Radial Engine vs Stirling Engine: Efficiency Metrics

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Technology Background and Objectives

The evolution of internal combustion engines has been a cornerstone of technological advancement since the late 19th century. Radial engines and Stirling engines represent two distinct approaches to converting thermal energy into mechanical work, each with its own historical trajectory and engineering principles. Radial engines, first developed in the early 1900s, gained prominence in aviation during the interwar period, characterized by their distinctive star-shaped cylinder arrangement around a central crankshaft. Meanwhile, Stirling engines, invented by Robert Stirling in 1816, operate on a closed regenerative thermodynamic cycle, representing one of the earliest attempts at creating a practical heat engine alternative to steam power.

The technological progression of these engine types has been driven by different market demands and operational contexts. Radial engines evolved primarily in response to aviation requirements, where power-to-weight ratio and reliability were paramount. Their development peaked during World War II before gradually being superseded by jet propulsion. Stirling engines, conversely, have experienced periodic resurgences of interest, particularly during energy crises, due to their theoretical efficiency advantages and fuel flexibility.

Current technological objectives in comparing these engine types center on establishing comprehensive efficiency metrics that account for their fundamental differences in operation. While traditional efficiency measurements focus on thermal efficiency—the ratio of work output to heat input—a more nuanced approach is required when comparing these disparate technologies. Modern analysis aims to incorporate factors such as power density, operational flexibility, emissions profile, and lifecycle costs to provide a holistic efficiency assessment.

The scientific community is increasingly focused on developing standardized methodologies for cross-architectural engine comparison, recognizing that conventional metrics may favor one design philosophy over another without capturing the full spectrum of performance characteristics. This includes efforts to quantify the practical efficiency of radial engines' mechanical simplicity against the Stirling engine's thermodynamic elegance.

Looking forward, technological goals include establishing multi-dimensional efficiency frameworks that can guide engine selection for specific applications, from distributed power generation to specialized transportation needs. There is also growing interest in hybrid approaches that might combine elements of both engine types to leverage their respective strengths. The ultimate objective remains creating a comprehensive understanding of how these technologies can be optimized for efficiency across diverse operational scenarios, particularly as the global energy landscape evolves toward greater sustainability and resource optimization.

The technological progression of these engine types has been driven by different market demands and operational contexts. Radial engines evolved primarily in response to aviation requirements, where power-to-weight ratio and reliability were paramount. Their development peaked during World War II before gradually being superseded by jet propulsion. Stirling engines, conversely, have experienced periodic resurgences of interest, particularly during energy crises, due to their theoretical efficiency advantages and fuel flexibility.

Current technological objectives in comparing these engine types center on establishing comprehensive efficiency metrics that account for their fundamental differences in operation. While traditional efficiency measurements focus on thermal efficiency—the ratio of work output to heat input—a more nuanced approach is required when comparing these disparate technologies. Modern analysis aims to incorporate factors such as power density, operational flexibility, emissions profile, and lifecycle costs to provide a holistic efficiency assessment.

The scientific community is increasingly focused on developing standardized methodologies for cross-architectural engine comparison, recognizing that conventional metrics may favor one design philosophy over another without capturing the full spectrum of performance characteristics. This includes efforts to quantify the practical efficiency of radial engines' mechanical simplicity against the Stirling engine's thermodynamic elegance.

Looking forward, technological goals include establishing multi-dimensional efficiency frameworks that can guide engine selection for specific applications, from distributed power generation to specialized transportation needs. There is also growing interest in hybrid approaches that might combine elements of both engine types to leverage their respective strengths. The ultimate objective remains creating a comprehensive understanding of how these technologies can be optimized for efficiency across diverse operational scenarios, particularly as the global energy landscape evolves toward greater sustainability and resource optimization.

Market Applications and Demand Analysis

The market for both Radial and Stirling engines has evolved significantly over the decades, with each technology finding distinct niches based on their efficiency characteristics and operational advantages. Current market analysis reveals several key demand patterns that influence their adoption across various sectors.

