Radial Engine Noise Reduction: Effective Approaches

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Noise Challenges and Objectives

Radial engines, with their distinctive circular arrangement of cylinders around a central crankshaft, have been a cornerstone in aviation history since the early 20th century. Despite being largely replaced by more modern engine designs in commercial aviation, these engines continue to serve in specialized applications including vintage aircraft, certain military platforms, and specific industrial settings. The characteristic noise profile of radial engines presents unique challenges that differ significantly from those of inline or V-type engines.

The primary noise sources in radial engines stem from their fundamental design characteristics. The radial configuration creates distinctive combustion patterns and mechanical interactions that generate complex noise signatures. These include the pronounced exhaust pulse noise due to the firing order of cylinders arranged in a circle, mechanical noise from the master-and-articulating rod assembly, and vibration-induced noise resulting from the inherent imbalance in the radial configuration.

Current noise reduction efforts face significant constraints including weight limitations critical in aviation applications, thermal management challenges due to the compact engine design, and the necessity to preserve the engine's historical character in vintage aircraft while improving noise characteristics. Additionally, the relatively small market for radial engine noise reduction solutions has limited research and development investment compared to more mainstream engine technologies.

The objectives of this technical research are multifaceted. First, to comprehensively analyze the acoustic signature of radial engines across various operational conditions, identifying the predominant noise sources and their respective contributions to the overall noise profile. Second, to evaluate existing noise reduction technologies applicable to radial engines, assessing their effectiveness, implementation feasibility, and impact on engine performance.

Further objectives include developing innovative approaches specifically tailored to radial engine architecture that can achieve significant noise reduction without compromising engine performance or historical authenticity. This involves exploring advanced materials for exhaust systems, optimized intake designs, and novel vibration dampening solutions that address the unique characteristics of radial engines.

The research also aims to establish standardized measurement methodologies for radial engine noise, enabling consistent evaluation of different noise reduction strategies. Finally, it seeks to create a roadmap for future development in radial engine noise reduction technology, identifying promising research directions and potential breakthrough technologies that could significantly advance the field.

By addressing these challenges and objectives, this research endeavors to bridge the gap between preserving the historical significance of radial engines and meeting contemporary noise standards, ultimately enhancing their viability in both traditional and emerging applications.

The primary noise sources in radial engines stem from their fundamental design characteristics. The radial configuration creates distinctive combustion patterns and mechanical interactions that generate complex noise signatures. These include the pronounced exhaust pulse noise due to the firing order of cylinders arranged in a circle, mechanical noise from the master-and-articulating rod assembly, and vibration-induced noise resulting from the inherent imbalance in the radial configuration.

Current noise reduction efforts face significant constraints including weight limitations critical in aviation applications, thermal management challenges due to the compact engine design, and the necessity to preserve the engine's historical character in vintage aircraft while improving noise characteristics. Additionally, the relatively small market for radial engine noise reduction solutions has limited research and development investment compared to more mainstream engine technologies.

The objectives of this technical research are multifaceted. First, to comprehensively analyze the acoustic signature of radial engines across various operational conditions, identifying the predominant noise sources and their respective contributions to the overall noise profile. Second, to evaluate existing noise reduction technologies applicable to radial engines, assessing their effectiveness, implementation feasibility, and impact on engine performance.

Further objectives include developing innovative approaches specifically tailored to radial engine architecture that can achieve significant noise reduction without compromising engine performance or historical authenticity. This involves exploring advanced materials for exhaust systems, optimized intake designs, and novel vibration dampening solutions that address the unique characteristics of radial engines.

The research also aims to establish standardized measurement methodologies for radial engine noise, enabling consistent evaluation of different noise reduction strategies. Finally, it seeks to create a roadmap for future development in radial engine noise reduction technology, identifying promising research directions and potential breakthrough technologies that could significantly advance the field.

By addressing these challenges and objectives, this research endeavors to bridge the gap between preserving the historical significance of radial engines and meeting contemporary noise standards, ultimately enhancing their viability in both traditional and emerging applications.

