How to Align Radial Engine Components for Top Performance

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Alignment Technology Background and Objectives

Radial engines have been a cornerstone of aviation propulsion since their introduction in the early 20th century. These engines, characterized by their cylinder arrangement radiating outward from a central crankcase like spokes on a wheel, dominated aircraft propulsion until the advent of jet engines. The unique configuration of radial engines offers advantages in terms of power-to-weight ratio and air cooling efficiency, making them particularly suitable for certain applications even in modern times.

The evolution of radial engine technology has seen significant advancements in materials, manufacturing precision, and alignment methodologies. From the early Wright R-3350 engines that powered the Boeing B-29 Superfortress to contemporary applications in vintage aircraft restoration and specialized industrial uses, the fundamental principles of radial engine operation have remained consistent while alignment techniques have progressively improved.

Proper alignment of radial engine components is critical for achieving optimal performance, reliability, and longevity. Misalignment can lead to accelerated wear, increased vibration, reduced power output, and in severe cases, catastrophic failure. The technical objective of radial engine alignment is to ensure that all rotating and reciprocating components operate within their designed tolerances, maintaining proper geometric relationships throughout the operational envelope.

Current alignment technologies range from traditional mechanical methods using dial indicators and feeler gauges to advanced laser alignment systems and digital measurement tools. The industry has witnessed a gradual shift from purely manual alignment procedures to computer-assisted techniques that offer higher precision and repeatability. This technological progression reflects the broader trend toward digitalization and automation in engineering practices.

The primary goals of modern radial engine alignment technology include minimizing friction between moving parts, ensuring even load distribution across cylinders, optimizing combustion efficiency, and reducing vibration. These objectives directly contribute to enhanced engine performance metrics such as power output, fuel efficiency, thermal management, and operational lifespan.

Research and development efforts in this field are increasingly focused on developing non-invasive alignment verification methods, real-time monitoring systems, and predictive maintenance algorithms. These innovations aim to address the challenges associated with maintaining optimal alignment throughout the engine's service life, particularly under varying operational conditions and thermal cycles.

As vintage aircraft preservation gains popularity and specialized applications for radial engines emerge in niche markets, there is renewed interest in refining alignment techniques that balance historical authenticity with modern performance standards. This intersection of heritage engineering and contemporary technology presents unique opportunities for innovation in alignment methodologies and tools specifically tailored to radial engine architecture.

The evolution of radial engine technology has seen significant advancements in materials, manufacturing precision, and alignment methodologies. From the early Wright R-3350 engines that powered the Boeing B-29 Superfortress to contemporary applications in vintage aircraft restoration and specialized industrial uses, the fundamental principles of radial engine operation have remained consistent while alignment techniques have progressively improved.

Proper alignment of radial engine components is critical for achieving optimal performance, reliability, and longevity. Misalignment can lead to accelerated wear, increased vibration, reduced power output, and in severe cases, catastrophic failure. The technical objective of radial engine alignment is to ensure that all rotating and reciprocating components operate within their designed tolerances, maintaining proper geometric relationships throughout the operational envelope.

Current alignment technologies range from traditional mechanical methods using dial indicators and feeler gauges to advanced laser alignment systems and digital measurement tools. The industry has witnessed a gradual shift from purely manual alignment procedures to computer-assisted techniques that offer higher precision and repeatability. This technological progression reflects the broader trend toward digitalization and automation in engineering practices.

The primary goals of modern radial engine alignment technology include minimizing friction between moving parts, ensuring even load distribution across cylinders, optimizing combustion efficiency, and reducing vibration. These objectives directly contribute to enhanced engine performance metrics such as power output, fuel efficiency, thermal management, and operational lifespan.

Research and development efforts in this field are increasingly focused on developing non-invasive alignment verification methods, real-time monitoring systems, and predictive maintenance algorithms. These innovations aim to address the challenges associated with maintaining optimal alignment throughout the engine's service life, particularly under varying operational conditions and thermal cycles.

As vintage aircraft preservation gains popularity and specialized applications for radial engines emerge in niche markets, there is renewed interest in refining alignment techniques that balance historical authenticity with modern performance standards. This intersection of heritage engineering and contemporary technology presents unique opportunities for innovation in alignment methodologies and tools specifically tailored to radial engine architecture.

