How to Detect Radial Engine Faults using Digital Analysis

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Fault Detection Background and Objectives

Radial engines have been a cornerstone of aviation propulsion since their introduction in the early 20th century. These engines, characterized by their cylinder arrangement radiating outward from a central crankshaft, dominated aircraft propulsion until the advent of jet engines. Despite being largely replaced in commercial aviation, radial engines continue to serve in various applications including vintage aircraft, agricultural planes, and certain industrial machinery, making their reliability and maintenance critical concerns.

The evolution of fault detection in radial engines has transitioned from purely mechanical inspections to increasingly sophisticated digital analysis methods. Historically, maintenance relied on visual inspections, sound analysis by experienced mechanics, and basic mechanical measurements. However, these traditional methods often failed to detect incipient failures until significant damage had occurred, resulting in costly repairs and potential safety hazards.

Digital analysis represents the next frontier in radial engine maintenance, offering unprecedented capabilities for early fault detection, predictive maintenance, and performance optimization. This technological approach leverages sensors, data acquisition systems, signal processing algorithms, and machine learning techniques to monitor engine parameters in real-time and identify anomalies before they manifest as catastrophic failures.

The primary objective of this technical research is to comprehensively explore how digital analysis methodologies can be effectively applied to radial engine fault detection. Specifically, we aim to identify the most promising digital technologies and analytical approaches that can accurately diagnose common radial engine issues such as valve train problems, bearing wear, cylinder compression loss, ignition irregularities, and lubrication system failures.

Additionally, this research seeks to establish a framework for implementing digital analysis systems that are both cost-effective and reliable for various radial engine applications. We will evaluate the technical feasibility of retrofitting existing radial engines with appropriate sensors and monitoring equipment, as well as developing specialized algorithms capable of distinguishing between normal operational variations and genuine fault indicators.

The long-term goal extends beyond mere fault detection to developing predictive maintenance capabilities that can forecast potential failures based on trend analysis and historical performance data. This would represent a paradigm shift in radial engine maintenance, moving from reactive repair to proactive preservation, thereby extending engine life, reducing operational costs, and enhancing safety across all applications where these distinctive power plants continue to serve.

The evolution of fault detection in radial engines has transitioned from purely mechanical inspections to increasingly sophisticated digital analysis methods. Historically, maintenance relied on visual inspections, sound analysis by experienced mechanics, and basic mechanical measurements. However, these traditional methods often failed to detect incipient failures until significant damage had occurred, resulting in costly repairs and potential safety hazards.

Digital analysis represents the next frontier in radial engine maintenance, offering unprecedented capabilities for early fault detection, predictive maintenance, and performance optimization. This technological approach leverages sensors, data acquisition systems, signal processing algorithms, and machine learning techniques to monitor engine parameters in real-time and identify anomalies before they manifest as catastrophic failures.

The primary objective of this technical research is to comprehensively explore how digital analysis methodologies can be effectively applied to radial engine fault detection. Specifically, we aim to identify the most promising digital technologies and analytical approaches that can accurately diagnose common radial engine issues such as valve train problems, bearing wear, cylinder compression loss, ignition irregularities, and lubrication system failures.

Additionally, this research seeks to establish a framework for implementing digital analysis systems that are both cost-effective and reliable for various radial engine applications. We will evaluate the technical feasibility of retrofitting existing radial engines with appropriate sensors and monitoring equipment, as well as developing specialized algorithms capable of distinguishing between normal operational variations and genuine fault indicators.

The long-term goal extends beyond mere fault detection to developing predictive maintenance capabilities that can forecast potential failures based on trend analysis and historical performance data. This would represent a paradigm shift in radial engine maintenance, moving from reactive repair to proactive preservation, thereby extending engine life, reducing operational costs, and enhancing safety across all applications where these distinctive power plants continue to serve.

Market Demand for Digital Engine Diagnostic Solutions

The global market for digital engine diagnostic solutions has witnessed substantial growth in recent years, driven by increasing demands for operational efficiency, safety enhancement, and cost reduction in various industries utilizing radial engines. Aviation, marine transport, power generation, and vintage automobile sectors represent the primary markets for these diagnostic technologies, with aviation leading the demand due to stringent safety regulations and high operational costs associated with engine failures.