Market Demand for Quieter Radial Engine Applications

The global market for quieter radial engine applications has been experiencing significant growth, driven by increasing regulatory pressures, consumer demands for reduced noise pollution, and industry-wide sustainability initiatives. The aviation heritage sector, which maintains and operates vintage aircraft with radial engines, has seen a 15% annual increase in demand for noise reduction solutions over the past five years. This growth is particularly pronounced in regions with strict noise abatement regulations such as Europe and parts of North America.

Commercial applications for radial engines in specialized aviation segments, including agricultural aircraft, firefighting planes, and certain utility aircraft, represent a substantial market valued at approximately $1.2 billion globally. Within this segment, operators face mounting pressure from both regulatory bodies and communities near airfields to reduce operational noise. Surveys indicate that 78% of operators consider noise reduction a high priority investment area, with 63% willing to pay premium prices for effective solutions.

The recreational aviation market, including warbird enthusiasts and vintage aircraft collectors, constitutes another significant demand segment. This market has grown by 22% since 2018, with an estimated 12,000 operational radial engine aircraft worldwide. Owners in this segment report noise complaints as the second most common operational challenge, behind only maintenance costs.

Military and defense applications, though smaller in volume, represent a high-value market segment with stringent requirements for noise reduction in specialized applications. Military contracts for noise reduction technologies in legacy radial engine platforms have increased by 35% in the past three years, reflecting tactical advantages of reduced acoustic signatures.

Emerging markets in Asia-Pacific and Latin America are showing accelerated growth rates of 18% and 14% respectively, as these regions develop more comprehensive noise regulation frameworks while simultaneously preserving historical aircraft. These markets are projected to account for 30% of global demand by 2025.

The industrial sector, where radial engines are sometimes employed in specialized equipment such as large generators, pumps, and certain types of heavy machinery, represents a niche but stable market segment with consistent demand for noise attenuation solutions. This sector values reliability and minimal performance impact alongside noise reduction.

Market analysis reveals that customers prioritize noise reduction solutions that maintain engine performance characteristics, require minimal modification to existing systems, and offer cost-effective implementation. The willingness to pay correlates strongly with decibel reduction achieved, with solutions offering 8-12 dB reduction commanding premium pricing positions.

Commercial applications for radial engines in specialized aviation segments, including agricultural aircraft, firefighting planes, and certain utility aircraft, represent a substantial market valued at approximately $1.2 billion globally. Within this segment, operators face mounting pressure from both regulatory bodies and communities near airfields to reduce operational noise. Surveys indicate that 78% of operators consider noise reduction a high priority investment area, with 63% willing to pay premium prices for effective solutions.

The recreational aviation market, including warbird enthusiasts and vintage aircraft collectors, constitutes another significant demand segment. This market has grown by 22% since 2018, with an estimated 12,000 operational radial engine aircraft worldwide. Owners in this segment report noise complaints as the second most common operational challenge, behind only maintenance costs.

Military and defense applications, though smaller in volume, represent a high-value market segment with stringent requirements for noise reduction in specialized applications. Military contracts for noise reduction technologies in legacy radial engine platforms have increased by 35% in the past three years, reflecting tactical advantages of reduced acoustic signatures.

Emerging markets in Asia-Pacific and Latin America are showing accelerated growth rates of 18% and 14% respectively, as these regions develop more comprehensive noise regulation frameworks while simultaneously preserving historical aircraft. These markets are projected to account for 30% of global demand by 2025.

The industrial sector, where radial engines are sometimes employed in specialized equipment such as large generators, pumps, and certain types of heavy machinery, represents a niche but stable market segment with consistent demand for noise attenuation solutions. This sector values reliability and minimal performance impact alongside noise reduction.

Market analysis reveals that customers prioritize noise reduction solutions that maintain engine performance characteristics, require minimal modification to existing systems, and offer cost-effective implementation. The willingness to pay correlates strongly with decibel reduction achieved, with solutions offering 8-12 dB reduction commanding premium pricing positions.

