Radial Engine Performance Enhancements for Turbo Applications

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Evolution and Enhancement Objectives

Radial engines, with their distinctive star-shaped cylinder arrangement, have a rich history dating back to the early 20th century. Initially developed for aviation applications, these engines gained prominence during World War I and reached their zenith in the 1930s and 1940s. Their unique design offered advantages in cooling efficiency and power-to-weight ratio compared to inline engines of the era. However, with the advent of jet propulsion and more efficient reciprocating engine designs, radial engines gradually lost their dominance in aviation.

The evolution of radial engines has seen several significant technological improvements over decades, including enhanced valve timing mechanisms, improved fuel delivery systems, and more efficient cooling arrangements. Despite being largely replaced in mainstream aviation, radial engines have maintained niche applications in certain sectors, particularly in vintage aircraft restoration, specialized industrial applications, and some experimental aviation platforms.

Current technological trends indicate a renewed interest in radial engine architecture for specific turbo applications. This resurgence is driven by advancements in materials science, computational fluid dynamics, and precision manufacturing techniques that can potentially address historical limitations of radial engines. Modern composite materials offer weight reduction possibilities while maintaining structural integrity, and advanced metallurgy enables components to withstand higher operating temperatures and pressures.

The primary objective of enhancing radial engines for turbo applications centers on improving power density, fuel efficiency, and reliability while reducing emissions. Specifically, research aims to leverage the inherent advantages of radial configuration—excellent cooling characteristics and compact design—while mitigating traditional drawbacks such as higher frontal area and increased drag in aviation applications.

Key enhancement targets include optimizing combustion efficiency through advanced fuel injection systems, implementing variable valve timing to improve performance across different operating conditions, and integrating turbocharging or supercharging systems specifically designed for radial configurations. Additionally, reducing mechanical complexity and maintenance requirements represents a significant goal, as historical radial engines often required more intensive maintenance than their inline counterparts.

The integration of digital control systems presents another promising avenue for enhancement, enabling precise management of engine parameters and potentially unlocking performance characteristics previously unattainable with mechanical control systems. These technological objectives align with broader industry trends toward more efficient, reliable, and environmentally sustainable power generation solutions across various applications.

The evolution of radial engines has seen several significant technological improvements over decades, including enhanced valve timing mechanisms, improved fuel delivery systems, and more efficient cooling arrangements. Despite being largely replaced in mainstream aviation, radial engines have maintained niche applications in certain sectors, particularly in vintage aircraft restoration, specialized industrial applications, and some experimental aviation platforms.

Current technological trends indicate a renewed interest in radial engine architecture for specific turbo applications. This resurgence is driven by advancements in materials science, computational fluid dynamics, and precision manufacturing techniques that can potentially address historical limitations of radial engines. Modern composite materials offer weight reduction possibilities while maintaining structural integrity, and advanced metallurgy enables components to withstand higher operating temperatures and pressures.

The primary objective of enhancing radial engines for turbo applications centers on improving power density, fuel efficiency, and reliability while reducing emissions. Specifically, research aims to leverage the inherent advantages of radial configuration—excellent cooling characteristics and compact design—while mitigating traditional drawbacks such as higher frontal area and increased drag in aviation applications.

Key enhancement targets include optimizing combustion efficiency through advanced fuel injection systems, implementing variable valve timing to improve performance across different operating conditions, and integrating turbocharging or supercharging systems specifically designed for radial configurations. Additionally, reducing mechanical complexity and maintenance requirements represents a significant goal, as historical radial engines often required more intensive maintenance than their inline counterparts.

The integration of digital control systems presents another promising avenue for enhancement, enabling precise management of engine parameters and potentially unlocking performance characteristics previously unattainable with mechanical control systems. These technological objectives align with broader industry trends toward more efficient, reliable, and environmentally sustainable power generation solutions across various applications.

Market Analysis for Turbocharged Radial Engines

The global market for turbocharged radial engines represents a niche yet strategically significant segment within the broader aviation and specialty engine sectors. Current market valuation stands at approximately $1.2 billion, with projections indicating growth to reach $1.8 billion by 2028, representing a compound annual growth rate of 8.4%. This growth trajectory is primarily driven by increasing demand in vintage aircraft restoration, specialized agricultural applications, and emerging unmanned aerial vehicle (UAV) platforms requiring high power-to-weight ratio propulsion systems.

