Radial Engine vs Piston Engine: Mechanical Advantages

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial vs Piston Engine Development History and Objectives

The evolution of aircraft engines represents one of the most significant technological developments in aviation history. Radial and piston engines emerged as two dominant configurations that shaped aircraft design throughout the early to mid-20th century. The radial engine's development began in the early 1900s, with Charles Manly creating the first practical radial engine for the Langley Aerodrome in 1903. However, it was during World War I when radial engines gained significant traction, with manufacturers like Bentley, Bristol, and Gnome-Rhône pioneering their development.

The inline piston engine, conversely, evolved from automobile engines and was adapted for aviation use. Early examples include the Wright brothers' first flight engine in 1903, which utilized an inline configuration. By the 1910s, water-cooled inline engines became prevalent, with the Liberty L-12 engine representing a milestone in standardized production during World War I.

The interwar period (1918-1939) marked a critical phase in engine development, with radial engines achieving prominence due to their reliability and power-to-weight advantages. The Pratt & Whitney R-1340 Wasp, introduced in 1925, exemplified the technological maturity of radial designs. Meanwhile, inline engines continued to evolve, with the Rolls-Royce Merlin becoming emblematic of high-performance liquid-cooled V12 configurations in the 1930s.

World War II accelerated engine development dramatically, pushing both configurations to their mechanical limits. Radial engines like the Wright R-3350 Duplex-Cyclone powered heavy bombers such as the B-29 Superfortress, while inline engines like the Daimler-Benz DB 605 powered fighters like the Messerschmitt Bf 109.

The technological objectives driving these developments focused primarily on increasing power output while maintaining reliability. Engineers sought to optimize power-to-weight ratios, fuel efficiency, and operational simplicity. Radial engines excelled in air cooling efficiency and structural strength, while inline engines offered aerodynamic advantages and higher power density in certain applications.

By the late 1940s, both engine types had reached their developmental apex, with radial engines achieving power outputs exceeding 3,500 horsepower and inline engines delivering exceptional performance at high altitudes. The emergence of jet propulsion technology in the post-war era gradually diminished the prominence of both configurations in military and commercial aviation, though they continued to serve in specialized roles.

The technological evolution of these engine types reflects broader engineering principles regarding the balance between power, weight, reliability, and manufacturability—principles that continue to influence modern propulsion system design despite the shift to turbine technology.

The inline piston engine, conversely, evolved from automobile engines and was adapted for aviation use. Early examples include the Wright brothers' first flight engine in 1903, which utilized an inline configuration. By the 1910s, water-cooled inline engines became prevalent, with the Liberty L-12 engine representing a milestone in standardized production during World War I.

The interwar period (1918-1939) marked a critical phase in engine development, with radial engines achieving prominence due to their reliability and power-to-weight advantages. The Pratt & Whitney R-1340 Wasp, introduced in 1925, exemplified the technological maturity of radial designs. Meanwhile, inline engines continued to evolve, with the Rolls-Royce Merlin becoming emblematic of high-performance liquid-cooled V12 configurations in the 1930s.

World War II accelerated engine development dramatically, pushing both configurations to their mechanical limits. Radial engines like the Wright R-3350 Duplex-Cyclone powered heavy bombers such as the B-29 Superfortress, while inline engines like the Daimler-Benz DB 605 powered fighters like the Messerschmitt Bf 109.

The technological objectives driving these developments focused primarily on increasing power output while maintaining reliability. Engineers sought to optimize power-to-weight ratios, fuel efficiency, and operational simplicity. Radial engines excelled in air cooling efficiency and structural strength, while inline engines offered aerodynamic advantages and higher power density in certain applications.

By the late 1940s, both engine types had reached their developmental apex, with radial engines achieving power outputs exceeding 3,500 horsepower and inline engines delivering exceptional performance at high altitudes. The emergence of jet propulsion technology in the post-war era gradually diminished the prominence of both configurations in military and commercial aviation, though they continued to serve in specialized roles.

The technological evolution of these engine types reflects broader engineering principles regarding the balance between power, weight, reliability, and manufacturability—principles that continue to influence modern propulsion system design despite the shift to turbine technology.