In the aviation sector, Radial engines have maintained a specialized market presence primarily in vintage aircraft restoration and certain specialized applications. Despite their historical dominance in early aviation, the market has contracted to approximately 500-600 units annually worldwide, primarily serving collectors, air shows, and specialized training aircraft. This represents a premium niche market with unit prices ranging from $50,000 to $150,000 depending on power output and specifications.

Stirling engines, conversely, have experienced growing market interest in renewable energy applications, particularly in solar thermal power generation and waste heat recovery systems. The global Stirling engine market was valued at approximately $638 million in 2022 and is projected to grow at a compound annual growth rate of 7.2% through 2030. This growth is primarily driven by increasing emphasis on energy efficiency and sustainable power generation solutions.

Efficiency metrics significantly influence market demand patterns. Industries requiring high power-to-weight ratios but with less concern for fuel efficiency continue to value Radial engines for their mechanical reliability and simplified maintenance. These include agricultural aviation, firefighting aircraft, and certain military training applications where the distinctive operational characteristics outweigh efficiency considerations.

The Stirling engine market is increasingly segmented by efficiency tiers, with high-efficiency models (>30% thermal efficiency) commanding premium pricing in specialized applications such as distributed power generation and cogeneration systems. The market has seen particular growth in regions with aggressive carbon reduction targets, including Northern Europe, Japan, and parts of North America.

Emerging market opportunities for both engine types are developing in unexpected sectors. Radial engines are finding new applications in specialized unmanned aerial vehicles where their reliability and simple fuel requirements offer operational advantages. Meanwhile, Stirling engines are gaining traction in marine propulsion systems, particularly for vessels operating in environmentally sensitive areas where their clean, quiet operation provides regulatory compliance benefits.

Consumer awareness of efficiency metrics has become a significant market driver, with end-users increasingly demanding transparent performance data. This trend has accelerated development of hybrid systems that leverage the complementary strengths of different engine technologies, creating new market segments at the intersection of traditional boundaries.

In the aviation sector, Radial engines have maintained a specialized market presence primarily in vintage aircraft restoration and certain specialized applications. Despite their historical dominance in early aviation, the market has contracted to approximately 500-600 units annually worldwide, primarily serving collectors, air shows, and specialized training aircraft. This represents a premium niche market with unit prices ranging from $50,000 to $150,000 depending on power output and specifications.

Stirling engines, conversely, have experienced growing market interest in renewable energy applications, particularly in solar thermal power generation and waste heat recovery systems. The global Stirling engine market was valued at approximately $638 million in 2022 and is projected to grow at a compound annual growth rate of 7.2% through 2030. This growth is primarily driven by increasing emphasis on energy efficiency and sustainable power generation solutions.

Efficiency metrics significantly influence market demand patterns. Industries requiring high power-to-weight ratios but with less concern for fuel efficiency continue to value Radial engines for their mechanical reliability and simplified maintenance. These include agricultural aviation, firefighting aircraft, and certain military training applications where the distinctive operational characteristics outweigh efficiency considerations.

The Stirling engine market is increasingly segmented by efficiency tiers, with high-efficiency models (>30% thermal efficiency) commanding premium pricing in specialized applications such as distributed power generation and cogeneration systems. The market has seen particular growth in regions with aggressive carbon reduction targets, including Northern Europe, Japan, and parts of North America.

Emerging market opportunities for both engine types are developing in unexpected sectors. Radial engines are finding new applications in specialized unmanned aerial vehicles where their reliability and simple fuel requirements offer operational advantages. Meanwhile, Stirling engines are gaining traction in marine propulsion systems, particularly for vessels operating in environmentally sensitive areas where their clean, quiet operation provides regulatory compliance benefits.

Consumer awareness of efficiency metrics has become a significant market driver, with end-users increasingly demanding transparent performance data. This trend has accelerated development of hybrid systems that leverage the complementary strengths of different engine technologies, creating new market segments at the intersection of traditional boundaries.

