How to Achieve Precision Flow Control in Microfluidic Systems

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Flow Control Background and Objectives

Microfluidic systems have evolved significantly over the past three decades, transforming from simple channel networks to sophisticated platforms capable of precise manipulation of fluids at the microscale. The field emerged in the early 1990s as an extension of microelectromechanical systems (MEMS) technology, with pioneering work by researchers at institutions like Stanford University and MIT establishing the fundamental principles of fluid behavior at microscale dimensions.

The evolution of microfluidic technology has been characterized by several distinct phases. Initially, simple channel-based systems dominated, followed by the development of more complex valve-based control mechanisms. Recent advancements have introduced digital microfluidics, droplet-based systems, and paper-based microfluidics, each expanding the application scope and precision capabilities of these systems.

Precision flow control represents the cornerstone challenge in microfluidic systems development. At microscale dimensions, fluid behavior is dominated by surface forces rather than inertial forces, resulting in laminar flow profiles that differ significantly from macroscale fluid dynamics. This fundamental difference necessitates specialized approaches to achieve precise control over fluid movement, mixing, and separation.

The primary technical objectives in microfluidic flow control include achieving nanoliter to picoliter volume precision, maintaining stable flow rates with minimal pulsation, enabling rapid switching between different flow states, and ensuring reproducibility across multiple experimental runs. These objectives are critical for applications ranging from point-of-care diagnostics to organ-on-chip platforms and high-throughput drug screening systems.

Current technological trends point toward integration of multiple control mechanisms, including pressure-driven flow, electrokinetic methods, centrifugal forces, and acoustic wave manipulation. The field is increasingly moving toward closed-loop control systems that incorporate real-time sensing and feedback mechanisms to maintain precise flow parameters despite environmental variations or system perturbations.

The miniaturization trajectory continues to push boundaries, with emerging research focusing on nanoliter and even femtoliter precision control. This extreme miniaturization enables unprecedented applications in single-cell analysis, molecular diagnostics, and synthetic biology, where precise manipulation of individual cells or molecules is required.

Interdisciplinary convergence is reshaping the field, with advances in materials science, artificial intelligence, and biosensing technologies being incorporated into next-generation microfluidic control systems. This convergence is expected to yield more intelligent, adaptive flow control mechanisms capable of responding dynamically to changing experimental conditions or biological samples.

The evolution of microfluidic technology has been characterized by several distinct phases. Initially, simple channel-based systems dominated, followed by the development of more complex valve-based control mechanisms. Recent advancements have introduced digital microfluidics, droplet-based systems, and paper-based microfluidics, each expanding the application scope and precision capabilities of these systems.

Precision flow control represents the cornerstone challenge in microfluidic systems development. At microscale dimensions, fluid behavior is dominated by surface forces rather than inertial forces, resulting in laminar flow profiles that differ significantly from macroscale fluid dynamics. This fundamental difference necessitates specialized approaches to achieve precise control over fluid movement, mixing, and separation.

The primary technical objectives in microfluidic flow control include achieving nanoliter to picoliter volume precision, maintaining stable flow rates with minimal pulsation, enabling rapid switching between different flow states, and ensuring reproducibility across multiple experimental runs. These objectives are critical for applications ranging from point-of-care diagnostics to organ-on-chip platforms and high-throughput drug screening systems.

Current technological trends point toward integration of multiple control mechanisms, including pressure-driven flow, electrokinetic methods, centrifugal forces, and acoustic wave manipulation. The field is increasingly moving toward closed-loop control systems that incorporate real-time sensing and feedback mechanisms to maintain precise flow parameters despite environmental variations or system perturbations.

The miniaturization trajectory continues to push boundaries, with emerging research focusing on nanoliter and even femtoliter precision control. This extreme miniaturization enables unprecedented applications in single-cell analysis, molecular diagnostics, and synthetic biology, where precise manipulation of individual cells or molecules is required.