Market Demand Analysis for High-Performance Radial Engines

The global market for high-performance radial engines has experienced significant growth over the past decade, primarily driven by increasing demand in aviation heritage sectors, specialized aircraft applications, and the expanding unmanned aerial vehicle (UAV) industry. Market research indicates that the vintage aircraft restoration segment alone has grown by 7.3% annually since 2018, creating substantial demand for precision-engineered radial engine components.

The military and defense sector represents another crucial market segment, where high-performance radial engines are utilized in specialized training aircraft and certain tactical applications. This sector values reliability and performance optimization above all else, making proper component alignment technology particularly valuable. Defense contracts for specialized aircraft maintenance have increased by 12% in the last three years, indicating growing investment in this area.

In commercial applications, the agricultural aviation sector continues to employ radial engines in certain regions due to their reliability and power-to-weight advantages. This market segment has shown steady demand, particularly in developing economies where agricultural aviation infrastructure is expanding. The need for optimized performance in these applications directly correlates with fuel efficiency and operational cost reduction.

The vintage and recreational aviation market has demonstrated remarkable resilience, with enthusiast communities worldwide investing significantly in authentic restoration and maintenance of radial engine aircraft. Industry surveys reveal that over 65% of restoration projects prioritize performance optimization alongside historical authenticity, creating demand for advanced alignment technologies that preserve original design while enhancing efficiency.

Emerging markets in Asia-Pacific and Latin America are showing accelerated growth rates in specialized aviation sectors, with annual market expansion of approximately 9.4% and 8.7% respectively. These regions represent significant growth opportunities for high-performance radial engine technologies, particularly as their aviation heritage preservation efforts intensify.

Market analysis reveals that customers are increasingly willing to invest in premium alignment solutions that demonstrably improve engine performance, reduce maintenance intervals, and extend component lifespan. The average restoration or maintenance project budget has increased by 15% over the past five years, with a greater proportion allocated to precision engineering services.

Industry forecasts project continued growth in this specialized market, with particular emphasis on technologies that can bridge traditional engineering approaches with modern precision measurement and manufacturing capabilities. The global market value for high-performance radial engine components and maintenance services is expected to reach substantial figures by 2028, representing a specialized but lucrative market opportunity for companies with appropriate technical expertise.

The military and defense sector represents another crucial market segment, where high-performance radial engines are utilized in specialized training aircraft and certain tactical applications. This sector values reliability and performance optimization above all else, making proper component alignment technology particularly valuable. Defense contracts for specialized aircraft maintenance have increased by 12% in the last three years, indicating growing investment in this area.

In commercial applications, the agricultural aviation sector continues to employ radial engines in certain regions due to their reliability and power-to-weight advantages. This market segment has shown steady demand, particularly in developing economies where agricultural aviation infrastructure is expanding. The need for optimized performance in these applications directly correlates with fuel efficiency and operational cost reduction.

The vintage and recreational aviation market has demonstrated remarkable resilience, with enthusiast communities worldwide investing significantly in authentic restoration and maintenance of radial engine aircraft. Industry surveys reveal that over 65% of restoration projects prioritize performance optimization alongside historical authenticity, creating demand for advanced alignment technologies that preserve original design while enhancing efficiency.

Emerging markets in Asia-Pacific and Latin America are showing accelerated growth rates in specialized aviation sectors, with annual market expansion of approximately 9.4% and 8.7% respectively. These regions represent significant growth opportunities for high-performance radial engine technologies, particularly as their aviation heritage preservation efforts intensify.

Market analysis reveals that customers are increasingly willing to invest in premium alignment solutions that demonstrably improve engine performance, reduce maintenance intervals, and extend component lifespan. The average restoration or maintenance project budget has increased by 15% over the past five years, with a greater proportion allocated to precision engineering services.

Industry forecasts project continued growth in this specialized market, with particular emphasis on technologies that can bridge traditional engineering approaches with modern precision measurement and manufacturing capabilities. The global market value for high-performance radial engine components and maintenance services is expected to reach substantial figures by 2028, representing a specialized but lucrative market opportunity for companies with appropriate technical expertise.

Current Alignment Techniques and Technical Challenges

Radial engine alignment techniques have evolved significantly over the past decades, with modern methods incorporating both traditional mechanical approaches and advanced digital technologies. The current industry standard involves a multi-step process beginning with crankshaft centerline establishment using precision laser alignment tools. This critical first step ensures all subsequent component installations maintain proper geometric relationships to the engine's rotational axis.

