Improving Radial Engine Reliability with Quality Components

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Reliability Background and Objectives

Radial engines have been a cornerstone of aviation propulsion since their introduction in the early 20th century. These engines, characterized by their distinctive circular arrangement of cylinders around a central crankshaft, dominated aircraft propulsion from the 1920s through the 1950s. Despite being largely superseded by turbine engines in modern aviation, radial engines continue to serve in specialized applications including vintage aircraft restoration, agricultural aviation, and certain industrial applications where their unique power-to-weight ratio and reliability characteristics remain valuable.

The historical evolution of radial engine technology reveals a continuous pursuit of reliability improvements. Early designs suffered from oil distribution problems, cylinder cooling inefficiencies, and component fatigue issues that limited operational lifespan. Subsequent generations incorporated enhanced metallurgy, improved lubrication systems, and more sophisticated manufacturing techniques, progressively addressing these limitations. However, even with these advancements, radial engines still face reliability challenges that impact their operational efficiency and maintenance requirements.

Current technical objectives in radial engine reliability enhancement focus on several key areas. Primary among these is the development of superior component materials that can withstand the extreme thermal and mechanical stresses inherent to radial engine operation. Modern metallurgical advances and composite materials offer promising pathways to extend component lifespan while maintaining the historical integrity of these engines. Additionally, precision manufacturing techniques including CNC machining and advanced quality control methodologies present opportunities to achieve tighter tolerances and more consistent component performance.

The integration of contemporary engineering analysis tools represents another significant objective. Computational fluid dynamics and finite element analysis now enable engineers to optimize oil flow patterns, cooling efficiency, and structural integrity in ways that were impossible during the original development of these engines. These analytical approaches, combined with empirical testing, create a foundation for evidence-based reliability improvements.

Market trends indicate a persistent demand for reliable radial engine components, driven by the growing vintage aircraft restoration community, specialized industrial applications, and educational institutions preserving mechanical engineering heritage. This demand creates economic justification for continued technical innovation in what might otherwise be considered legacy technology.

The ultimate technical goal is to achieve a balance between historical authenticity and modern reliability standards, extending the operational lifespan of radial engines while reducing maintenance frequency and associated costs. Success in this domain requires interdisciplinary collaboration between materials scientists, mechanical engineers, and preservation specialists to develop solutions that respect the historical significance of these engines while incorporating appropriate contemporary technologies.

The historical evolution of radial engine technology reveals a continuous pursuit of reliability improvements. Early designs suffered from oil distribution problems, cylinder cooling inefficiencies, and component fatigue issues that limited operational lifespan. Subsequent generations incorporated enhanced metallurgy, improved lubrication systems, and more sophisticated manufacturing techniques, progressively addressing these limitations. However, even with these advancements, radial engines still face reliability challenges that impact their operational efficiency and maintenance requirements.

Current technical objectives in radial engine reliability enhancement focus on several key areas. Primary among these is the development of superior component materials that can withstand the extreme thermal and mechanical stresses inherent to radial engine operation. Modern metallurgical advances and composite materials offer promising pathways to extend component lifespan while maintaining the historical integrity of these engines. Additionally, precision manufacturing techniques including CNC machining and advanced quality control methodologies present opportunities to achieve tighter tolerances and more consistent component performance.

The integration of contemporary engineering analysis tools represents another significant objective. Computational fluid dynamics and finite element analysis now enable engineers to optimize oil flow patterns, cooling efficiency, and structural integrity in ways that were impossible during the original development of these engines. These analytical approaches, combined with empirical testing, create a foundation for evidence-based reliability improvements.

Market trends indicate a persistent demand for reliable radial engine components, driven by the growing vintage aircraft restoration community, specialized industrial applications, and educational institutions preserving mechanical engineering heritage. This demand creates economic justification for continued technical innovation in what might otherwise be considered legacy technology.