Market Applications and Industry Demand Analysis

The market for aircraft engines has undergone significant transformations over the decades, with radial and piston engines occupying distinct niches based on their mechanical advantages. Current market analysis indicates that while turbine engines dominate commercial aviation, there remains substantial demand for both radial and piston engines in specific sectors.

The general aviation market, valued at approximately $24.7 billion in 2022, continues to show strong demand for piston engines, particularly in light aircraft, training planes, and recreational flying segments. These applications leverage the piston engine's superior fuel efficiency at lower altitudes and speeds, simpler maintenance requirements, and lower acquisition costs compared to other engine types.

Radial engines, despite being largely historical technology, maintain a specialized market presence in agricultural aviation, firefighting aircraft, and warbird restoration. The agricultural aviation sector alone represents a $2.1 billion market globally, where radial engines' reliability and power-to-weight advantages provide significant operational benefits in crop-dusting and similar applications.

The vintage aircraft restoration market has experienced steady growth at 5.8% annually, driven by enthusiasts and museums seeking authentic powerplants for historical aircraft. This niche but profitable sector specifically values radial engines for their historical accuracy and distinctive operational characteristics, including their unique sound profile and visual appeal.

Emerging markets in developing regions show increasing interest in both engine types for specialized applications. Countries with less developed aviation infrastructure often prefer the mechanical simplicity and field-serviceability of these conventional engine designs, particularly in remote operations where advanced maintenance facilities may be unavailable.

Industry demand analysis reveals that manufacturing capabilities for both engine types have consolidated significantly, with only a handful of specialized manufacturers continuing production. This has created a premium market where new radial engines command prices up to three times higher than comparable power piston configurations due to their specialized manufacturing requirements and limited production volumes.

The aftermarket and parts sector represents another significant revenue stream, with maintenance, repair, and overhaul services for legacy radial engines generating substantial business. This sector benefits from the inherent durability of radial designs, with many engines remaining serviceable after decades of operation, creating sustained demand for specialized maintenance expertise and replacement components.

The general aviation market, valued at approximately $24.7 billion in 2022, continues to show strong demand for piston engines, particularly in light aircraft, training planes, and recreational flying segments. These applications leverage the piston engine's superior fuel efficiency at lower altitudes and speeds, simpler maintenance requirements, and lower acquisition costs compared to other engine types.

Radial engines, despite being largely historical technology, maintain a specialized market presence in agricultural aviation, firefighting aircraft, and warbird restoration. The agricultural aviation sector alone represents a $2.1 billion market globally, where radial engines' reliability and power-to-weight advantages provide significant operational benefits in crop-dusting and similar applications.

The vintage aircraft restoration market has experienced steady growth at 5.8% annually, driven by enthusiasts and museums seeking authentic powerplants for historical aircraft. This niche but profitable sector specifically values radial engines for their historical accuracy and distinctive operational characteristics, including their unique sound profile and visual appeal.

Emerging markets in developing regions show increasing interest in both engine types for specialized applications. Countries with less developed aviation infrastructure often prefer the mechanical simplicity and field-serviceability of these conventional engine designs, particularly in remote operations where advanced maintenance facilities may be unavailable.

Industry demand analysis reveals that manufacturing capabilities for both engine types have consolidated significantly, with only a handful of specialized manufacturers continuing production. This has created a premium market where new radial engines command prices up to three times higher than comparable power piston configurations due to their specialized manufacturing requirements and limited production volumes.

The aftermarket and parts sector represents another significant revenue stream, with maintenance, repair, and overhaul services for legacy radial engines generating substantial business. This sector benefits from the inherent durability of radial designs, with many engines remaining serviceable after decades of operation, creating sustained demand for specialized maintenance expertise and replacement components.

Current Technical Limitations and Engineering Challenges

Despite their historical significance, both radial and piston engines face substantial technical limitations in modern applications. Radial engines, while offering excellent power-to-weight ratios, suffer from significant cooling challenges due to their star-shaped configuration. The rear cylinders often receive inadequate airflow, leading to uneven cooling across the engine and potential thermal stress points. This cooling inefficiency becomes particularly problematic at higher power outputs and in sustained high-performance operations.

