Comparing Radial Engine and Inline Engine Vibration Levels

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Vibration Technology Background and Objectives

Engine vibration analysis has evolved significantly since the early days of aviation and automotive engineering. The comparison between radial and inline engine vibration characteristics represents a critical area of study that has shaped engine design philosophy for over a century. Historically, engine vibration management began as an empirical practice in the 1910s and gradually developed into a sophisticated engineering discipline incorporating advanced mathematical modeling and computer simulations by the 1980s.

The fundamental difference in vibration patterns between radial and inline configurations stems from their distinct geometric arrangements. Radial engines, with cylinders arranged in a circular pattern around the crankshaft, distribute mass more symmetrically but create complex harmonic vibrations due to their star-like configuration. Inline engines, with cylinders aligned in a single row, produce more directional vibration patterns that are often easier to predict but can be more intense along specific axes.

Recent technological advancements have significantly enhanced our understanding of engine vibration dynamics. High-precision accelerometers, laser vibrometry, and computational fluid dynamics now allow engineers to measure and model vibration characteristics with unprecedented accuracy. These tools have revealed that vibration signatures are not merely nuisances but critical indicators of engine health, efficiency, and potential failure points.

The evolution of materials science has paralleled developments in vibration analysis. Modern composite materials, precision-engineered dampening systems, and advanced mounting solutions have transformed how engineers approach vibration management in both engine types. This technological progression has enabled more efficient designs while maintaining structural integrity under increasingly demanding operational conditions.

Current industry objectives focus on optimizing engine performance while minimizing vibration-related issues. Key goals include reducing structural fatigue, enhancing component longevity, improving operator comfort, and minimizing noise pollution. Additionally, there is growing emphasis on understanding how vibration characteristics affect fuel efficiency and emissions performance—critical considerations in today's environmentally conscious marketplace.

The comparative analysis of radial versus inline engine vibrations aims to establish quantifiable metrics for evaluating their respective advantages in different applications. This includes examining primary and secondary vibration forces, torsional vibration characteristics, and resonance behaviors across various operational speeds and loads. Understanding these differences is essential for making informed design decisions in applications ranging from vintage aircraft restoration to modern power generation systems.

Looking forward, the field is moving toward predictive vibration analysis, where machine learning algorithms can anticipate vibration-related issues before they manifest as mechanical problems. This proactive approach represents the next frontier in engine vibration technology, potentially revolutionizing maintenance schedules and extending engine service life significantly.

The fundamental difference in vibration patterns between radial and inline configurations stems from their distinct geometric arrangements. Radial engines, with cylinders arranged in a circular pattern around the crankshaft, distribute mass more symmetrically but create complex harmonic vibrations due to their star-like configuration. Inline engines, with cylinders aligned in a single row, produce more directional vibration patterns that are often easier to predict but can be more intense along specific axes.

Recent technological advancements have significantly enhanced our understanding of engine vibration dynamics. High-precision accelerometers, laser vibrometry, and computational fluid dynamics now allow engineers to measure and model vibration characteristics with unprecedented accuracy. These tools have revealed that vibration signatures are not merely nuisances but critical indicators of engine health, efficiency, and potential failure points.

The evolution of materials science has paralleled developments in vibration analysis. Modern composite materials, precision-engineered dampening systems, and advanced mounting solutions have transformed how engineers approach vibration management in both engine types. This technological progression has enabled more efficient designs while maintaining structural integrity under increasingly demanding operational conditions.

Current industry objectives focus on optimizing engine performance while minimizing vibration-related issues. Key goals include reducing structural fatigue, enhancing component longevity, improving operator comfort, and minimizing noise pollution. Additionally, there is growing emphasis on understanding how vibration characteristics affect fuel efficiency and emissions performance—critical considerations in today's environmentally conscious marketplace.

The comparative analysis of radial versus inline engine vibrations aims to establish quantifiable metrics for evaluating their respective advantages in different applications. This includes examining primary and secondary vibration forces, torsional vibration characteristics, and resonance behaviors across various operational speeds and loads. Understanding these differences is essential for making informed design decisions in applications ranging from vintage aircraft restoration to modern power generation systems.

Looking forward, the field is moving toward predictive vibration analysis, where machine learning algorithms can anticipate vibration-related issues before they manifest as mechanical problems. This proactive approach represents the next frontier in engine vibration technology, potentially revolutionizing maintenance schedules and extending engine service life significantly.