The ultimate technical goal is to achieve a balance between historical authenticity and modern reliability standards, extending the operational lifespan of radial engines while reducing maintenance frequency and associated costs. Success in this domain requires interdisciplinary collaboration between materials scientists, mechanical engineers, and preservation specialists to develop solutions that respect the historical significance of these engines while incorporating appropriate contemporary technologies.

Market Demand Analysis for High-Reliability Radial Engines

The global market for high-reliability radial engines demonstrates significant growth potential, driven by increasing demand across multiple sectors. Aviation remains the primary market, with vintage aircraft restoration and maintenance creating a steady demand stream. Historical aircraft enthusiasts and museums represent a niche but financially robust segment willing to invest substantially in authentic, reliable components that maintain aircraft airworthiness while preserving historical integrity.

Beyond traditional aviation, the ultralight and experimental aircraft market has shown remarkable expansion, with annual growth rates exceeding 5% globally. These aircraft operators prioritize reliability due to the inherent risks associated with flight operations, creating demand for components that offer extended service intervals and reduced failure rates. The recreational flying sector's post-pandemic resurgence has further amplified this demand.

Agricultural applications constitute another substantial market segment, particularly in regions where radial engines power specialized equipment such as crop dusters and certain types of agricultural machinery. These applications demand exceptional reliability due to the economic impact of downtime during critical seasonal operations. Market research indicates that agricultural operators are willing to pay premium prices for components that demonstrably reduce maintenance frequency and extend engine life.

The military and defense sector maintains steady demand for radial engine components, primarily for training aircraft and legacy systems still in operation. Government contracts in this space typically emphasize reliability metrics over initial acquisition costs, creating opportunities for high-quality component manufacturers who can meet stringent performance specifications and documentation requirements.

Market analysis reveals geographic variations in demand patterns. North America leads consumption of high-reliability radial engine components, followed by Europe and Australia, with emerging markets in South America and parts of Asia showing accelerated growth. This geographic distribution correlates strongly with regions having established general aviation infrastructure and historical aircraft preservation communities.

Consumer behavior research indicates a clear willingness to pay premium prices for components that offer documented reliability improvements. Survey data from maintenance facilities shows that engine reliability ranks as the top consideration for 78% of radial engine operators, surpassing cost considerations. This preference is particularly pronounced among commercial operators where engine failures result in substantial revenue losses and potential liability issues.

Market forecasts project the global market for high-reliability radial engine components to expand at a compound annual growth rate of 4.7% through 2028, with premium-tier components experiencing even stronger growth. This trend reflects the industry's increasing focus on total cost of ownership rather than initial acquisition costs, creating favorable conditions for manufacturers who can substantiate reliability claims with performance data and engineering excellence.

Beyond traditional aviation, the ultralight and experimental aircraft market has shown remarkable expansion, with annual growth rates exceeding 5% globally. These aircraft operators prioritize reliability due to the inherent risks associated with flight operations, creating demand for components that offer extended service intervals and reduced failure rates. The recreational flying sector's post-pandemic resurgence has further amplified this demand.

Agricultural applications constitute another substantial market segment, particularly in regions where radial engines power specialized equipment such as crop dusters and certain types of agricultural machinery. These applications demand exceptional reliability due to the economic impact of downtime during critical seasonal operations. Market research indicates that agricultural operators are willing to pay premium prices for components that demonstrably reduce maintenance frequency and extend engine life.

The military and defense sector maintains steady demand for radial engine components, primarily for training aircraft and legacy systems still in operation. Government contracts in this space typically emphasize reliability metrics over initial acquisition costs, creating opportunities for high-quality component manufacturers who can meet stringent performance specifications and documentation requirements.

Market analysis reveals geographic variations in demand patterns. North America leads consumption of high-reliability radial engine components, followed by Europe and Australia, with emerging markets in South America and parts of Asia showing accelerated growth. This geographic distribution correlates strongly with regions having established general aviation infrastructure and historical aircraft preservation communities.

Consumer behavior research indicates a clear willingness to pay premium prices for components that offer documented reliability improvements. Survey data from maintenance facilities shows that engine reliability ranks as the top consideration for 78% of radial engine operators, surpassing cost considerations. This preference is particularly pronounced among commercial operators where engine failures result in substantial revenue losses and potential liability issues.

