cooling structures, or thermally conductive materials to precisely control temperature distributions across the microfluidic platform, thereby regulating evaporation rates and maintaining system stability.Expand Specific Solutions04 Surface modifications for evaporation control

Surface modifications play a crucial role in controlling evaporation in open-channel microfluidic systems. Hydrophobic and hydrophilic patterning, chemical treatments, and nano/micro-structured surfaces can be engineered to manipulate fluid behavior and evaporation characteristics. These modifications can create regions with differential evaporation rates, enabling precise fluid handling, sample concentration, or controlled drying processes for analytical applications.Expand Specific Solutions05 Evaporation-based concentration and separation techniques

Open-channel microfluidic systems can leverage controlled evaporation for sample concentration and separation applications. By designing channels with specific geometries and surface properties, particles or molecules in solution can be concentrated as the liquid evaporates. This principle enables the development of sensitive detection methods, sample preparation techniques, and separation processes that enhance analytical capabilities without requiring complex instrumentation or high power consumption.Expand Specific Solutions

Leading Research Groups and Companies in Microfluidic Technology

The microfluidic evaporation reduction market is currently in its growth phase, with increasing applications in pharmaceutical, medical diagnostics, and analytical chemistry sectors. The global microfluidics market is projected to reach approximately $50 billion by 2026, with evaporation control solutions representing a significant segment. Technology maturity varies across players, with research institutions like California Institute of Technology and University of Michigan pioneering fundamental innovations, while companies such as 10X Genomics and miDIAGNOSTICS are commercializing practical applications. CSEM, Fraunhofer-Gesellschaft, and IMEC Nederland lead in developing specialized surface treatments and channel designs, while Samsung Electronics and Canon are integrating these technologies into broader product ecosystems. Collaboration between academic institutions and industry partners is accelerating development of novel evaporation mitigation strategies for open-channel microfluidic systems.

California Institute of Technology

Technical Solution: California Institute of Technology (Caltech) has developed innovative approaches to combat evaporation in open-channel microfluidic systems through their pioneering research in microfluidics and nanofabrication. Their solution involves a multi-layered strategy incorporating specialized surface engineering and environmental control mechanisms. Caltech researchers have created microstructured surfaces with precisely controlled wettability patterns that establish stable air-liquid interfaces, significantly reducing evaporation rates. Their technology utilizes nanoscale topographical features that create energy barriers against evaporation while maintaining fluid accessibility. Additionally, they've developed localized humidity control systems that generate saturated microenvironments directly above critical fluid interfaces without requiring enclosure of the entire device. Caltech's approach also incorporates thermally responsive polymers that form reversible barriers at the air-liquid interface when triggered by temperature changes, providing dynamic evaporation control during different stages of microfluidic operations. Their research has demonstrated that strategic placement of hydrogel reservoirs adjacent to open channels can maintain local humidity levels and compensate for evaporative losses through controlled moisture release.

Strengths: Highly sophisticated approach based on fundamental physical principles, offering precise control over evaporation rates with minimal impact on sample accessibility and analytical procedures. Their solutions are adaptable to various microfluidic designs and applications. Weaknesses: Some of their more advanced surface engineering approaches require specialized fabrication techniques that may increase manufacturing complexity and cost for commercial implementation.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has developed comprehensive solutions for reducing evaporation in open-channel microfluidic systems through their advanced research in microfluidics and biomicrofluidic technologies. Their approach combines innovative materials science with precise environmental control strategies. Michigan researchers have engineered specialized hydrogel-based channel linings that maintain high local humidity while allowing open access to the fluid channel. These hydrogel structures serve as water reservoirs that release moisture at rates matching evaporation, effectively maintaining fluid volumes over extended periods. Additionally, they've developed microstructured "evaporation shields" - arrays of micropillars or barriers that create stagnant air layers above the fluid surface, significantly reducing vapor diffusion rates without fully enclosing the channel. Their technology also incorporates thermally responsive polymers that can dynamically adjust their configuration to control evaporation rates based on operational requirements. Michigan's research has demonstrated that strategic implementation of localized surface tension gradients (Marangoni effects) can counteract evaporative flows and maintain stable fluid interfaces in open channels. They've also pioneered the use of biocompatible surfactants that form protective monolayers at the air-liquid interface, reducing evaporation while maintaining sample integrity for biological applications.

Strengths: Highly adaptable solutions that can be tailored to specific application requirements, with particular effectiveness in biological and biomedical microfluidic systems where sample integrity is critical. Their approaches maintain the benefits of open access while significantly extending operational times. Weaknesses: Some of their more advanced hydrogel-based solutions may require periodic rehydration or replacement for extended operations, and the surfactant approaches may introduce compatibility challenges with certain analytical techniques.