Market research indicates that the digital diagnostic solutions market for aircraft engines alone is projected to grow at a compound annual growth rate of 7.8% through 2028, reflecting the industry's recognition of predictive maintenance as a critical operational strategy. This growth is particularly pronounced in regions with extensive aviation networks such as North America, Europe, and increasingly in Asia-Pacific markets.

The demand for radial engine diagnostic solutions is being shaped by several key factors. First, regulatory bodies worldwide have implemented more stringent maintenance and safety requirements, necessitating more sophisticated diagnostic capabilities. The Federal Aviation Administration and European Union Aviation Safety Agency have both updated their maintenance directives to emphasize predictive analytics and real-time monitoring systems.

Second, the economic imperative for minimizing downtime has become increasingly significant. Unscheduled maintenance events can cost operators hundreds of thousands of dollars per day in lost revenue, making early fault detection systems highly valuable. Organizations operating legacy radial engines are particularly motivated to adopt these technologies as replacement parts become scarcer and more expensive.

Third, the insurance industry has begun offering premium reductions for operators who implement advanced diagnostic systems, creating additional financial incentives for adoption. These incentives have proven particularly effective in the marine and power generation sectors, where insurance costs represent a significant operational expense.

The market also shows distinct segmentation based on technological sophistication. Entry-level solutions focusing on basic vibration analysis and temperature monitoring represent approximately 45% of current market share, while advanced systems incorporating machine learning algorithms and comprehensive sensor arrays account for 35%. The remaining market consists of highly specialized solutions tailored to specific engine types or operational environments.

Customer surveys reveal that key purchasing criteria include integration capabilities with existing maintenance systems, accuracy of fault prediction, ease of data interpretation, and total cost of ownership. Notably, there is growing demand for solutions that can be retrofitted to older radial engines without requiring extensive modifications, particularly in vintage aircraft and marine applications where preserving original components is valued.

Market research indicates that the digital diagnostic solutions market for aircraft engines alone is projected to grow at a compound annual growth rate of 7.8% through 2028, reflecting the industry's recognition of predictive maintenance as a critical operational strategy. This growth is particularly pronounced in regions with extensive aviation networks such as North America, Europe, and increasingly in Asia-Pacific markets.

The demand for radial engine diagnostic solutions is being shaped by several key factors. First, regulatory bodies worldwide have implemented more stringent maintenance and safety requirements, necessitating more sophisticated diagnostic capabilities. The Federal Aviation Administration and European Union Aviation Safety Agency have both updated their maintenance directives to emphasize predictive analytics and real-time monitoring systems.

Second, the economic imperative for minimizing downtime has become increasingly significant. Unscheduled maintenance events can cost operators hundreds of thousands of dollars per day in lost revenue, making early fault detection systems highly valuable. Organizations operating legacy radial engines are particularly motivated to adopt these technologies as replacement parts become scarcer and more expensive.

Third, the insurance industry has begun offering premium reductions for operators who implement advanced diagnostic systems, creating additional financial incentives for adoption. These incentives have proven particularly effective in the marine and power generation sectors, where insurance costs represent a significant operational expense.

The market also shows distinct segmentation based on technological sophistication. Entry-level solutions focusing on basic vibration analysis and temperature monitoring represent approximately 45% of current market share, while advanced systems incorporating machine learning algorithms and comprehensive sensor arrays account for 35%. The remaining market consists of highly specialized solutions tailored to specific engine types or operational environments.

Customer surveys reveal that key purchasing criteria include integration capabilities with existing maintenance systems, accuracy of fault prediction, ease of data interpretation, and total cost of ownership. Notably, there is growing demand for solutions that can be retrofitted to older radial engines without requiring extensive modifications, particularly in vintage aircraft and marine applications where preserving original components is valued.

Current Challenges in Radial Engine Fault Detection

Despite significant advancements in digital analysis techniques, radial engine fault detection continues to face several substantial challenges. The complex mechanical structure of radial engines, with their unique star-shaped cylinder arrangement, creates distinctive vibration and acoustic signatures that are difficult to isolate and interpret. Traditional sensors often struggle to capture the full spectrum of operational parameters necessary for comprehensive fault analysis.