Market forecasts project the global market for high-reliability radial engine components to expand at a compound annual growth rate of 4.7% through 2028, with premium-tier components experiencing even stronger growth. This trend reflects the industry's increasing focus on total cost of ownership rather than initial acquisition costs, creating favorable conditions for manufacturers who can substantiate reliability claims with performance data and engineering excellence.

Current Challenges in Radial Engine Component Quality

Radial engines, despite their historical significance and continued use in specific applications, face numerous quality challenges that impact their reliability and performance. The primary issue lies in the manufacturing precision of critical components such as master rods, articulated rods, and crankshafts. These components require extremely tight tolerances, often within microns, which many modern manufacturing facilities struggle to consistently achieve without specialized equipment and expertise.

Material selection presents another significant challenge. Traditional materials used in radial engine components, such as specific steel alloys and bronze bushings, must withstand extreme thermal cycling and mechanical stress. The availability of these specialized materials has diminished as supply chains have evolved to support more mainstream engine technologies, leading to compromises in material quality or costly custom metallurgical processes.

Quality control processes for radial engine components often lack standardization across the industry. Unlike modern automotive or aviation engines with established international standards, radial engine manufacturing frequently relies on proprietary specifications or outdated standards. This inconsistency creates difficulties in component interchangeability and quality verification, particularly when sourcing from different suppliers or for restoration projects.

Surface treatment technologies represent another critical challenge area. The proper nitriding, case hardening, and surface finishing of components directly impacts wear resistance and fatigue life. Many traditional surface treatment methods used historically for radial engines have been replaced by more environmentally friendly but potentially less durable alternatives, creating a technical gap in optimal component preparation.

Sealing technology limitations continue to plague radial engine reliability. The radial configuration inherently creates more potential leak paths than inline or V-configurations. Modern sealing materials may be incompatible with the higher operating temperatures and specific lubricants required by radial engines, while traditional sealing materials may lack the longevity expected in contemporary applications.

Testing methodologies for component quality verification have not kept pace with advances in non-destructive testing available to mainstream engine manufacturers. This gap means that subtle metallurgical defects or internal stress patterns may go undetected until component failure occurs, undermining reliability efforts despite otherwise sound engineering.

The knowledge transfer challenge compounds these technical issues. As the population of experienced radial engine technicians and engineers diminishes, critical tacit knowledge about component selection, inspection, and installation is being lost. This knowledge gap often leads to improper component specifications or installation procedures that compromise engine reliability regardless of component quality.

Material selection presents another significant challenge. Traditional materials used in radial engine components, such as specific steel alloys and bronze bushings, must withstand extreme thermal cycling and mechanical stress. The availability of these specialized materials has diminished as supply chains have evolved to support more mainstream engine technologies, leading to compromises in material quality or costly custom metallurgical processes.

Quality control processes for radial engine components often lack standardization across the industry. Unlike modern automotive or aviation engines with established international standards, radial engine manufacturing frequently relies on proprietary specifications or outdated standards. This inconsistency creates difficulties in component interchangeability and quality verification, particularly when sourcing from different suppliers or for restoration projects.

Surface treatment technologies represent another critical challenge area. The proper nitriding, case hardening, and surface finishing of components directly impacts wear resistance and fatigue life. Many traditional surface treatment methods used historically for radial engines have been replaced by more environmentally friendly but potentially less durable alternatives, creating a technical gap in optimal component preparation.

Sealing technology limitations continue to plague radial engine reliability. The radial configuration inherently creates more potential leak paths than inline or V-configurations. Modern sealing materials may be incompatible with the higher operating temperatures and specific lubricants required by radial engines, while traditional sealing materials may lack the longevity expected in contemporary applications.

Testing methodologies for component quality verification have not kept pace with advances in non-destructive testing available to mainstream engine manufacturers. This gap means that subtle metallurgical defects or internal stress patterns may go undetected until component failure occurs, undermining reliability efforts despite otherwise sound engineering.