Interdisciplinary convergence is reshaping the field, with advances in materials science, artificial intelligence, and biosensing technologies being incorporated into next-generation microfluidic control systems. This convergence is expected to yield more intelligent, adaptive flow control mechanisms capable of responding dynamically to changing experimental conditions or biological samples.

Market Analysis for Precision Microfluidic Applications

The global microfluidics market is experiencing robust growth, projected to reach $42.7 billion by 2027, with a compound annual growth rate (CAGR) of 14.3% from 2022. This growth is primarily driven by increasing demand for precision flow control technologies across various industries, particularly in healthcare, pharmaceuticals, and life sciences.

In the healthcare sector, microfluidic systems with precise flow control capabilities are revolutionizing point-of-care diagnostics, enabling rapid and accurate disease detection with minimal sample volumes. The market for these diagnostic applications alone is expected to grow at a CAGR of 16.8% through 2027, reflecting the critical need for technologies that can reliably manipulate fluids at the microscale.

Pharmaceutical companies represent another significant market segment, increasingly adopting microfluidic platforms for drug discovery and development processes. These systems allow for high-throughput screening and precise dosing, reducing development costs by up to 30% and accelerating time-to-market for new therapeutics. Industry reports indicate that approximately 65% of major pharmaceutical companies have integrated some form of microfluidic technology into their R&D pipelines.

The academic and research sector continues to be a steady consumer of precision microfluidic systems, with universities and research institutions accounting for approximately 22% of the total market. This segment is particularly focused on advancing fundamental capabilities in flow control, often serving as the innovation engine for technologies that later find commercial applications.

Geographically, North America leads the market with a 38% share, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to witness the fastest growth, with a projected CAGR of 17.2% through 2027, driven by increasing healthcare expenditure and expanding biotechnology sectors in countries like China, Japan, and South Korea.

Consumer demand trends indicate a growing preference for integrated microfluidic systems that offer precise flow control alongside other functionalities such as sensing, mixing, and separation. End-users are increasingly seeking solutions that provide not just accuracy but also reproducibility and automation capabilities, with 78% of surveyed users citing reliability as their top purchasing criterion.

Emerging applications in organ-on-a-chip technologies, synthetic biology, and personalized medicine are expected to create new market opportunities, potentially adding $3.5 billion to the market by 2030. These applications demand unprecedented levels of flow control precision, creating both challenges and opportunities for technology developers in this space.

In the healthcare sector, microfluidic systems with precise flow control capabilities are revolutionizing point-of-care diagnostics, enabling rapid and accurate disease detection with minimal sample volumes. The market for these diagnostic applications alone is expected to grow at a CAGR of 16.8% through 2027, reflecting the critical need for technologies that can reliably manipulate fluids at the microscale.

Pharmaceutical companies represent another significant market segment, increasingly adopting microfluidic platforms for drug discovery and development processes. These systems allow for high-throughput screening and precise dosing, reducing development costs by up to 30% and accelerating time-to-market for new therapeutics. Industry reports indicate that approximately 65% of major pharmaceutical companies have integrated some form of microfluidic technology into their R&D pipelines.

The academic and research sector continues to be a steady consumer of precision microfluidic systems, with universities and research institutions accounting for approximately 22% of the total market. This segment is particularly focused on advancing fundamental capabilities in flow control, often serving as the innovation engine for technologies that later find commercial applications.

Geographically, North America leads the market with a 38% share, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to witness the fastest growth, with a projected CAGR of 17.2% through 2027, driven by increasing healthcare expenditure and expanding biotechnology sectors in countries like China, Japan, and South Korea.

Consumer demand trends indicate a growing preference for integrated microfluidic systems that offer precise flow control alongside other functionalities such as sensing, mixing, and separation. End-users are increasingly seeking solutions that provide not just accuracy but also reproducibility and automation capabilities, with 78% of surveyed users citing reliability as their top purchasing criterion.

