Radial Engine vs Two-Stroke Engine: Emission Standards

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial and Two-Stroke Engine Evolution and Objectives

Radial engines and two-stroke engines represent two distinct approaches to internal combustion technology, each with its own evolutionary path shaped by technological advancements and changing market demands. The radial engine, first developed in the early 20th century, gained prominence during the golden age of aviation between the 1920s and 1940s. Its unique circular arrangement of cylinders around a central crankshaft offered exceptional power-to-weight ratios and reliability, making it the preferred choice for aircraft propulsion during World War II.

Meanwhile, two-stroke engines followed a parallel but distinct development trajectory. Originally patented by Karl Benz in 1879, these engines achieved widespread adoption in smaller applications due to their mechanical simplicity, lightweight design, and high power output relative to their size. By the mid-20th century, two-stroke engines had become ubiquitous in motorcycles, chainsaws, outboard motors, and other applications requiring compact power sources.

The technological evolution of both engine types has been significantly influenced by increasingly stringent emission standards. Radial engines, primarily used in aviation, faced less regulatory pressure until recent decades, when concerns about environmental impact began to affect all combustion technologies. Their development focused more on performance optimization rather than emissions control.

Two-stroke engines, however, have undergone substantial transformation in response to emission regulations. Their inherently higher hydrocarbon and particulate emissions, resulting from the scavenging process where fuel-air mixture can escape unburned, posed significant challenges as environmental standards tightened globally from the 1970s onward.

The primary objective in modern development of these engines centers on reconciling their inherent performance advantages with contemporary emission requirements. For radial engines, this means preserving their reliability and power characteristics while reducing NOx and CO2 emissions. For two-stroke engines, the focus has been on addressing their fundamental combustion inefficiencies through innovations like direct injection, catalytic converters, and electronic fuel management systems.

Looking forward, the technological trajectory for both engine types is increasingly shaped by the global push toward carbon neutrality. While electric and hydrogen technologies may eventually supplant internal combustion engines in many applications, there remains significant interest in developing interim solutions that can extend the viability of these established technologies through improved efficiency and reduced environmental impact. This includes exploration of sustainable biofuels, hybrid systems, and advanced materials that could help these classic engine designs meet future emission standards while maintaining their unique performance characteristics.

Meanwhile, two-stroke engines followed a parallel but distinct development trajectory. Originally patented by Karl Benz in 1879, these engines achieved widespread adoption in smaller applications due to their mechanical simplicity, lightweight design, and high power output relative to their size. By the mid-20th century, two-stroke engines had become ubiquitous in motorcycles, chainsaws, outboard motors, and other applications requiring compact power sources.

The technological evolution of both engine types has been significantly influenced by increasingly stringent emission standards. Radial engines, primarily used in aviation, faced less regulatory pressure until recent decades, when concerns about environmental impact began to affect all combustion technologies. Their development focused more on performance optimization rather than emissions control.

Two-stroke engines, however, have undergone substantial transformation in response to emission regulations. Their inherently higher hydrocarbon and particulate emissions, resulting from the scavenging process where fuel-air mixture can escape unburned, posed significant challenges as environmental standards tightened globally from the 1970s onward.

The primary objective in modern development of these engines centers on reconciling their inherent performance advantages with contemporary emission requirements. For radial engines, this means preserving their reliability and power characteristics while reducing NOx and CO2 emissions. For two-stroke engines, the focus has been on addressing their fundamental combustion inefficiencies through innovations like direct injection, catalytic converters, and electronic fuel management systems.

Looking forward, the technological trajectory for both engine types is increasingly shaped by the global push toward carbon neutrality. While electric and hydrogen technologies may eventually supplant internal combustion engines in many applications, there remains significant interest in developing interim solutions that can extend the viability of these established technologies through improved efficiency and reduced environmental impact. This includes exploration of sustainable biofuels, hybrid systems, and advanced materials that could help these classic engine designs meet future emission standards while maintaining their unique performance characteristics.

Market Demand Analysis for Low-Emission Engine Technologies

The global market for low-emission engine technologies has experienced significant growth in recent years, driven primarily by increasingly stringent environmental regulations and growing consumer awareness about environmental impacts. The comparison between radial engines and two-stroke engines in terms of emission standards reveals distinct market dynamics and opportunities.