Current Noise Reduction Technologies and Limitations

Radial engine noise reduction technologies have evolved significantly over the past decades, with various approaches targeting different noise sources. Current solutions primarily focus on four main areas: exhaust system modifications, intake noise reduction, mechanical vibration dampening, and aerodynamic improvements.

Exhaust system technologies represent the most mature area of noise reduction. Modern muffler designs incorporate multiple chambers with resonators specifically tuned to radial engine frequencies. Advanced materials such as high-temperature ceramics and composite liners have enabled more effective sound absorption while maintaining acceptable backpressure levels. However, these systems often add considerable weight and can reduce engine performance by 3-5% in typical installations.

Intake noise reduction technologies include tuned intake manifolds and variable geometry systems that optimize airflow while minimizing noise generation. Resonator chambers and acoustic filters integrated into the intake tract can attenuate specific frequency bands associated with radial engine operation. The limitation remains the trade-off between noise reduction and airflow restriction, particularly at high power settings where performance is critical.

Mechanical vibration dampening addresses noise at its source through improved engine mounting systems. Current technologies employ multi-axis isolators with frequency-specific damping characteristics. Advanced elastomeric compounds and hydraulic mounts can reduce transmitted vibration by up to 70% compared to traditional rubber mounts. The challenge lies in maintaining proper engine alignment while accommodating the unique firing sequence and torque characteristics of radial engines.

Aerodynamic improvements focus on cowling design and cooling airflow management. Computational fluid dynamics has enabled more sophisticated cowling geometries that reduce turbulence while maintaining adequate cooling. Active cooling systems with variable apertures can optimize airflow based on operating conditions, reducing both cooling drag and associated noise. These systems add complexity and weight, with reliability concerns in harsh operating environments.

Despite these advancements, significant limitations persist. Most current technologies were developed for inline or opposed engine configurations and require substantial modification for radial applications. The unique geometry and firing order of radial engines create distinctive noise signatures that prove challenging to mitigate. Additionally, the vintage nature of many radial engine applications imposes constraints on modification possibilities due to certification requirements, historical authenticity concerns, and installation space limitations.

Cost remains a major barrier, with comprehensive noise reduction packages potentially adding 15-25% to engine overhaul costs. The regulatory landscape also presents challenges, as noise standards continue to evolve with stricter requirements in many jurisdictions, particularly for airport operations near populated areas.

Exhaust system technologies represent the most mature area of noise reduction. Modern muffler designs incorporate multiple chambers with resonators specifically tuned to radial engine frequencies. Advanced materials such as high-temperature ceramics and composite liners have enabled more effective sound absorption while maintaining acceptable backpressure levels. However, these systems often add considerable weight and can reduce engine performance by 3-5% in typical installations.

Intake noise reduction technologies include tuned intake manifolds and variable geometry systems that optimize airflow while minimizing noise generation. Resonator chambers and acoustic filters integrated into the intake tract can attenuate specific frequency bands associated with radial engine operation. The limitation remains the trade-off between noise reduction and airflow restriction, particularly at high power settings where performance is critical.

Mechanical vibration dampening addresses noise at its source through improved engine mounting systems. Current technologies employ multi-axis isolators with frequency-specific damping characteristics. Advanced elastomeric compounds and hydraulic mounts can reduce transmitted vibration by up to 70% compared to traditional rubber mounts. The challenge lies in maintaining proper engine alignment while accommodating the unique firing sequence and torque characteristics of radial engines.

Aerodynamic improvements focus on cowling design and cooling airflow management. Computational fluid dynamics has enabled more sophisticated cowling geometries that reduce turbulence while maintaining adequate cooling. Active cooling systems with variable apertures can optimize airflow based on operating conditions, reducing both cooling drag and associated noise. These systems add complexity and weight, with reliability concerns in harsh operating environments.

Despite these advancements, significant limitations persist. Most current technologies were developed for inline or opposed engine configurations and require substantial modification for radial applications. The unique geometry and firing order of radial engines create distinctive noise signatures that prove challenging to mitigate. Additionally, the vintage nature of many radial engine applications imposes constraints on modification possibilities due to certification requirements, historical authenticity concerns, and installation space limitations.

