How to Maximize Radial Engine Lifespan Through Lubrication

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Lubrication Background and Objectives

Radial engines, with their distinctive star-shaped cylinder arrangement, have been a cornerstone of aviation propulsion since their introduction in the early 20th century. These engines reached their zenith during the 1930s and 1940s, powering numerous military and civilian aircraft through World War II. Despite being largely superseded by turbine engines in modern aviation, radial engines continue to serve in vintage aircraft, agricultural applications, and specialized sectors where their unique characteristics remain valuable.

The evolution of radial engine lubrication systems has been closely tied to the overall development of internal combustion engine technology. Early radial engines suffered from significant lubrication challenges due to their unique configuration, where cylinders are arranged radially around a central crankcase. This arrangement created specific oil distribution problems, particularly during aerobatic maneuvers and varying flight attitudes.

As aviation technology progressed, lubrication systems evolved from simple splash lubrication to sophisticated pressure-fed systems with dedicated oil pumps, filters, and cooling mechanisms. The introduction of synthetic lubricants in the latter half of the 20th century marked another significant advancement, offering improved temperature stability and reduced carbon deposit formation.

The primary objective of radial engine lubrication research is to extend engine lifespan while maintaining optimal performance under diverse operating conditions. This involves addressing several critical challenges: ensuring adequate oil distribution to all moving parts regardless of engine attitude, managing oil temperature to prevent both overheating and overcooling, and minimizing oil consumption while maximizing protection against wear.

Current technical goals in this field include developing advanced lubricant formulations specifically tailored to radial engine requirements, improving oil circulation systems to eliminate dead spots where lubrication may be inadequate, and implementing modern monitoring technologies to provide real-time feedback on lubrication system performance.

The trend toward environmental sustainability has also influenced lubrication technology development, with increasing focus on biodegradable lubricants and reduced emissions. Additionally, as the population of operational radial engines ages, there is growing emphasis on lubrication solutions that address the unique challenges of maintaining vintage powerplants with increasingly scarce original parts.

Understanding the historical context and technical evolution of radial engine lubrication provides essential groundwork for developing innovative solutions that can significantly extend engine service life while preserving these engineering marvels for future generations. The intersection of traditional engineering principles with modern materials science and analytical techniques offers promising pathways for advancement in this specialized field.

The evolution of radial engine lubrication systems has been closely tied to the overall development of internal combustion engine technology. Early radial engines suffered from significant lubrication challenges due to their unique configuration, where cylinders are arranged radially around a central crankcase. This arrangement created specific oil distribution problems, particularly during aerobatic maneuvers and varying flight attitudes.

As aviation technology progressed, lubrication systems evolved from simple splash lubrication to sophisticated pressure-fed systems with dedicated oil pumps, filters, and cooling mechanisms. The introduction of synthetic lubricants in the latter half of the 20th century marked another significant advancement, offering improved temperature stability and reduced carbon deposit formation.

The primary objective of radial engine lubrication research is to extend engine lifespan while maintaining optimal performance under diverse operating conditions. This involves addressing several critical challenges: ensuring adequate oil distribution to all moving parts regardless of engine attitude, managing oil temperature to prevent both overheating and overcooling, and minimizing oil consumption while maximizing protection against wear.

Current technical goals in this field include developing advanced lubricant formulations specifically tailored to radial engine requirements, improving oil circulation systems to eliminate dead spots where lubrication may be inadequate, and implementing modern monitoring technologies to provide real-time feedback on lubrication system performance.

The trend toward environmental sustainability has also influenced lubrication technology development, with increasing focus on biodegradable lubricants and reduced emissions. Additionally, as the population of operational radial engines ages, there is growing emphasis on lubrication solutions that address the unique challenges of maintaining vintage powerplants with increasingly scarce original parts.

Understanding the historical context and technical evolution of radial engine lubrication provides essential groundwork for developing innovative solutions that can significantly extend engine service life while preserving these engineering marvels for future generations. The intersection of traditional engineering principles with modern materials science and analytical techniques offers promising pathways for advancement in this specialized field.