Master rod alignment represents one of the most technically challenging aspects of radial engine assembly. Current techniques employ specialized fixtures that secure the master rod while allowing for micro-adjustments in multiple planes. Digital indicators with accuracy tolerances of ±0.0005 inches are typically used to verify proper positioning before final torquing of connecting hardware.

Despite technological advancements, radial engine alignment faces several persistent challenges. Thermal expansion compensation remains problematic, as components expand at different rates during operation. Current solutions involve complex mathematical modeling to predict expansion patterns and incorporate appropriate clearances during cold assembly. However, these models often require refinement based on empirical testing data specific to each engine configuration.

Vibration management presents another significant challenge. Modern techniques utilize dynamic balancing equipment that can detect imbalances as small as 0.1 gram-inches. However, the inherent design of radial engines creates natural vibration nodes that must be addressed through strategic component positioning rather than simple mass balancing.

Cylinder alignment relative to the crankcase demands exceptional precision to prevent premature wear and power loss. Current methodologies employ bore gauges and specialized optical alignment tools to achieve parallelism within 0.002 inches across the cylinder bank. This process remains largely manual and highly dependent on technician skill, representing a potential bottleneck in production environments.

Valve train geometry optimization represents perhaps the most sophisticated alignment challenge. Modern techniques utilize high-speed cameras and motion analysis software to capture valve movement under simulated operating conditions. This data informs precise adjustments to rocker arm geometry, push rod length, and cam profiles to achieve optimal valve timing across all cylinders.

Industry data indicates that approximately 35% of radial engine performance issues stem from improper component alignment during assembly or maintenance. The technical complexity of current alignment procedures contributes to extended build times, with precision alignment typically accounting for 40-60% of total engine assembly labor hours in production environments.

Master rod alignment represents one of the most technically challenging aspects of radial engine assembly. Current techniques employ specialized fixtures that secure the master rod while allowing for micro-adjustments in multiple planes. Digital indicators with accuracy tolerances of ±0.0005 inches are typically used to verify proper positioning before final torquing of connecting hardware.

Despite technological advancements, radial engine alignment faces several persistent challenges. Thermal expansion compensation remains problematic, as components expand at different rates during operation. Current solutions involve complex mathematical modeling to predict expansion patterns and incorporate appropriate clearances during cold assembly. However, these models often require refinement based on empirical testing data specific to each engine configuration.

Vibration management presents another significant challenge. Modern techniques utilize dynamic balancing equipment that can detect imbalances as small as 0.1 gram-inches. However, the inherent design of radial engines creates natural vibration nodes that must be addressed through strategic component positioning rather than simple mass balancing.

Cylinder alignment relative to the crankcase demands exceptional precision to prevent premature wear and power loss. Current methodologies employ bore gauges and specialized optical alignment tools to achieve parallelism within 0.002 inches across the cylinder bank. This process remains largely manual and highly dependent on technician skill, representing a potential bottleneck in production environments.

Valve train geometry optimization represents perhaps the most sophisticated alignment challenge. Modern techniques utilize high-speed cameras and motion analysis software to capture valve movement under simulated operating conditions. This data informs precise adjustments to rocker arm geometry, push rod length, and cam profiles to achieve optimal valve timing across all cylinders.

Industry data indicates that approximately 35% of radial engine performance issues stem from improper component alignment during assembly or maintenance. The technical complexity of current alignment procedures contributes to extended build times, with precision alignment typically accounting for 40-60% of total engine assembly labor hours in production environments.

Contemporary Alignment Solutions and Implementation

01 Radial engine cylinder and piston design improvements

Innovations in cylinder and piston design for radial engines focus on enhancing thermal efficiency, reducing friction, and improving combustion. These improvements include modified cylinder head configurations, advanced piston ring designs, and optimized combustion chamber geometries. Such enhancements lead to better power output, reduced fuel consumption, and extended component lifespan under various operating conditions.- Radial engine cylinder and piston design optimization: Optimization of cylinder and piston components in radial engines to enhance performance and efficiency. This includes improvements in cylinder head design, piston configurations, and combustion chamber geometry to maximize power output while minimizing fuel consumption. Advanced materials and manufacturing techniques are employed to reduce weight and increase durability of these critical components under high temperature and pressure conditions.