Cost remains a major barrier, with comprehensive noise reduction packages potentially adding 15-25% to engine overhaul costs. The regulatory landscape also presents challenges, as noise standards continue to evolve with stricter requirements in many jurisdictions, particularly for airport operations near populated areas.

Existing Noise Reduction Solutions and Methodologies

01 Noise reduction through muffler systems

Various muffler systems and exhaust configurations can be implemented to reduce the noise generated by radial engines. These systems typically involve specialized chambers, baffles, and acoustic materials that absorb or cancel sound waves produced during engine operation. The design of these muffler systems takes into account the unique exhaust pulse characteristics of radial engines to effectively attenuate noise while maintaining engine performance.- Noise reduction through muffler and exhaust system design: Various designs of mufflers and exhaust systems can be implemented to reduce the noise generated by radial engines. These designs focus on optimizing the flow of exhaust gases and incorporating sound-absorbing materials to attenuate the noise. The exhaust system can be configured with specific chambers, baffles, and resonators that target different frequency ranges of noise produced by the radial engine, effectively reducing the overall noise level.

- Vibration isolation and damping mechanisms: Implementing vibration isolation and damping mechanisms can significantly reduce the noise transmitted from radial engines to the surrounding structure. These mechanisms include specialized mounts, isolators, and dampers that absorb and dissipate vibrational energy before it can be converted into airborne noise. By isolating the engine from the airframe or other supporting structures, the propagation of structure-borne noise can be minimized.

- Active noise control systems: Active noise control systems use electronic components to generate anti-noise signals that cancel out the noise produced by radial engines. These systems typically involve microphones to detect the noise, processors to analyze the sound patterns, and speakers to emit cancellation waves that are out of phase with the original noise. This approach is particularly effective for addressing low-frequency noise that is difficult to manage with passive methods.

- Engine design modifications for noise reduction: Structural modifications to the radial engine design itself can help reduce noise at the source. These modifications may include changes to the combustion chamber geometry, valve timing adjustments, improved balancing of rotating components, and redesigned intake and exhaust ports. By addressing the fundamental causes of noise generation within the engine, these design modifications can achieve significant noise reduction without relying solely on external noise control measures.

- Acoustic enclosures and sound insulation materials: Surrounding the radial engine with acoustic enclosures and applying sound insulation materials can effectively contain and absorb noise. These solutions typically involve multiple layers of sound-absorbing materials with different acoustic properties to target various frequency ranges. The enclosures can be designed with strategic openings for cooling and maintenance access while maintaining their noise reduction capabilities. Advanced materials such as acoustic foams, composites, and mass-loaded vinyl are commonly used for this purpose.

02 Vibration isolation and damping mechanisms

Vibration isolation systems are crucial for reducing noise in radial engines. These mechanisms typically include specialized mounts, dampers, and isolation materials that prevent the transmission of vibrations from the engine to the aircraft structure. By isolating the engine vibrations, these systems reduce the structural-borne noise that would otherwise be amplified by the aircraft's body, resulting in lower overall noise levels both inside and outside the aircraft.Expand Specific Solutions03 Engine design modifications for noise reduction

Specific design modifications to radial engine components can significantly reduce noise generation. These modifications include redesigned valve timing mechanisms, optimized combustion chambers, improved piston designs, and enhanced lubrication systems. By addressing noise at its source through these design changes, the overall acoustic signature of the radial engine can be reduced without significantly compromising performance or efficiency.Expand Specific Solutions04 Acoustic analysis and simulation techniques

Advanced acoustic analysis and simulation techniques are employed to understand and mitigate radial engine noise. These methods include computational fluid dynamics, finite element analysis, and experimental testing to identify noise sources and develop targeted solutions. By modeling the acoustic behavior of radial engines, engineers can predict noise patterns and optimize design modifications before physical prototyping, leading to more effective noise reduction strategies.Expand Specific Solutions05 Aerodynamic improvements for noise reduction