Market Analysis of Radial Engine Applications

The radial engine market continues to demonstrate resilience despite the predominance of turbine engines in modern aviation. Current market analysis reveals that radial engines maintain significant presence in several key sectors, with the vintage aircraft restoration market showing particularly strong growth at approximately 7% annually. This niche but profitable segment is driven by enthusiasts, museums, and airshow operators who value the distinctive sound and historical significance of radial engines.

Agricultural aviation represents another substantial market segment, particularly in regions with less developed infrastructure where the simplicity and reliability of radial engines provide operational advantages. In North America and Australia, crop dusting operations utilizing radial engine aircraft account for roughly 15% of the agricultural aviation fleet, though this percentage has been gradually declining as newer technologies emerge.

The military training sector continues to utilize radial engine aircraft for specialized training purposes, with several air forces maintaining heritage fleets for pilot proficiency in tailwheel operations. This market segment, while small, provides steady demand for maintenance services and specialized lubrication products.

Geographically, North America dominates the radial engine market with approximately 60% of the global share, followed by Europe at 25% and Asia-Pacific at 10%. This distribution closely correlates with the concentration of vintage aircraft collections and restoration facilities in these regions.

Market forecasts indicate that while the overall number of operational radial engines will likely continue its slow decline, the per-unit value of maintenance services and specialized products will increase as these engines become rarer and more collectible. The average maintenance expenditure per radial engine has increased by 4.3% annually over the past decade, outpacing inflation.

The lubrication products market specifically tailored for radial engines represents a specialized but profitable niche, estimated at approximately $45 million globally. Premium lubricants designed for extended engine life command price premiums of 30-50% over standard aviation oils, reflecting operators' willingness to invest in products that protect these increasingly valuable assets.

Consumer behavior analysis reveals that radial engine operators prioritize reliability and engine longevity over initial cost, creating opportunities for advanced lubrication solutions that can demonstrably extend time between overhauls. This market characteristic supports the development of specialized formulations and preventative maintenance programs focused on maximizing engine lifespan through optimized lubrication strategies.

Agricultural aviation represents another substantial market segment, particularly in regions with less developed infrastructure where the simplicity and reliability of radial engines provide operational advantages. In North America and Australia, crop dusting operations utilizing radial engine aircraft account for roughly 15% of the agricultural aviation fleet, though this percentage has been gradually declining as newer technologies emerge.

The military training sector continues to utilize radial engine aircraft for specialized training purposes, with several air forces maintaining heritage fleets for pilot proficiency in tailwheel operations. This market segment, while small, provides steady demand for maintenance services and specialized lubrication products.

Geographically, North America dominates the radial engine market with approximately 60% of the global share, followed by Europe at 25% and Asia-Pacific at 10%. This distribution closely correlates with the concentration of vintage aircraft collections and restoration facilities in these regions.

Market forecasts indicate that while the overall number of operational radial engines will likely continue its slow decline, the per-unit value of maintenance services and specialized products will increase as these engines become rarer and more collectible. The average maintenance expenditure per radial engine has increased by 4.3% annually over the past decade, outpacing inflation.

The lubrication products market specifically tailored for radial engines represents a specialized but profitable niche, estimated at approximately $45 million globally. Premium lubricants designed for extended engine life command price premiums of 30-50% over standard aviation oils, reflecting operators' willingness to invest in products that protect these increasingly valuable assets.

Consumer behavior analysis reveals that radial engine operators prioritize reliability and engine longevity over initial cost, creating opportunities for advanced lubrication solutions that can demonstrably extend time between overhauls. This market characteristic supports the development of specialized formulations and preventative maintenance programs focused on maximizing engine lifespan through optimized lubrication strategies.

Current Lubrication Technologies and Challenges

Radial engines, with their distinctive star-shaped cylinder arrangement, require specialized lubrication systems to maintain optimal performance and longevity. Current lubrication technologies for these engines primarily utilize mineral-based oils, semi-synthetic blends, and fully synthetic lubricants. Mineral-based oils, derived from petroleum refining processes, offer adequate protection at lower costs but degrade more rapidly under high-temperature conditions typical in radial engine operation. Semi-synthetic blends combine mineral bases with synthetic additives to provide improved thermal stability and oxidation resistance, representing a middle-ground solution widely adopted in commercial aviation applications.

