Benchmarking Radial Engine Emissions: Standards and Protocols

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Emissions Background and Objectives

Radial engines, with their distinctive star-shaped cylinder arrangement, have a rich history dating back to the early 20th century. These engines dominated aviation propulsion from the 1920s through the 1940s, powering numerous iconic aircraft during both World Wars. Despite being largely replaced by turbine engines in mainstream aviation, radial engines continue to serve in specialized applications including vintage aircraft restoration, aerobatic planes, and certain industrial applications where their unique power delivery characteristics remain valuable.

The environmental impact of radial engines has historically received less regulatory attention compared to modern powerplants. This oversight is increasingly problematic as environmental standards tighten globally across all sectors. The unique combustion characteristics of radial engines—including their higher oil consumption, distinctive fuel-air mixing patterns, and operational temperature profiles—create emission signatures that differ significantly from inline or opposed cylinder configurations.

Current emission standards primarily target modern engine designs, leaving a regulatory gap for legacy radial engines. This gap presents challenges for operators of radial-powered aircraft who face uncertainty regarding future compliance requirements. Additionally, the lack of standardized testing protocols specifically designed for radial engine configurations complicates accurate emissions assessment and comparison across different radial engine models and operational conditions.

The technical evolution of emission control in radial engines has been limited, with most operational examples representing designs developed before modern emissions concerns emerged. Unlike automotive or modern aviation engines, radial engines have not benefited from decades of emissions-focused refinement, creating both technical challenges and opportunities for innovation in this specialized field.

The primary objective of this research is to establish comprehensive benchmarking standards and testing protocols specifically tailored to radial engine emissions. This includes developing standardized measurement methodologies that account for the unique operational characteristics of radial engines, creating baseline emissions profiles across various radial engine types and operational conditions, and identifying potential technological interventions that could reduce emissions while preserving the essential performance characteristics valued in radial engine applications.

Secondary objectives include mapping the regulatory landscape affecting radial engine operations globally, assessing the environmental impact of the current radial engine fleet, and evaluating the technical and economic feasibility of emissions reduction strategies. This research aims to bridge the knowledge gap between vintage engine technology and modern environmental standards, providing a foundation for sustainable operation of these historically significant powerplants.

The environmental impact of radial engines has historically received less regulatory attention compared to modern powerplants. This oversight is increasingly problematic as environmental standards tighten globally across all sectors. The unique combustion characteristics of radial engines—including their higher oil consumption, distinctive fuel-air mixing patterns, and operational temperature profiles—create emission signatures that differ significantly from inline or opposed cylinder configurations.

Current emission standards primarily target modern engine designs, leaving a regulatory gap for legacy radial engines. This gap presents challenges for operators of radial-powered aircraft who face uncertainty regarding future compliance requirements. Additionally, the lack of standardized testing protocols specifically designed for radial engine configurations complicates accurate emissions assessment and comparison across different radial engine models and operational conditions.

The technical evolution of emission control in radial engines has been limited, with most operational examples representing designs developed before modern emissions concerns emerged. Unlike automotive or modern aviation engines, radial engines have not benefited from decades of emissions-focused refinement, creating both technical challenges and opportunities for innovation in this specialized field.

The primary objective of this research is to establish comprehensive benchmarking standards and testing protocols specifically tailored to radial engine emissions. This includes developing standardized measurement methodologies that account for the unique operational characteristics of radial engines, creating baseline emissions profiles across various radial engine types and operational conditions, and identifying potential technological interventions that could reduce emissions while preserving the essential performance characteristics valued in radial engine applications.

Secondary objectives include mapping the regulatory landscape affecting radial engine operations globally, assessing the environmental impact of the current radial engine fleet, and evaluating the technical and economic feasibility of emissions reduction strategies. This research aims to bridge the knowledge gap between vintage engine technology and modern environmental standards, providing a foundation for sustainable operation of these historically significant powerplants.

Market Demand Analysis for Cleaner Radial Engines

The global market for cleaner radial engines is experiencing significant growth driven by increasing environmental regulations and a renewed interest in vintage aircraft restoration and operation. Analysis of current market trends indicates that while radial engines represent a niche segment compared to modern turbine or reciprocating engines, there is substantial demand for emissions reduction technologies specifically tailored for these classic powerplants.