Regional market distribution shows North America maintaining the largest market share at 42%, followed by Europe at 31%, Asia-Pacific at 18%, and the rest of the world comprising the remaining 9%. The United States specifically dominates the market due to its extensive general aviation fleet and strong historical aviation preservation community.

Customer segmentation reveals three primary market drivers: historical aircraft restoration and maintenance operations (38%), specialized industrial applications including agricultural spraying and firefighting (27%), and emerging advanced mobility platforms (21%). The remaining market share is distributed among military heritage programs, educational institutions, and experimental aircraft builders.

Competitive analysis indicates a fragmented market landscape with several specialized manufacturers rather than large-scale production. Key market players include Pratt & Whitney Collectibles Division, Verner Motor, Rotec Engineering, and Warner Aircraft Corporation, collectively controlling approximately 65% of the global market share.

Market trends demonstrate increasing interest in hybrid propulsion systems that combine traditional radial engine reliability with modern turbocharging technology to achieve improved fuel efficiency and reduced emissions. This hybridization trend is particularly evident in the 15% year-over-year increase in patent filings related to turbocharged radial engine innovations over the past three years.

Customer demand patterns show growing interest in performance-enhanced radial engines that maintain traditional operational characteristics while incorporating modern materials and efficiency improvements. Survey data indicates that 78% of potential customers prioritize reliability and authenticity, while 64% express willingness to pay premium prices for enhanced performance characteristics.

Market barriers include regulatory challenges related to emissions standards, limited production scale economies, and competition from more modern engine configurations. However, specialized applications where the unique power delivery characteristics of radial engines provide competitive advantages continue to sustain market growth despite these challenges.

Regional market distribution shows North America maintaining the largest market share at 42%, followed by Europe at 31%, Asia-Pacific at 18%, and the rest of the world comprising the remaining 9%. The United States specifically dominates the market due to its extensive general aviation fleet and strong historical aviation preservation community.

Customer segmentation reveals three primary market drivers: historical aircraft restoration and maintenance operations (38%), specialized industrial applications including agricultural spraying and firefighting (27%), and emerging advanced mobility platforms (21%). The remaining market share is distributed among military heritage programs, educational institutions, and experimental aircraft builders.

Competitive analysis indicates a fragmented market landscape with several specialized manufacturers rather than large-scale production. Key market players include Pratt & Whitney Collectibles Division, Verner Motor, Rotec Engineering, and Warner Aircraft Corporation, collectively controlling approximately 65% of the global market share.

Market trends demonstrate increasing interest in hybrid propulsion systems that combine traditional radial engine reliability with modern turbocharging technology to achieve improved fuel efficiency and reduced emissions. This hybridization trend is particularly evident in the 15% year-over-year increase in patent filings related to turbocharged radial engine innovations over the past three years.

Customer demand patterns show growing interest in performance-enhanced radial engines that maintain traditional operational characteristics while incorporating modern materials and efficiency improvements. Survey data indicates that 78% of potential customers prioritize reliability and authenticity, while 64% express willingness to pay premium prices for enhanced performance characteristics.

Market barriers include regulatory challenges related to emissions standards, limited production scale economies, and competition from more modern engine configurations. However, specialized applications where the unique power delivery characteristics of radial engines provide competitive advantages continue to sustain market growth despite these challenges.

Technical Challenges in Radial Engine Turbocharging

Radial engine turbocharging presents a unique set of technical challenges that stem from the inherent design characteristics of these engines. The radial configuration, with cylinders arranged in a circular pattern around the crankshaft, creates complex airflow dynamics that complicate turbocharger integration. One primary challenge is the uneven exhaust pulse timing due to the firing order of radial engines, which can lead to inefficient energy extraction by the turbocharger turbine and result in turbo lag or inconsistent boost pressure.

Thermal management represents another significant hurdle in radial engine turbocharging. The compact arrangement of cylinders creates concentrated heat zones, particularly problematic when adding a turbocharger system that generates additional thermal load. This heat concentration can lead to component fatigue, reduced reliability, and potential material failures if not properly addressed through advanced cooling solutions and heat-resistant materials.

The physical integration of turbocharger systems presents spatial constraints unique to radial engines. Unlike inline or V-configuration engines where turbochargers can be mounted alongside the engine block, radial engines offer limited peripheral space for turbocharger placement. Engineers must develop creative mounting solutions that maintain proper exhaust gas flow while ensuring the turbocharger remains accessible for maintenance and operates at optimal temperatures.