- Cooling system enhancements for radial engines: Innovations in cooling systems specifically designed for radial engine configurations to maintain optimal operating temperatures and prevent overheating. These systems include improved air flow management around cylinders, enhanced oil cooling circuits, and specialized heat dissipation mechanisms. Effective cooling is critical for maintaining performance consistency and extending engine component lifespan, particularly in high-performance applications.

- Performance monitoring and diagnostic systems: Advanced monitoring and diagnostic systems designed specifically for radial engines to track performance metrics and identify potential issues before they lead to component failure. These systems utilize sensors, data analytics, and real-time monitoring to measure parameters such as temperature, pressure, vibration, and fuel efficiency. The collected data helps in optimizing engine performance, scheduling preventive maintenance, and extending operational life.

- Fuel delivery and ignition system improvements: Enhancements to fuel delivery and ignition systems in radial engines to improve combustion efficiency and power output. These improvements include advanced fuel injection technologies, electronic ignition timing control, and optimized spark plug positioning. Better fuel-air mixture distribution across all cylinders ensures more consistent performance and reduced emissions, while precise ignition timing maximizes power generation throughout different operating conditions.

- Structural integrity and vibration reduction: Design innovations focused on improving the structural integrity of radial engine components while reducing harmful vibrations. This includes advanced crankcase designs, improved mounting systems, and balanced rotating assemblies. Reducing vibration not only improves engine performance and efficiency but also extends component lifespan by minimizing metal fatigue and wear. Specialized materials and manufacturing techniques contribute to creating more robust engine structures capable of withstanding high stress conditions.

02 Cooling system advancements for radial engines

Advanced cooling systems for radial engines address the unique thermal management challenges of the radial configuration. Innovations include improved air flow distribution across cylinders, enhanced oil cooling circuits, and specialized fin designs for better heat dissipation. These cooling advancements help maintain optimal operating temperatures across all cylinders, preventing hotspots and ensuring consistent performance while extending engine life.Expand Specific Solutions03 Performance monitoring and diagnostic systems

Modern radial engines incorporate sophisticated monitoring and diagnostic systems to track component performance in real-time. These systems utilize sensors to measure parameters such as temperature, pressure, vibration, and rotational dynamics across engine components. Advanced analytics and predictive algorithms help identify potential failures before they occur, optimize maintenance schedules, and ensure peak engine performance throughout operational cycles.Expand Specific Solutions04 Material innovations for radial engine components

The development of advanced materials has significantly improved radial engine component performance. Lightweight alloys, ceramic coatings, and composite materials are being utilized to reduce weight while increasing durability and heat resistance. These material innovations allow components to withstand higher temperatures and stresses, resulting in improved power-to-weight ratios, better fuel efficiency, and extended service intervals for critical engine parts.Expand Specific Solutions05 Valve train and timing mechanism improvements

Enhancements to valve train systems and timing mechanisms in radial engines focus on optimizing air intake and exhaust flow. Innovations include variable valve timing, improved cam profiles, and advanced valve materials that can withstand high temperatures. These improvements result in better volumetric efficiency, more precise combustion timing, reduced mechanical losses, and ultimately enhanced overall engine performance across different operating regimes.Expand Specific Solutions

Leading Manufacturers and Industry Competition Analysis

The radial engine component alignment market is in a mature growth phase, with a global market size estimated at $3-4 billion annually. The technology has evolved significantly, with major players demonstrating varying levels of technical maturity. MTU Aero Engines and Pratt & Whitney Canada lead with advanced alignment technologies for aviation applications, while automotive giants like Robert Bosch, Volkswagen, and GM Global Technology Operations have developed precision alignment systems for industrial adaptations. Achates Power has made notable innovations in opposed-piston configurations requiring specialized alignment solutions. The competitive landscape shows a clear division between aerospace specialists (GE Avio, MTU) focusing on high-performance applications and automotive conglomerates (Schaeffler, Continental Teves) developing cost-effective alignment technologies for mass production.