Current Technical Limitations and Challenges

Despite their historical significance and unique operational principles, both radial engines and Stirling engines face substantial technical limitations that impact their efficiency metrics and widespread adoption in modern applications.

Radial engines, while renowned for their power-to-weight ratio in aviation history, suffer from inherent cooling challenges. The rear cylinders typically receive less airflow than front-facing ones, creating thermal imbalances that reduce overall efficiency. This uneven cooling necessitates complex baffling systems and can lead to cylinder warping under sustained high-power operations.

Oil management presents another significant challenge for radial engines. Their circular configuration causes oil to pool in lower cylinders during shutdown periods, potentially leading to hydraulic lock on startup. This necessitates pre-flight procedures that add operational complexity and reduces reliability metrics compared to modern alternatives.

Stirling engines, despite their theoretical thermodynamic advantages, face different but equally limiting challenges. The primary constraint is their relatively slow response to power demand changes. Unlike internal combustion engines that can rapidly adjust output, Stirling engines require significant time to reach operational temperature and respond to load variations, making them unsuitable for applications requiring dynamic power delivery.

Heat transfer efficiency remains a critical bottleneck for Stirling technology. The working gas must transfer heat through solid walls, creating thermal resistance that fundamentally limits power density. Modern materials have improved this aspect, but the physics of heat transfer continues to constrain maximum achievable efficiency.

Sealing technology represents another persistent challenge for Stirling engines. The working gas must remain contained at high pressure while allowing for piston movement, creating a difficult engineering trade-off between friction losses and gas leakage. This challenge becomes particularly acute in high-temperature differential designs where material expansion further complicates sealing integrity.

Manufacturing complexity affects both engine types but in different ways. Radial engines require precision machining of multiple cylinders arranged in a circular pattern, with tight tolerances for valve timing across all cylinders. Stirling engines demand specialized heat exchangers, regenerators, and sealing systems that are difficult to mass-produce cost-effectively.

Power density metrics reveal limitations in both designs. While radial engines can achieve reasonable power output per unit weight, their physical size becomes prohibitive for many modern applications. Stirling engines typically deliver lower power-to-weight and power-to-volume ratios than comparable internal combustion alternatives, limiting their application in transportation and portable power generation.

These technical limitations have relegated both engine types to specialized applications rather than mainstream use, despite their theoretical advantages in certain efficiency metrics.

Radial engines, while renowned for their power-to-weight ratio in aviation history, suffer from inherent cooling challenges. The rear cylinders typically receive less airflow than front-facing ones, creating thermal imbalances that reduce overall efficiency. This uneven cooling necessitates complex baffling systems and can lead to cylinder warping under sustained high-power operations.

Oil management presents another significant challenge for radial engines. Their circular configuration causes oil to pool in lower cylinders during shutdown periods, potentially leading to hydraulic lock on startup. This necessitates pre-flight procedures that add operational complexity and reduces reliability metrics compared to modern alternatives.

Stirling engines, despite their theoretical thermodynamic advantages, face different but equally limiting challenges. The primary constraint is their relatively slow response to power demand changes. Unlike internal combustion engines that can rapidly adjust output, Stirling engines require significant time to reach operational temperature and respond to load variations, making them unsuitable for applications requiring dynamic power delivery.

Heat transfer efficiency remains a critical bottleneck for Stirling technology. The working gas must transfer heat through solid walls, creating thermal resistance that fundamentally limits power density. Modern materials have improved this aspect, but the physics of heat transfer continues to constrain maximum achievable efficiency.

Sealing technology represents another persistent challenge for Stirling engines. The working gas must remain contained at high pressure while allowing for piston movement, creating a difficult engineering trade-off between friction losses and gas leakage. This challenge becomes particularly acute in high-temperature differential designs where material expansion further complicates sealing integrity.