Oil management systems face particular challenges in turbocharged radial engines. The centrifugal forces generated by the radial configuration can create oil distribution issues that are exacerbated when turbochargers, with their high-speed bearings requiring precise lubrication, are introduced to the system. Ensuring consistent oil pressure and flow throughout all operating conditions becomes critical to prevent premature bearing failure in the turbocharger.

Boost control and engine management systems require sophisticated calibration for turbocharged radial engines. The unique volumetric efficiency characteristics of radial engines across their RPM range necessitate carefully tuned wastegate control and boost mapping to prevent detonation while maximizing performance. Modern electronic control systems must be specifically programmed to account for the radial engine's distinctive breathing characteristics.

Material selection presents another challenge, as components must withstand both the vibration patterns specific to radial engines and the increased pressure and temperature stresses introduced by turbocharging. Traditional materials used in naturally aspirated radial engines may prove insufficient under these enhanced operating conditions, requiring aerospace-grade alloys and advanced manufacturing techniques.

Finally, maintaining the historical authenticity and characteristic sound of radial engines while implementing modern turbocharging technology represents a unique challenge for applications in vintage aircraft restoration or heritage projects where preserving the engine's original character is valued alongside performance improvements.

Thermal management represents another significant hurdle in radial engine turbocharging. The compact arrangement of cylinders creates concentrated heat zones, particularly problematic when adding a turbocharger system that generates additional thermal load. This heat concentration can lead to component fatigue, reduced reliability, and potential material failures if not properly addressed through advanced cooling solutions and heat-resistant materials.

The physical integration of turbocharger systems presents spatial constraints unique to radial engines. Unlike inline or V-configuration engines where turbochargers can be mounted alongside the engine block, radial engines offer limited peripheral space for turbocharger placement. Engineers must develop creative mounting solutions that maintain proper exhaust gas flow while ensuring the turbocharger remains accessible for maintenance and operates at optimal temperatures.

Oil management systems face particular challenges in turbocharged radial engines. The centrifugal forces generated by the radial configuration can create oil distribution issues that are exacerbated when turbochargers, with their high-speed bearings requiring precise lubrication, are introduced to the system. Ensuring consistent oil pressure and flow throughout all operating conditions becomes critical to prevent premature bearing failure in the turbocharger.

Boost control and engine management systems require sophisticated calibration for turbocharged radial engines. The unique volumetric efficiency characteristics of radial engines across their RPM range necessitate carefully tuned wastegate control and boost mapping to prevent detonation while maximizing performance. Modern electronic control systems must be specifically programmed to account for the radial engine's distinctive breathing characteristics.

Material selection presents another challenge, as components must withstand both the vibration patterns specific to radial engines and the increased pressure and temperature stresses introduced by turbocharging. Traditional materials used in naturally aspirated radial engines may prove insufficient under these enhanced operating conditions, requiring aerospace-grade alloys and advanced manufacturing techniques.

Finally, maintaining the historical authenticity and characteristic sound of radial engines while implementing modern turbocharging technology represents a unique challenge for applications in vintage aircraft restoration or heritage projects where preserving the engine's original character is valued alongside performance improvements.

Current Turbocharging Solutions for Radial Engines

01 Radial engine design optimization

Various design improvements for radial engines focus on optimizing the arrangement of cylinders, crankshaft configurations, and overall engine geometry to enhance performance. These optimizations include modifications to the cylinder layout, improved cooling systems, and structural enhancements that reduce weight while maintaining strength. Such design improvements contribute to better power output, fuel efficiency, and overall engine reliability.- Radial engine design optimization for performance enhancement: Various design modifications can be implemented to optimize radial engine performance. These include improvements to cylinder arrangement, cooling systems, and overall structural design. By optimizing these elements, engineers can achieve better power output, fuel efficiency, and operational reliability. Advanced materials and manufacturing techniques further contribute to performance enhancements in modern radial engine designs.

- Electronic control systems for radial engines: Implementation of electronic control systems significantly improves radial engine performance. These systems enable precise management of fuel injection, ignition timing, and air-fuel mixture. Advanced sensors and processors allow real-time adjustments based on operating conditions, resulting in optimized combustion efficiency, reduced emissions, and enhanced power output. Electronic controls also facilitate better integration with vehicle systems for comprehensive performance management.