Current market analysis indicates that the global low-emission engine market was valued at approximately $152 billion in 2022, with projections suggesting a compound annual growth rate of 8.7% through 2030. This growth is particularly pronounced in regions with strict emission regulations such as Europe, North America, and increasingly in Asia-Pacific markets, especially China and Japan.

The demand for radial engines, despite their historical significance in aviation, has contracted significantly in commercial applications due to their higher emission profiles compared to alternative technologies. However, niche markets persist in vintage aircraft restoration, specialized agricultural applications, and certain military sectors where their unique power-to-weight characteristics remain valuable. These niche segments represent approximately 2% of the overall engine market.

Two-stroke engines, traditionally known for their high emission levels, have undergone substantial technological evolution. Market research indicates growing demand for advanced two-stroke engines with improved emission controls, particularly in developing economies where cost considerations often outweigh environmental concerns. The marine sector, small equipment manufacturing, and recreational vehicle industries continue to drive demand for improved two-stroke technologies.

Consumer preferences are increasingly favoring engines with lower environmental footprints. A recent industry survey revealed that 73% of consumers in developed markets consider environmental impact as a "very important" factor in purchasing decisions related to engine-powered equipment. This trend is gradually extending to emerging markets, with environmental consciousness rising among middle-class consumers.

Regulatory landscapes significantly shape market demand patterns. The implementation of Euro 7 standards in Europe, Tier 4 Final in the US, and China VI emission standards has created substantial market pressure for cleaner engine technologies. These regulations have effectively created market barriers for traditional high-emission engines while opening opportunities for innovative low-emission alternatives.

Economic factors also influence market demand considerably. The total cost of ownership, including compliance with emission standards, maintenance requirements, and fuel efficiency, has become a primary consideration for industrial and commercial buyers. This has created a competitive advantage for engines that can demonstrate superior emission performance while maintaining operational efficiency.

Current market analysis indicates that the global low-emission engine market was valued at approximately $152 billion in 2022, with projections suggesting a compound annual growth rate of 8.7% through 2030. This growth is particularly pronounced in regions with strict emission regulations such as Europe, North America, and increasingly in Asia-Pacific markets, especially China and Japan.

The demand for radial engines, despite their historical significance in aviation, has contracted significantly in commercial applications due to their higher emission profiles compared to alternative technologies. However, niche markets persist in vintage aircraft restoration, specialized agricultural applications, and certain military sectors where their unique power-to-weight characteristics remain valuable. These niche segments represent approximately 2% of the overall engine market.

Two-stroke engines, traditionally known for their high emission levels, have undergone substantial technological evolution. Market research indicates growing demand for advanced two-stroke engines with improved emission controls, particularly in developing economies where cost considerations often outweigh environmental concerns. The marine sector, small equipment manufacturing, and recreational vehicle industries continue to drive demand for improved two-stroke technologies.

Consumer preferences are increasingly favoring engines with lower environmental footprints. A recent industry survey revealed that 73% of consumers in developed markets consider environmental impact as a "very important" factor in purchasing decisions related to engine-powered equipment. This trend is gradually extending to emerging markets, with environmental consciousness rising among middle-class consumers.

Regulatory landscapes significantly shape market demand patterns. The implementation of Euro 7 standards in Europe, Tier 4 Final in the US, and China VI emission standards has created substantial market pressure for cleaner engine technologies. These regulations have effectively created market barriers for traditional high-emission engines while opening opportunities for innovative low-emission alternatives.

Economic factors also influence market demand considerably. The total cost of ownership, including compliance with emission standards, maintenance requirements, and fuel efficiency, has become a primary consideration for industrial and commercial buyers. This has created a competitive advantage for engines that can demonstrate superior emission performance while maintaining operational efficiency.

Current Emission Standards and Technical Challenges

Emission standards for internal combustion engines have evolved significantly over the past decades, becoming increasingly stringent to address growing environmental concerns. Currently, major regulatory frameworks include the Euro standards (Europe), Tier/LEV standards (US), and China National standards, each establishing progressively lower limits for pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), hydrocarbons (HC), and particulate matter (PM).

For radial engines, which were predominantly used in aviation applications before the jet age, emission regulations have been relatively lenient compared to automotive standards. However, the International Civil Aviation Organization (ICAO) has established standards that are becoming more restrictive, particularly for NOx emissions. These vintage engine designs face significant challenges in meeting modern requirements due to their fundamental combustion characteristics and mechanical layout.