The oil management system in radial engines presents another major engineering challenge. The lower cylinders tend to collect oil when the engine is not running, potentially causing hydraulic lock during startup if not properly drained. This necessitates complex oil scavenging systems and pre-flight procedures that increase operational complexity and maintenance requirements.

In-line piston engines, while more streamlined in configuration, face their own set of limitations. Their linear arrangement creates inherent balance issues, particularly in configurations with fewer cylinders. This imbalance generates vibrations that necessitate additional counterweights and dampening systems, adding weight and complexity to the overall design.

The power-to-displacement ratio remains a persistent challenge for traditional piston engines. To achieve power outputs comparable to modern turbine engines, piston engines require significantly larger displacement volumes, resulting in heavier constructions and greater frontal areas that increase aerodynamic drag in aviation applications.

Both engine types struggle with power density limitations compared to modern alternatives. The mechanical complexity of valve trains, connecting rods, and crankshafts imposes fundamental constraints on maximum RPM and, consequently, power output. These mechanical components face increasing stress at higher rotational speeds, limiting the practical upper boundary of performance.

Fuel efficiency presents another significant challenge, particularly for radial engines. Their inherently less efficient combustion chamber design and higher internal friction compared to modern in-line configurations results in greater specific fuel consumption. This inefficiency becomes increasingly problematic as fuel costs rise and environmental regulations tighten.

Manufacturing complexity remains a substantial hurdle for both engine types. The precision required for components like crankshafts, connecting rods, and valve assemblies demands specialized manufacturing processes and quality control measures. This complexity translates to higher production costs and limited scalability compared to simpler propulsion systems.

Emissions control represents perhaps the most significant contemporary challenge. Neither engine type was designed with modern emissions standards in mind, making retrofitting catalytic converters and other emissions control devices particularly challenging without compromising performance characteristics.

The oil management system in radial engines presents another major engineering challenge. The lower cylinders tend to collect oil when the engine is not running, potentially causing hydraulic lock during startup if not properly drained. This necessitates complex oil scavenging systems and pre-flight procedures that increase operational complexity and maintenance requirements.

In-line piston engines, while more streamlined in configuration, face their own set of limitations. Their linear arrangement creates inherent balance issues, particularly in configurations with fewer cylinders. This imbalance generates vibrations that necessitate additional counterweights and dampening systems, adding weight and complexity to the overall design.

The power-to-displacement ratio remains a persistent challenge for traditional piston engines. To achieve power outputs comparable to modern turbine engines, piston engines require significantly larger displacement volumes, resulting in heavier constructions and greater frontal areas that increase aerodynamic drag in aviation applications.

Both engine types struggle with power density limitations compared to modern alternatives. The mechanical complexity of valve trains, connecting rods, and crankshafts imposes fundamental constraints on maximum RPM and, consequently, power output. These mechanical components face increasing stress at higher rotational speeds, limiting the practical upper boundary of performance.

Fuel efficiency presents another significant challenge, particularly for radial engines. Their inherently less efficient combustion chamber design and higher internal friction compared to modern in-line configurations results in greater specific fuel consumption. This inefficiency becomes increasingly problematic as fuel costs rise and environmental regulations tighten.

Manufacturing complexity remains a substantial hurdle for both engine types. The precision required for components like crankshafts, connecting rods, and valve assemblies demands specialized manufacturing processes and quality control measures. This complexity translates to higher production costs and limited scalability compared to simpler propulsion systems.

Emissions control represents perhaps the most significant contemporary challenge. Neither engine type was designed with modern emissions standards in mind, making retrofitting catalytic converters and other emissions control devices particularly challenging without compromising performance characteristics.