- Cooling and thermal management solutions: Effective thermal management is crucial for maintaining optimal radial engine performance. Innovative cooling solutions address the inherent heat distribution challenges in radial configurations. These include advanced air cooling designs, liquid cooling systems, and hybrid approaches. Proper thermal management prevents overheating, reduces thermal stress on components, and ensures consistent performance across various operating conditions.

- Performance modeling and simulation techniques: Computational modeling and simulation techniques provide valuable insights for radial engine performance optimization. These methods enable engineers to analyze combustion dynamics, structural integrity, and thermal behavior without extensive physical testing. Advanced simulation tools facilitate the prediction of performance parameters under various operating conditions, allowing for iterative design improvements and validation before prototype manufacturing.

- Alternative fuel adaptations for radial engines: Adapting radial engines to operate efficiently with alternative fuels represents a significant area of performance enhancement. Modifications to fuel delivery systems, combustion chambers, and control algorithms enable the use of biofuels, hydrogen, or synthetic fuels. These adaptations can improve energy efficiency, reduce environmental impact, and potentially increase power output while maintaining the distinctive operational characteristics of radial engine configurations.

02 Combustion efficiency and fuel management

Innovations in combustion chamber design, fuel injection systems, and mixture control mechanisms significantly improve radial engine performance. Advanced fuel management systems optimize the air-fuel ratio across different operating conditions, while enhanced ignition timing control ensures optimal combustion. These technologies result in increased power output, reduced fuel consumption, and lower emissions from radial engines.Expand Specific Solutions03 Cooling and thermal management systems

Effective thermal management is crucial for radial engine performance. Advanced cooling systems incorporate improved air flow designs, enhanced heat dissipation mechanisms, and optimized cooling fin arrangements. Some innovations include liquid cooling adaptations for traditionally air-cooled radial engines and composite materials with superior thermal properties. These improvements prevent overheating, maintain optimal operating temperatures, and extend engine lifespan.Expand Specific Solutions04 Electronic control and monitoring systems

Modern radial engines incorporate sophisticated electronic control units (ECUs) and monitoring systems to optimize performance. These systems provide real-time adjustment of engine parameters, predictive maintenance capabilities, and performance diagnostics. Advanced sensors monitor critical variables such as temperature, pressure, and vibration, allowing for precise control of engine operation and early detection of potential issues, thereby enhancing reliability and efficiency.Expand Specific Solutions05 Power output enhancement technologies

Various technologies specifically focus on increasing the power output of radial engines. These include supercharging and turbocharging systems adapted for radial configurations, advanced valve timing mechanisms, and performance-optimized exhaust systems. Some innovations also incorporate hybrid technologies or auxiliary power systems that complement the radial engine's operation. These enhancements significantly improve the power-to-weight ratio and overall performance characteristics.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The radial engine performance enhancement market for turbo applications is currently in a growth phase, with increasing demand driven by efficiency requirements across aerospace and automotive sectors. The market is characterized by a mix of established players and emerging specialists, with an estimated global value of $3-4 billion. Technologically, the field is moderately mature but evolving rapidly, with companies at different development stages. Industry leaders like Safran Aircraft Engines, Rolls-Royce Deutschland, and Mitsubishi Heavy Industries are advancing core technologies, while specialized firms such as BMTS Technology and Honeywell International Technologies focus on innovative turbocharger solutions. Automotive giants Ford and Great Wall Motor are integrating these advancements into their vehicle platforms, creating a competitive ecosystem balancing traditional engineering with cutting-edge performance optimization.

Mitsubishi Heavy Industries Engine & Turbocharger Ltd.

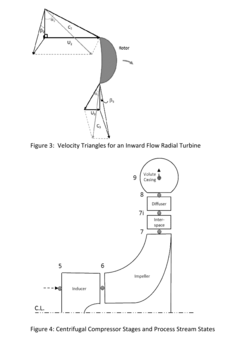

Technical Solution: Mitsubishi Heavy Industries Engine & Turbocharger has developed advanced radial engine technologies for turbocharging applications, focusing on their Variable Geometry Turbocharger (VGT) system. Their solution incorporates innovative aerodynamic designs for radial turbine wheels that optimize flow characteristics across varying engine speeds. The company has implemented specialized blade profiling techniques that reduce inertial losses while maintaining structural integrity under high-temperature operating conditions. Their proprietary thermal management system addresses heat-related performance degradation in radial engines, utilizing advanced ceramic coatings and optimized cooling channels to maintain optimal operating temperatures. Additionally, they've integrated electronic control systems that dynamically adjust vane positions based on real-time engine parameters, ensuring peak efficiency throughout the operating range.