Two-stroke engines, commonly found in small equipment, motorcycles, and marine applications, face even more severe regulatory pressure. Their inherent design, which combines intake and exhaust processes in a single piston stroke, traditionally results in higher emissions of unburned hydrocarbons and particulate matter. The EU Stage V regulations and US EPA Phase 3 standards have effectively pushed conventional two-stroke designs out of many markets unless significant modifications are implemented.

The technical challenges for both engine types stem from their fundamental design principles. Radial engines, with their star-shaped cylinder arrangement and relatively primitive fuel delivery systems, struggle with uneven fuel distribution and combustion efficiency. Their large displacement and high operating temperatures also contribute to elevated NOx formation. Modern emission control technologies like catalytic converters and electronic fuel injection are difficult to retrofit to these heritage designs without compromising their historical authenticity or operational characteristics.

Two-stroke engines face the inherent challenge of short-circuiting, where a portion of the fresh fuel-air mixture escapes through the exhaust port during the scavenging process. This results in high hydrocarbon emissions and fuel inefficiency. While direct injection technology has partially addressed this issue by injecting fuel after the exhaust port closes, implementing such systems increases complexity and cost significantly for what are traditionally simple, low-cost engines.

Both engine types also face challenges with the global transition to lower-sulfur and alternative fuels. Radial engines often require specialized lubricants and fuel additives that may conflict with modern fuel standards, while two-stroke engines traditionally rely on oil-fuel mixtures that contribute significantly to particulate emissions.

The regulatory landscape continues to evolve, with upcoming standards focusing increasingly on greenhouse gas emissions alongside traditional pollutants, presenting additional compliance hurdles for these legacy engine designs.

For radial engines, which were predominantly used in aviation applications before the jet age, emission regulations have been relatively lenient compared to automotive standards. However, the International Civil Aviation Organization (ICAO) has established standards that are becoming more restrictive, particularly for NOx emissions. These vintage engine designs face significant challenges in meeting modern requirements due to their fundamental combustion characteristics and mechanical layout.

Two-stroke engines, commonly found in small equipment, motorcycles, and marine applications, face even more severe regulatory pressure. Their inherent design, which combines intake and exhaust processes in a single piston stroke, traditionally results in higher emissions of unburned hydrocarbons and particulate matter. The EU Stage V regulations and US EPA Phase 3 standards have effectively pushed conventional two-stroke designs out of many markets unless significant modifications are implemented.

The technical challenges for both engine types stem from their fundamental design principles. Radial engines, with their star-shaped cylinder arrangement and relatively primitive fuel delivery systems, struggle with uneven fuel distribution and combustion efficiency. Their large displacement and high operating temperatures also contribute to elevated NOx formation. Modern emission control technologies like catalytic converters and electronic fuel injection are difficult to retrofit to these heritage designs without compromising their historical authenticity or operational characteristics.

Two-stroke engines face the inherent challenge of short-circuiting, where a portion of the fresh fuel-air mixture escapes through the exhaust port during the scavenging process. This results in high hydrocarbon emissions and fuel inefficiency. While direct injection technology has partially addressed this issue by injecting fuel after the exhaust port closes, implementing such systems increases complexity and cost significantly for what are traditionally simple, low-cost engines.

Both engine types also face challenges with the global transition to lower-sulfur and alternative fuels. Radial engines often require specialized lubricants and fuel additives that may conflict with modern fuel standards, while two-stroke engines traditionally rely on oil-fuel mixtures that contribute significantly to particulate emissions.

The regulatory landscape continues to evolve, with upcoming standards focusing increasingly on greenhouse gas emissions alongside traditional pollutants, presenting additional compliance hurdles for these legacy engine designs.

Comparative Analysis of Current Emission Reduction Solutions

01 Emission control systems for radial engines

Radial engines can be equipped with specialized emission control systems to meet stringent emission standards. These systems may include catalytic converters, exhaust gas recirculation (EGR) systems, and advanced fuel injection technologies specifically designed for the unique configuration of radial engines. The circular arrangement of cylinders in radial engines requires customized emission control solutions that can effectively treat exhaust gases while maintaining engine performance and efficiency.- Emission control systems for radial engines: Radial engines can be equipped with specialized emission control systems to meet stringent emission standards. These systems typically include exhaust gas recirculation (EGR), catalytic converters specifically designed for the unique exhaust configuration of radial engines, and advanced fuel injection systems that optimize combustion. The radial arrangement of cylinders presents unique challenges for emissions control, requiring specialized solutions to ensure uniform combustion across all cylinders.