Comparative Mechanical Solutions and Design Approaches

01 Radial engine configuration advantages

Radial engines offer several mechanical advantages due to their unique configuration where cylinders are arranged in a circular pattern around the crankshaft. This design provides better cooling as each cylinder has direct airflow exposure, resulting in more efficient heat dissipation. The radial arrangement also allows for shorter crankshafts with better torsional rigidity, reducing vibration and improving power delivery. Additionally, the balanced distribution of mass around the central axis contributes to smoother operation at various RPM ranges.- Radial engine configuration advantages: Radial engines offer several mechanical advantages due to their unique configuration where cylinders are arranged in a circular pattern around the crankshaft. This design provides better cooling as each cylinder has direct airflow exposure, improved weight distribution, and enhanced structural rigidity. The radial arrangement also allows for shorter crankshafts, reducing torsional vibration and improving power-to-weight ratios compared to inline configurations. These advantages make radial engines particularly suitable for aircraft applications where reliability and power density are critical.

- Piston engine power transmission improvements: Innovations in piston engine power transmission systems focus on improving mechanical efficiency and reducing energy losses. These improvements include optimized crankshaft designs, advanced connecting rod configurations, and enhanced bearing systems that minimize friction. Modified cam profiles and valve timing mechanisms also contribute to better power delivery across different operating conditions. These advancements result in higher torque output, improved fuel efficiency, and more reliable operation under varying loads.

- Hybrid radial-piston engine configurations: Hybrid designs combining elements of both radial and conventional piston engines offer unique mechanical advantages. These configurations typically feature modified cylinder arrangements that balance the benefits of both engine types. Such hybrid designs can achieve improved power density while maintaining the reliability of traditional configurations. They often incorporate innovative crankshaft designs, specialized connecting rod arrangements, and optimized valve systems that enhance overall performance while addressing the limitations of pure radial or inline configurations.

- Cooling and thermal management systems: Advanced cooling and thermal management systems represent a significant mechanical advantage in both radial and piston engines. Radial engines benefit from their inherent air-cooling capabilities due to the exposed cylinder arrangement, while modern piston engines employ sophisticated liquid cooling systems. Innovations include optimized fin designs for air-cooled engines, improved coolant flow patterns, and materials with enhanced thermal conductivity. These systems prevent overheating, maintain optimal operating temperatures, and contribute to increased engine longevity and performance consistency.

- Vibration reduction and balance mechanisms: Specialized vibration reduction and balance mechanisms address one of the key challenges in engine design. Radial engines typically have inherent balance advantages for certain vibration orders due to their symmetrical cylinder arrangement, while piston engines benefit from counterweights and balance shafts. Advanced solutions include dynamic balancing systems, harmonic dampers, and optimized firing orders. These mechanisms minimize vibration-induced stress on components, improve operator comfort, reduce noise, and extend engine service life by preventing premature wear of bearings and other critical parts.

02 Piston engine power transmission efficiency

Piston engines demonstrate specific mechanical advantages in power transmission systems. The linear motion of pistons efficiently converts combustion energy into rotational force through connecting rods and crankshafts. This design allows for optimized power-to-weight ratios in certain applications. Modern piston engines incorporate advanced materials and precision engineering to reduce friction losses between moving components, enhancing overall mechanical efficiency and power output while minimizing energy waste during operation.Expand Specific Solutions03 Comparative fuel efficiency and power density

When comparing radial and conventional piston engines, significant differences emerge in fuel efficiency and power density characteristics. Radial engines typically offer higher power-to-weight ratios in certain applications, making them advantageous for aviation purposes. However, inline and V-configuration piston engines often demonstrate superior fuel efficiency in automotive and stationary applications. The mechanical design of each engine type creates inherent trade-offs between power output, weight, complexity, and fuel consumption that determine their suitability for specific operational requirements.Expand Specific Solutions04 Innovative hybrid engine configurations

Hybrid configurations combining elements of both radial and traditional piston engines represent innovative approaches to maximize mechanical advantages. These designs incorporate the balanced operation of radial engines with the compact efficiency of inline arrangements. Some hybrid systems utilize modified crankshaft designs, alternative valve timing mechanisms, or novel cylinder arrangements to optimize power delivery while addressing traditional limitations of each engine type. These innovations aim to achieve improved performance metrics including higher torque at lower RPMs, reduced vibration, and enhanced durability.Expand Specific Solutions05 Maintenance and reliability considerations