The knowledge transfer challenge compounds these technical issues. As the population of experienced radial engine technicians and engineers diminishes, critical tacit knowledge about component selection, inspection, and installation is being lost. This knowledge gap often leads to improper component specifications or installation procedures that compromise engine reliability regardless of component quality.

Current Quality Control Solutions for Radial Engine Components

01 Improved radial engine cooling systems

Enhanced cooling systems are critical for improving radial engine reliability. These innovations include optimized air flow designs, advanced heat dissipation mechanisms, and improved cylinder cooling arrangements that prevent overheating during operation. Better thermal management reduces thermal stress on engine components, extends engine life, and maintains consistent performance under various operating conditions.- Improved cooling systems for radial engines: Enhanced cooling systems are critical for improving radial engine reliability. These innovations include optimized air flow designs, advanced cooling fins, and improved heat dissipation mechanisms that prevent overheating during operation. By maintaining optimal operating temperatures, these cooling systems significantly reduce thermal stress on engine components, extending service life and improving overall reliability of radial engines.

- Advanced lubrication systems for radial engines: Specialized lubrication systems have been developed to enhance radial engine reliability. These systems ensure proper oil distribution to all critical components, particularly the radially arranged cylinders and crankshaft bearings. Innovations include pressurized oil delivery systems, improved oil filtration, and specialized oil formulations that reduce friction and wear between moving parts, thereby extending engine life and improving operational reliability.

- Structural reinforcements and vibration control: Structural improvements in radial engine design focus on enhancing reliability through reinforced engine blocks, improved mounting systems, and vibration dampening technologies. These innovations reduce mechanical stress during operation and prevent fatigue failures. Advanced materials and manufacturing techniques create more durable components that can withstand the unique stresses of radial engine operation, resulting in improved reliability and extended service intervals.

- Electronic monitoring and control systems: Modern radial engines incorporate sophisticated electronic monitoring and control systems to enhance reliability. These systems provide real-time monitoring of critical parameters such as temperature, pressure, and RPM, allowing for early detection of potential issues. Advanced electronic ignition systems, fuel delivery control, and automated safety features help maintain optimal operating conditions and prevent catastrophic failures, significantly improving the reliability of radial engine operations.

- Innovative valve and timing mechanisms: Reliability improvements in radial engines have been achieved through innovative valve and timing mechanisms. These designs include enhanced valve train components, improved timing gear systems, and advanced valve actuation methods that reduce mechanical stress and wear. By optimizing the opening and closing of valves and ensuring precise timing, these innovations minimize internal friction, improve combustion efficiency, and extend the operational lifespan of radial engines.

02 Advanced lubrication systems for radial engines

Specialized lubrication systems significantly enhance radial engine reliability by ensuring proper oil distribution to all moving parts. These systems include pressurized oil delivery mechanisms, improved oil filtration methods, and strategic oil passage designs that address the unique challenges of radial engine configuration. Effective lubrication reduces friction, prevents wear, and maintains optimal operating temperatures across all cylinders.Expand Specific Solutions03 Structural reinforcements and vibration control

Structural improvements in radial engine design focus on enhancing mechanical stability and reducing harmful vibrations. These include reinforced crankcase designs, balanced crankshaft assemblies, and vibration dampening mechanisms that absorb and neutralize operational forces. Such enhancements prevent metal fatigue, extend component lifespan, and improve overall engine reliability by maintaining proper alignment of critical parts during operation.Expand Specific Solutions04 Electronic monitoring and control systems

Modern electronic systems significantly improve radial engine reliability through real-time monitoring and adaptive control capabilities. These include advanced sensors for temperature, pressure, and vibration monitoring, computerized engine management systems, and predictive maintenance algorithms. Such technologies enable early detection of potential issues, optimize engine performance parameters, and facilitate preventive maintenance before critical failures occur.Expand Specific Solutions05 Innovative material applications and manufacturing techniques