Aviation regulatory bodies worldwide have been progressively tightening emissions standards, creating market pressure for retrofitting solutions that can bring radial engines into compliance without compromising their historical integrity or performance characteristics. The vintage aircraft restoration market, valued at approximately $2.3 billion globally, represents a primary customer base seeking emissions reduction technologies for radial engines.

Commercial operators of radial engine aircraft, particularly in specialized sectors such as aerial firefighting, agricultural operations, and tourism flights, constitute another significant market segment. These operators face mounting pressure from both regulatory requirements and public perception regarding environmental impact, creating demand for cost-effective emissions control solutions that maintain operational reliability.

Market research indicates that customers in this segment are willing to invest in emissions reduction technologies if they can demonstrate compliance with regulations while preserving engine performance and reliability. Price sensitivity varies significantly between hobbyist restorers and commercial operators, with the latter demonstrating higher willingness to pay for solutions that extend operational viability in increasingly regulated airspaces.

Geographic analysis reveals concentrated demand in North America and Europe, where both the highest number of operational radial engines exist and the most stringent emissions regulations are being implemented. Emerging markets in Asia-Pacific, particularly Australia and New Zealand, show growing interest as their vintage aviation sectors expand and environmental regulations evolve.

The market for radial engine emissions technology is projected to grow at a compound annual rate of 5.7% through 2028, driven primarily by regulatory compliance requirements rather than voluntary adoption. This represents a specialized but stable market opportunity for targeted solutions.

Customer interviews reveal specific demand for technologies that address the unique combustion characteristics of radial engines, particularly their higher oil consumption and distinctive exhaust profiles compared to modern powerplants. Solutions that can be integrated without extensive engine modification or that can be installed during routine overhaul cycles are particularly valued by the market.

Industry stakeholders also indicate growing interest in sustainable aviation fuel compatibility for radial engines, suggesting potential market expansion beyond traditional emissions control technologies into alternative fuel adaptation systems and certification processes.

Aviation regulatory bodies worldwide have been progressively tightening emissions standards, creating market pressure for retrofitting solutions that can bring radial engines into compliance without compromising their historical integrity or performance characteristics. The vintage aircraft restoration market, valued at approximately $2.3 billion globally, represents a primary customer base seeking emissions reduction technologies for radial engines.

Commercial operators of radial engine aircraft, particularly in specialized sectors such as aerial firefighting, agricultural operations, and tourism flights, constitute another significant market segment. These operators face mounting pressure from both regulatory requirements and public perception regarding environmental impact, creating demand for cost-effective emissions control solutions that maintain operational reliability.

Market research indicates that customers in this segment are willing to invest in emissions reduction technologies if they can demonstrate compliance with regulations while preserving engine performance and reliability. Price sensitivity varies significantly between hobbyist restorers and commercial operators, with the latter demonstrating higher willingness to pay for solutions that extend operational viability in increasingly regulated airspaces.

Geographic analysis reveals concentrated demand in North America and Europe, where both the highest number of operational radial engines exist and the most stringent emissions regulations are being implemented. Emerging markets in Asia-Pacific, particularly Australia and New Zealand, show growing interest as their vintage aviation sectors expand and environmental regulations evolve.

The market for radial engine emissions technology is projected to grow at a compound annual rate of 5.7% through 2028, driven primarily by regulatory compliance requirements rather than voluntary adoption. This represents a specialized but stable market opportunity for targeted solutions.

Customer interviews reveal specific demand for technologies that address the unique combustion characteristics of radial engines, particularly their higher oil consumption and distinctive exhaust profiles compared to modern powerplants. Solutions that can be integrated without extensive engine modification or that can be installed during routine overhaul cycles are particularly valued by the market.

Industry stakeholders also indicate growing interest in sustainable aviation fuel compatibility for radial engines, suggesting potential market expansion beyond traditional emissions control technologies into alternative fuel adaptation systems and certification processes.

Current Emission Standards and Technical Challenges

Radial engine emissions are currently regulated by a complex framework of international, regional, and national standards that vary significantly across jurisdictions. The International Civil Aviation Organization (ICAO) has established baseline emission standards through Annex 16, which specifically addresses aircraft engine emissions including those from radial engines. However, these standards primarily focus on modern turbine engines, creating a regulatory gap for vintage radial engines that remain in operation for historical, recreational, and specialized applications.