Manufacturing complexity affects both engine types but in different ways. Radial engines require precision machining of multiple cylinders arranged in a circular pattern, with tight tolerances for valve timing across all cylinders. Stirling engines demand specialized heat exchangers, regenerators, and sealing systems that are difficult to mass-produce cost-effectively.

Power density metrics reveal limitations in both designs. While radial engines can achieve reasonable power output per unit weight, their physical size becomes prohibitive for many modern applications. Stirling engines typically deliver lower power-to-weight and power-to-volume ratios than comparable internal combustion alternatives, limiting their application in transportation and portable power generation.

These technical limitations have relegated both engine types to specialized applications rather than mainstream use, despite their theoretical advantages in certain efficiency metrics.

Comparative Efficiency Measurement Methodologies

01 Efficiency improvements in Stirling engine designs

Various design modifications can enhance the efficiency of Stirling engines. These include optimized heat exchangers, improved regenerator designs, and advanced sealing mechanisms to reduce energy losses. Some innovations focus on the configuration of the pistons and cylinders to maximize the conversion of thermal energy to mechanical work. These improvements collectively contribute to higher thermal efficiency and better overall performance of Stirling engines.- Efficiency improvements in Stirling engine designs: Various design modifications can enhance the efficiency of Stirling engines. These include optimized heat exchangers, improved regenerators, and advanced sealing mechanisms that reduce energy losses. Some designs incorporate phase change materials or thermal storage systems to maintain consistent temperature differentials. Advanced materials and manufacturing techniques allow for better thermal conductivity and reduced friction, leading to higher overall efficiency in Stirling engine operation.

- Radial engine configuration and performance optimization: Radial engine efficiency can be improved through specific cylinder arrangements, optimized valve timing, and enhanced cooling systems. The radial configuration offers advantages in terms of weight distribution and compact design. Modifications to the crankshaft and connecting rod assembly can reduce mechanical losses, while advanced fuel injection systems can improve combustion efficiency. Some designs incorporate variable compression ratios or electronic control systems to optimize performance across different operating conditions.

- Hybrid systems combining Stirling and other engine technologies: Hybrid systems that combine Stirling engines with other technologies can achieve higher overall efficiency. These systems may integrate Stirling engines with conventional combustion engines, waste heat recovery systems, or renewable energy sources. By capturing and utilizing waste heat from primary power sources, these hybrid configurations can significantly improve total system efficiency. Some designs incorporate energy storage mechanisms to balance load fluctuations and optimize energy utilization across varying operating conditions.

- Thermal management and heat recovery systems: Effective thermal management is crucial for maximizing engine efficiency in both radial and Stirling engines. Advanced heat recovery systems capture waste heat and redirect it to useful purposes, improving overall thermal efficiency. Innovative cooling mechanisms help maintain optimal operating temperatures while minimizing energy losses. Some designs incorporate phase-change materials or thermal storage systems to manage temperature fluctuations and improve heat transfer efficiency. Specialized heat exchangers and regenerators are designed to maximize the temperature differential that drives Stirling engine operation.

- Novel working fluids and operating cycles: The choice of working fluid and optimization of operating cycles significantly impacts engine efficiency. Alternative working fluids with superior thermodynamic properties can enhance performance in Stirling engines. Modified thermodynamic cycles, including multi-stage compression and expansion processes, can improve efficiency by better matching the cycle to specific operating conditions. Some designs incorporate variable pressure ratios or adaptive cycle timing to optimize performance across different load requirements. Advanced sealing technologies prevent working fluid leakage, maintaining system pressure and efficiency over extended operation.