Key Patents and Literature on Microfluidic Evaporation Control

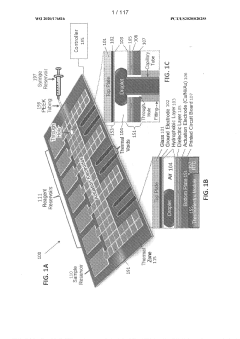

Digital microfluidics devices and methods of using them

PatentWO2020176816A1

Innovation

- The development of air-matrix DMF apparatuses with a disposable cartridge that includes a grid-patterned ground electrode and a flexible dielectric layer, where the dielectric is securely held to the electrodes using a vacuum system through openings in the drive electrodes, allowing for larger air gaps and improved droplet manipulation.

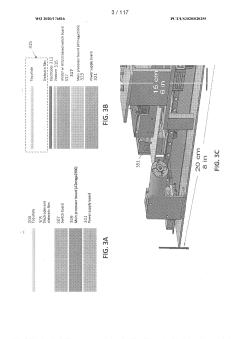

Microfluidic system

PatentWO2022223618A1

Innovation

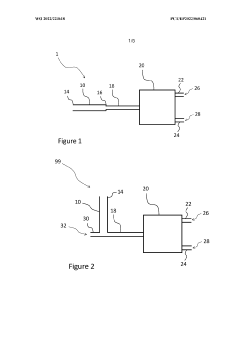

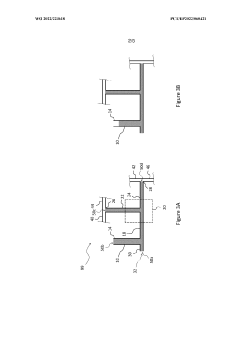

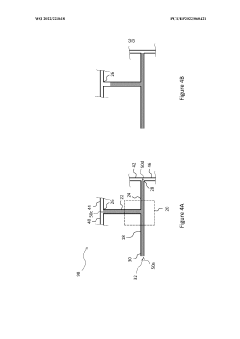

- A microfluidic system with a compensating channel that exerts a retention capillary pressure to refill liquid in outlet channels, preventing evaporation and air intrusion, using a network of capillary channels with varying dimensions and materials to manage capillary pressures, allowing passive compensation without the need for pumps or user intervention.

Material Science Innovations for Microfluidic Applications

Recent advancements in material science have opened new frontiers for addressing evaporation challenges in open-channel microfluidic systems. Novel hydrophobic coatings derived from fluoropolymers and silicone-based compounds have demonstrated significant reduction in surface tension at liquid-air interfaces, effectively minimizing evaporation rates by up to 40% compared to untreated surfaces. These coatings maintain optical transparency while providing chemical resistance, making them ideal for analytical applications requiring visual observation.

Biomimetic materials inspired by natural water-retention mechanisms found in desert-dwelling organisms represent another promising innovation. For instance, materials mimicking the Namib desert beetle's shell structure can facilitate selective condensation while reducing overall evaporation. These materials incorporate alternating hydrophobic and hydrophilic regions that create microscopic water-trapping structures, extending experimental viability in open microfluidic systems from minutes to hours.

Responsive polymers that dynamically adjust their properties based on environmental conditions have emerged as a versatile solution. Temperature-responsive polymers like poly(N-isopropylacrylamide) (PNIPAM) can form protective barriers when ambient temperatures rise above critical thresholds, automatically counteracting increased evaporation rates during extended operations. Similarly, humidity-responsive materials can expand to seal channels when detecting decreased moisture levels.

Nanocomposite materials incorporating graphene oxide and other two-dimensional materials have demonstrated exceptional barrier properties against water vapor transmission. When applied as thin films or incorporated into channel walls, these materials create tortuous paths for water molecules, significantly impeding evaporation while maintaining the open-channel configuration necessary for certain applications. Recent studies have shown evaporation reduction of up to 85% in controlled laboratory conditions.

Liquid-infused porous surfaces (LIPS) represent an innovative approach combining solid substrates with immiscible lubricating liquids. These surfaces maintain a stable liquid layer that prevents direct contact between the working fluid and air, dramatically reducing evaporation while preserving access to the fluid for sensing or manipulation. The self-healing properties of LIPS provide additional advantages for long-term operation in variable environmental conditions.

Advances in biodegradable and sustainable materials have also yielded promising evaporation-resistant solutions derived from modified cellulose, chitosan, and other naturally occurring polymers. These materials offer comparable performance to synthetic alternatives while addressing growing concerns regarding environmental impact and biocompatibility in biological and medical microfluidic applications.

Biomimetic materials inspired by natural water-retention mechanisms found in desert-dwelling organisms represent another promising innovation. For instance, materials mimicking the Namib desert beetle's shell structure can facilitate selective condensation while reducing overall evaporation. These materials incorporate alternating hydrophobic and hydrophilic regions that create microscopic water-trapping structures, extending experimental viability in open microfluidic systems from minutes to hours.

Responsive polymers that dynamically adjust their properties based on environmental conditions have emerged as a versatile solution. Temperature-responsive polymers like poly(N-isopropylacrylamide) (PNIPAM) can form protective barriers when ambient temperatures rise above critical thresholds, automatically counteracting increased evaporation rates during extended operations. Similarly, humidity-responsive materials can expand to seal channels when detecting decreased moisture levels.