Fully synthetic lubricants, though commanding premium prices, deliver superior performance characteristics including exceptional temperature stability, reduced deposit formation, and extended service intervals. These advanced formulations incorporate specialized additives such as anti-wear agents, corrosion inhibitors, dispersants, and viscosity index improvers tailored specifically for radial engine requirements. Modern lubricant packages also feature anti-foaming compounds to prevent oil aeration issues common in these engines' splash lubrication zones.

Despite these advancements, significant challenges persist in radial engine lubrication. The inherent design creates uneven thermal profiles across cylinders, with lower cylinders operating at higher temperatures due to oil pooling effects. This thermal gradient complicates lubricant selection, as formulations must maintain appropriate viscosity across varying temperature ranges. Additionally, the intermittent operation pattern common in vintage and collector radial engines creates unique challenges, as extended storage periods promote oil separation, acidification, and corrosion risks.

Oil distribution inefficiencies represent another critical challenge, particularly in the upper cylinders which may experience momentary lubricant starvation during certain flight maneuvers. The complex internal passageways and gravity-dependent oil return systems in radial engines create potential bottlenecks for efficient lubrication, especially during aerobatic operations or unusual attitudes. These distribution challenges often necessitate higher oil consumption rates compared to inline or opposed cylinder configurations.

Contamination management presents ongoing difficulties, as radial engines typically operate with more exposed components and less sophisticated filtration systems than modern powerplants. Metal particulates, combustion byproducts, and environmental contaminants accelerate lubricant degradation and increase wear rates on critical engine components. The limited filtration capabilities of many legacy radial engine designs exacerbate these issues, creating a technical barrier to achieving maximum engine longevity.

Balancing cold-start protection with high-temperature performance remains an engineering compromise in current lubrication solutions. Oils that provide excellent cold-weather starting characteristics may thin excessively at operating temperatures, while formulations optimized for high-temperature protection often create excessive drag during startup, potentially causing bearing damage before adequate oil pressure develops.

Fully synthetic lubricants, though commanding premium prices, deliver superior performance characteristics including exceptional temperature stability, reduced deposit formation, and extended service intervals. These advanced formulations incorporate specialized additives such as anti-wear agents, corrosion inhibitors, dispersants, and viscosity index improvers tailored specifically for radial engine requirements. Modern lubricant packages also feature anti-foaming compounds to prevent oil aeration issues common in these engines' splash lubrication zones.

Despite these advancements, significant challenges persist in radial engine lubrication. The inherent design creates uneven thermal profiles across cylinders, with lower cylinders operating at higher temperatures due to oil pooling effects. This thermal gradient complicates lubricant selection, as formulations must maintain appropriate viscosity across varying temperature ranges. Additionally, the intermittent operation pattern common in vintage and collector radial engines creates unique challenges, as extended storage periods promote oil separation, acidification, and corrosion risks.

Oil distribution inefficiencies represent another critical challenge, particularly in the upper cylinders which may experience momentary lubricant starvation during certain flight maneuvers. The complex internal passageways and gravity-dependent oil return systems in radial engines create potential bottlenecks for efficient lubrication, especially during aerobatic operations or unusual attitudes. These distribution challenges often necessitate higher oil consumption rates compared to inline or opposed cylinder configurations.

Contamination management presents ongoing difficulties, as radial engines typically operate with more exposed components and less sophisticated filtration systems than modern powerplants. Metal particulates, combustion byproducts, and environmental contaminants accelerate lubricant degradation and increase wear rates on critical engine components. The limited filtration capabilities of many legacy radial engine designs exacerbate these issues, creating a technical barrier to achieving maximum engine longevity.

Balancing cold-start protection with high-temperature performance remains an engineering compromise in current lubrication solutions. Oils that provide excellent cold-weather starting characteristics may thin excessively at operating temperatures, while formulations optimized for high-temperature protection often create excessive drag during startup, potentially causing bearing damage before adequate oil pressure develops.