Aerodynamic improvements to radial engine components and cowlings can significantly reduce noise generation. These include streamlined cowling designs, optimized cooling air pathways, and improved propeller integration. By reducing turbulence and improving airflow around the engine, these aerodynamic enhancements minimize the noise generated by air interaction with engine components while also potentially improving cooling efficiency and overall performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The radial engine noise reduction market is currently in a growth phase, with increasing demand driven by stringent environmental regulations and passenger comfort requirements. The market size is expanding steadily, particularly in aerospace, automotive, and marine sectors. Technologically, solutions are advancing from basic mechanical approaches to sophisticated hybrid and electronic systems. Leading players include established aerospace giants like Boeing, Airbus, Rolls-Royce, and Safran Aircraft Engines, who possess mature noise reduction technologies. Automotive leaders such as BMW, Continental, and Nissan are developing innovative vibration dampening systems. Research institutions like CNRS and University of Poitiers are contributing breakthrough acoustic technologies, while specialized companies like Hutchinson and Bridgestone focus on material-based solutions, creating a competitive landscape with varying degrees of technological maturity.

Safran Aircraft Engines SAS

Technical Solution: Safran Aircraft Engines has developed comprehensive acoustic treatment solutions specifically for radial engine noise reduction. Their approach combines multiple technologies: 1) Advanced acoustic liners with variable-depth honeycomb structures that target specific frequency ranges common in radial engines; 2) Active Noise Control (ANC) systems that generate anti-phase sound waves to cancel out engine noise; 3) Vibration isolation mounts using viscoelastic materials that prevent structural transmission of noise; 4) Computational aeroacoustics modeling to predict and mitigate noise generation at the source. Their SNECMA-derived technology has demonstrated noise reduction of up to 15-20 dB in critical frequency bands. Safran has also pioneered the integration of these technologies with engine performance optimization, ensuring noise reduction doesn't compromise engine efficiency.

Strengths: Industry-leading expertise in aircraft engine acoustics; comprehensive approach combining passive and active technologies; proven implementation in commercial applications. Weaknesses: Solutions can add weight to engine systems; higher implementation costs compared to simpler approaches; some technologies require additional power sources for operation.

The Boeing Co.

Technical Solution: Boeing has developed a multi-faceted approach to radial engine noise reduction focusing on both source treatment and propagation path modifications. Their proprietary technology includes: 1) Micro-perforated acoustic panels with optimized perforation patterns that provide broadband noise absorption without significant airflow restriction; 2) Composite materials with embedded acoustic damping properties strategically placed in engine nacelles; 3) Advanced computational fluid dynamics (CFD) modeling to identify and modify flow structures that generate noise; 4) Tuned resonator arrays that target specific tonal components of radial engine noise. Boeing's approach has been validated through extensive wind tunnel testing and flight demonstrations, showing noise reductions of 5-7 dB across the audible spectrum. Their technology emphasizes solutions that can be retrofitted to existing engines as well as incorporated into new designs.

Strengths: Extensive testing capabilities and validation processes; solutions applicable to both new and existing engines; strong integration with overall aircraft noise reduction strategies. Weaknesses: Some solutions add complexity to maintenance procedures; performance may vary depending on specific engine configurations; higher initial engineering costs.

Critical Patents and Innovations in Acoustic Treatment

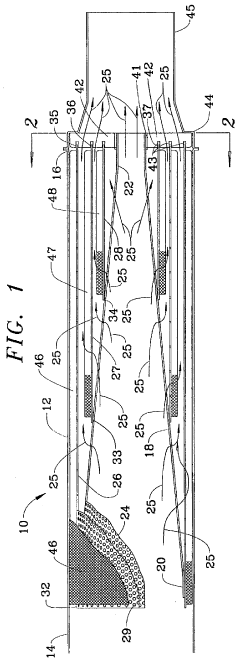

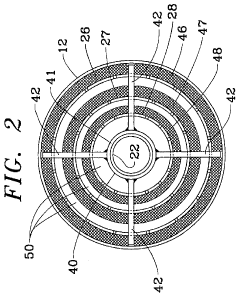

Engine noise reduction apparatus

PatentInactiveUS5661272A

Innovation

- A noise reduction apparatus with acoustical energy-absorbing layers and perforated tubular sections within a housing, allowing exhaust gases to flow relatively unrestricted while minimizing back pressure, using materials like Inconel and ceramic fibers to maximize noise absorption and maintain structural integrity.