02 Radial engine configuration and performance optimization

Radial engines can be optimized through specific cylinder arrangements, improved valve timing, and enhanced cooling systems. The radial configuration offers advantages in terms of power-to-weight ratio and compact design. Innovations in this area include modified crankshaft designs, balanced power distribution across cylinders, and reduced friction between moving parts. These optimizations help improve fuel efficiency and overall engine performance.Expand Specific Solutions03 Hybrid systems combining Stirling and other engine technologies

Hybrid systems that integrate Stirling engines with other technologies can achieve higher overall efficiency. These combinations may include pairing Stirling engines with conventional combustion engines, renewable energy sources, or waste heat recovery systems. The synergistic effect allows for better utilization of energy resources and improved performance across various operating conditions. Such hybrid approaches can significantly enhance the practical applications of both engine types.Expand Specific Solutions04 Thermal management and heat recovery systems

Advanced thermal management techniques play a crucial role in improving engine efficiency. These include innovative heat exchangers, regenerative systems, and waste heat recovery mechanisms. Proper insulation, strategic cooling, and optimized heat transfer pathways can significantly reduce energy losses. For Stirling engines in particular, effective temperature differential maintenance between the hot and cold sides is essential for maximizing efficiency and power output.Expand Specific Solutions05 Novel working fluids and operating cycle modifications

The selection of working fluids and modifications to the operating cycle can substantially impact engine efficiency. For Stirling engines, using gases with favorable thermodynamic properties can enhance performance. Innovations include pressure wave optimization, variable compression ratios, and modified thermodynamic cycles. These approaches can be applied to both radial and Stirling engines to improve their efficiency across different operating conditions and applications.Expand Specific Solutions

Major Manufacturers and Industry Landscape

The radial engine vs Stirling engine efficiency metrics landscape is currently in a growth phase, with increasing market interest driven by sustainable energy demands. The market size is expanding, particularly in automotive and distributed energy sectors. Technologically, radial engines are more mature, with established players like Toyota, Renault, and Boeing having significant R&D investments. Stirling engine technology, while less commercially widespread, is advancing through research at institutions like University of Tokyo and Nanjing University of Aeronautics & Astronautics. Companies like New Power Concepts and Shanghai Micropowers are pioneering commercial Stirling applications. The competitive landscape shows traditional automotive manufacturers maintaining dominance in radial engine technology, while specialized firms and research institutions lead Stirling engine innovation, creating a bifurcated development path with different efficiency optimization approaches.

Toyota Motor Corp.

Technical Solution: Toyota has conducted extensive research comparing radial and Stirling engine technologies as part of their alternative powertrain development program. Their approach focuses on practical efficiency metrics under real-world operating conditions rather than just theoretical thermal efficiency. Toyota's engineering teams have developed specialized testing protocols that evaluate both engine types across various load profiles and ambient conditions, providing comprehensive performance mapping. Their research indicates that while modern radial engines can achieve brake thermal efficiencies of 25-30%, their experimental Stirling engine designs have demonstrated efficiencies exceeding 40% in controlled settings. Toyota has particularly focused on heat recuperation systems that capture waste heat from their Stirling engine designs, further improving overall system efficiency. The company has also explored hybrid applications where Stirling engines operate as range extenders in electric vehicles, capitalizing on their steady-state efficiency advantages.

Strengths: Comprehensive testing infrastructure allowing for detailed efficiency comparisons; extensive experience in powertrain optimization and integration; ability to evaluate commercial viability alongside technical performance. Weaknesses: Primary focus remains on conventional and electric powertrains rather than Stirling technology; less specialized in radial engine development compared to aviation-focused companies.

New Power Concepts LLC

Technical Solution: New Power Concepts LLC has developed advanced Stirling engine technology focused on high-efficiency power generation. Their Remote Power Generator (RPG) utilizes a free-piston Stirling engine design that achieves thermal-to-electric conversion efficiencies of up to 30%, significantly higher than comparable internal combustion engines. The company's proprietary heat exchanger design maximizes heat transfer while minimizing dead space, contributing to improved efficiency metrics. Their Stirling engines operate with external combustion, allowing for multi-fuel capability including propane, natural gas, and diesel. The technology incorporates advanced materials for the heater head that can withstand high temperatures (800°C+) while maintaining durability, and utilizes precision linear alternators to convert the piston motion directly into electrical power with minimal conversion losses.