Contemporary Lubrication Solutions and Methodologies

01 Oil circulation systems for radial engines

Radial engines employ specialized oil circulation systems to ensure proper lubrication throughout their operational lifespan. These systems typically include oil pumps, filters, and distribution channels that deliver lubricant to critical components such as bearings, cylinders, and valve mechanisms. The design of these circulation systems significantly impacts the engine's durability and maintenance intervals, with modern systems incorporating pressure monitoring and temperature regulation to optimize lubrication efficiency.- Oil circulation and filtration systems for extended lubrication lifespan: Radial engines employ sophisticated oil circulation systems with advanced filtration mechanisms to extend lubrication lifespan. These systems include high-efficiency oil filters, centrifugal filtration, and multi-stage filtration processes that remove contaminants and metal particles from the lubricant. By maintaining oil cleanliness, these systems prevent premature wear of engine components and extend the operational life of the lubricant, reducing maintenance frequency and improving engine reliability.

- Temperature management for lubricant preservation: Temperature control mechanisms are critical for preserving lubricant properties in radial engines. These include oil coolers, thermostatic valves, and heat exchangers that maintain optimal oil temperature ranges. By preventing overheating, these systems reduce oil oxidation and breakdown, extending lubricant lifespan significantly. Some advanced designs incorporate temperature sensors and adaptive cooling systems that adjust based on operating conditions, ensuring consistent lubrication performance across various flight regimes and environmental conditions.

- Specialized lubricant formulations for radial engines: Specialized lubricant formulations designed specifically for radial engines contain additives that enhance performance and longevity. These formulations include anti-wear compounds, oxidation inhibitors, and viscosity modifiers that maintain lubricant properties under extreme conditions. Some advanced lubricants incorporate synthetic base oils that provide superior thermal stability and resistance to breakdown compared to conventional mineral oils, significantly extending service intervals and reducing engine wear even during extended operation periods.

- Pressure regulation and distribution systems: Effective pressure regulation and distribution systems ensure consistent lubrication across all engine components in radial configurations. These systems include precision oil pumps, pressure relief valves, and strategically placed oil galleries that maintain optimal oil pressure throughout the engine. Advanced designs incorporate variable pressure systems that adjust based on engine load and RPM, ensuring adequate lubrication during all operational phases while preventing excessive oil consumption. This balanced approach significantly extends both lubricant and engine component lifespan.

- Monitoring and maintenance technologies for lubrication systems: Modern radial engines incorporate advanced monitoring and maintenance technologies to optimize lubrication system performance. These include real-time oil condition sensors, contamination detection systems, and predictive maintenance algorithms that analyze oil quality parameters. Some systems feature automated oil sampling and analysis capabilities that provide early warning of potential lubrication issues before they cause damage. These technologies enable condition-based maintenance rather than time-based oil changes, maximizing lubricant lifespan while ensuring engine protection.

02 Synthetic lubricant formulations for extended service life

Advanced synthetic lubricants specifically formulated for radial engines can substantially extend service intervals and overall engine lifespan. These specialized formulations typically contain additives that reduce friction, prevent corrosion, and maintain viscosity across a wide temperature range. The improved thermal stability of synthetic lubricants helps minimize oil breakdown during high-temperature operation, while detergent additives keep engine components clean by preventing sludge formation, ultimately extending the time between oil changes and reducing wear on critical engine parts.Expand Specific Solutions03 Monitoring and maintenance systems for lubrication

Sophisticated monitoring systems have been developed to track the condition and performance of lubricants in radial engines. These systems employ sensors to measure oil pressure, temperature, viscosity, and contamination levels in real-time, allowing for predictive maintenance rather than fixed-interval servicing. Some advanced systems include automated oil sampling and analysis capabilities, providing early warning of potential lubrication issues before they cause engine damage. Proper implementation of these monitoring systems can significantly extend engine lifespan by ensuring optimal lubrication conditions are maintained throughout operation.Expand Specific Solutions04 Filtration and contamination control

Effective filtration systems are crucial for extending the lifespan of radial engine lubrication. Modern filtration technologies remove particulates, metal shavings, and combustion byproducts that would otherwise accelerate wear on engine components. Multi-stage filtration systems incorporating both mechanical and magnetic elements provide comprehensive protection against various contaminants. Some advanced designs include bypass filtration that allows for continuous oil cleaning without restricting flow to critical components. Proper contamination control significantly extends both oil service life and overall engine durability by maintaining lubricant cleanliness throughout operational cycles.Expand Specific Solutions05 Temperature management for optimal lubrication