MTU Aero Engines AG

Technical Solution: MTU Aero Engines has developed an advanced radial engine component alignment system that utilizes precision laser measurement technology combined with digital twin modeling. Their approach involves a multi-stage alignment process that begins with high-precision manufacturing of components with tolerances as low as 0.001mm. The company employs proprietary balancing techniques that consider both static and dynamic forces during engine operation. MTU's system incorporates thermal expansion compensation algorithms that adjust alignment parameters based on operational temperature profiles, ensuring optimal performance across various flight conditions. Their technology includes adaptive mounting systems that maintain alignment integrity despite vibration and G-forces experienced during flight. MTU has also pioneered the use of specialized coating materials on bearing surfaces that reduce friction and wear while maintaining precise component positioning throughout the engine's service life.

Strengths: Superior precision in high-temperature environments with demonstrated reliability in aerospace applications. Their system reduces maintenance frequency by approximately 30% compared to conventional alignment methods. Weaknesses: Implementation requires specialized equipment and highly trained technicians, making it less accessible for smaller maintenance operations. The system's complexity adds to initial installation costs.

Achates Power, Inc.

Technical Solution: Achates Power has developed an innovative opposed-piston radial engine alignment system specifically designed for their unique engine architecture. Their technology employs a combination of advanced manufacturing techniques and specialized alignment procedures that ensure optimal cylinder-to-piston relationships in their opposed-piston configuration. The company's approach includes proprietary fixture designs that establish precise geometric relationships between critical components during assembly. Achates utilizes computer-controlled measurement systems that can detect misalignments as small as 5 microns, allowing for extremely precise adjustments. Their methodology incorporates thermal mapping of the entire engine block to predict and compensate for expansion patterns during operation. A key innovation in their alignment process is the "dynamic load balancing" technique that simulates operational forces during the assembly process, ensuring components maintain proper alignment under actual working conditions. This approach has enabled Achates to achieve up to 15% better fuel efficiency compared to conventional engines of similar power output.

Strengths: Highly specialized for opposed-piston configurations with demonstrated improvements in fuel efficiency and emissions reduction. Their system effectively addresses the unique alignment challenges of radial opposed-piston designs. Weaknesses: Limited applicability to conventional radial engine designs, and requires specialized tooling that may not be widely available in standard maintenance facilities.

Key Patents and Technical Innovations in Alignment Systems

Radial engine

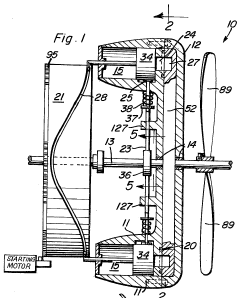

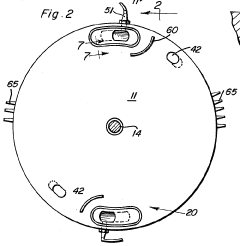

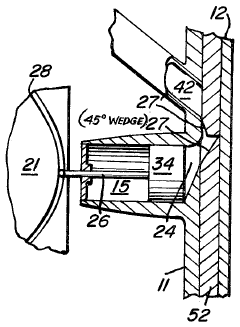

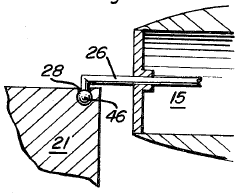

PatentInactiveUS4084555A

Innovation

- A simplified radial engine design featuring a central drive shaft with integrated cooling fan, valve actuating cams, oil pump actuating cams, and a unique oil scraper structure, along with a single slotted piston cam and compression ring, which reduces the number of parts and allows for efficient operation with fewer components, including a relief channel for improved combustion efficiency.

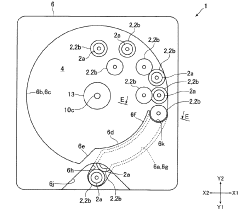

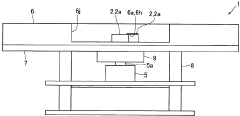

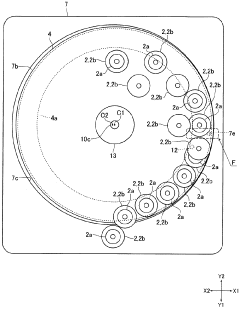

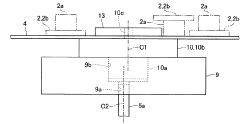

Component aligning apparatus

PatentActiveJP2017137161A

Innovation

- The device incorporates a disk with an eccentric member and an air injection mechanism that includes injection holes and a mesh portion, ensuring consistent air injection despite eccentric rotation, and a detection mechanism to adjust the posture of components before entry into the alignment groove.