Signal processing remains a critical bottleneck in radial engine diagnostics. The overlapping frequencies generated by multiple cylinders firing in sequence create complex waveforms that conventional Fast Fourier Transform (FFT) methods cannot adequately decompose. This signal complexity is further exacerbated by environmental noise, transmission path distortions, and variable operating conditions that mask subtle fault indicators.

Data acquisition systems face significant hurdles in capturing high-fidelity information at sufficient sampling rates without introducing prohibitive costs or implementation complexities. The harsh operating environments of radial engines, characterized by extreme temperatures, vibrations, and electromagnetic interference, frequently compromise sensor reliability and measurement accuracy.

Feature extraction and selection present another major challenge. Identifying which signal characteristics most reliably indicate specific fault conditions requires extensive experimental validation across diverse operating scenarios. Current algorithms often demonstrate inconsistent performance when confronted with novel fault patterns or when operating conditions deviate from those represented in training datasets.

Real-time processing capabilities remain insufficient for many applications, particularly in aviation where immediate fault detection is critical for safety. The computational demands of advanced signal processing techniques often exceed the capabilities of embedded systems typically deployed in engine monitoring applications.

Validation methodologies represent another significant obstacle. The rarity of certain fault conditions in operational environments makes it difficult to collect comprehensive datasets for algorithm development and testing. Simulated faults may not accurately represent the complex manifestations of actual mechanical failures, leading to potential gaps in detection capability.

Integration challenges persist between modern digital analysis systems and legacy radial engine designs that lack built-in monitoring provisions. Retrofitting sophisticated monitoring equipment often requires significant engineering compromises that can affect detection accuracy or reliability.

Knowledge transfer between domain experts and data scientists remains problematic, with engine mechanics' experiential knowledge proving difficult to formalize into algorithmic approaches. This communication gap frequently results in digital analysis systems that fail to incorporate valuable heuristic insights from maintenance professionals with extensive hands-on experience.

Signal processing remains a critical bottleneck in radial engine diagnostics. The overlapping frequencies generated by multiple cylinders firing in sequence create complex waveforms that conventional Fast Fourier Transform (FFT) methods cannot adequately decompose. This signal complexity is further exacerbated by environmental noise, transmission path distortions, and variable operating conditions that mask subtle fault indicators.

Data acquisition systems face significant hurdles in capturing high-fidelity information at sufficient sampling rates without introducing prohibitive costs or implementation complexities. The harsh operating environments of radial engines, characterized by extreme temperatures, vibrations, and electromagnetic interference, frequently compromise sensor reliability and measurement accuracy.

Feature extraction and selection present another major challenge. Identifying which signal characteristics most reliably indicate specific fault conditions requires extensive experimental validation across diverse operating scenarios. Current algorithms often demonstrate inconsistent performance when confronted with novel fault patterns or when operating conditions deviate from those represented in training datasets.

Real-time processing capabilities remain insufficient for many applications, particularly in aviation where immediate fault detection is critical for safety. The computational demands of advanced signal processing techniques often exceed the capabilities of embedded systems typically deployed in engine monitoring applications.

Validation methodologies represent another significant obstacle. The rarity of certain fault conditions in operational environments makes it difficult to collect comprehensive datasets for algorithm development and testing. Simulated faults may not accurately represent the complex manifestations of actual mechanical failures, leading to potential gaps in detection capability.

Integration challenges persist between modern digital analysis systems and legacy radial engine designs that lack built-in monitoring provisions. Retrofitting sophisticated monitoring equipment often requires significant engineering compromises that can affect detection accuracy or reliability.

Knowledge transfer between domain experts and data scientists remains problematic, with engine mechanics' experiential knowledge proving difficult to formalize into algorithmic approaches. This communication gap frequently results in digital analysis systems that fail to incorporate valuable heuristic insights from maintenance professionals with extensive hands-on experience.