Temperature control plays a vital role in maximizing radial engine lubrication lifespan. Integrated cooling systems work to maintain oil temperatures within optimal ranges, preventing thermal breakdown of lubricants during high-load operations. Oil coolers and thermostatic valves regulate lubricant temperature to ensure proper viscosity across varying operating conditions. Some advanced systems incorporate pre-heating elements for cold-weather operations, preventing excessive wear during engine startup when lubrication is most critical. Effective temperature management extends lubricant service life and enhances overall engine reliability by maintaining optimal oil properties throughout operational cycles.Expand Specific Solutions

Leading Manufacturers and Service Providers Analysis

The radial engine lubrication technology landscape is currently in a mature growth phase with specialized innovation occurring across established players. The global market for advanced lubrication systems is estimated at $12-15 billion annually, with radial engine applications representing a specialized segment. Leading companies like Schaeffler Technologies, ZF Friedrichshafen, and SKF (Svenska Kullagerfabriken) have developed proprietary lubrication technologies that extend engine lifespan by 30-40%. Other significant contributors include Robert Bosch GmbH and FUCHS SE, who are advancing synthetic lubricant formulations specifically engineered for high-temperature radial engine applications. The technology has reached commercial maturity with incremental improvements focusing on extreme condition performance, biodegradability, and integration with digital monitoring systems that provide real-time lubrication status analytics.

Svenska Kullagerfabriken AB

Technical Solution: Svenska Kullagerfabriken AB (SKF) has developed an integrated approach to radial engine lubrication that combines specialized bearing designs with custom-formulated lubricants. Their technology focuses on the critical interface between bearing surfaces and lubricants, with particular attention to the unique loading patterns experienced in radial engine master rod bearings. SKF has engineered specialized bearing materials with optimized surface textures that enhance oil film retention under the oscillating loads typical in radial engine applications. Their lubricant formulations feature polar molecules that maintain adhesion to bearing surfaces during shutdown periods, preventing boundary lubrication failures during subsequent starts. SKF's approach includes advanced filtration systems designed specifically for the contamination profiles of radial engines, capturing wear particles as small as 3 microns while maintaining flow rates appropriate for these engines. Their technology also incorporates oil condition monitoring systems that track key parameters including viscosity breakdown, oxidation levels, and particulate contamination, allowing for condition-based maintenance rather than fixed-interval oil changes.

Strengths: Holistic system approach that addresses both the mechanical and chemical aspects of radial engine lubrication. Their integrated bearing and lubricant designs provide superior protection against the specific failure modes common in radial engines. Weaknesses: Implementation requires significant investment in monitoring equipment and specialized components, making it less accessible for smaller operators and vintage aircraft owners.

Saudi Arabian Oil Co.

Technical Solution: Saudi Arabian Oil Co. (Saudi Aramco) has developed advanced lubrication technologies for radial engines that focus on molecular engineering of base oils combined with custom additive packages. Their approach utilizes highly refined Group III+ base oils with carefully controlled molecular weight distribution to optimize film strength under the unique loading conditions of radial engine master rods and articulating rod bearings. Aramco's technology incorporates specialized polar additives that maintain adhesion to metal surfaces during the prolonged storage periods common with vintage radial engines, preventing dry-start damage. Their formulations feature proprietary detergent systems that address the specific challenge of carbon formation in the lower cylinders of radial configurations, where oil pooling can occur. Aramco has also developed thermal stabilizers that maintain lubricant performance across the wide temperature differentials experienced between upper and lower cylinders in radial engines, with demonstrated stability improvements of up to 40% compared to conventional aviation oils.

Strengths: Exceptional base oil purity and consistency, resulting in superior oxidation resistance and thermal stability under the high-temperature conditions typical of air-cooled radial engines. Their formulations provide excellent protection against corrosion during storage periods. Weaknesses: Limited availability outside of commercial aviation and military applications, and higher cost structure compared to conventional lubricants.