- Two-stroke engine emission reduction technologies: Two-stroke engines can meet modern emission standards through various technological innovations. These include direct fuel injection systems that reduce unburned fuel loss, stratified scavenging techniques that minimize the mixing of fresh charge with exhaust gases, and specialized catalytic converters designed for the unique exhaust characteristics of two-stroke engines. Advanced electronic control units can optimize the timing of fuel delivery and ignition to significantly reduce emissions while maintaining performance.

- Exhaust aftertreatment systems for compliance: Aftertreatment systems play a crucial role in helping both radial and two-stroke engines meet emission standards. These systems include selective catalytic reduction (SCR) technology that uses urea injection to reduce NOx emissions, particulate filters that capture soot and other particulate matter, and oxidation catalysts that convert carbon monoxide and hydrocarbons into less harmful compounds. The integration of these aftertreatment components must be carefully engineered to accommodate the unique operating characteristics of each engine type.

- Fuel system modifications for emission reduction: Modifications to the fuel systems of both radial and two-stroke engines can significantly reduce emissions. These modifications include electronic fuel injection systems that precisely control fuel delivery, fuel reformulation technologies that optimize combustion characteristics, and advanced carburetion systems with emission-focused designs. Fuel system modifications often focus on reducing the air-fuel ratio variability across different operating conditions, which is particularly challenging in multi-cylinder radial configurations and in the rapid combustion cycle of two-stroke engines.

- Innovative engine design approaches for emission compliance: Novel engine design approaches can help radial and two-stroke engines meet emission standards without extensive aftertreatment. These include variable compression ratio mechanisms, advanced piston and combustion chamber designs that promote more complete combustion, and hybrid power systems that combine conventional engine operation with electric assistance during high-emission operating conditions. Some designs incorporate variable valve timing or specialized scavenging port configurations to optimize the combustion process across different load conditions.

02 Two-stroke engine emission reduction technologies

Various technologies have been developed to reduce emissions from two-stroke engines while preserving their power-to-weight advantages. These include direct fuel injection systems that minimize unburned fuel loss, stratified scavenging techniques, and catalytic aftertreatment systems specifically designed for two-stroke operation. Advanced electronic control units can optimize combustion timing and fuel delivery to significantly reduce hydrocarbon and particulate emissions that traditionally plague two-stroke engines.Expand Specific Solutions03 Fuel system modifications for emission compliance

Modifications to fuel delivery systems play a crucial role in helping both radial and two-stroke engines meet emission standards. These modifications include electronic fuel injection systems that precisely control fuel-air ratios, fuel reformulation technologies, and alternative fuel compatibility systems. By optimizing fuel atomization and distribution, these systems can significantly reduce the formation of pollutants during combustion while maintaining or improving engine performance characteristics.Expand Specific Solutions04 Exhaust aftertreatment solutions

Specialized exhaust aftertreatment solutions have been developed to address the unique emission challenges of radial and two-stroke engines. These include compact catalytic converter designs that can fit within space constraints, particulate filters optimized for two-stroke operation, and multi-stage treatment systems that can handle the specific exhaust composition of these engine types. These aftertreatment technologies are critical for meeting increasingly stringent emission regulations while preserving the inherent advantages of these engine designs.Expand Specific Solutions05 Electronic control and monitoring systems

Advanced electronic control and monitoring systems are essential for ensuring radial and two-stroke engines meet emission standards under various operating conditions. These systems include sensors that continuously monitor exhaust composition, adaptive control algorithms that optimize engine parameters in real-time, and diagnostic capabilities that can detect and address emission-related issues. By precisely controlling combustion parameters and adjusting operation based on feedback, these electronic systems enable engines to maintain compliance with emission standards throughout their operational life.Expand Specific Solutions

Key Manufacturers and Regulatory Bodies in Engine Industry

The emission standards landscape for radial versus two-stroke engines is evolving through a transitional phase, with the market estimated at $15-20 billion globally. Two-stroke engines, traditionally dominant in small equipment applications, face increasing regulatory pressure due to higher emissions. Companies like Stihl, Arctic Cat, and Ningbo Daye are investing in cleaner two-stroke technologies, while Achates Power and Westport Fuel Systems are developing innovative radial engine designs with improved emission profiles. Lubrizol and GEO2 Technologies are advancing complementary filtration and additive solutions. The technology maturity varies significantly, with established manufacturers like Caterpillar and Bosch implementing incremental improvements while newer entrants such as Alpha-Otto and 4Qt are pursuing disruptive approaches to meet increasingly stringent global emission standards.