Strengths: Superior thermal management capabilities allow for higher operating temperatures and improved efficiency. Advanced materials science expertise enables lightweight yet durable component design. Weaknesses: Higher manufacturing costs compared to conventional systems. More complex maintenance requirements due to sophisticated electronic control systems.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered significant advancements in radial engine performance for turbo applications through their DualBoost technology. This innovative approach combines a dual-sided compressor wheel with an advanced radial turbine design, effectively increasing boost pressure while minimizing turbo lag. Their system incorporates aerodynamically optimized blade geometry that maintains efficiency across a broader operating range. Honeywell's solution also features their patented Mixed Flow Technology (MFT), which blends axial and radial flow characteristics to achieve superior performance at high pressure ratios. The company has developed specialized thermal barrier coatings that extend component lifespan under extreme temperature conditions. Their integrated wastegate control system provides precise boost regulation, while advanced bearing systems reduce friction losses and improve transient response. These technologies collectively deliver up to 20% improvement in power density compared to conventional radial engine turbo systems.

Strengths: Exceptional transient response characteristics reduce turbo lag significantly. Highly efficient aerodynamic designs provide excellent power-to-weight ratio. Comprehensive integration with engine management systems. Weaknesses: Premium pricing structure limits accessibility for some applications. Higher complexity requires specialized maintenance expertise.

Key Patents in Radial Engine Forced Induction

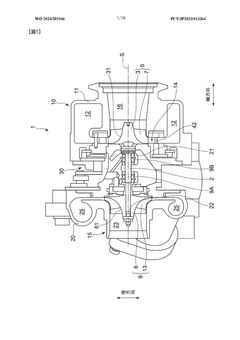

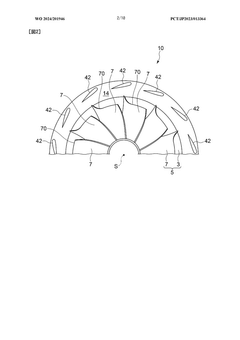

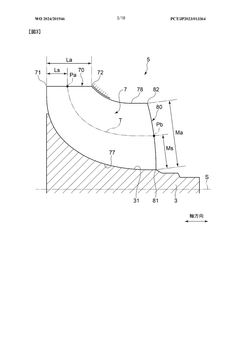

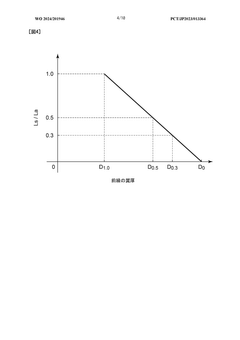

Radial turbine wheel, radial turbine, and turbocharger

PatentWO2024201946A1

Innovation

- The leading edge of the turbine blades is designed with a continuously decreasing thickness from 0.2 to 1.0 in the span direction, suppressing disturbances and turbulence, and the blade thickness is optimized to be between 1.3 and 2.2 times at specific positions, reducing secondary flow losses.

Performance analysis and monitoring of radial turbomachinery

PatentInactiveUS20150199495A1

Innovation

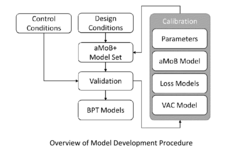

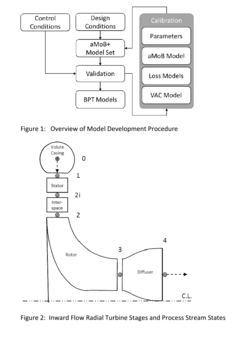

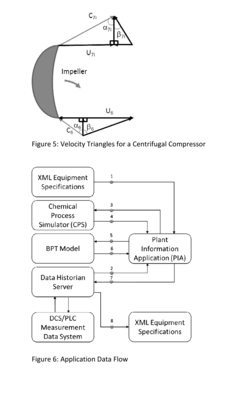

- A process that includes real-time performance monitoring and analysis using Chemical Process Simulation systems and radial turbo-machinery performance models to compare actual and target performance, incorporating Angular Momentum Balance models and vane-angle control models to accurately describe equipment performance at off-design conditions.