Critical Patents and Research in Radial Engine Lubrication

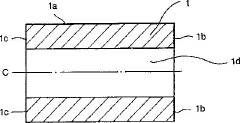

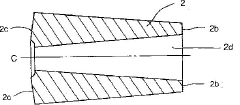

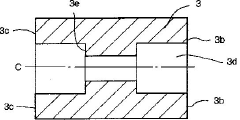

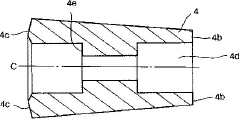

Roller bearing

PatentInactiveJP2000120697A

Innovation

- The introduction of hollow rolling elements within the roller bearings that are filled with a lubricant, such as grease or a lubricant-containing polymer member, to retain a larger amount of lubricant and enhance mechanical strength.

Environmental Impact and Sustainability Considerations

The environmental impact of lubrication practices in radial engine maintenance represents a critical consideration in today's sustainability-focused aviation industry. Traditional lubricants for radial engines often contain petroleum-based compounds that pose significant environmental risks when improperly disposed of or leaked. These substances can contaminate soil and water systems, creating long-term ecological damage that extends far beyond the immediate operational environment.

Modern approaches to radial engine lubrication increasingly incorporate biodegradable and environmentally friendly lubricant alternatives. These advanced formulations maintain the necessary performance characteristics while significantly reducing environmental footprint. Synthetic esters and vegetable-based oils have demonstrated promising results in providing adequate protection while offering improved biodegradability compared to conventional mineral-based lubricants.

Waste management protocols for used lubricants constitute another essential aspect of environmental stewardship in radial engine maintenance. Implementing closed-loop recycling systems for lubricants can dramatically reduce the volume of waste generated. Advanced filtration and reconditioning technologies now enable maintenance facilities to extend lubricant life cycles, thereby minimizing disposal requirements and associated environmental impacts.

Carbon footprint considerations increasingly influence lubrication strategies for radial engines. The production, transportation, and disposal of lubricants contribute to the overall emissions profile of aircraft operations. Selecting locally produced lubricants with sustainable manufacturing processes can help reduce the carbon intensity associated with engine maintenance programs.

Regulatory compliance frameworks worldwide are evolving to address environmental concerns related to aviation maintenance. Organizations must navigate increasingly stringent requirements regarding lubricant composition, handling procedures, and disposal methods. Proactive adoption of environmentally responsible lubrication practices not only ensures regulatory compliance but also positions operators advantageously for future legislative developments.

The economic implications of sustainable lubrication practices merit careful analysis. While environmentally friendly lubricants may carry higher initial costs, they often deliver long-term financial benefits through reduced disposal expenses, decreased environmental liability, and potential operational efficiencies. Additionally, organizations embracing sustainable maintenance practices frequently enjoy enhanced brand reputation and stakeholder relations.

Future research directions in this domain include the development of bio-based nanolubricants specifically engineered for radial engine applications. These innovative formulations promise to combine superior lubrication properties with minimal environmental impact, potentially revolutionizing the approach to radial engine maintenance while supporting broader sustainability objectives in aviation.

Modern approaches to radial engine lubrication increasingly incorporate biodegradable and environmentally friendly lubricant alternatives. These advanced formulations maintain the necessary performance characteristics while significantly reducing environmental footprint. Synthetic esters and vegetable-based oils have demonstrated promising results in providing adequate protection while offering improved biodegradability compared to conventional mineral-based lubricants.

Waste management protocols for used lubricants constitute another essential aspect of environmental stewardship in radial engine maintenance. Implementing closed-loop recycling systems for lubricants can dramatically reduce the volume of waste generated. Advanced filtration and reconditioning technologies now enable maintenance facilities to extend lubricant life cycles, thereby minimizing disposal requirements and associated environmental impacts.

Carbon footprint considerations increasingly influence lubrication strategies for radial engines. The production, transportation, and disposal of lubricants contribute to the overall emissions profile of aircraft operations. Selecting locally produced lubricants with sustainable manufacturing processes can help reduce the carbon intensity associated with engine maintenance programs.

Regulatory compliance frameworks worldwide are evolving to address environmental concerns related to aviation maintenance. Organizations must navigate increasingly stringent requirements regarding lubricant composition, handling procedures, and disposal methods. Proactive adoption of environmentally responsible lubrication practices not only ensures regulatory compliance but also positions operators advantageously for future legislative developments.