Nanocomposite materials incorporating graphene oxide and other two-dimensional materials have demonstrated exceptional barrier properties against water vapor transmission. When applied as thin films or incorporated into channel walls, these materials create tortuous paths for water molecules, significantly impeding evaporation while maintaining the open-channel configuration necessary for certain applications. Recent studies have shown evaporation reduction of up to 85% in controlled laboratory conditions.

Liquid-infused porous surfaces (LIPS) represent an innovative approach combining solid substrates with immiscible lubricating liquids. These surfaces maintain a stable liquid layer that prevents direct contact between the working fluid and air, dramatically reducing evaporation while preserving access to the fluid for sensing or manipulation. The self-healing properties of LIPS provide additional advantages for long-term operation in variable environmental conditions.

Advances in biodegradable and sustainable materials have also yielded promising evaporation-resistant solutions derived from modified cellulose, chitosan, and other naturally occurring polymers. These materials offer comparable performance to synthetic alternatives while addressing growing concerns regarding environmental impact and biocompatibility in biological and medical microfluidic applications.

Environmental Impact and Sustainability Considerations

The environmental impact of open-channel microfluidic systems extends beyond their immediate applications, particularly when considering evaporation reduction strategies. Traditional evaporation control methods often involve chemical additives or oil-based sealants that can introduce environmental contaminants when disposed of. These substances may persist in water systems, potentially disrupting aquatic ecosystems and contributing to broader environmental pollution concerns.

Water conservation represents a critical sustainability aspect of microfluidic system design. In regions facing water scarcity, the cumulative impact of water loss through evaporation in research and industrial applications becomes significant. Implementing effective evaporation reduction techniques directly contributes to water conservation efforts, aligning microfluidic technologies with sustainable development goals and responsible resource management practices.

Energy consumption associated with evaporation compensation mechanisms presents another environmental consideration. Systems requiring continuous fluid replenishment or temperature control to counteract evaporation effects typically demand additional energy inputs. By minimizing evaporation through passive or low-energy solutions, the overall carbon footprint of microfluidic operations can be substantially reduced, supporting broader climate action initiatives.

The life cycle assessment of evaporation control materials reveals important sustainability implications. Biodegradable or recyclable materials for humidity chambers and channel covers offer environmentally preferable alternatives to petroleum-based polymers. Similarly, biomimetic approaches inspired by natural water conservation mechanisms present opportunities for developing sustainable evaporation reduction strategies with minimal ecological impact.

Regulatory compliance and environmental standards increasingly influence microfluidic system design and operation. Organizations developing these technologies must navigate evolving regulations regarding chemical usage, waste disposal, and resource efficiency. Proactive adoption of environmentally conscious evaporation control methods not only ensures regulatory compliance but also positions developers favorably in markets where sustainability credentials drive purchasing decisions.

Cross-disciplinary collaboration between microfluidic engineers and environmental scientists can accelerate the development of sustainable solutions. By incorporating principles of green chemistry and circular economy into evaporation control strategies, researchers can minimize waste generation while maximizing resource efficiency throughout the product lifecycle, creating truly sustainable microfluidic technologies for future applications.

Water conservation represents a critical sustainability aspect of microfluidic system design. In regions facing water scarcity, the cumulative impact of water loss through evaporation in research and industrial applications becomes significant. Implementing effective evaporation reduction techniques directly contributes to water conservation efforts, aligning microfluidic technologies with sustainable development goals and responsible resource management practices.

Energy consumption associated with evaporation compensation mechanisms presents another environmental consideration. Systems requiring continuous fluid replenishment or temperature control to counteract evaporation effects typically demand additional energy inputs. By minimizing evaporation through passive or low-energy solutions, the overall carbon footprint of microfluidic operations can be substantially reduced, supporting broader climate action initiatives.

The life cycle assessment of evaporation control materials reveals important sustainability implications. Biodegradable or recyclable materials for humidity chambers and channel covers offer environmentally preferable alternatives to petroleum-based polymers. Similarly, biomimetic approaches inspired by natural water conservation mechanisms present opportunities for developing sustainable evaporation reduction strategies with minimal ecological impact.

Regulatory compliance and environmental standards increasingly influence microfluidic system design and operation. Organizations developing these technologies must navigate evolving regulations regarding chemical usage, waste disposal, and resource efficiency. Proactive adoption of environmentally conscious evaporation control methods not only ensures regulatory compliance but also positions developers favorably in markets where sustainability credentials drive purchasing decisions.

Cross-disciplinary collaboration between microfluidic engineers and environmental scientists can accelerate the development of sustainable solutions. By incorporating principles of green chemistry and circular economy into evaporation control strategies, researchers can minimize waste generation while maximizing resource efficiency throughout the product lifecycle, creating truly sustainable microfluidic technologies for future applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!