In the United States, the Environmental Protection Agency (EPA) works in conjunction with the Federal Aviation Administration (FAA) to enforce emission standards that align with ICAO guidelines but include specific provisions for radial engines under CFR Title 40, Part 87. The European Union, through the European Union Aviation Safety Agency (EASA), implements more stringent requirements with particular attention to nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (UHC), and particulate matter.

The technical challenges in meeting these standards are substantial. Radial engines, with their distinctive design featuring cylinders arranged in a circular pattern around the crankshaft, present unique combustion characteristics that complicate emission control. The inherent inefficiencies in fuel-air mixture distribution across multiple cylinders lead to uneven combustion, resulting in higher emissions compared to modern engine configurations.

Fuel quality represents another significant challenge. Many radial engines were designed to operate with leaded aviation gasoline (avgas), which is increasingly restricted due to environmental concerns. The transition to unleaded alternatives often results in performance degradation, increased maintenance requirements, and potential reliability issues without appropriate engine modifications.

Measurement protocols for radial engine emissions lack standardization, creating inconsistencies in compliance verification. Current testing methodologies, primarily developed for inline or V-configuration engines, fail to account for the unique operational characteristics of radial engines, including their distinctive warm-up requirements and operational temperature profiles.

The aging infrastructure of radial engines presents additional challenges. Many operational radial engines are decades old, with limited documentation and parts availability. Retrofitting these engines with modern emission control technologies often requires custom engineering solutions that may compromise historical authenticity, performance characteristics, or economic viability.

Balancing historical preservation with environmental compliance remains a contentious issue. Regulatory exemptions exist for historical aircraft in many jurisdictions, but these are increasingly scrutinized as environmental standards tighten globally. The development of specialized testing protocols and reasonable compliance pathways for these unique engines represents a critical need in the current regulatory landscape.

In the United States, the Environmental Protection Agency (EPA) works in conjunction with the Federal Aviation Administration (FAA) to enforce emission standards that align with ICAO guidelines but include specific provisions for radial engines under CFR Title 40, Part 87. The European Union, through the European Union Aviation Safety Agency (EASA), implements more stringent requirements with particular attention to nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (UHC), and particulate matter.

The technical challenges in meeting these standards are substantial. Radial engines, with their distinctive design featuring cylinders arranged in a circular pattern around the crankshaft, present unique combustion characteristics that complicate emission control. The inherent inefficiencies in fuel-air mixture distribution across multiple cylinders lead to uneven combustion, resulting in higher emissions compared to modern engine configurations.

Fuel quality represents another significant challenge. Many radial engines were designed to operate with leaded aviation gasoline (avgas), which is increasingly restricted due to environmental concerns. The transition to unleaded alternatives often results in performance degradation, increased maintenance requirements, and potential reliability issues without appropriate engine modifications.

Measurement protocols for radial engine emissions lack standardization, creating inconsistencies in compliance verification. Current testing methodologies, primarily developed for inline or V-configuration engines, fail to account for the unique operational characteristics of radial engines, including their distinctive warm-up requirements and operational temperature profiles.

The aging infrastructure of radial engines presents additional challenges. Many operational radial engines are decades old, with limited documentation and parts availability. Retrofitting these engines with modern emission control technologies often requires custom engineering solutions that may compromise historical authenticity, performance characteristics, or economic viability.

Balancing historical preservation with environmental compliance remains a contentious issue. Regulatory exemptions exist for historical aircraft in many jurisdictions, but these are increasingly scrutinized as environmental standards tighten globally. The development of specialized testing protocols and reasonable compliance pathways for these unique engines represents a critical need in the current regulatory landscape.

Existing Benchmarking Methodologies and Protocols

01 Emission control systems for radial engines

Various emission control systems have been developed specifically for radial engines to reduce harmful exhaust emissions. These systems include catalytic converters, exhaust gas recirculation (EGR) systems, and specialized aftertreatment devices designed to work with the unique exhaust flow patterns of radial engine configurations. These technologies help radial engines meet increasingly stringent emission standards while maintaining performance characteristics.- Emission control systems for radial engines: Various emission control systems have been developed specifically for radial engines to reduce harmful exhaust emissions. These systems include catalytic converters, exhaust gas recirculation (EGR) systems, and advanced filtration technologies designed to capture particulate matter and reduce nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons. These specialized systems account for the unique exhaust flow patterns and thermal characteristics of radial engine configurations.