Current Digital Analysis Methods for Engine Diagnostics

01 Vibration-based fault detection methods

Vibration analysis is a key technique for detecting faults in radial engines. These methods involve monitoring vibration patterns and signatures to identify abnormal engine behavior. Advanced signal processing algorithms analyze vibration data to detect early signs of mechanical failures, bearing defects, or imbalances in the radial engine components. Real-time monitoring systems can continuously track vibration characteristics and alert operators when measurements exceed predetermined thresholds.- Vibration-based fault detection methods: Vibration analysis is a key technique for detecting faults in radial engines. These methods involve monitoring vibration patterns and signatures to identify abnormal conditions that may indicate engine malfunctions. Advanced signal processing algorithms analyze vibration data to detect changes in frequency spectra, amplitude, or phase relationships that correspond to specific fault conditions. This approach enables early detection of mechanical issues such as bearing failures, imbalance, or structural defects before they lead to catastrophic failures.

- Electronic control unit (ECU) diagnostic systems: Modern radial engines employ sophisticated electronic control units that continuously monitor engine parameters and perform real-time diagnostics. These systems collect data from various sensors throughout the engine to detect anomalies in performance metrics such as temperature, pressure, fuel flow, and rotational speed. When deviations from normal operating parameters are detected, the ECU can trigger warning indicators, adjust engine operation to prevent damage, or store fault codes for maintenance personnel to analyze. This approach enables comprehensive monitoring of engine health and facilitates preventive maintenance.

- Machine learning and AI-based fault prediction: Advanced fault detection systems for radial engines incorporate machine learning algorithms and artificial intelligence to predict potential failures before they occur. These systems analyze historical operational data to establish baseline performance patterns and identify subtle deviations that may indicate developing problems. By recognizing patterns that precede specific failure modes, these predictive systems can alert operators to potential issues with sufficient lead time for preventive maintenance. This approach significantly reduces unplanned downtime and extends engine service life through condition-based maintenance strategies.

- Combustion analysis and monitoring systems: Specialized systems for monitoring the combustion process in radial engines can detect irregularities that indicate potential faults. These systems analyze parameters such as cylinder pressure, exhaust gas composition, ignition timing, and combustion temperature to identify misfires, valve leakage, or fuel delivery problems. Real-time monitoring of the combustion process allows for immediate detection of performance degradation in individual cylinders, enabling targeted maintenance and preventing cascading failures that could affect the entire engine.

- Oil analysis and lubrication system monitoring: Monitoring the engine's lubrication system provides critical insights into radial engine health. These detection methods analyze oil properties such as viscosity, contamination levels, and the presence of metal particles that indicate component wear. Advanced systems may include real-time oil quality sensors, magnetic chip detectors, or pressure differential monitoring across critical lubrication pathways. By detecting changes in oil condition or the presence of wear debris, these systems can identify developing mechanical problems before they cause significant damage, particularly in bearing surfaces and other friction interfaces common in radial engine designs.

02 Electronic control unit diagnostics

Electronic control unit (ECU) based diagnostic systems play a crucial role in modern radial engine fault detection. These systems utilize onboard computers to monitor engine parameters, process sensor data, and identify anomalies in engine performance. ECU diagnostics can detect issues related to fuel injection, ignition timing, and air-fuel mixture. The systems often incorporate self-diagnostic capabilities that can identify sensor failures and communication errors within the engine management system.Expand Specific Solutions03 Acoustic emission and noise analysis

Acoustic emission and noise analysis techniques detect radial engine faults by monitoring sound patterns produced during engine operation. These methods use microphones and acoustic sensors to capture engine noise, which is then analyzed using spectral analysis and pattern recognition algorithms. Changes in acoustic signatures can indicate various engine problems such as valve issues, combustion irregularities, or mechanical wear. This non-intrusive approach allows for continuous monitoring without affecting engine performance.Expand Specific Solutions04 Temperature and thermal imaging diagnostics

Temperature monitoring and thermal imaging provide valuable insights into radial engine health by detecting abnormal heat patterns. Infrared cameras and temperature sensors can identify hotspots that may indicate friction issues, cooling system failures, or combustion problems. Thermal mapping of the engine during operation helps in early detection of component failures before they lead to catastrophic breakdowns. These methods are particularly effective for identifying issues related to cylinder head temperatures and exhaust system problems in radial engines.Expand Specific Solutions05 Machine learning and predictive maintenance