Andreas Stihl AG & Co. KG

Technical Solution: Stihl has developed advanced emission control technologies for their two-stroke engines, focusing on stratified scavenging systems that reduce fuel loss during the scavenging process. Their 2-MIX engine technology combines a cylinder with four-channel technology and a stratified charge system that creates a layer of fresh air between the burned gases and the fresh fuel-air mixture, reducing the amount of unburned fuel lost during gas exchange by up to 20%. Additionally, Stihl has implemented electronic engine management systems (M-Tronic) that automatically adjust fuel-air mixtures based on operating conditions, further optimizing combustion efficiency and reducing emissions. Their catalytic converters specifically designed for small two-stroke applications have demonstrated capability to reduce hydrocarbon emissions by up to 80% compared to non-catalyzed versions.

Strengths: Significant reduction in fuel consumption (up to 20% less) while maintaining high power output; advanced electronic management systems that optimize performance across varying conditions; effective catalytic technology specifically designed for small engines. Weaknesses: Still produces more emissions than four-stroke alternatives; requires premium fuel for optimal emission performance; catalytic converters add cost and weight to handheld equipment.

Achates Power, Inc.

Technical Solution: Achates Power has developed a revolutionary opposed-piston two-stroke engine architecture that fundamentally addresses emission challenges through innovative design rather than just aftertreatment. Their opposed-piston configuration eliminates the cylinder head—traditionally a major source of heat loss and combustion inefficiency—resulting in a more thermally efficient combustion process that inherently produces fewer emissions. The design features two pistons per cylinder moving in opposite directions, with ports at each end controlling intake and exhaust flow, eliminating the need for valves and their associated losses. This architecture achieves approximately 30% better fuel efficiency than conventional four-stroke engines of similar output, directly translating to proportional reductions in CO2 emissions. For meeting stringent NOx and particulate matter regulations, Achates has implemented advanced common rail direct injection systems with multiple injectors per cylinder, creating optimized spray patterns that ensure more complete combustion. Their uniflow scavenging design, where intake and exhaust ports are at opposite ends of the cylinder, significantly improves gas exchange efficiency and reduces unburned hydrocarbon emissions by approximately 40% compared to conventional two-stroke designs.

Strengths: Fundamentally more efficient architecture that inherently produces fewer emissions; excellent power density allowing smaller displacement engines to produce equivalent power; lower heat rejection requiring less cooling system capacity. Weaknesses: Represents a significant departure from conventional engine manufacturing techniques requiring new production infrastructure; more complex lubrication requirements for the dual-piston design; challenges in adapting to very small applications like handheld equipment.

Core Technologies in Modern Engine Emission Control

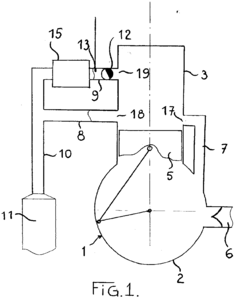

Two-stroke engine

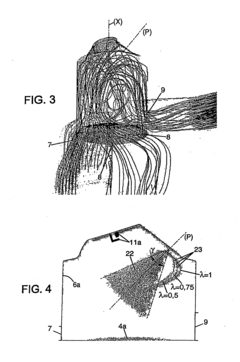

PatentInactiveEP0484226A1

Innovation

- A two-stroke engine design with a dual exhaust system, featuring a primary exhaust orifice near the bottom dead center and a secondary orifice above, along with a split exhaust line and a trifunctional catalytic converter, allows for pre-exhaust of hot combustion gases before scavenging air enters, enabling effective treatment of nitrogen oxides and optimizing fuel injection.