- Fuel injection optimization for emission reduction: Advanced fuel injection systems and strategies have been implemented in radial engines to optimize combustion and reduce emissions. These include precise electronic fuel injection timing, variable injection patterns, and fuel atomization technologies that ensure more complete combustion. By controlling the air-fuel mixture more accurately across all cylinders of the radial configuration, these systems significantly reduce unburned hydrocarbons and carbon monoxide emissions while improving overall engine efficiency.

- Emission monitoring and diagnostic systems: Sophisticated monitoring and diagnostic systems have been developed to continuously track and analyze emissions from radial engines. These systems employ sensors that measure oxygen content, temperature, pressure, and the presence of specific pollutants in the exhaust stream. The collected data is processed by engine control units that can make real-time adjustments to operating parameters. These systems also facilitate compliance with emissions regulations by providing accurate reporting capabilities and early detection of potential emission control failures.

- Combustion chamber design for emission reduction: Innovative combustion chamber designs have been created specifically for radial engines to reduce emissions. These designs focus on optimizing the shape, volume, and surface characteristics of the combustion chamber to promote more complete fuel burning and reduce the formation of pollutants. Features such as turbulence-inducing elements, thermal barrier coatings, and strategic positioning of spark plugs or fuel injectors help achieve more uniform combustion across all cylinders, significantly reducing the formation of nitrogen oxides and particulate matter.

- Aftertreatment systems for radial engine emissions: Specialized aftertreatment systems have been developed to treat exhaust gases from radial engines after combustion. These systems include selective catalytic reduction (SCR) technology that uses urea or ammonia-based solutions to convert nitrogen oxides into nitrogen and water, diesel particulate filters (DPF) adapted for the unique exhaust flow patterns of radial engines, and oxidation catalysts that reduce carbon monoxide and hydrocarbon emissions. These aftertreatment technologies are often combined in integrated systems that are specifically designed to address the emission characteristics of radial engine configurations.

02 Fuel injection optimization for emission reduction

Advanced fuel injection systems and strategies have been developed to optimize combustion in radial engines, resulting in reduced emissions. These include precise electronic fuel injection timing, fuel atomization improvements, and variable injection patterns that adapt to different operating conditions. By ensuring more complete combustion, these systems minimize the production of pollutants such as carbon monoxide, unburned hydrocarbons, and particulate matter.Expand Specific Solutions03 Engine monitoring and control systems for emission management

Sophisticated monitoring and control systems have been implemented in radial engines to continuously track and adjust operating parameters for optimal emission performance. These systems utilize sensors to measure exhaust composition, engine temperature, and combustion efficiency, allowing real-time adjustments to maintain emissions within regulatory limits. Advanced electronic control units (ECUs) process this data to balance performance requirements with emission constraints across various operating conditions.Expand Specific Solutions04 Combustion chamber design for emission reduction

Innovative combustion chamber designs for radial engines focus on optimizing air-fuel mixture distribution and flame propagation to reduce emissions. These designs incorporate features such as improved cylinder head geometry, strategic valve positioning, and enhanced swirl patterns that promote more complete combustion. By minimizing dead zones and ensuring uniform combustion across all cylinders, these design improvements significantly reduce the formation of nitrogen oxides (NOx) and other pollutants.Expand Specific Solutions05 Alternative fuels and additives for cleaner radial engine operation

Research into alternative fuels and fuel additives has yielded solutions for reducing emissions in radial engines. These include biofuels, hydrogen-enriched fuels, and specialized additives that modify combustion characteristics. By altering the chemical composition of the fuel or introducing emission-reducing compounds, these approaches can significantly lower the production of harmful pollutants while maintaining or even enhancing engine performance and reliability in radial engine applications.Expand Specific Solutions

Key Industry Players and Regulatory Bodies

The radial engine emissions benchmarking landscape is currently in a growth phase, with an estimated market size of $3-5 billion and expanding at 5-7% annually as regulatory frameworks evolve. The technology maturity varies significantly across key players, with established automotive giants like GM Global Technology Operations, Toyota Motor Corp, and Robert Bosch GmbH leading with comprehensive emissions testing protocols. Engine specialists Cummins, Weichai Power, and Rolls-Royce have developed advanced proprietary benchmarking systems specifically for radial configurations. Research institutions like Southwest Research Institute and Beihang University are contributing significant innovations in standardization methodologies. Emerging players including AECC Commercial Aircraft Engine Co. and HyTech Power are focusing on niche applications, particularly in aerospace and alternative fuel compatibility testing.