Advanced machine learning algorithms and artificial intelligence techniques are increasingly used for predictive maintenance in radial engines. These systems analyze historical and real-time data to predict potential failures before they occur. By identifying patterns and correlations in engine parameters, these systems can detect subtle changes that precede major faults. Predictive maintenance approaches reduce downtime by scheduling maintenance activities based on actual engine condition rather than fixed intervals, optimizing engine reliability and operational efficiency.Expand Specific Solutions

Leading Companies in Engine Monitoring Systems

The radial engine fault detection market is currently in a growth phase, with increasing adoption of digital analysis technologies. The market size is expanding due to rising demand for predictive maintenance in aviation and automotive sectors. Technologically, the field is reaching maturity with companies like Bosch, Siemens, and Renault leading commercial applications, while academic institutions such as Nanjing University of Aeronautics & Astronautics and Northwestern Polytechnical University drive research innovation. AECC Commercial Aircraft Engine and Kawasaki Heavy Industries are developing specialized solutions for aerospace applications, while automotive manufacturers including BMW, Audi, and Honda are integrating these technologies into engine monitoring systems. The convergence of digital signal processing, machine learning, and IoT connectivity is accelerating market development, with collaboration between academic and industrial players enhancing technological capabilities.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive digital analysis platform for radial engine fault detection that integrates multiple sensor technologies with edge computing capabilities. Their system employs a network of smart sensors including high-precision accelerometers, acoustic emission detectors, and current/voltage monitors to capture a complete picture of engine health. The solution features proprietary signal processing algorithms that apply advanced time-frequency analysis techniques to isolate fault signatures from normal operational noise. Bosch's platform incorporates machine learning models trained on millions of hours of engine operation data, enabling pattern recognition for incipient faults before they manifest as performance issues. Their system performs real-time comparison between actual sensor readings and digital twin models of healthy engine operation, with deviations flagged for further analysis. The architecture includes edge processing units that perform preliminary analysis at the sensor level, reducing data transmission requirements while enabling real-time alerts for critical faults that require immediate attention.

Strengths: Highly scalable architecture suitable for various engine sizes; robust edge computing reduces cloud dependency; extensive automotive industry experience enhances practical implementation. Weaknesses: Complex installation process requires specialized expertise; higher initial cost compared to basic monitoring systems; requires periodic software updates to maintain detection accuracy.

SNECMA SA

Technical Solution: SNECMA has pioneered a digital analysis framework specifically optimized for radial aircraft engines that combines traditional vibration monitoring with advanced thermal imaging and exhaust gas analysis. Their system employs distributed temperature sensors at critical points to create thermal maps that reveal abnormal heat patterns indicative of specific faults. This thermal data is correlated with high-precision vibration signatures captured through piezoelectric sensors with specialized mounting techniques that minimize signal distortion. SNECMA's approach includes real-time spectral analysis of exhaust gases using infrared spectroscopy to detect combustion anomalies that may indicate valve or timing issues. Their proprietary signal processing algorithms apply adaptive filtering techniques to separate fault signatures from normal operational variations across different flight regimes. The system incorporates a self-learning component that continuously refines its fault detection thresholds based on operational data, allowing it to adapt to engine wear patterns over time and maintain detection sensitivity throughout the engine lifecycle.

Strengths: Aerospace-grade reliability with extremely low false alarm rates; specialized algorithms for different flight phases; integration with aircraft health monitoring systems. Weaknesses: Higher initial implementation cost; requires periodic recalibration; primarily optimized for aviation applications rather than industrial settings.

Key Technologies in Radial Engine Fault Detection

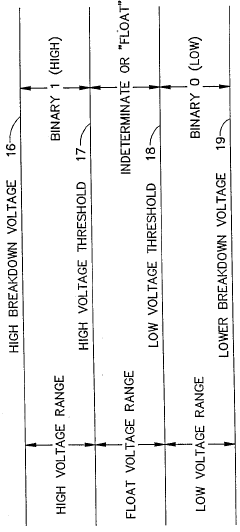

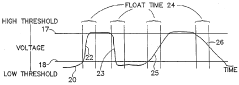

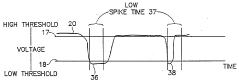

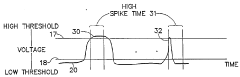

Digital signal fault detector

PatentInactiveUS4965800A

Innovation

- A fault detector device that continuously monitors digital circuit signals for spike, float, and noise faults using dedicated detectors, generating a characteristic signal for immediate display or storage, allowing users to focus on specific error-indicating signal characteristics without needing to sift through large amounts of data.