Emerging applications in organ-on-a-chip technologies, synthetic biology, and personalized medicine are expected to create new market opportunities, potentially adding $3.5 billion to the market by 2030. These applications demand unprecedented levels of flow control precision, creating both challenges and opportunities for technology developers in this space.

Current Challenges in Microfluidic Flow Control

Despite significant advancements in microfluidic technology, precision flow control remains one of the most challenging aspects in microfluidic systems. The fundamental difficulty stems from the physics of fluid behavior at the microscale, where surface forces dominate over volume forces, creating flow dynamics that differ substantially from macroscale systems. Viscous forces become predominant, and the Reynolds number is typically low, resulting in laminar flow regimes that present unique control challenges.

Current microfluidic pumping mechanisms face several critical limitations. Syringe pumps, while widely used, often exhibit pulsatile flow characteristics and delayed response times that compromise precision in dynamic applications. Pressure-driven systems struggle with accurate pressure-to-flow rate conversions due to varying channel resistances and compliance effects in polymer-based devices. These issues become particularly problematic when working with biological samples or in applications requiring sub-nanoliter precision.

Material constraints further complicate flow control efforts. PDMS (polydimethylsiloxane), the most common material for microfluidic devices, exhibits elastomeric properties that cause channel deformation under pressure, leading to unpredictable flow behaviors. Additionally, PDMS absorbs small hydrophobic molecules and swells in the presence of certain organic solvents, altering channel dimensions during operation and disrupting carefully calibrated flow parameters.

Integration challenges between flow control components and sensing elements create another layer of complexity. The miniaturization of valves, pumps, and flow sensors while maintaining precision remains technically demanding. Commercial solutions often require bulky external equipment that contradicts the inherent advantages of microfluidic miniaturization. This size mismatch creates significant hurdles for point-of-care applications and portable diagnostic devices.

Bubble formation and removal represent persistent operational challenges. Even microscopic air bubbles can obstruct channels, alter flow patterns, and compromise experimental results. Current degassing techniques are often time-consuming and not fully effective, particularly in continuous-flow applications where system interruption is not feasible.

The interface between digital control systems and physical fluid manipulation presents additional difficulties. Response latency in feedback control loops limits real-time flow adjustments, while software integration across different hardware components often lacks standardization. This creates compatibility issues that impede the development of plug-and-play microfluidic systems.

For applications requiring multi-phase flows or handling of non-Newtonian fluids (common in biological samples), the challenges multiply exponentially. Controlling the precise position of fluid interfaces, preventing cross-contamination, and maintaining consistent flow rates across varying viscosities demand sophisticated control mechanisms that current technology struggles to provide consistently and affordably.

Current microfluidic pumping mechanisms face several critical limitations. Syringe pumps, while widely used, often exhibit pulsatile flow characteristics and delayed response times that compromise precision in dynamic applications. Pressure-driven systems struggle with accurate pressure-to-flow rate conversions due to varying channel resistances and compliance effects in polymer-based devices. These issues become particularly problematic when working with biological samples or in applications requiring sub-nanoliter precision.

Material constraints further complicate flow control efforts. PDMS (polydimethylsiloxane), the most common material for microfluidic devices, exhibits elastomeric properties that cause channel deformation under pressure, leading to unpredictable flow behaviors. Additionally, PDMS absorbs small hydrophobic molecules and swells in the presence of certain organic solvents, altering channel dimensions during operation and disrupting carefully calibrated flow parameters.

Integration challenges between flow control components and sensing elements create another layer of complexity. The miniaturization of valves, pumps, and flow sensors while maintaining precision remains technically demanding. Commercial solutions often require bulky external equipment that contradicts the inherent advantages of microfluidic miniaturization. This size mismatch creates significant hurdles for point-of-care applications and portable diagnostic devices.

Bubble formation and removal represent persistent operational challenges. Even microscopic air bubbles can obstruct channels, alter flow patterns, and compromise experimental results. Current degassing techniques are often time-consuming and not fully effective, particularly in continuous-flow applications where system interruption is not feasible.