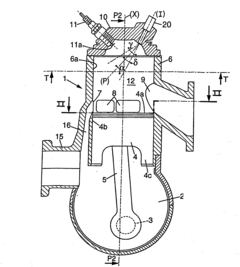

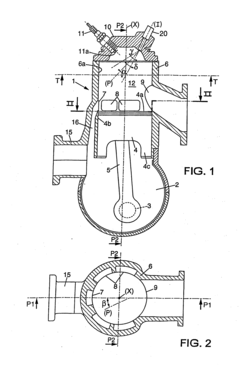

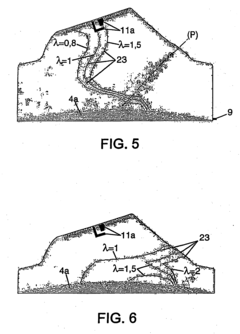

Direct injection two-stroke engine

PatentInactiveUS20090139485A1

Innovation

- The engine features a fuel jet diffuser angle of 15° to 75°, early fuel injection starting 20° to 45° before exhaust port closure, and adjustable injection pressure and axis orientation based on gas flow to achieve a stoichiometric air/fuel mixture near the sparkplug, minimizing fuel loss and pollutant emission.

Environmental Impact Assessment of Engine Technologies

The environmental impact of engine technologies represents a critical dimension in the comparative analysis of radial and two-stroke engines. Radial engines, with their star-shaped cylinder arrangement, typically produce higher levels of carbon emissions per unit of power generated compared to modern alternatives. This is primarily due to their older design philosophy that predates stringent emission regulations. The incomplete combustion characteristic of radial engines results in significant unburned hydrocarbon release, contributing to photochemical smog formation in urban environments.

Two-stroke engines present a different environmental profile. Their simpler design, which completes a power cycle in just two piston movements, inherently produces higher emissions of particulate matter and unburned hydrocarbons. This is largely attributable to the lubricating oil that mixes with fuel during combustion, resulting in a distinctive blue smoke that contains harmful polycyclic aromatic hydrocarbons (PAHs).

When evaluated against current emission standards such as Euro 6 or EPA Tier 3, both engine types face significant compliance challenges. Radial engines, predominantly used in vintage aircraft and specialty applications, often operate under exemptions or grandfather clauses in regulatory frameworks. Two-stroke engines have seen their applications narrow considerably, with many jurisdictions restricting their use in consumer products due to emission concerns.

The nitrogen oxide (NOx) emissions profile differs markedly between these technologies. Radial engines typically operate at lower compression ratios and temperatures, potentially producing less NOx than high-compression alternatives. However, two-stroke engines generate significant NOx during their power stroke due to high combustion temperatures, despite their shorter combustion cycle.

Water pollution represents another environmental dimension in this comparison. Two-stroke engines used in marine applications discharge a significant portion of their fuel-oil mixture directly into water bodies, causing persistent contamination that affects aquatic ecosystems. Radial engines, rarely used in marine contexts, contribute less to direct water pollution but may impact watersheds through airborne deposition of combustion byproducts.

Recent technological adaptations, including direct injection systems for two-stroke engines and electronic engine management for radial designs, have somewhat mitigated these environmental impacts. However, fundamental design limitations continue to position both engine types as environmentally challenged when compared to four-stroke alternatives or emerging electric propulsion systems.

Two-stroke engines present a different environmental profile. Their simpler design, which completes a power cycle in just two piston movements, inherently produces higher emissions of particulate matter and unburned hydrocarbons. This is largely attributable to the lubricating oil that mixes with fuel during combustion, resulting in a distinctive blue smoke that contains harmful polycyclic aromatic hydrocarbons (PAHs).

When evaluated against current emission standards such as Euro 6 or EPA Tier 3, both engine types face significant compliance challenges. Radial engines, predominantly used in vintage aircraft and specialty applications, often operate under exemptions or grandfather clauses in regulatory frameworks. Two-stroke engines have seen their applications narrow considerably, with many jurisdictions restricting their use in consumer products due to emission concerns.

The nitrogen oxide (NOx) emissions profile differs markedly between these technologies. Radial engines typically operate at lower compression ratios and temperatures, potentially producing less NOx than high-compression alternatives. However, two-stroke engines generate significant NOx during their power stroke due to high combustion temperatures, despite their shorter combustion cycle.

Water pollution represents another environmental dimension in this comparison. Two-stroke engines used in marine applications discharge a significant portion of their fuel-oil mixture directly into water bodies, causing persistent contamination that affects aquatic ecosystems. Radial engines, rarely used in marine contexts, contribute less to direct water pollution but may impact watersheds through airborne deposition of combustion byproducts.