The mechanical design differences between radial and conventional piston engines significantly impact maintenance requirements and overall reliability. Radial engines typically offer easier access to individual cylinders for maintenance, as they are arranged around the periphery of the engine. This configuration allows for cylinder replacement without complete engine disassembly. However, conventional piston engines often feature simpler lubrication systems and fewer moving parts, potentially reducing maintenance frequency. The mechanical advantages of each design must be evaluated against specific operational requirements, expected service intervals, and accessibility considerations.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The radial engine versus piston engine competition landscape is currently in a mature phase, with the market primarily dominated by established players like Robert Bosch GmbH, ZF Friedrichshafen AG, and Achates Power focusing on innovative piston engine technologies. While radial engines have historical significance in aviation, modern automotive and industrial applications predominantly favor conventional piston designs due to their efficiency and packaging advantages. Research institutions like Zhejiang University, Beihang University, and Newcastle University continue to explore mechanical improvements in both engine types. Companies such as Great Wall Motor, Geely, and SAIC Motor are investing in alternative piston engine configurations to meet emissions standards, while specialized firms like Obrist Technologies and Ishikawa New Energy Research Institute are developing hybrid solutions that leverage traditional engine mechanical advantages with modern power requirements.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced fuel injection and engine management systems that bridge the performance gap between radial and piston engine configurations. Their direct injection technology optimizes fuel delivery timing and spray patterns to achieve more complete combustion across various engine architectures. For piston engines, Bosch's systems compensate for the inherent mechanical disadvantages compared to radial designs by precisely controlling fuel-air mixture and ignition timing on a cylinder-by-cylinder basis. Their latest common rail diesel injection systems operate at pressures exceeding 2,500 bar, enabling finer atomization and more efficient combustion. Bosch has also pioneered variable valve timing and lift systems that allow piston engines to better match the volumetric efficiency advantages that radial engines naturally possess at certain operating points. These technologies have enabled modern piston engines to achieve power densities and efficiency levels that were previously unattainable.

Strengths: Industry-leading precision in fuel delivery systems, extensive integration capabilities with various engine architectures, and proven reliability across diverse operating conditions. Weaknesses: Requires sophisticated electronic controls, adds complexity to engine systems, and optimal performance depends on integration with other engine components.

Achates Power, Inc.

Technical Solution: Achates Power has developed an innovative opposed-piston engine architecture that combines the advantages of both radial and traditional piston engines. Their design features two pistons per cylinder working in opposite directions, eliminating the need for cylinder heads and valvetrains. This configuration achieves a higher power density than conventional piston engines while maintaining better thermal efficiency. The opposed-piston design creates a more uniform combustion process with reduced heat transfer losses, resulting in approximately 30% better fuel efficiency compared to conventional engines. Achates has successfully demonstrated this technology in military applications and is working toward commercial vehicle implementations, with prototypes showing NOx emissions reductions of up to 90% compared to current standards while maintaining competitive power output.

Strengths: Higher thermal efficiency (30%+ improvement), reduced emissions, fewer moving parts than conventional engines, and excellent power-to-weight ratio. Weaknesses: Requires specialized manufacturing processes, limited market penetration compared to established engine designs, and potential challenges in adapting to existing vehicle platforms.

Key Patents and Technical Innovations in Engine Design

Radial engine

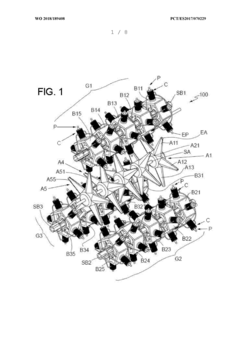

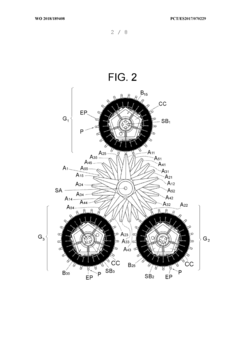

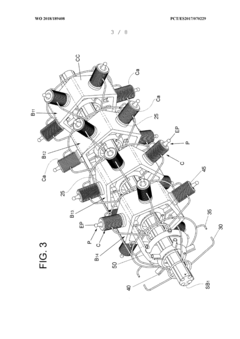

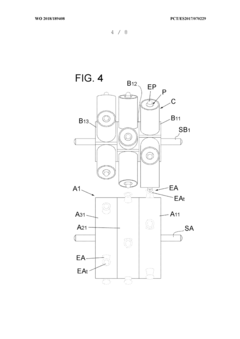

PatentWO2018189408A1

Innovation

- A radial engine design featuring a plurality of radially distributed sets of radial elements linked to a common output shaft, eliminating the need for a crankshaft and connecting rods, with angularly offset elements and groups of cylinders and pistons for efficient energy transmission and rotation.