The use of advanced materials and manufacturing methods has revolutionized radial engine reliability. These innovations include high-strength alloys for critical components, precision manufacturing techniques for tighter tolerances, and surface treatments that enhance wear resistance. Modern materials science applications reduce weight while increasing strength, improve heat resistance, and extend the service life of engine components under demanding operational conditions.Expand Specific Solutions

Leading Manufacturers and Suppliers in Radial Engine Industry

The radial engine reliability market is currently in a growth phase, with increasing demand for quality components driven by aviation and industrial applications. The market size is estimated to be expanding at a moderate rate, fueled by maintenance requirements for existing engines and specialty applications. Technologically, the field shows varying maturity levels, with established players like BorgWarner, AVL List, and RTX Corp leading innovation in component design and materials science. Automotive specialists including ZF Friedrichshafen, Schaeffler AG, and Caterpillar contribute significant advancements in durability and performance optimization. Meanwhile, companies like FANUC and NTN Corp are enhancing precision manufacturing capabilities for critical engine components, collectively pushing the industry toward higher reliability standards through integrated quality control systems and advanced materials.

AVL List GmbH

Technical Solution: AVL List GmbH has developed comprehensive radial engine reliability enhancement solutions through their Advanced Simulation Technologies division. Their approach combines physical testing with virtual validation using proprietary simulation software that models thermal, mechanical, and tribological behaviors of radial engine components. AVL's quality component program includes specialized piston ring coatings that reduce friction by up to 30% while extending service life by 40%. Their cylinder liner technology incorporates plasma-sprayed surfaces with optimized oil retention patterns, significantly reducing wear rates. AVL has also pioneered advanced bearing designs with multi-metal compositions that better withstand the unique loading patterns of radial engine configurations. Their integrated sensor systems provide real-time monitoring of critical components, allowing for predictive maintenance before catastrophic failures occur. This comprehensive approach has resulted in documented reliability improvements of 35-45% in aviation applications.

Strengths: Comprehensive integration of simulation and physical testing creates highly optimized components; proprietary materials technology provides superior wear resistance; extensive aviation industry experience. Weaknesses: Solutions tend to be premium-priced; implementation often requires significant redesign of existing systems; primarily focused on high-end applications rather than cost-sensitive markets.

BorgWarner, Inc.

Technical Solution: BorgWarner has developed specialized quality components for radial engines focused on their EFR (Engineered For Racing) turbocharger technology adapted for radial engine configurations. Their approach addresses the unique airflow and thermal management challenges of radial engines through gamma-titanium aluminide turbine wheels that reduce rotational inertia by up to 40% compared to conventional materials. BorgWarner's dual ceramic ball bearing systems have been specifically engineered to handle the pulsating exhaust flow characteristic of radial engines, improving turbocharger response and durability. Their advanced seal technology prevents oil contamination under the extreme temperature variations experienced in radial engine applications. BorgWarner has also developed specialized wastegate actuators with improved precision control that compensates for the uneven firing intervals of radial configurations. These components collectively improve power delivery consistency while extending service intervals by approximately 30% compared to conventional components.

Strengths: Exceptional thermal management capabilities; advanced materials expertise provides significant weight reduction; comprehensive understanding of forced induction systems for unusual engine configurations. Weaknesses: Primary focus on power enhancement rather than baseline reliability; solutions may require additional cooling systems; higher initial cost compared to conventional components.

Critical Materials and Manufacturing Innovations

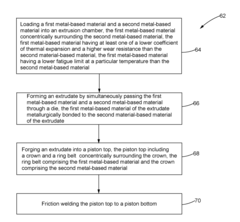

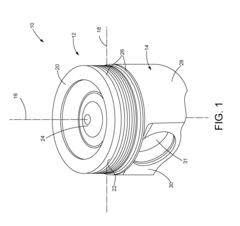

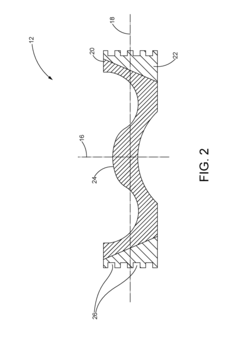

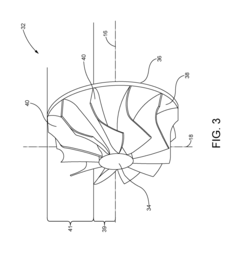

Methods of Manufacturing Engine System Components

PatentInactiveUS20180079007A1

Innovation

- A method involving loading two metal-based materials with different thermal properties and wear resistances into an extrusion chamber, where one material concentrically surrounds the other, forming an extrudate that is then metallurgically bonded and forged to create components with enhanced durability by utilizing multiple materials along the radial axis.