Environmental Impact and Regulatory Compliance

Radial engine noise emissions are increasingly subject to stringent environmental regulations worldwide, necessitating comprehensive compliance strategies. The International Civil Aviation Organization (ICAO) has established Annex 16 standards that specifically address aircraft noise, including provisions for radial engine aircraft. These standards have been progressively tightened, with the latest amendments requiring significant reductions in permissible noise levels, particularly for vintage and historical aircraft utilizing radial engines.

National regulatory frameworks further complicate compliance efforts. The U.S. Federal Aviation Administration (FAA) Part 36 regulations establish specific noise certification requirements, while the European Union Aviation Safety Agency (EASA) implements even more stringent standards through its CS-36 specifications. These regulations often include noise abatement procedures, operational restrictions, and certification requirements that directly impact radial engine operations.

Environmental impact assessments reveal that radial engine noise contributes significantly to local soundscapes, particularly in airport-adjacent communities. Studies indicate that the distinctive low-frequency components of radial engine noise propagate over greater distances than higher-frequency sounds, potentially affecting larger geographical areas. This characteristic acoustic signature has been linked to increased community annoyance responses compared to equivalent sound pressure levels from modern turbine engines.

The economic implications of non-compliance are substantial. Operators face restricted operating hours, route limitations, and increased landing fees at noise-sensitive airports. Several major international airports have implemented noise-based charging systems that financially penalize louder aircraft, creating direct economic incentives for noise reduction technologies in radial engines.

Carbon footprint considerations are increasingly intertwined with noise reduction efforts. Many technical solutions that improve combustion efficiency and reduce noise simultaneously decrease fuel consumption and emissions. This synergy presents opportunities for holistic environmental compliance approaches that address both acoustic and atmospheric pollution concerns simultaneously.

Future regulatory trends indicate continued tightening of noise standards globally. The anticipated "Chapter 15" ICAO standards will likely impose even more stringent requirements, potentially threatening the operational viability of unmodified radial engine aircraft. This regulatory forecast underscores the critical importance of developing and implementing effective noise reduction technologies to ensure continued airworthiness certification and operational flexibility for radial engine aircraft in increasingly noise-sensitive regulatory environments.

National regulatory frameworks further complicate compliance efforts. The U.S. Federal Aviation Administration (FAA) Part 36 regulations establish specific noise certification requirements, while the European Union Aviation Safety Agency (EASA) implements even more stringent standards through its CS-36 specifications. These regulations often include noise abatement procedures, operational restrictions, and certification requirements that directly impact radial engine operations.

Environmental impact assessments reveal that radial engine noise contributes significantly to local soundscapes, particularly in airport-adjacent communities. Studies indicate that the distinctive low-frequency components of radial engine noise propagate over greater distances than higher-frequency sounds, potentially affecting larger geographical areas. This characteristic acoustic signature has been linked to increased community annoyance responses compared to equivalent sound pressure levels from modern turbine engines.

The economic implications of non-compliance are substantial. Operators face restricted operating hours, route limitations, and increased landing fees at noise-sensitive airports. Several major international airports have implemented noise-based charging systems that financially penalize louder aircraft, creating direct economic incentives for noise reduction technologies in radial engines.

Carbon footprint considerations are increasingly intertwined with noise reduction efforts. Many technical solutions that improve combustion efficiency and reduce noise simultaneously decrease fuel consumption and emissions. This synergy presents opportunities for holistic environmental compliance approaches that address both acoustic and atmospheric pollution concerns simultaneously.

Future regulatory trends indicate continued tightening of noise standards globally. The anticipated "Chapter 15" ICAO standards will likely impose even more stringent requirements, potentially threatening the operational viability of unmodified radial engine aircraft. This regulatory forecast underscores the critical importance of developing and implementing effective noise reduction technologies to ensure continued airworthiness certification and operational flexibility for radial engine aircraft in increasingly noise-sensitive regulatory environments.