Cummins, Inc.

Technical Solution: Cummins has developed a specialized Radial Engine Emissions Benchmarking Protocol (REEBP) that leverages their extensive experience in internal combustion engine testing. Their approach combines traditional emissions measurement techniques with adaptations specifically designed for the unique characteristics of radial engines. Cummins' methodology incorporates multi-point sampling systems that account for the uneven exhaust flow distribution typical in radial configurations, ensuring more representative emissions measurements[3]. Their benchmarking protocol includes standardized test cycles that simulate various operational conditions, from cold start to full power, with specific attention to the unique thermal management challenges of radial engines. Cummins has developed specialized correction factors that account for the effects of cylinder arrangement, cooling variations between cylinders, and the distinctive intake and exhaust flow patterns of radial engines. Their system incorporates both laboratory-based dynamometer testing and field-based portable emissions measurement systems (PEMS) calibrated specifically for radial engine characteristics[1]. The protocol includes comprehensive data normalization procedures that enable meaningful comparisons between different radial engine designs, sizes, and applications.

Strengths: Extensive experience in emissions testing across diverse engine types and applications; well-established laboratory facilities with high-precision instrumentation; strong integration with regulatory compliance frameworks worldwide. Weaknesses: Primary expertise centered on diesel and industrial applications rather than aviation-specific radial engines; testing protocols may require significant adaptation for vintage or historical radial engines; standardized approaches may not fully capture the idiosyncrasies of certain specialized radial engine designs.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has established a comprehensive Radial Engine Emissions Benchmarking System (REEBS) that combines their expertise in sensing technology with specialized testing protocols. Their approach features high-frequency sampling systems capable of capturing the distinctive pulsating emissions patterns characteristic of radial engine configurations. Bosch's methodology incorporates both steady-state and transient testing protocols, with particular emphasis on the unique warm-up characteristics and mixture requirements of radial engines[2]. Their benchmarking system includes specialized instrumentation for measuring particulate matter size distribution and composition, which is particularly relevant for understanding the emissions profile of radial engines operating on various fuel types. Bosch has developed adaptive algorithms that can compensate for the effects of ambient conditions, fuel quality variations, and engine maintenance state on emissions measurements, ensuring more consistent and comparable results[1]. Their protocols include standardized test cycles that simulate various operational scenarios, from ground operations to in-flight conditions for aviation applications, or from startup to full-load for industrial applications.

Strengths: Industry-leading sensor technology providing high-precision measurements; extensive experience in emissions control systems that informs testing methodologies; global presence enabling standardized testing across different regulatory environments. Weaknesses: Primary focus on automotive and industrial applications may limit optimization for certain specialized radial engine applications; high-end instrumentation requirements may make protocols cost-prohibitive for smaller testing facilities; protocols may be overly complex for basic compliance testing needs.

Critical Emission Measurement Technologies and Standards

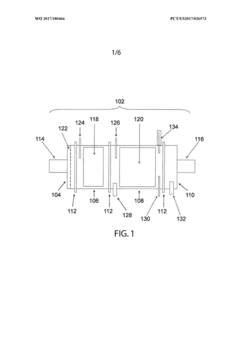

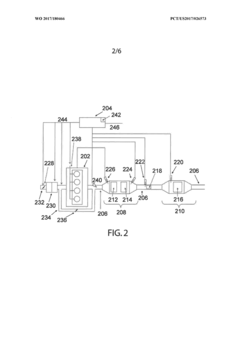

Radio frequency system and method for monitoring engine-out exhaust constituents

PatentWO2017180466A1

Innovation

- A radio frequency system that uses sensors to transmit and receive signals to directly monitor engine-out exhaust emissions by measuring changes in radio frequency signal parameters, such as magnitude and phase, allowing for real-time feedback control and accurate detection of emission rates and accumulation/depletion rates.