The interface between digital control systems and physical fluid manipulation presents additional difficulties. Response latency in feedback control loops limits real-time flow adjustments, while software integration across different hardware components often lacks standardization. This creates compatibility issues that impede the development of plug-and-play microfluidic systems.

For applications requiring multi-phase flows or handling of non-Newtonian fluids (common in biological samples), the challenges multiply exponentially. Controlling the precise position of fluid interfaces, preventing cross-contamination, and maintaining consistent flow rates across varying viscosities demand sophisticated control mechanisms that current technology struggles to provide consistently and affordably.

State-of-the-Art Flow Control Solutions

01 Microvalve-based flow control systems

Microfluidic systems utilize specialized microvalves to achieve precise flow control in small channels. These valves can be actuated through various mechanisms including pneumatic, electromagnetic, or piezoelectric methods to regulate fluid movement with high precision. The integration of these microvalves allows for dynamic control of flow rates, direction, and timing in complex microfluidic networks, enabling applications in analytical chemistry, medical diagnostics, and biological research.- Microvalve-based flow control systems: Microvalve-based systems provide precise control over fluid flow in microfluidic devices. These systems utilize various actuation mechanisms including electromagnetic, piezoelectric, or thermally-controlled microvalves to regulate flow rates with high precision. The integration of these microvalves enables dynamic flow control, allowing for automated and programmable fluid handling in complex microfluidic applications such as lab-on-a-chip devices and analytical systems.

- Pressure-driven flow control techniques: Pressure-driven flow control techniques utilize precisely regulated pressure differentials to manage fluid movement in microfluidic channels. These systems incorporate pressure sensors, regulators, and feedback control mechanisms to maintain stable flow rates despite variations in channel geometry or fluid properties. Advanced pressure-driven systems can achieve nanoliter-level precision and are particularly valuable for applications requiring pulseless flow, such as cell culture, chemical synthesis, and high-precision analytical procedures.

- Integrated sensors for flow monitoring and control: Microfluidic systems with integrated sensors enable real-time monitoring and adjustment of flow parameters. These sensors measure variables such as flow rate, pressure, temperature, and fluid composition, providing feedback to control systems that automatically adjust flow conditions. The integration of MEMS-based sensors, optical detection systems, and electrochemical sensors allows for closed-loop control of microfluidic processes, enhancing reproducibility and precision in applications ranging from point-of-care diagnostics to high-throughput screening platforms.

- Digital microfluidics for droplet manipulation: Digital microfluidic systems enable precise control over individual droplets within microfluidic platforms. These systems utilize electrowetting, acoustic forces, or surface tension effects to generate, transport, merge, and split droplets with volumes in the nanoliter to picoliter range. The ability to manipulate discrete fluid volumes provides advantages for applications requiring precise reagent metering, parallel processing, and minimal sample consumption, such as single-cell analysis, digital PCR, and combinatorial chemistry.

- Microfluidic pumping mechanisms: Advanced microfluidic pumping mechanisms provide the driving force for precise fluid movement within microchannels. These include electrokinetic pumps that utilize electroosmotic flow, peristaltic micropumps that use sequential actuation of membrane elements, and centrifugal microfluidics that harness rotational forces. Each pumping mechanism offers distinct advantages for specific applications, with considerations including flow rate stability, pulsation characteristics, biocompatibility, and power requirements determining the optimal choice for particular microfluidic implementations.