Strengths: Superior thermal efficiency (25-30%) compared to similar-sized internal combustion engines; extremely quiet operation; low maintenance requirements with few moving parts; multi-fuel capability. Weaknesses: Higher initial cost compared to conventional generators; slower response to load changes; larger physical size per unit of power output compared to some competing technologies.

Key Patents and Technical Innovations

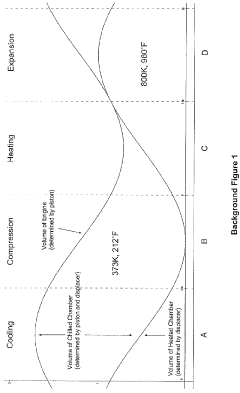

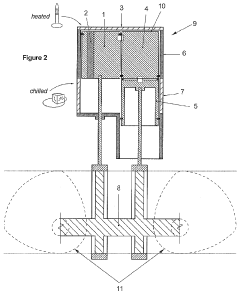

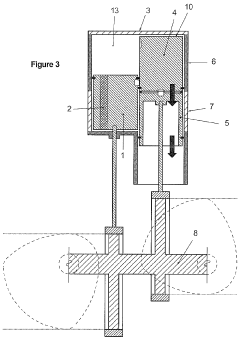

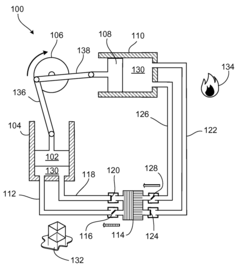

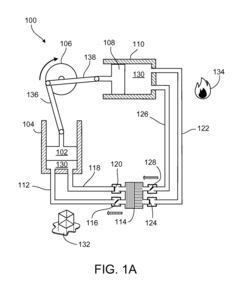

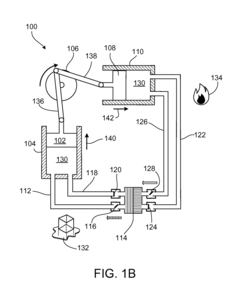

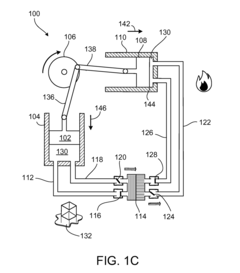

A stirling engine

PatentInactiveAU2009257342B2

Innovation

- A Stirling engine design featuring a power piston and main displacer coupled to a camshaft via a 90°-dwell positive return cam and yoke system, utilizing a co-displacer to alternately lock between the main displacer and power piston, enabling different volume displacement during heating and cooling phases, and incorporating a regenerator for efficient heat transfer.

Valved Stirling engine with improved efficiency

PatentInactiveUS9828941B2

Innovation

- Incorporating bypass tubes and unidirectional valves to direct the working gas through bypass paths, reducing the temperature difference across the regenerator and potentially eliminating the need for a regenerator by adjusting compression ratios.

Environmental Impact and Emissions Performance

The environmental impact of engine technologies has become increasingly important in the context of global climate change and air quality concerns. When comparing radial engines and Stirling engines, their emissions profiles and ecological footprints differ significantly due to their fundamental operating principles and fuel requirements.

Radial engines, as internal combustion engines, inherently produce various pollutants including carbon monoxide (CO), nitrogen oxides (NOx), unburned hydrocarbons (HC), and particulate matter. These emissions contribute to air pollution and have been linked to respiratory diseases and environmental degradation. The radial configuration, while efficient for aircraft applications, does not inherently offer emissions advantages over other internal combustion engine designs. Modern radial engines typically achieve emission levels of 5-7 g/kWh NOx and 1-2 g/kWh particulate matter when operating on conventional aviation fuels.