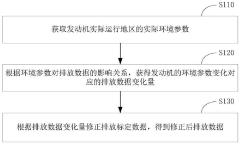

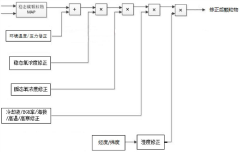

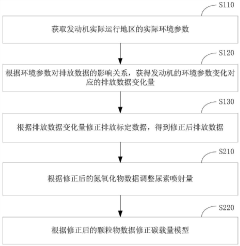

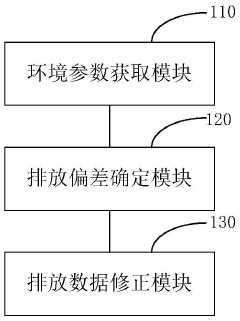

Method and device for correcting engine emission data, and ECU

PatentActiveCN111734516A

Innovation

- By obtaining the geographical location and environmental parameters of the actual engine operating area, calculate the impact of environmental parameters on emission data, correct the emission calibration data, and adjust the urea injection volume and carbon load model to make the difference between the corrected emission data and the actual emission data Minimum.

Environmental Impact Assessment

Radial engines, while historically significant in aviation, present unique environmental challenges that require comprehensive assessment. The emissions profile of these engines differs substantially from modern inline or turbine designs, with higher levels of unburned hydrocarbons and particulate matter due to their combustion cycle characteristics and older technology foundations.

The environmental footprint of radial engines extends beyond direct emissions. Carbon dioxide output per unit of power generated typically exceeds that of modern powerplants by 15-30%, contributing disproportionately to greenhouse gas accumulations. Nitrogen oxide emissions also present concerns, particularly in low-altitude operations where these compounds can contribute to smog formation and respiratory health issues in surrounding communities.

Noise pollution represents another significant environmental impact factor. Radial engines produce distinctive sound signatures with higher decibel levels across broader frequency ranges than contemporary engines. This acoustic profile affects not only human populations in proximity to operational areas but also wildlife habitats, potentially disrupting breeding patterns and communication among various species.

Water and soil contamination risks arise from the higher oil consumption characteristic of radial engine designs. These engines typically require greater quantities of lubricants that may contain heavy metals and other persistent environmental contaminants. Leakage and disposal practices therefore warrant particular attention in environmental management protocols.

Life-cycle assessment reveals additional environmental considerations. The manufacturing processes for radial engine components often involve energy-intensive casting and machining operations. Furthermore, maintenance requirements typically exceed those of modern engines, necessitating more frequent replacement of parts and consumables throughout the operational lifespan.

Mitigation strategies must balance historical preservation values against environmental protection imperatives. Potential approaches include modified fuel formulations to reduce emissions, enhanced oil containment systems, and operational restrictions in environmentally sensitive areas. Retrofitting with catalytic converters or other emissions control technologies presents technical challenges but may offer viable pathways to emissions reduction while preserving these historically significant powerplants.

The establishment of appropriate environmental impact thresholds for radial engines requires consideration of their limited operational hours in modern contexts, typically in heritage aircraft with restricted flight schedules rather than in daily commercial service.

The environmental footprint of radial engines extends beyond direct emissions. Carbon dioxide output per unit of power generated typically exceeds that of modern powerplants by 15-30%, contributing disproportionately to greenhouse gas accumulations. Nitrogen oxide emissions also present concerns, particularly in low-altitude operations where these compounds can contribute to smog formation and respiratory health issues in surrounding communities.

Noise pollution represents another significant environmental impact factor. Radial engines produce distinctive sound signatures with higher decibel levels across broader frequency ranges than contemporary engines. This acoustic profile affects not only human populations in proximity to operational areas but also wildlife habitats, potentially disrupting breeding patterns and communication among various species.

Water and soil contamination risks arise from the higher oil consumption characteristic of radial engine designs. These engines typically require greater quantities of lubricants that may contain heavy metals and other persistent environmental contaminants. Leakage and disposal practices therefore warrant particular attention in environmental management protocols.