Digital analysis method and apparatus for service, and storage medium and terminal

PatentWO2023284689A1

Innovation

- By obtaining time and space constraints, digitizing business phenomena and environmental data, conducting attribution analysis to generate prediction warnings, and generating optimal decisions based on the analysis results, combined with the One-Class SVM algorithm, conduct coupling analysis of business phenomena and environment to optimize business the effect of the measures.

Regulatory Standards for Aircraft Engine Monitoring

Aircraft engine monitoring is governed by a comprehensive framework of regulatory standards established by international and national aviation authorities. The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) have developed stringent requirements for engine health monitoring systems, particularly for radial engines which remain in service in various specialized aircraft. These regulations are codified in documents such as FAR Part 33 (Airworthiness Standards: Aircraft Engines) and EASA CS-E (Certification Specifications for Engines), which mandate specific monitoring capabilities and fault detection thresholds.

The International Civil Aviation Organization (ICAO) provides overarching guidance through Annex 8 (Airworthiness of Aircraft), which has been adopted by 193 member states. These standards require continuous monitoring of critical engine parameters and establish minimum requirements for fault detection sensitivity, accuracy, and response time. For digital analysis systems applied to radial engine monitoring, these regulations typically specify sampling rates of at least 20 Hz for critical parameters and data retention periods of 25 flight hours or more.

Regulatory bodies also mandate certification processes for monitoring equipment. DO-178C (Software Considerations in Airborne Systems and Equipment Certification) establishes software development and verification standards for aviation systems, with radial engine monitoring systems typically requiring Design Assurance Level B or C compliance. Similarly, DO-254 governs hardware aspects of these systems, ensuring reliability in the harsh operating environments experienced by aircraft engines.

Maintenance regulations, including those in FAR Part 43 and EASA Part-M, establish requirements for how fault detection data must be integrated into maintenance programs. These regulations mandate specific inspection intervals based on digital monitoring results and establish protocols for addressing detected anomalies. The standards require that digital analysis systems for radial engines must detect incipient failures at least 50 flight hours before potential catastrophic failure.

Recent regulatory updates have increasingly focused on cybersecurity aspects of digital monitoring systems. The FAA's Special Conditions for Aircraft Systems Information Security Protection and EASA's ED-202A (Airworthiness Security Process Specification) establish requirements for protecting engine monitoring data from unauthorized access or tampering, recognizing that modern digital analysis systems are increasingly connected to broader aircraft networks.

Compliance with these regulatory standards represents a significant challenge for developers of digital analysis systems for radial engine fault detection, requiring extensive testing and validation. However, these standards also provide a framework that ensures monitoring systems deliver consistent, reliable performance across the global aviation fleet.

The International Civil Aviation Organization (ICAO) provides overarching guidance through Annex 8 (Airworthiness of Aircraft), which has been adopted by 193 member states. These standards require continuous monitoring of critical engine parameters and establish minimum requirements for fault detection sensitivity, accuracy, and response time. For digital analysis systems applied to radial engine monitoring, these regulations typically specify sampling rates of at least 20 Hz for critical parameters and data retention periods of 25 flight hours or more.

Regulatory bodies also mandate certification processes for monitoring equipment. DO-178C (Software Considerations in Airborne Systems and Equipment Certification) establishes software development and verification standards for aviation systems, with radial engine monitoring systems typically requiring Design Assurance Level B or C compliance. Similarly, DO-254 governs hardware aspects of these systems, ensuring reliability in the harsh operating environments experienced by aircraft engines.

Maintenance regulations, including those in FAR Part 43 and EASA Part-M, establish requirements for how fault detection data must be integrated into maintenance programs. These regulations mandate specific inspection intervals based on digital monitoring results and establish protocols for addressing detected anomalies. The standards require that digital analysis systems for radial engines must detect incipient failures at least 50 flight hours before potential catastrophic failure.