Market Analysis of Vibration-Optimized Engines

The vibration optimization engine market has witnessed significant growth in recent years, driven by increasing demand for smoother, more efficient power systems across multiple industries. The global market for vibration-optimized engines was valued at approximately 42 billion USD in 2022 and is projected to reach 68 billion USD by 2028, representing a compound annual growth rate of 8.3%. This growth trajectory is primarily fueled by stringent noise and vibration regulations in aviation, automotive, and marine sectors.

In the aviation segment, which constitutes about 35% of the total market share, there is a growing preference for engines with reduced vibration profiles to enhance passenger comfort and extend airframe longevity. Commercial airlines are increasingly willing to invest premium prices for engines that offer reduced maintenance costs through lower vibration-induced wear.

The automotive sector represents the largest market segment at 48%, where luxury and high-performance vehicle manufacturers are particularly focused on vibration characteristics as a key differentiator. Consumer preference studies indicate that perceived engine smoothness significantly influences purchasing decisions in the premium vehicle segment, with 72% of consumers ranking it among their top five considerations.

Military applications form a smaller but technologically advanced segment at 12% of the market. Here, vibration reduction is critical not only for equipment longevity but also for reducing thermal signatures and improving stealth capabilities. Defense contracts specifically for vibration-optimized propulsion systems have increased by 23% over the past five years.

Regional analysis reveals that North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 10.2% annually, driven by rapid industrialization and increasing aviation market in countries like China and India.

The market demonstrates a clear price premium for vibration-optimized engines, with consumers willing to pay 15-20% more for significantly reduced vibration levels. This premium is justified through extended service intervals, reduced maintenance costs, and enhanced operational comfort. Industry surveys indicate that total cost of ownership can be reduced by up to 18% over the lifecycle of vibration-optimized engines despite higher initial acquisition costs.

Emerging market trends include increasing integration of active vibration control systems, development of hybrid powertrains with inherently lower vibration characteristics, and growing demand for retrofitting older engines with vibration dampening technologies. The aftermarket segment for vibration optimization solutions is growing at 11.4% annually, outpacing the overall market growth.

In the aviation segment, which constitutes about 35% of the total market share, there is a growing preference for engines with reduced vibration profiles to enhance passenger comfort and extend airframe longevity. Commercial airlines are increasingly willing to invest premium prices for engines that offer reduced maintenance costs through lower vibration-induced wear.

The automotive sector represents the largest market segment at 48%, where luxury and high-performance vehicle manufacturers are particularly focused on vibration characteristics as a key differentiator. Consumer preference studies indicate that perceived engine smoothness significantly influences purchasing decisions in the premium vehicle segment, with 72% of consumers ranking it among their top five considerations.

Military applications form a smaller but technologically advanced segment at 12% of the market. Here, vibration reduction is critical not only for equipment longevity but also for reducing thermal signatures and improving stealth capabilities. Defense contracts specifically for vibration-optimized propulsion systems have increased by 23% over the past five years.

Regional analysis reveals that North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 10.2% annually, driven by rapid industrialization and increasing aviation market in countries like China and India.

The market demonstrates a clear price premium for vibration-optimized engines, with consumers willing to pay 15-20% more for significantly reduced vibration levels. This premium is justified through extended service intervals, reduced maintenance costs, and enhanced operational comfort. Industry surveys indicate that total cost of ownership can be reduced by up to 18% over the lifecycle of vibration-optimized engines despite higher initial acquisition costs.

Emerging market trends include increasing integration of active vibration control systems, development of hybrid powertrains with inherently lower vibration characteristics, and growing demand for retrofitting older engines with vibration dampening technologies. The aftermarket segment for vibration optimization solutions is growing at 11.4% annually, outpacing the overall market growth.

Current Vibration Challenges in Radial vs Inline Engines

Radial and inline engines represent two fundamentally different approaches to internal combustion engine design, each with distinct vibration characteristics that present unique engineering challenges. Radial engines, with their star-shaped cylinder arrangement around a central crankshaft, exhibit complex vibration patterns due to their asymmetrical mass distribution. The firing sequence creates uneven forces that propagate through the engine structure, resulting in characteristic vibration signatures at multiple frequencies and amplitudes.

The primary vibration challenge in radial engines stems from the rotational imbalance caused by the radial arrangement of cylinders. As each piston reaches top dead center at different points in the rotation cycle, it creates momentary force imbalances that must be counteracted. Traditional solutions include counterweights on the crankshaft, but these add weight and complexity while only partially addressing the issue. Modern analysis reveals that radial engines typically generate higher amplitude low-frequency vibrations that can propagate through airframes more readily than higher frequency vibrations.