02 Pressure-driven flow control mechanisms

Pressure-driven systems employ precisely controlled pressure differentials to manipulate fluid flow in microfluidic channels. These systems utilize pressure regulators, pumps, and sensors to maintain stable flow conditions with minimal pulsation. Advanced pressure-driven mechanisms can compensate for changes in viscosity, temperature, and channel dimensions to ensure consistent flow rates. This approach is particularly valuable for applications requiring stable, pulseless flow such as cell culture, chemical synthesis, and high-precision analytical procedures.Expand Specific Solutions03 Integrated sensor feedback control systems

Microfluidic platforms incorporating integrated sensors enable real-time monitoring and feedback control of flow parameters. These systems utilize flow sensors, pressure sensors, or optical detection methods to continuously measure flow conditions and automatically adjust control parameters. The feedback loop architecture allows for rapid response to changing conditions, maintaining precise flow control even under variable external conditions. This approach significantly enhances reproducibility and reliability in applications such as point-of-care diagnostics and automated chemical analysis.Expand Specific Solutions04 Digital microfluidics and droplet control

Digital microfluidic systems manipulate discrete droplets rather than continuous flows, offering precise control over small fluid volumes. These platforms employ electrowetting, acoustic forces, or surface tension effects to generate, move, split, and merge droplets with high precision. The ability to handle individual droplets as discrete reaction vessels enables parallel processing, reduced reagent consumption, and enhanced analytical sensitivity. Applications include high-throughput screening, single-cell analysis, and multiplexed diagnostic assays.Expand Specific Solutions05 Microfluidic flow control for biological applications

Specialized microfluidic systems designed for biological applications incorporate flow control mechanisms optimized for cell handling, biomolecular analysis, and physiological modeling. These systems maintain biocompatible conditions while precisely controlling shear forces, concentration gradients, and temporal exposure patterns. Advanced biological microfluidics may include temperature control, gas exchange capabilities, and matrix integration for 3D cell culture. The precise flow control enables applications such as organ-on-chip models, controlled cell differentiation, and high-resolution cell sorting.Expand Specific Solutions

Leading Companies and Research Institutions in Microfluidics

Microfluidic precision flow control technology is currently in a growth phase, with the market expanding rapidly due to increasing applications in healthcare, pharmaceuticals, and research. The global market size is estimated to reach several billion dollars by 2025, driven by demand for point-of-care diagnostics and lab-on-a-chip technologies. Technologically, the field shows varying maturity levels across different applications. Leading companies like Advanced Liquid Logic and Elvesys have developed sophisticated digital microfluidic platforms, while established players such as bioMérieux and Caliper Life Sciences are integrating microfluidic technologies into commercial diagnostic systems. Research institutions including Duke University, Institut Curie, and CNRS continue to advance fundamental technologies, while industrial players like Intel and Huawei are exploring microfluidics for cooling applications in electronics.

Advanced Liquid Logic, Inc.

Technical Solution: Advanced Liquid Logic has pioneered digital microfluidics technology for precise flow control using electrowetting-on-dielectric (EWOD) principles. Their platform manipulates discrete droplets (typically nanoliter to microliter volumes) on an array of electrodes coated with hydrophobic insulator. By applying controlled voltages to specific electrodes, they create localized changes in surface tension that enable droplet operations including transport, splitting, merging, and mixing with exceptional precision. The company's proprietary technology incorporates capacitive feedback sensing to verify droplet presence and movement, ensuring reliable operation. Their integrated circuit designs allow for thousands of independently addressable electrodes, enabling complex fluidic protocols on a single chip without mechanical pumps or valves. This technology has been successfully implemented in diagnostic applications requiring precise reagent handling and mixing.

Strengths: Offers programmable, reconfigurable fluid handling without moving parts; achieves precise control of individual droplets at nanoliter scale; eliminates cross-contamination concerns through digital isolation of samples. Weaknesses: Requires specialized surface treatments that may degrade over time; limited to relatively low throughput applications; operation can be affected by fluid properties like viscosity and surface tension.

Duke University

Technical Solution: Duke University has developed advanced microfluidic flow control systems centered around elastomeric valve technology and pneumatic control architectures. Their research teams have created multilayer soft lithography techniques that enable the fabrication of integrated microfluidic circuits with thousands of valves and hundreds of individually addressable chambers. The university's approach utilizes pressure-actuated membrane valves made from polydimethylsiloxane (PDMS) that can be precisely controlled to regulate fluid flow with nanoliter precision. Duke researchers have pioneered multiplexed control systems that allow complex fluidic operations with minimal external connections, significantly reducing device footprint and complexity. Their innovations include specialized valve geometries that minimize dead volume and enhance mixing efficiency, as well as control algorithms that enable precise temporal control of multiple fluid streams. The university has also developed optical monitoring systems integrated with their microfluidic platforms to provide real-time feedback on flow conditions and enable closed-loop control for maintaining precise flow rates despite variations in channel conditions or fluid properties.