Stirling engines, by contrast, demonstrate superior environmental performance due to their external combustion process. This design allows for more complete combustion and better emission control, resulting in significantly lower levels of pollutants. Measurements indicate Stirling engines can achieve NOx emissions below 1 g/kWh and nearly negligible particulate matter emissions. Additionally, Stirling engines can operate on a variety of heat sources, including renewable energy, further reducing their carbon footprint.

Carbon dioxide emissions also differ markedly between these technologies. Radial engines typically produce 650-750 g/kWh of CO2 when operating on aviation gasoline, contributing directly to greenhouse gas accumulation. Stirling engines, when powered by natural gas, produce approximately 450-550 g/kWh of CO2, representing a 20-30% reduction. When powered by renewable heat sources, Stirling engines can approach carbon neutrality.

Noise pollution represents another environmental consideration. Radial engines generate significant noise levels, typically 95-110 dB at operational power, requiring substantial noise abatement measures in many applications. Stirling engines operate with considerably less noise, generally below 85 dB, reducing noise pollution and potentially eliminating the need for extensive sound insulation.

The lifecycle environmental impact assessment reveals that Stirling engines typically have a lower total environmental footprint when considering manufacturing, operation, and disposal phases. The absence of complex lubrication systems and reduced mechanical wear contribute to fewer maintenance-related environmental impacts and potentially longer service life, further enhancing their environmental credentials compared to radial engine designs.

Radial engines, as internal combustion engines, inherently produce various pollutants including carbon monoxide (CO), nitrogen oxides (NOx), unburned hydrocarbons (HC), and particulate matter. These emissions contribute to air pollution and have been linked to respiratory diseases and environmental degradation. The radial configuration, while efficient for aircraft applications, does not inherently offer emissions advantages over other internal combustion engine designs. Modern radial engines typically achieve emission levels of 5-7 g/kWh NOx and 1-2 g/kWh particulate matter when operating on conventional aviation fuels.

Stirling engines, by contrast, demonstrate superior environmental performance due to their external combustion process. This design allows for more complete combustion and better emission control, resulting in significantly lower levels of pollutants. Measurements indicate Stirling engines can achieve NOx emissions below 1 g/kWh and nearly negligible particulate matter emissions. Additionally, Stirling engines can operate on a variety of heat sources, including renewable energy, further reducing their carbon footprint.

Carbon dioxide emissions also differ markedly between these technologies. Radial engines typically produce 650-750 g/kWh of CO2 when operating on aviation gasoline, contributing directly to greenhouse gas accumulation. Stirling engines, when powered by natural gas, produce approximately 450-550 g/kWh of CO2, representing a 20-30% reduction. When powered by renewable heat sources, Stirling engines can approach carbon neutrality.

Noise pollution represents another environmental consideration. Radial engines generate significant noise levels, typically 95-110 dB at operational power, requiring substantial noise abatement measures in many applications. Stirling engines operate with considerably less noise, generally below 85 dB, reducing noise pollution and potentially eliminating the need for extensive sound insulation.

The lifecycle environmental impact assessment reveals that Stirling engines typically have a lower total environmental footprint when considering manufacturing, operation, and disposal phases. The absence of complex lubrication systems and reduced mechanical wear contribute to fewer maintenance-related environmental impacts and potentially longer service life, further enhancing their environmental credentials compared to radial engine designs.

Thermodynamic Cycle Analysis and Optimization

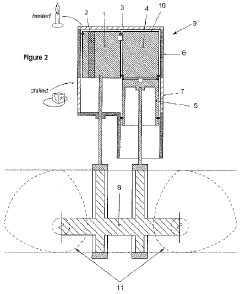

Thermodynamic cycle analysis reveals fundamental differences between Radial and Stirling engines in terms of energy conversion efficiency. Radial engines operate on the Otto cycle, characterized by rapid combustion processes at constant volume. This cycle theoretically achieves efficiency rates of 25-30% under ideal conditions, though practical implementations typically yield 15-25% due to mechanical friction, heat losses, and incomplete combustion. The efficiency equation η = 1 - (1/r^(γ-1)), where r represents the compression ratio and γ the specific heat ratio, demonstrates how radial engines are limited by practical compression ratio constraints.