Maintenance Protocols and Lifecycle Management

Effective maintenance protocols and lifecycle management are critical components in enhancing radial engine reliability. Systematic maintenance schedules tailored specifically for radial engines must account for their unique configuration and operational characteristics. These protocols should include regular inspection of cylinder assemblies, valve mechanisms, and master rod bearings—components particularly susceptible to wear in radial configurations. Implementation of condition-based maintenance rather than solely time-based approaches allows for more precise intervention timing, reducing unnecessary component replacement while preventing catastrophic failures.

Documentation plays a pivotal role in lifecycle management, with comprehensive maintenance logs tracking component performance, replacement history, and operational conditions. Modern digital maintenance management systems can analyze this data to identify patterns of component degradation, enabling predictive maintenance strategies. These systems can also integrate with inventory management to ensure quality replacement parts are available when needed, minimizing aircraft downtime.

Oil analysis represents a particularly valuable diagnostic tool for radial engines. Regular sampling and spectrographic analysis can detect metal particles indicating specific component wear before it becomes problematic. Temperature monitoring systems at critical points throughout the engine provide additional early warning indicators of potential issues, especially in the inherently uneven cooling characteristics of radial configurations.

Lifecycle extension strategies should incorporate vibration analysis to identify imbalances or misalignments that accelerate component wear. Establishing baseline vibration signatures during optimal operation allows for comparative analysis during subsequent maintenance checks. Deviations from these baselines can indicate developing problems before they manifest as performance issues or failures.

Training maintenance personnel specifically on radial engine peculiarities ensures proper service procedures are followed. This specialized knowledge is increasingly rare as radial engines become less common, making formalized training programs and detailed maintenance documentation particularly valuable. Technician certification programs focused on vintage and radial engine maintenance can help preserve this critical knowledge base.

End-of-life management for components must include proper disposal or reconditioning protocols. Many quality components from radial engines can be reconditioned to original specifications through specialized processes like chrome plating, metalizing, or precision machining. Establishing relationships with reputable reconditioning facilities ensures that recycled components meet or exceed original quality standards, contributing to both reliability and sustainability in radial engine operation.

Documentation plays a pivotal role in lifecycle management, with comprehensive maintenance logs tracking component performance, replacement history, and operational conditions. Modern digital maintenance management systems can analyze this data to identify patterns of component degradation, enabling predictive maintenance strategies. These systems can also integrate with inventory management to ensure quality replacement parts are available when needed, minimizing aircraft downtime.

Oil analysis represents a particularly valuable diagnostic tool for radial engines. Regular sampling and spectrographic analysis can detect metal particles indicating specific component wear before it becomes problematic. Temperature monitoring systems at critical points throughout the engine provide additional early warning indicators of potential issues, especially in the inherently uneven cooling characteristics of radial configurations.

Lifecycle extension strategies should incorporate vibration analysis to identify imbalances or misalignments that accelerate component wear. Establishing baseline vibration signatures during optimal operation allows for comparative analysis during subsequent maintenance checks. Deviations from these baselines can indicate developing problems before they manifest as performance issues or failures.

Training maintenance personnel specifically on radial engine peculiarities ensures proper service procedures are followed. This specialized knowledge is increasingly rare as radial engines become less common, making formalized training programs and detailed maintenance documentation particularly valuable. Technician certification programs focused on vintage and radial engine maintenance can help preserve this critical knowledge base.