Strengths: Highly scalable valve architecture allows for complex integrated circuits; soft lithography fabrication techniques are relatively accessible to research labs; systems can be adapted for a wide range of biological and chemical applications. Weaknesses: Pneumatic control systems require external pressure sources and controllers; PDMS material has limitations including solvent compatibility issues and potential for absorption of small hydrophobic molecules; scaling to industrial production can be challenging.

Key Patents and Technical Breakthroughs

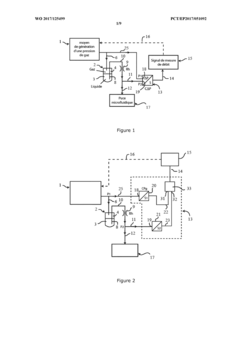

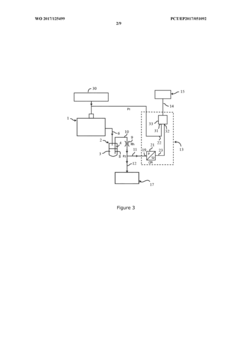

System for measuring the flow rate of a liquid and use of same

PatentWO2017125499A1

Innovation

- A system that measures microfluidic flow rate by calculating the pressure difference between a gas overhead and the liquid downstream of a hydraulic resistance, using a single pressure sensor to generate a signal proportional to the flow rate, with a capillary tube or restriction that minimizes clogging risks and allows for precise control of the liquid flow.

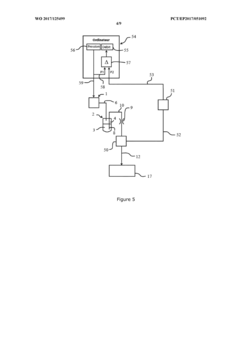

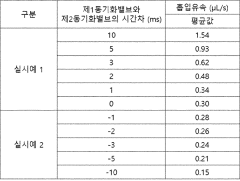

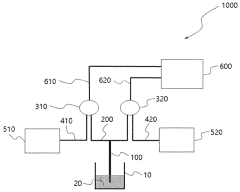

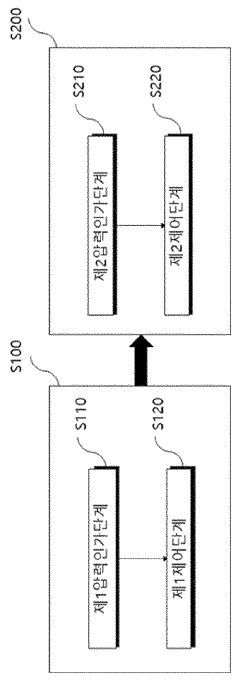

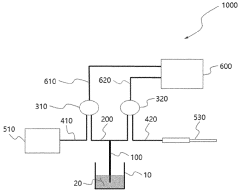

Microfluidic flow velocity precise-control device using synchronously operating dual valves and microfluidic flow velocity precise-control method using same

PatentWO2024080722A1

Innovation

- A microfluidic flow rate precision control device utilizing a synchronized double valve system, where two synchronization valves operate with a controlled time difference to adjust pressure and vacuum, allowing precise control of fluid flow rates within microfluidic tubes.

Materials Science Advancements for Microfluidics

Recent advancements in materials science have revolutionized the field of microfluidics, particularly in achieving precision flow control. Traditional materials like glass and silicon are increasingly being complemented or replaced by polymers such as polydimethylsiloxane (PDMS), which offers superior elasticity, optical transparency, and biocompatibility. These properties make PDMS particularly valuable for applications requiring precise manipulation of biological samples.