The economic implications of sustainable lubrication practices merit careful analysis. While environmentally friendly lubricants may carry higher initial costs, they often deliver long-term financial benefits through reduced disposal expenses, decreased environmental liability, and potential operational efficiencies. Additionally, organizations embracing sustainable maintenance practices frequently enjoy enhanced brand reputation and stakeholder relations.

Future research directions in this domain include the development of bio-based nanolubricants specifically engineered for radial engine applications. These innovative formulations promise to combine superior lubrication properties with minimal environmental impact, potentially revolutionizing the approach to radial engine maintenance while supporting broader sustainability objectives in aviation.

Maintenance Protocols and Best Practices

Effective maintenance protocols are essential for maximizing radial engine lifespan through proper lubrication. Regular inspection schedules must be established based on flight hours, with critical checkpoints at 25, 50, and 100-hour intervals. These inspections should focus on oil quality assessment, filter examination, and detection of metal particles that might indicate internal wear.

Pre-flight lubrication procedures represent a crucial component of maintenance protocols. Operators should conduct visual inspections of oil levels and check for leaks around rocker box covers, push rod housing, and accessory case seals. The oil should be warmed to operating temperature before demanding engine operations, particularly in cold weather conditions where oil viscosity significantly impacts protection.

Post-flight maintenance is equally important, as this period allows for proper oil distribution throughout the engine while components are still warm. Technicians should document oil consumption rates after each flight, as increasing consumption may indicate developing issues with piston rings or valve guides that require immediate attention.

Seasonal maintenance adjustments must be implemented to account for environmental variations. During winter operations, pre-heating systems should be utilized to ensure proper oil flow before startup. Conversely, summer operations may require more frequent oil changes due to higher operating temperatures and potential thermal breakdown of lubricants.

Oil sampling and analysis should be conducted at regular intervals as part of preventive maintenance. These analyses can detect contaminants, fuel dilution, and wear metals before they cause catastrophic failure. Trending data from sequential oil analyses provides valuable insights into engine health and can predict potential failures before they occur.

Documentation practices form the backbone of effective maintenance protocols. Detailed records of all lubrication-related activities, including oil change dates, brands used, filter replacements, and any abnormalities discovered during inspections should be meticulously maintained. This historical data enables technicians to identify patterns and make informed decisions about maintenance intervals.

Training requirements for maintenance personnel must emphasize the unique characteristics of radial engine lubrication systems. Technicians should understand the importance of proper oil distribution during engine storage periods, the correct procedures for engine preservation when aircraft will be inactive for extended periods, and the specific requirements for breaking in newly overhauled engines with appropriate lubrication protocols.

Pre-flight lubrication procedures represent a crucial component of maintenance protocols. Operators should conduct visual inspections of oil levels and check for leaks around rocker box covers, push rod housing, and accessory case seals. The oil should be warmed to operating temperature before demanding engine operations, particularly in cold weather conditions where oil viscosity significantly impacts protection.

Post-flight maintenance is equally important, as this period allows for proper oil distribution throughout the engine while components are still warm. Technicians should document oil consumption rates after each flight, as increasing consumption may indicate developing issues with piston rings or valve guides that require immediate attention.

Seasonal maintenance adjustments must be implemented to account for environmental variations. During winter operations, pre-heating systems should be utilized to ensure proper oil flow before startup. Conversely, summer operations may require more frequent oil changes due to higher operating temperatures and potential thermal breakdown of lubricants.

Oil sampling and analysis should be conducted at regular intervals as part of preventive maintenance. These analyses can detect contaminants, fuel dilution, and wear metals before they cause catastrophic failure. Trending data from sequential oil analyses provides valuable insights into engine health and can predict potential failures before they occur.

Documentation practices form the backbone of effective maintenance protocols. Detailed records of all lubrication-related activities, including oil change dates, brands used, filter replacements, and any abnormalities discovered during inspections should be meticulously maintained. This historical data enables technicians to identify patterns and make informed decisions about maintenance intervals.

Training requirements for maintenance personnel must emphasize the unique characteristics of radial engine lubrication systems. Technicians should understand the importance of proper oil distribution during engine storage periods, the correct procedures for engine preservation when aircraft will be inactive for extended periods, and the specific requirements for breaking in newly overhauled engines with appropriate lubrication protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!