Thermal Management Strategies for Turbocharged Radials

Thermal management represents a critical challenge in turbocharged radial engine applications, where heat generation is significantly amplified compared to naturally aspirated configurations. The integration of turbocharging systems with radial engines creates unique thermal conditions that require specialized management strategies to maintain optimal performance and component longevity.

Conventional cooling approaches for radial engines typically rely on air-cooling mechanisms with finned cylinders arranged in a circular pattern. However, when turbocharging is introduced, exhaust gas temperatures can increase by 150-200°C, creating thermal stress points particularly at the turbocharger mounting interface and in cylinders nearest to the exhaust manifold connection.

Advanced computational fluid dynamics (CFD) modeling has enabled the development of more efficient cooling fin designs that optimize airflow across the engine's radial configuration. Recent innovations include asymmetrical fin patterns that direct greater cooling capacity to cylinders experiencing the highest thermal loads. These designs have demonstrated temperature reductions of 15-20% in critical areas without requiring additional cooling system weight.

Oil cooling systems have evolved significantly for turbocharged radial applications, with dual-circuit designs becoming increasingly common. These systems employ separate cooling circuits for the engine and turbocharger, allowing for optimized oil temperatures in each component. Synthetic oils with higher temperature tolerances (up to 300°C) have been specifically formulated to withstand the increased thermal stress in turbocharged environments.

Intercooling technology has proven essential for managing charge air temperatures in turbocharged radial engines. Compact air-to-air and air-to-liquid intercoolers designed specifically for the spatial constraints of radial engine installations have shown efficiency improvements of 8-12% by reducing intake air temperatures by up to 100°C. This not only improves volumetric efficiency but also reduces thermal stress on combustion chamber components.

Thermal barrier coatings (TBCs) applied to exhaust components and critical engine surfaces have demonstrated significant benefits in heat management. Ceramic-based coatings with thermal conductivity values below 1.5 W/m·K can reduce heat transfer to surrounding components by up to 30%, allowing more thermal energy to be utilized by the turbocharger while protecting sensitive engine components from excessive heat exposure.

Electronic thermal management systems incorporating multiple temperature sensors and adaptive cooling strategies represent the cutting edge of thermal control in turbocharged radial applications. These systems can modulate cooling airflow, oil circulation rates, and even turbocharger wastegate operation based on real-time thermal conditions, maintaining optimal operating temperatures across varying power demands and environmental conditions.

Conventional cooling approaches for radial engines typically rely on air-cooling mechanisms with finned cylinders arranged in a circular pattern. However, when turbocharging is introduced, exhaust gas temperatures can increase by 150-200°C, creating thermal stress points particularly at the turbocharger mounting interface and in cylinders nearest to the exhaust manifold connection.

Advanced computational fluid dynamics (CFD) modeling has enabled the development of more efficient cooling fin designs that optimize airflow across the engine's radial configuration. Recent innovations include asymmetrical fin patterns that direct greater cooling capacity to cylinders experiencing the highest thermal loads. These designs have demonstrated temperature reductions of 15-20% in critical areas without requiring additional cooling system weight.

Oil cooling systems have evolved significantly for turbocharged radial applications, with dual-circuit designs becoming increasingly common. These systems employ separate cooling circuits for the engine and turbocharger, allowing for optimized oil temperatures in each component. Synthetic oils with higher temperature tolerances (up to 300°C) have been specifically formulated to withstand the increased thermal stress in turbocharged environments.

Intercooling technology has proven essential for managing charge air temperatures in turbocharged radial engines. Compact air-to-air and air-to-liquid intercoolers designed specifically for the spatial constraints of radial engine installations have shown efficiency improvements of 8-12% by reducing intake air temperatures by up to 100°C. This not only improves volumetric efficiency but also reduces thermal stress on combustion chamber components.

Thermal barrier coatings (TBCs) applied to exhaust components and critical engine surfaces have demonstrated significant benefits in heat management. Ceramic-based coatings with thermal conductivity values below 1.5 W/m·K can reduce heat transfer to surrounding components by up to 30%, allowing more thermal energy to be utilized by the turbocharger while protecting sensitive engine components from excessive heat exposure.