Surface modification techniques have emerged as critical enablers for precision flow control. By altering the hydrophobicity or hydrophilicity of channel surfaces, researchers can manipulate fluid behavior at the microscale with unprecedented accuracy. Techniques such as plasma treatment, chemical vapor deposition, and layer-by-layer assembly allow for tailored surface properties that can enhance or inhibit fluid flow in specific regions of microfluidic devices.

Smart materials represent another frontier in microfluidic flow control. Stimuli-responsive polymers that change their properties in response to temperature, pH, light, or electrical signals enable dynamic control of fluid behavior. For instance, thermally responsive hydrogels can act as valves, expanding or contracting to regulate flow rates with minimal external intervention, thus reducing system complexity while improving precision.

Nanomaterials integration has significantly enhanced flow sensing and control capabilities. Carbon nanotubes, graphene, and metallic nanoparticles incorporated into microfluidic channels provide exceptional sensing capabilities for flow rate, pressure, and chemical composition. These materials offer high surface-to-volume ratios and unique electrical properties that translate to improved sensitivity and response times in flow control systems.

Biomimetic materials inspired by natural systems are increasingly being explored for specialized flow control applications. Materials that mimic the non-wetting properties of lotus leaves or the directional fluid transport mechanisms of tree xylem offer innovative approaches to passive flow control. These biomimetic solutions often require less external energy input while maintaining high precision in specific applications.

3D-printable materials with tailored properties are transforming microfluidic device fabrication. Advanced resins and composite materials compatible with high-resolution stereolithography allow for complex channel geometries and integrated flow control elements that would be impossible with traditional fabrication methods. This enables rapid prototyping and iteration of novel flow control mechanisms with increasingly fine resolution.

The integration of these material advances with computational modeling and design tools is accelerating innovation in microfluidic flow control. Multiphysics simulations that account for material properties, surface interactions, and fluid dynamics enable predictive design of next-generation microfluidic systems with unprecedented precision in flow control across diverse applications from healthcare diagnostics to chemical synthesis.

Surface modification techniques have emerged as critical enablers for precision flow control. By altering the hydrophobicity or hydrophilicity of channel surfaces, researchers can manipulate fluid behavior at the microscale with unprecedented accuracy. Techniques such as plasma treatment, chemical vapor deposition, and layer-by-layer assembly allow for tailored surface properties that can enhance or inhibit fluid flow in specific regions of microfluidic devices.

Smart materials represent another frontier in microfluidic flow control. Stimuli-responsive polymers that change their properties in response to temperature, pH, light, or electrical signals enable dynamic control of fluid behavior. For instance, thermally responsive hydrogels can act as valves, expanding or contracting to regulate flow rates with minimal external intervention, thus reducing system complexity while improving precision.

Nanomaterials integration has significantly enhanced flow sensing and control capabilities. Carbon nanotubes, graphene, and metallic nanoparticles incorporated into microfluidic channels provide exceptional sensing capabilities for flow rate, pressure, and chemical composition. These materials offer high surface-to-volume ratios and unique electrical properties that translate to improved sensitivity and response times in flow control systems.

Biomimetic materials inspired by natural systems are increasingly being explored for specialized flow control applications. Materials that mimic the non-wetting properties of lotus leaves or the directional fluid transport mechanisms of tree xylem offer innovative approaches to passive flow control. These biomimetic solutions often require less external energy input while maintaining high precision in specific applications.

3D-printable materials with tailored properties are transforming microfluidic device fabrication. Advanced resins and composite materials compatible with high-resolution stereolithography allow for complex channel geometries and integrated flow control elements that would be impossible with traditional fabrication methods. This enables rapid prototyping and iteration of novel flow control mechanisms with increasingly fine resolution.