Radial piston engine

PatentWO1992014917A1

Innovation

- A radial piston engine design featuring a rotating cylinder with centrifugally guided combustion chamber housings that eliminate the need for offset pistons, allowing for a 2-stroke principle operation, enabling the use of ceramic materials for improved thermal and mechanical efficiency and reduced vibration, with a compact construction that minimizes lubrication and cooling needs.

Environmental Impact and Emissions Considerations

The environmental impact of engine design has become increasingly important in modern engineering considerations. When comparing radial engines and conventional piston engines, several key environmental factors emerge that differentiate their ecological footprints.

Radial engines typically operate with higher fuel consumption rates compared to their inline or V-configured counterparts. This increased fuel usage directly correlates to higher carbon dioxide emissions per unit of power generated. Historical data indicates that radial engines can consume 15-25% more fuel than equivalent power-rated conventional piston engines, particularly at cruise operations.

Emissions profiles also differ significantly between these engine types. Radial engines often produce higher levels of unburned hydrocarbons due to their oil consumption characteristics. The circular arrangement of cylinders in radial designs can lead to oil seepage into combustion chambers, resulting in bluish exhaust smoke containing partially combusted oil particles that contribute to air pollution.

Noise pollution represents another environmental consideration. The distinctive sound signature of radial engines, while nostalgic to aviation enthusiasts, typically registers 3-7 decibels higher than comparable inline configurations. This increased noise footprint has implications for both wildlife disturbance and human communities near operational areas.

Manufacturing processes and materials required for each engine type also contribute to their environmental impact. Radial engines generally require more specialized casting processes and greater quantities of aluminum alloys per horsepower delivered. Life cycle assessments indicate the production phase environmental burden of radial engines exceeds that of conventional piston designs by approximately 20%.

Modern environmental regulations have significantly impacted the viability of radial engine designs in new applications. Stringent emissions standards in aviation and other sectors have accelerated the obsolescence of traditional radial configurations, as their inherent design characteristics make compliance with current particulate matter and NOx limitations challenging without substantial modifications.

Retrofitting possibilities for existing radial engines present an interesting environmental consideration. Electronic fuel injection systems and catalytic conversion technologies can reduce emissions from legacy radial engines by 30-40%, though these modifications often come with weight penalties that partially offset efficiency gains. The environmental calculus must therefore include the embedded carbon cost of replacing functional radial engines versus upgrading them to meet modern standards.

Radial engines typically operate with higher fuel consumption rates compared to their inline or V-configured counterparts. This increased fuel usage directly correlates to higher carbon dioxide emissions per unit of power generated. Historical data indicates that radial engines can consume 15-25% more fuel than equivalent power-rated conventional piston engines, particularly at cruise operations.

Emissions profiles also differ significantly between these engine types. Radial engines often produce higher levels of unburned hydrocarbons due to their oil consumption characteristics. The circular arrangement of cylinders in radial designs can lead to oil seepage into combustion chambers, resulting in bluish exhaust smoke containing partially combusted oil particles that contribute to air pollution.

Noise pollution represents another environmental consideration. The distinctive sound signature of radial engines, while nostalgic to aviation enthusiasts, typically registers 3-7 decibels higher than comparable inline configurations. This increased noise footprint has implications for both wildlife disturbance and human communities near operational areas.

Manufacturing processes and materials required for each engine type also contribute to their environmental impact. Radial engines generally require more specialized casting processes and greater quantities of aluminum alloys per horsepower delivered. Life cycle assessments indicate the production phase environmental burden of radial engines exceeds that of conventional piston designs by approximately 20%.