Recent regulatory updates have increasingly focused on cybersecurity aspects of digital monitoring systems. The FAA's Special Conditions for Aircraft Systems Information Security Protection and EASA's ED-202A (Airworthiness Security Process Specification) establish requirements for protecting engine monitoring data from unauthorized access or tampering, recognizing that modern digital analysis systems are increasingly connected to broader aircraft networks.

Compliance with these regulatory standards represents a significant challenge for developers of digital analysis systems for radial engine fault detection, requiring extensive testing and validation. However, these standards also provide a framework that ensures monitoring systems deliver consistent, reliable performance across the global aviation fleet.

Cost-Benefit Analysis of Predictive Maintenance Systems

Implementing predictive maintenance systems for radial engine fault detection requires careful evaluation of financial implications. Initial investment costs for such systems typically range from $50,000 to $250,000 depending on the scale of implementation, complexity of the engine systems, and sophistication of the digital analysis tools employed. This includes hardware components (sensors, data acquisition systems, computing infrastructure), software licenses, integration services, and staff training.

Operational costs must also be considered, including system maintenance (approximately 10-15% of initial investment annually), software updates, data storage, and potential cloud service subscriptions. Additionally, specialized personnel may be required to interpret analysis results and implement maintenance recommendations, adding $60,000-$100,000 in annual labor costs.

The benefits side of the equation presents compelling financial advantages. Studies across various industries indicate that predictive maintenance can reduce unplanned downtime by 30-50% compared to traditional maintenance approaches. For radial engines in critical applications, this translates to significant operational savings, as each hour of downtime typically costs between $10,000-$50,000 depending on the application context.

Maintenance cost reductions represent another substantial benefit, with organizations reporting 25-30% decreases in maintenance expenses through optimized scheduling and reduced emergency repairs. Parts inventory can be reduced by 20-25% through more accurate forecasting of component failures, freeing up capital previously tied to excess inventory.

The return on investment timeline varies by implementation scale and industry, but most organizations report ROI achievement within 12-24 months. Aviation and power generation sectors tend to see faster returns due to the high costs associated with engine failures in these domains.

Risk mitigation benefits, while harder to quantify, include reduced safety incidents, regulatory compliance improvements, and enhanced reputation. These factors contribute significantly to the long-term value proposition but are often underrepresented in traditional cost-benefit calculations.

Sensitivity analysis reveals that the most critical factors affecting ROI include the accuracy of fault detection algorithms, the cost of sensor implementation, and the baseline frequency of engine failures. Organizations with aging radial engine fleets or those operating in harsh conditions typically realize greater benefits from these systems.

Operational costs must also be considered, including system maintenance (approximately 10-15% of initial investment annually), software updates, data storage, and potential cloud service subscriptions. Additionally, specialized personnel may be required to interpret analysis results and implement maintenance recommendations, adding $60,000-$100,000 in annual labor costs.

The benefits side of the equation presents compelling financial advantages. Studies across various industries indicate that predictive maintenance can reduce unplanned downtime by 30-50% compared to traditional maintenance approaches. For radial engines in critical applications, this translates to significant operational savings, as each hour of downtime typically costs between $10,000-$50,000 depending on the application context.

Maintenance cost reductions represent another substantial benefit, with organizations reporting 25-30% decreases in maintenance expenses through optimized scheduling and reduced emergency repairs. Parts inventory can be reduced by 20-25% through more accurate forecasting of component failures, freeing up capital previously tied to excess inventory.

The return on investment timeline varies by implementation scale and industry, but most organizations report ROI achievement within 12-24 months. Aviation and power generation sectors tend to see faster returns due to the high costs associated with engine failures in these domains.

Risk mitigation benefits, while harder to quantify, include reduced safety incidents, regulatory compliance improvements, and enhanced reputation. These factors contribute significantly to the long-term value proposition but are often underrepresented in traditional cost-benefit calculations.

Sensitivity analysis reveals that the most critical factors affecting ROI include the accuracy of fault detection algorithms, the cost of sensor implementation, and the baseline frequency of engine failures. Organizations with aging radial engine fleets or those operating in harsh conditions typically realize greater benefits from these systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!