Recent technological adaptations, including direct injection systems for two-stroke engines and electronic engine management for radial designs, have somewhat mitigated these environmental impacts. However, fundamental design limitations continue to position both engine types as environmentally challenged when compared to four-stroke alternatives or emerging electric propulsion systems.

Global Policy Trends in Engine Emission Regulation

Engine emission regulations have evolved significantly over the past decades, with increasingly stringent standards being implemented globally to address environmental and health concerns. The European Union has been at the forefront with its Euro standards, progressing from Euro 1 in 1992 to the current Euro 6 standards, with Euro 7 on the horizon. These regulations have progressively reduced allowable emissions of nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter (PM).

In North America, the Environmental Protection Agency (EPA) has established Tier 1 through Tier 4 standards for non-road engines, while on-road vehicles follow separate regulatory frameworks. The California Air Resources Board (CARB) often implements even stricter requirements that frequently become templates for national standards. Japan has similarly implemented staged emission regulations through its JMLIT standards.

Emerging economies have been adopting variations of these established regulatory frameworks. China has implemented China I through China VI standards, largely modeled after European regulations but with implementation timelines reflecting their economic and industrial development stages. India's Bharat Stage (BS) emission standards have accelerated rapidly, jumping from BS IV to BS VI (equivalent to Euro 6) in 2020, skipping the intermediate stage entirely.

When comparing radial engines and two-stroke engines under these regulatory frameworks, significant differences emerge. Radial engines, primarily used in vintage aircraft and specialized applications, often benefit from "grandfather clauses" or heritage exemptions in many jurisdictions. However, when new radial engines are manufactured, they face considerable challenges meeting modern emission standards without substantial modifications.

Two-stroke engines, once ubiquitous in motorcycles, marine applications, and small utility equipment, have faced particularly stringent regulatory pressure due to their inherently higher emissions profiles. The traditional two-stroke design, with its oil-fuel mixture and incomplete combustion cycle, produces significantly higher hydrocarbon and particulate emissions than four-stroke alternatives.

The regulatory trend is clearly moving toward technology-neutral performance standards rather than prescriptive design requirements. This approach focuses on the emissions outcome rather than the engine architecture, theoretically allowing both radial and two-stroke designs to continue if they can meet the increasingly stringent thresholds through technological innovation.

Recent policy developments indicate a shift toward lifecycle emissions assessment rather than focusing solely on operational emissions. This holistic approach considers manufacturing, operation, and disposal phases, potentially creating new challenges and opportunities for both engine types as regulators increasingly factor carbon footprints and sustainability metrics into their frameworks.

In North America, the Environmental Protection Agency (EPA) has established Tier 1 through Tier 4 standards for non-road engines, while on-road vehicles follow separate regulatory frameworks. The California Air Resources Board (CARB) often implements even stricter requirements that frequently become templates for national standards. Japan has similarly implemented staged emission regulations through its JMLIT standards.

Emerging economies have been adopting variations of these established regulatory frameworks. China has implemented China I through China VI standards, largely modeled after European regulations but with implementation timelines reflecting their economic and industrial development stages. India's Bharat Stage (BS) emission standards have accelerated rapidly, jumping from BS IV to BS VI (equivalent to Euro 6) in 2020, skipping the intermediate stage entirely.

When comparing radial engines and two-stroke engines under these regulatory frameworks, significant differences emerge. Radial engines, primarily used in vintage aircraft and specialized applications, often benefit from "grandfather clauses" or heritage exemptions in many jurisdictions. However, when new radial engines are manufactured, they face considerable challenges meeting modern emission standards without substantial modifications.

Two-stroke engines, once ubiquitous in motorcycles, marine applications, and small utility equipment, have faced particularly stringent regulatory pressure due to their inherently higher emissions profiles. The traditional two-stroke design, with its oil-fuel mixture and incomplete combustion cycle, produces significantly higher hydrocarbon and particulate emissions than four-stroke alternatives.

The regulatory trend is clearly moving toward technology-neutral performance standards rather than prescriptive design requirements. This approach focuses on the emissions outcome rather than the engine architecture, theoretically allowing both radial and two-stroke designs to continue if they can meet the increasingly stringent thresholds through technological innovation.

Recent policy developments indicate a shift toward lifecycle emissions assessment rather than focusing solely on operational emissions. This holistic approach considers manufacturing, operation, and disposal phases, potentially creating new challenges and opportunities for both engine types as regulators increasingly factor carbon footprints and sustainability metrics into their frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!