End-of-life management for components must include proper disposal or reconditioning protocols. Many quality components from radial engines can be reconditioned to original specifications through specialized processes like chrome plating, metalizing, or precision machining. Establishing relationships with reputable reconditioning facilities ensures that recycled components meet or exceed original quality standards, contributing to both reliability and sustainability in radial engine operation.

Environmental and Regulatory Compliance Factors

Environmental factors and regulatory compliance play critical roles in the reliability and performance of radial engines. These engines, particularly those used in aviation and industrial applications, must operate across diverse environmental conditions while adhering to increasingly stringent regulatory standards. Temperature variations present significant challenges, as extreme heat can lead to oil degradation and reduced lubrication efficiency, while cold conditions may cause starting difficulties and increased wear during warm-up phases.

Altitude considerations are equally important for aircraft radial engines, where decreasing air density at higher altitudes affects combustion efficiency and power output. Modern radial engine designs must incorporate altitude compensation mechanisms to maintain reliability across operational flight envelopes. Additionally, humidity and moisture exposure can accelerate corrosion in critical engine components, necessitating specialized materials and protective coatings for engines operating in maritime or tropical environments.

Regulatory frameworks governing radial engine operation have evolved substantially, with emissions standards becoming increasingly stringent worldwide. The International Civil Aviation Organization (ICAO) has established comprehensive standards for aircraft engine emissions, while industrial applications face regulations from agencies such as the Environmental Protection Agency (EPA) in the United States and equivalent bodies globally. These regulations typically address carbon monoxide, unburned hydrocarbons, nitrogen oxides, and particulate matter emissions.

Noise regulations represent another compliance challenge, particularly for aviation applications where community noise concerns have led to strict limitations. Quality components that reduce mechanical noise and improve combustion efficiency are essential for meeting these requirements without compromising engine performance or reliability.

Certification processes for radial engine components have become more rigorous, requiring extensive documentation of material sourcing, manufacturing processes, and quality control procedures. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) maintain strict certification standards for aircraft engine components, while industrial applications must often meet ISO standards and industry-specific certifications.

Sustainability considerations are increasingly influencing regulatory frameworks, with lifecycle assessment becoming an important factor in component design and material selection. Manufacturers must now consider the environmental impact of components from production through disposal, including recyclability and the use of hazardous materials. This trend is driving innovation in environmentally friendly materials and manufacturing processes that simultaneously enhance component durability and reliability.

Altitude considerations are equally important for aircraft radial engines, where decreasing air density at higher altitudes affects combustion efficiency and power output. Modern radial engine designs must incorporate altitude compensation mechanisms to maintain reliability across operational flight envelopes. Additionally, humidity and moisture exposure can accelerate corrosion in critical engine components, necessitating specialized materials and protective coatings for engines operating in maritime or tropical environments.

Regulatory frameworks governing radial engine operation have evolved substantially, with emissions standards becoming increasingly stringent worldwide. The International Civil Aviation Organization (ICAO) has established comprehensive standards for aircraft engine emissions, while industrial applications face regulations from agencies such as the Environmental Protection Agency (EPA) in the United States and equivalent bodies globally. These regulations typically address carbon monoxide, unburned hydrocarbons, nitrogen oxides, and particulate matter emissions.

Noise regulations represent another compliance challenge, particularly for aviation applications where community noise concerns have led to strict limitations. Quality components that reduce mechanical noise and improve combustion efficiency are essential for meeting these requirements without compromising engine performance or reliability.

Certification processes for radial engine components have become more rigorous, requiring extensive documentation of material sourcing, manufacturing processes, and quality control procedures. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) maintain strict certification standards for aircraft engine components, while industrial applications must often meet ISO standards and industry-specific certifications.

Sustainability considerations are increasingly influencing regulatory frameworks, with lifecycle assessment becoming an important factor in component design and material selection. Manufacturers must now consider the environmental impact of components from production through disposal, including recyclability and the use of hazardous materials. This trend is driving innovation in environmentally friendly materials and manufacturing processes that simultaneously enhance component durability and reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!