Life-cycle assessment reveals additional environmental considerations. The manufacturing processes for radial engine components often involve energy-intensive casting and machining operations. Furthermore, maintenance requirements typically exceed those of modern engines, necessitating more frequent replacement of parts and consumables throughout the operational lifespan.

Mitigation strategies must balance historical preservation values against environmental protection imperatives. Potential approaches include modified fuel formulations to reduce emissions, enhanced oil containment systems, and operational restrictions in environmentally sensitive areas. Retrofitting with catalytic converters or other emissions control technologies presents technical challenges but may offer viable pathways to emissions reduction while preserving these historically significant powerplants.

The establishment of appropriate environmental impact thresholds for radial engines requires consideration of their limited operational hours in modern contexts, typically in heritage aircraft with restricted flight schedules rather than in daily commercial service.

International Compliance Framework

The global nature of radial engine applications necessitates a comprehensive understanding of international emission standards and compliance frameworks. Currently, radial engine emissions are regulated through a complex network of international, regional, and national regulatory bodies, each with distinct requirements and enforcement mechanisms. The International Civil Aviation Organization (ICAO) establishes baseline standards for aircraft engines, including specialized provisions for radial engines used in aviation applications, through its Committee on Aviation Environmental Protection (CAEP).

The European Union Aviation Safety Agency (EASA) and the United States Federal Aviation Administration (FAA) have developed region-specific frameworks that often exceed ICAO requirements, particularly regarding nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions. These frameworks incorporate both performance-based standards and technology-forcing regulations designed to drive continuous improvement in radial engine environmental performance.

For non-aviation applications, the International Maritime Organization (IMO) governs emissions from radial engines used in maritime settings through MARPOL Annex VI regulations. Similarly, industrial applications fall under frameworks established by the International Organization for Standardization (ISO), particularly ISO 8178 for non-road mobile machinery emissions testing.

Compliance verification methodologies vary significantly across jurisdictions, creating challenges for manufacturers operating in global markets. The European approach emphasizes type-approval testing with conformity of production requirements, while the North American model relies more heavily on manufacturer self-certification with regulatory oversight. Asia-Pacific regions have adopted hybrid approaches, often combining elements from both European and North American frameworks.

Recent developments in international harmonization efforts include the Global Technical Regulation (GTR) initiatives under the United Nations Economic Commission for Europe (UNECE), which aim to standardize test procedures and measurement protocols for engine emissions across borders. The International Committee for Clean Transportation (ICCT) has been instrumental in promoting best practices and facilitating knowledge transfer between regulatory authorities.

Emerging economies present unique challenges within the international compliance landscape, as they balance environmental protection goals with economic development priorities. Many have adopted phased implementation schedules for emission standards, creating a complex matrix of requirements based on engine size, application, and geographic location of operation.

The European Union Aviation Safety Agency (EASA) and the United States Federal Aviation Administration (FAA) have developed region-specific frameworks that often exceed ICAO requirements, particularly regarding nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions. These frameworks incorporate both performance-based standards and technology-forcing regulations designed to drive continuous improvement in radial engine environmental performance.

For non-aviation applications, the International Maritime Organization (IMO) governs emissions from radial engines used in maritime settings through MARPOL Annex VI regulations. Similarly, industrial applications fall under frameworks established by the International Organization for Standardization (ISO), particularly ISO 8178 for non-road mobile machinery emissions testing.

Compliance verification methodologies vary significantly across jurisdictions, creating challenges for manufacturers operating in global markets. The European approach emphasizes type-approval testing with conformity of production requirements, while the North American model relies more heavily on manufacturer self-certification with regulatory oversight. Asia-Pacific regions have adopted hybrid approaches, often combining elements from both European and North American frameworks.

Recent developments in international harmonization efforts include the Global Technical Regulation (GTR) initiatives under the United Nations Economic Commission for Europe (UNECE), which aim to standardize test procedures and measurement protocols for engine emissions across borders. The International Committee for Clean Transportation (ICCT) has been instrumental in promoting best practices and facilitating knowledge transfer between regulatory authorities.

Emerging economies present unique challenges within the international compliance landscape, as they balance environmental protection goals with economic development priorities. Many have adopted phased implementation schedules for emission standards, creating a complex matrix of requirements based on engine size, application, and geographic location of operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!