The integration of these material advances with computational modeling and design tools is accelerating innovation in microfluidic flow control. Multiphysics simulations that account for material properties, surface interactions, and fluid dynamics enable predictive design of next-generation microfluidic systems with unprecedented precision in flow control across diverse applications from healthcare diagnostics to chemical synthesis.

Integration with IoT and Automation Systems

The integration of microfluidic systems with IoT (Internet of Things) and automation technologies represents a significant advancement in precision flow control capabilities. Modern microfluidic platforms increasingly incorporate wireless connectivity modules that enable remote monitoring and control of flow parameters through dedicated mobile applications or web interfaces. This connectivity facilitates real-time data collection, analysis, and adjustment of flow conditions without requiring physical presence at the device, substantially enhancing operational efficiency in research and industrial settings.

Cloud-based platforms have emerged as critical components in this integration, offering centralized data storage and processing capabilities for microfluidic systems. These platforms enable sophisticated data analytics, including pattern recognition and predictive maintenance algorithms that can anticipate system failures before they occur. The implementation of machine learning algorithms further enhances system performance by continuously optimizing flow parameters based on historical data and desired outcomes, effectively creating self-improving systems that become more precise over time.

Standardized communication protocols such as MQTT (Message Queuing Telemetry Transport) and OPC UA (Open Platform Communications Unified Architecture) are increasingly being adopted to ensure seamless integration between microfluidic devices and broader laboratory or manufacturing automation systems. These protocols facilitate the coordination of microfluidic operations with other automated processes, creating comprehensive workflows that minimize human intervention and associated variability.

Digital twin technology represents another frontier in microfluidic system automation, allowing for the creation of virtual replicas of physical systems that can simulate flow behaviors under various conditions. This capability enables operators to test parameter adjustments virtually before implementing them in the actual system, reducing experimental iterations and resource consumption while accelerating development cycles.

The integration of voice-controlled interfaces and augmented reality (AR) systems is beginning to transform how researchers and technicians interact with microfluidic platforms. These technologies allow for hands-free operation and visualization of flow parameters overlaid on physical devices, particularly valuable in sterile environments or when handling hazardous materials where minimal physical contact is preferred.

Security considerations have become increasingly important as microfluidic systems join the IoT ecosystem. Encryption protocols, secure authentication mechanisms, and regular security updates are being implemented to protect sensitive data and prevent unauthorized access to system controls, especially critical in applications involving proprietary processes or clinical samples.

Cloud-based platforms have emerged as critical components in this integration, offering centralized data storage and processing capabilities for microfluidic systems. These platforms enable sophisticated data analytics, including pattern recognition and predictive maintenance algorithms that can anticipate system failures before they occur. The implementation of machine learning algorithms further enhances system performance by continuously optimizing flow parameters based on historical data and desired outcomes, effectively creating self-improving systems that become more precise over time.

Standardized communication protocols such as MQTT (Message Queuing Telemetry Transport) and OPC UA (Open Platform Communications Unified Architecture) are increasingly being adopted to ensure seamless integration between microfluidic devices and broader laboratory or manufacturing automation systems. These protocols facilitate the coordination of microfluidic operations with other automated processes, creating comprehensive workflows that minimize human intervention and associated variability.

Digital twin technology represents another frontier in microfluidic system automation, allowing for the creation of virtual replicas of physical systems that can simulate flow behaviors under various conditions. This capability enables operators to test parameter adjustments virtually before implementing them in the actual system, reducing experimental iterations and resource consumption while accelerating development cycles.

The integration of voice-controlled interfaces and augmented reality (AR) systems is beginning to transform how researchers and technicians interact with microfluidic platforms. These technologies allow for hands-free operation and visualization of flow parameters overlaid on physical devices, particularly valuable in sterile environments or when handling hazardous materials where minimal physical contact is preferred.

Security considerations have become increasingly important as microfluidic systems join the IoT ecosystem. Encryption protocols, secure authentication mechanisms, and regular security updates are being implemented to protect sensitive data and prevent unauthorized access to system controls, especially critical in applications involving proprietary processes or clinical samples.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!