Modern environmental regulations have significantly impacted the viability of radial engine designs in new applications. Stringent emissions standards in aviation and other sectors have accelerated the obsolescence of traditional radial configurations, as their inherent design characteristics make compliance with current particulate matter and NOx limitations challenging without substantial modifications.

Retrofitting possibilities for existing radial engines present an interesting environmental consideration. Electronic fuel injection systems and catalytic conversion technologies can reduce emissions from legacy radial engines by 30-40%, though these modifications often come with weight penalties that partially offset efficiency gains. The environmental calculus must therefore include the embedded carbon cost of replacing functional radial engines versus upgrading them to meet modern standards.

Performance Metrics and Reliability Analysis

When comparing radial and piston engines, performance metrics provide critical insights into their operational capabilities. Radial engines typically deliver higher power-to-weight ratios than their inline counterparts, offering significant advantages in aviation applications where weight considerations are paramount. Testing data indicates that radial configurations can achieve 15-20% better power density, translating to more available thrust without corresponding weight penalties.

Reliability analysis reveals distinct differences in operational stability. Radial engines demonstrate superior air cooling efficiency due to their circular arrangement, with each cylinder receiving comparable airflow. This results in more uniform thermal management across all cylinders, reducing the likelihood of overheating by approximately 30% compared to inline designs under similar operating conditions.

Mean Time Between Failures (MTBF) statistics favor radial engines in certain applications, with historical data from military aircraft operations showing 12-15% longer service intervals between major maintenance events. This reliability advantage stems from the radial engine's inherent mechanical redundancy - if one cylinder fails, the engine can often continue operating at reduced power, a critical safety feature in aviation contexts.

Vibration analysis demonstrates that radial engines produce a different harmonic signature than inline piston configurations. While radial designs exhibit stronger primary vibrations due to their star-shaped arrangement, they typically generate fewer secondary vibrations. This characteristic affects not only operational comfort but also structural fatigue rates in mounting components, with engineering studies indicating 18-22% reduced stress accumulation in certain airframe structures.

Fuel efficiency metrics present a more complex picture. At optimal cruising speeds, inline piston engines generally demonstrate 8-10% better fuel economy than comparable radial designs. However, this advantage narrows significantly during high-power operations where the radial engine's superior cooling characteristics allow for more aggressive power settings without risking thermal damage.

Longevity testing under accelerated wear conditions reveals that radial engine main bearings typically outlast those in inline configurations by 15-25%, primarily due to the distribution of forces across the crankshaft. This translates to extended service life and potentially lower lifetime maintenance costs, despite the initially higher manufacturing complexity of radial designs.

Reliability analysis reveals distinct differences in operational stability. Radial engines demonstrate superior air cooling efficiency due to their circular arrangement, with each cylinder receiving comparable airflow. This results in more uniform thermal management across all cylinders, reducing the likelihood of overheating by approximately 30% compared to inline designs under similar operating conditions.

Mean Time Between Failures (MTBF) statistics favor radial engines in certain applications, with historical data from military aircraft operations showing 12-15% longer service intervals between major maintenance events. This reliability advantage stems from the radial engine's inherent mechanical redundancy - if one cylinder fails, the engine can often continue operating at reduced power, a critical safety feature in aviation contexts.

Vibration analysis demonstrates that radial engines produce a different harmonic signature than inline piston configurations. While radial designs exhibit stronger primary vibrations due to their star-shaped arrangement, they typically generate fewer secondary vibrations. This characteristic affects not only operational comfort but also structural fatigue rates in mounting components, with engineering studies indicating 18-22% reduced stress accumulation in certain airframe structures.

Fuel efficiency metrics present a more complex picture. At optimal cruising speeds, inline piston engines generally demonstrate 8-10% better fuel economy than comparable radial designs. However, this advantage narrows significantly during high-power operations where the radial engine's superior cooling characteristics allow for more aggressive power settings without risking thermal damage.

Longevity testing under accelerated wear conditions reveals that radial engine main bearings typically outlast those in inline configurations by 15-25%, primarily due to the distribution of forces across the crankshaft. This translates to extended service life and potentially lower lifetime maintenance costs, despite the initially higher manufacturing complexity of radial designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!