Electronic thermal management systems incorporating multiple temperature sensors and adaptive cooling strategies represent the cutting edge of thermal control in turbocharged radial applications. These systems can modulate cooling airflow, oil circulation rates, and even turbocharger wastegate operation based on real-time thermal conditions, maintaining optimal operating temperatures across varying power demands and environmental conditions.

Emissions Compliance for Modern Radial Applications

As radial engines find new applications in modern turbo systems, emissions compliance has become a critical challenge for manufacturers and engineers. Traditional radial engines were developed in an era with minimal environmental regulations, but today's strict emissions standards require significant adaptations to make these engines viable in contemporary settings.

The primary emissions concerns for radial engines include nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (HC), and particulate matter. These pollutants are subject to increasingly stringent regulations across global markets, with the European Union's Euro standards, the United States EPA requirements, and emerging Asian regulations creating a complex compliance landscape.

Several technological approaches have emerged to address emissions challenges in modern radial applications. Electronic fuel injection systems have largely replaced traditional carburetors, allowing for precise fuel metering and optimized air-fuel ratios across different operating conditions. This technology alone can reduce emissions by 15-30% compared to conventional systems.

Exhaust gas recirculation (EGR) has been successfully adapted for radial configurations, though with unique engineering challenges due to the engine's circular arrangement. Modern EGR systems for radials typically achieve 10-20% NOx reduction without significant performance penalties when properly calibrated.

Catalytic converter technology has also evolved specifically for radial engine applications. The distinctive exhaust pulse patterns and temperature profiles of radial engines require specially designed catalyst formulations and housing geometries. Three-way catalytic converters optimized for radial engines have demonstrated efficiency rates of 85-95% for HC, CO, and NOx reduction.

Advanced combustion chamber designs represent another frontier in emissions compliance. Computational fluid dynamics modeling has enabled the development of optimized chamber geometries that promote more complete combustion while maintaining the radial engine's characteristic power delivery and reliability. These redesigned chambers can reduce raw emissions by up to 25% before after-treatment.

The integration of modern engine management systems presents both opportunities and challenges. While digital control units can optimize timing and mixture for emissions compliance, the unique firing order and thermal characteristics of radial engines require specialized algorithms and sensor arrangements that differ significantly from inline or V-configuration engines.

For manufacturers pursuing turbo applications with radial engines, a comprehensive emissions strategy typically combines multiple approaches, with testing showing that integrated systems can achieve compliance with current standards while maintaining the distinctive performance characteristics that make radial engines attractive for specialized applications.

The primary emissions concerns for radial engines include nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (HC), and particulate matter. These pollutants are subject to increasingly stringent regulations across global markets, with the European Union's Euro standards, the United States EPA requirements, and emerging Asian regulations creating a complex compliance landscape.

Several technological approaches have emerged to address emissions challenges in modern radial applications. Electronic fuel injection systems have largely replaced traditional carburetors, allowing for precise fuel metering and optimized air-fuel ratios across different operating conditions. This technology alone can reduce emissions by 15-30% compared to conventional systems.

Exhaust gas recirculation (EGR) has been successfully adapted for radial configurations, though with unique engineering challenges due to the engine's circular arrangement. Modern EGR systems for radials typically achieve 10-20% NOx reduction without significant performance penalties when properly calibrated.

Catalytic converter technology has also evolved specifically for radial engine applications. The distinctive exhaust pulse patterns and temperature profiles of radial engines require specially designed catalyst formulations and housing geometries. Three-way catalytic converters optimized for radial engines have demonstrated efficiency rates of 85-95% for HC, CO, and NOx reduction.

Advanced combustion chamber designs represent another frontier in emissions compliance. Computational fluid dynamics modeling has enabled the development of optimized chamber geometries that promote more complete combustion while maintaining the radial engine's characteristic power delivery and reliability. These redesigned chambers can reduce raw emissions by up to 25% before after-treatment.

The integration of modern engine management systems presents both opportunities and challenges. While digital control units can optimize timing and mixture for emissions compliance, the unique firing order and thermal characteristics of radial engines require specialized algorithms and sensor arrangements that differ significantly from inline or V-configuration engines.

For manufacturers pursuing turbo applications with radial engines, a comprehensive emissions strategy typically combines multiple approaches, with testing showing that integrated systems can achieve compliance with current standards while maintaining the distinctive performance characteristics that make radial engines attractive for specialized applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!