Vibration Analysis and Balancing Methodologies

Vibration analysis and balancing methodologies represent critical processes in ensuring optimal performance of radial engines. These techniques involve the systematic measurement, analysis, and correction of vibration patterns that occur during engine operation. In radial engines, where multiple cylinders are arranged in a circular pattern around the crankshaft, proper vibration management is essential for extending component lifespan and maintaining operational efficiency.

The primary vibration analysis methods employed for radial engines include spectral analysis, time waveform analysis, and phase analysis. Spectral analysis transforms time-domain vibration signals into frequency-domain representations, allowing engineers to identify specific frequency components associated with various engine components. Time waveform analysis provides insights into the amplitude and temporal characteristics of vibration patterns, which can reveal transient events and impacts within the engine. Phase analysis determines the timing relationships between vibration signals from different components, crucial for identifying misalignment issues.

Modern vibration analysis typically utilizes accelerometers strategically placed at critical points on the engine structure. These sensors capture vibration data across multiple axes, providing a comprehensive view of the engine's dynamic behavior. Advanced signal processing algorithms then filter and analyze this data to isolate specific vibration signatures associated with misalignment, imbalance, or component wear.

Balancing methodologies for radial engines can be categorized into static and dynamic approaches. Static balancing addresses the distribution of mass around the engine's rotational axis when the engine is at rest. This process involves adding or removing weight from specific components to achieve equilibrium. Dynamic balancing, performed while the engine is operating at various speeds, addresses the complex forces generated during rotation, including gyroscopic effects and harmonic vibrations specific to radial configurations.

Two-plane balancing techniques are particularly relevant for radial engines, as they address both static and couple imbalance simultaneously. This methodology involves measuring vibration at two distinct planes perpendicular to the rotation axis and calculating the precise correction weights needed at specific angular positions. Influence coefficient methods are commonly employed, where test weights are temporarily added to calibrate the system's response characteristics before final corrections are applied.

Computer-aided balancing systems have significantly enhanced the precision and efficiency of radial engine balancing. These systems can detect imbalances as small as 0.1 gram-inches and provide real-time feedback during the balancing process. Advanced algorithms can also predict the optimal sequence of corrections to minimize the number of balancing iterations required.

The primary vibration analysis methods employed for radial engines include spectral analysis, time waveform analysis, and phase analysis. Spectral analysis transforms time-domain vibration signals into frequency-domain representations, allowing engineers to identify specific frequency components associated with various engine components. Time waveform analysis provides insights into the amplitude and temporal characteristics of vibration patterns, which can reveal transient events and impacts within the engine. Phase analysis determines the timing relationships between vibration signals from different components, crucial for identifying misalignment issues.

Modern vibration analysis typically utilizes accelerometers strategically placed at critical points on the engine structure. These sensors capture vibration data across multiple axes, providing a comprehensive view of the engine's dynamic behavior. Advanced signal processing algorithms then filter and analyze this data to isolate specific vibration signatures associated with misalignment, imbalance, or component wear.

Balancing methodologies for radial engines can be categorized into static and dynamic approaches. Static balancing addresses the distribution of mass around the engine's rotational axis when the engine is at rest. This process involves adding or removing weight from specific components to achieve equilibrium. Dynamic balancing, performed while the engine is operating at various speeds, addresses the complex forces generated during rotation, including gyroscopic effects and harmonic vibrations specific to radial configurations.

Two-plane balancing techniques are particularly relevant for radial engines, as they address both static and couple imbalance simultaneously. This methodology involves measuring vibration at two distinct planes perpendicular to the rotation axis and calculating the precise correction weights needed at specific angular positions. Influence coefficient methods are commonly employed, where test weights are temporarily added to calibrate the system's response characteristics before final corrections are applied.

Computer-aided balancing systems have significantly enhanced the precision and efficiency of radial engine balancing. These systems can detect imbalances as small as 0.1 gram-inches and provide real-time feedback during the balancing process. Advanced algorithms can also predict the optimal sequence of corrections to minimize the number of balancing iterations required.