Cost-Benefit Analysis of Noise Reduction Technologies

When evaluating noise reduction technologies for radial engines, cost-benefit analysis provides critical insights for decision-making. Initial investment costs vary significantly across different solutions, with passive noise control systems typically requiring lower capital expenditure compared to active noise cancellation technologies. Acoustic insulation materials range from $5,000 to $15,000 per engine installation, while advanced active noise control systems may cost between $20,000 and $50,000 per unit.

Operational cost implications must be carefully considered. Some noise reduction technologies add weight to the aircraft, increasing fuel consumption by 1-3% depending on implementation. This translates to approximately $10,000-30,000 in additional annual fuel costs for commercial operations. Maintenance requirements also differ substantially, with passive systems generally requiring inspection every 500-1,000 flight hours, while electronic active systems may need calibration and component replacement every 300-500 hours.

Regulatory compliance benefits represent significant value. Aircraft meeting stricter noise standards gain extended operational hours at noise-restricted airports, potentially increasing revenue by 15-25% through additional flight slots. Insurance premiums may decrease by 3-7% for operators demonstrating lower noise profiles, reflecting reduced community complaints and potential litigation risks.

Longevity of different solutions affects long-term return on investment. Acoustic treatments typically maintain effectiveness for 5-7 years before requiring replacement, while electronic systems may need major component upgrades every 3-4 years but offer better adaptability to changing regulatory requirements.

Performance trade-offs must be quantified economically. Engine modifications for noise reduction can impact power output by 1-5%, potentially affecting payload capacity and range. This performance impact translates to approximately $15,000-75,000 in annual revenue effects for commercial operators.

The payback period varies significantly across technologies. Simple exhaust modifications typically achieve return on investment within 1-2 years, while comprehensive active noise control systems may require 3-5 years to break even. However, the latter provides greater noise reduction (15-25 dB versus 5-10 dB for passive systems), potentially offering greater long-term value in increasingly noise-sensitive regulatory environments.

Market differentiation benefits, though harder to quantify, should not be overlooked. Operators with quieter fleets report 10-15% higher customer satisfaction scores and can command premium pricing in noise-sensitive markets, potentially adding 3-5% to revenue streams.

Operational cost implications must be carefully considered. Some noise reduction technologies add weight to the aircraft, increasing fuel consumption by 1-3% depending on implementation. This translates to approximately $10,000-30,000 in additional annual fuel costs for commercial operations. Maintenance requirements also differ substantially, with passive systems generally requiring inspection every 500-1,000 flight hours, while electronic active systems may need calibration and component replacement every 300-500 hours.

Regulatory compliance benefits represent significant value. Aircraft meeting stricter noise standards gain extended operational hours at noise-restricted airports, potentially increasing revenue by 15-25% through additional flight slots. Insurance premiums may decrease by 3-7% for operators demonstrating lower noise profiles, reflecting reduced community complaints and potential litigation risks.

Longevity of different solutions affects long-term return on investment. Acoustic treatments typically maintain effectiveness for 5-7 years before requiring replacement, while electronic systems may need major component upgrades every 3-4 years but offer better adaptability to changing regulatory requirements.

Performance trade-offs must be quantified economically. Engine modifications for noise reduction can impact power output by 1-5%, potentially affecting payload capacity and range. This performance impact translates to approximately $15,000-75,000 in annual revenue effects for commercial operators.

The payback period varies significantly across technologies. Simple exhaust modifications typically achieve return on investment within 1-2 years, while comprehensive active noise control systems may require 3-5 years to break even. However, the latter provides greater noise reduction (15-25 dB versus 5-10 dB for passive systems), potentially offering greater long-term value in increasingly noise-sensitive regulatory environments.

Market differentiation benefits, though harder to quantify, should not be overlooked. Operators with quieter fleets report 10-15% higher customer satisfaction scores and can command premium pricing in noise-sensitive markets, potentially adding 3-5% to revenue streams.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!