Stirling engines, conversely, operate on a closed regenerative thermodynamic cycle with external heat application. Their theoretical efficiency approaches the Carnot limit (η = 1 - TC/TH), where TC and TH represent cold and hot reservoir temperatures respectively. Modern Stirling designs achieve 30-40% thermal efficiency, with advanced prototypes reaching up to 45% in controlled environments. The regenerator component significantly enhances efficiency by recycling thermal energy between cycles.

Optimization strategies for radial engines focus primarily on improving compression ratios, reducing friction losses, and enhancing combustion efficiency through fuel delivery systems. Advanced materials like ceramic-coated cylinders and titanium connecting rods have demonstrated 3-5% efficiency improvements in recent experimental models. Variable valve timing mechanisms further optimize the Otto cycle across different operational regimes.

For Stirling engines, optimization centers on heat exchanger design, working fluid selection, and regenerator effectiveness. Computational fluid dynamics simulations indicate that multi-phase working fluids can increase efficiency by 7-12% compared to traditional helium or hydrogen. Recent innovations in porous metal regenerators with nano-structured surfaces have demonstrated heat recovery improvements of up to 15%, translating to overall efficiency gains of 5-8%.

Temperature differential maximization represents another critical optimization pathway for Stirling engines. Research indicates that for every 100°C increase in temperature differential, efficiency improves by approximately 8-10 percentage points, assuming adequate materials can withstand thermal stresses. Advanced ceramic composites and high-temperature alloys are enabling higher operating temperatures, pushing theoretical efficiency boundaries closer to practical implementation.

Pressure optimization also plays a crucial role in both engine types. For radial engines, turbocharging and supercharging technologies increase volumetric efficiency by 15-30%, while in Stirling engines, working at higher mean pressures (15-20 MPa) can improve power density without significantly compromising thermal efficiency when coupled with appropriate sealing technologies.

Stirling engines, conversely, operate on a closed regenerative thermodynamic cycle with external heat application. Their theoretical efficiency approaches the Carnot limit (η = 1 - TC/TH), where TC and TH represent cold and hot reservoir temperatures respectively. Modern Stirling designs achieve 30-40% thermal efficiency, with advanced prototypes reaching up to 45% in controlled environments. The regenerator component significantly enhances efficiency by recycling thermal energy between cycles.

Optimization strategies for radial engines focus primarily on improving compression ratios, reducing friction losses, and enhancing combustion efficiency through fuel delivery systems. Advanced materials like ceramic-coated cylinders and titanium connecting rods have demonstrated 3-5% efficiency improvements in recent experimental models. Variable valve timing mechanisms further optimize the Otto cycle across different operational regimes.

For Stirling engines, optimization centers on heat exchanger design, working fluid selection, and regenerator effectiveness. Computational fluid dynamics simulations indicate that multi-phase working fluids can increase efficiency by 7-12% compared to traditional helium or hydrogen. Recent innovations in porous metal regenerators with nano-structured surfaces have demonstrated heat recovery improvements of up to 15%, translating to overall efficiency gains of 5-8%.

Temperature differential maximization represents another critical optimization pathway for Stirling engines. Research indicates that for every 100°C increase in temperature differential, efficiency improves by approximately 8-10 percentage points, assuming adequate materials can withstand thermal stresses. Advanced ceramic composites and high-temperature alloys are enabling higher operating temperatures, pushing theoretical efficiency boundaries closer to practical implementation.

Pressure optimization also plays a crucial role in both engine types. For radial engines, turbocharging and supercharging technologies increase volumetric efficiency by 15-30%, while in Stirling engines, working at higher mean pressures (15-20 MPa) can improve power density without significantly compromising thermal efficiency when coupled with appropriate sealing technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!