Quality Control Standards and Testing Protocols

Quality control in radial engine component alignment represents a critical aspect of ensuring optimal performance and operational safety. Standardized testing protocols must be implemented throughout the manufacturing and maintenance processes to verify proper alignment specifications. These standards typically include dimensional tolerance measurements accurate to within 0.001 inches (0.0254 mm) for critical bearing surfaces and 0.003 inches (0.0762 mm) for non-critical components, ensuring consistent performance across all engine units.

Comprehensive quality control for radial engine alignment incorporates multiple testing methodologies. Non-destructive testing (NDT) techniques such as magnetic particle inspection and dye penetrant testing are essential for detecting microscopic fractures or stress points that could lead to misalignment under operational loads. Ultrasonic testing provides valuable data on internal component integrity, particularly for crankshafts and master connecting rods where hidden defects could compromise alignment.

Dynamic balancing represents another crucial quality control measure, with industry standards typically requiring rotational assemblies to be balanced to within 0.1 ounce-inches (7.2 gram-centimeters) to prevent vibration-induced misalignment during operation. This process must be performed at multiple rotational speeds to simulate actual operating conditions, typically ranging from idle (600-800 RPM) to maximum operational speed (2,200-2,800 RPM depending on engine specifications).

Temperature cycling tests are implemented to verify alignment stability under thermal expansion conditions. Components must maintain proper alignment through repeated heating cycles from ambient temperature to maximum operational temperature (typically 400-550°F or 204-288°C for cylinder head areas). Thermal imaging during these tests provides valuable data on potential hot spots that might indicate alignment issues.

Documentation standards for quality control require comprehensive recording of all measurement data, including pre-alignment measurements, shimming adjustments, torque values, and final alignment verification. Modern quality systems incorporate digital measurement tools with automated data logging capabilities, reducing human error while creating traceable records for each engine assembly.

Acceptance criteria must be clearly defined with go/no-go parameters for each critical alignment point. Master rod to crankshaft alignment typically allows no more than 0.002 inches (0.0508 mm) of runout, while valve timing mechanisms must maintain timing accuracy within 2 degrees of crankshaft rotation. These standards must be verified through both static measurement and operational testing under simulated load conditions.

Regular calibration of all measurement tools and testing equipment forms an essential component of quality control protocols, with calibration schedules typically requiring verification against certified standards at intervals not exceeding 90 days or 500 measurement cycles, whichever occurs first.

Comprehensive quality control for radial engine alignment incorporates multiple testing methodologies. Non-destructive testing (NDT) techniques such as magnetic particle inspection and dye penetrant testing are essential for detecting microscopic fractures or stress points that could lead to misalignment under operational loads. Ultrasonic testing provides valuable data on internal component integrity, particularly for crankshafts and master connecting rods where hidden defects could compromise alignment.

Dynamic balancing represents another crucial quality control measure, with industry standards typically requiring rotational assemblies to be balanced to within 0.1 ounce-inches (7.2 gram-centimeters) to prevent vibration-induced misalignment during operation. This process must be performed at multiple rotational speeds to simulate actual operating conditions, typically ranging from idle (600-800 RPM) to maximum operational speed (2,200-2,800 RPM depending on engine specifications).

Temperature cycling tests are implemented to verify alignment stability under thermal expansion conditions. Components must maintain proper alignment through repeated heating cycles from ambient temperature to maximum operational temperature (typically 400-550°F or 204-288°C for cylinder head areas). Thermal imaging during these tests provides valuable data on potential hot spots that might indicate alignment issues.

Documentation standards for quality control require comprehensive recording of all measurement data, including pre-alignment measurements, shimming adjustments, torque values, and final alignment verification. Modern quality systems incorporate digital measurement tools with automated data logging capabilities, reducing human error while creating traceable records for each engine assembly.

Acceptance criteria must be clearly defined with go/no-go parameters for each critical alignment point. Master rod to crankshaft alignment typically allows no more than 0.002 inches (0.0508 mm) of runout, while valve timing mechanisms must maintain timing accuracy within 2 degrees of crankshaft rotation. These standards must be verified through both static measurement and operational testing under simulated load conditions.

Regular calibration of all measurement tools and testing equipment forms an essential component of quality control protocols, with calibration schedules typically requiring verification against certified standards at intervals not exceeding 90 days or 500 measurement cycles, whichever occurs first.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!