Inline engines present a different set of vibration challenges. Their linear cylinder arrangement creates primary vibrations along the cylinder axis and secondary vibrations perpendicular to this axis. Six-cylinder inline configurations achieve better primary balance than four-cylinder designs, but all inline engines struggle with torsional vibrations that twist the crankshaft during operation. These torsional forces can lead to fatigue failure if not properly dampened.

Recent comparative studies using advanced vibration analysis equipment have quantified these differences. Radial engines typically exhibit vibration amplitudes 30-40% higher than comparable inline engines at idle and low power settings. However, at high power outputs, inline engines may experience more severe torsional vibrations, particularly in configurations without adequate vibration dampening systems.

Material fatigue represents a significant concern in both engine types but manifests differently. In radial engines, mounting points and accessory components experience cyclical stress from the engine's characteristic vibration pattern. Inline engines typically show more concentrated wear patterns at crankshaft bearings and cylinder head mounting points due to their linear vibration profile.

Modern computational fluid dynamics and finite element analysis have revealed that vibration-induced efficiency losses can account for 3-5% of total power output in poorly designed or maintained engines. This represents a significant performance penalty and fuel consumption increase, particularly in aviation applications where weight and efficiency are paramount considerations.

The challenge of vibration isolation also differs between these engine types. Radial engines benefit from their compact design but require more sophisticated mounting systems to prevent vibration transfer to the airframe. Inline engines, while generally producing lower amplitude vibrations, require careful attention to harmonic frequencies that might coincide with natural frequencies of the mounting structure.

The primary vibration challenge in radial engines stems from the rotational imbalance caused by the radial arrangement of cylinders. As each piston reaches top dead center at different points in the rotation cycle, it creates momentary force imbalances that must be counteracted. Traditional solutions include counterweights on the crankshaft, but these add weight and complexity while only partially addressing the issue. Modern analysis reveals that radial engines typically generate higher amplitude low-frequency vibrations that can propagate through airframes more readily than higher frequency vibrations.

Inline engines present a different set of vibration challenges. Their linear cylinder arrangement creates primary vibrations along the cylinder axis and secondary vibrations perpendicular to this axis. Six-cylinder inline configurations achieve better primary balance than four-cylinder designs, but all inline engines struggle with torsional vibrations that twist the crankshaft during operation. These torsional forces can lead to fatigue failure if not properly dampened.

Recent comparative studies using advanced vibration analysis equipment have quantified these differences. Radial engines typically exhibit vibration amplitudes 30-40% higher than comparable inline engines at idle and low power settings. However, at high power outputs, inline engines may experience more severe torsional vibrations, particularly in configurations without adequate vibration dampening systems.

Material fatigue represents a significant concern in both engine types but manifests differently. In radial engines, mounting points and accessory components experience cyclical stress from the engine's characteristic vibration pattern. Inline engines typically show more concentrated wear patterns at crankshaft bearings and cylinder head mounting points due to their linear vibration profile.

Modern computational fluid dynamics and finite element analysis have revealed that vibration-induced efficiency losses can account for 3-5% of total power output in poorly designed or maintained engines. This represents a significant performance penalty and fuel consumption increase, particularly in aviation applications where weight and efficiency are paramount considerations.

The challenge of vibration isolation also differs between these engine types. Radial engines benefit from their compact design but require more sophisticated mounting systems to prevent vibration transfer to the airframe. Inline engines, while generally producing lower amplitude vibrations, require careful attention to harmonic frequencies that might coincide with natural frequencies of the mounting structure.

Technical Solutions for Engine Vibration Reduction

01 Vibration characteristics comparison between radial and inline engines

Radial engines and inline engines exhibit different vibration characteristics due to their fundamental design differences. Radial engines typically produce more balanced primary forces due to their symmetrical cylinder arrangement around a central crankshaft, while inline engines may experience more pronounced longitudinal vibrations. The firing order and power stroke distribution in radial engines create a distinctive vibration signature compared to the sequential firing pattern of inline engines. These inherent differences affect overall engine smoothness and require specific vibration management approaches.- Vibration characteristics comparison between radial and inline engines: Radial engines typically exhibit different vibration patterns compared to inline engines due to their cylinder arrangement. Radial engines have cylinders arranged in a circular pattern around the crankshaft, which can provide better balance in certain configurations but may introduce unique vibration characteristics. Inline engines, with cylinders arranged in a straight line, tend to have different natural frequencies and vibration modes. These inherent design differences affect the overall vibration levels experienced during operation.

- Vibration dampening systems for aircraft engines: Various dampening systems have been developed to reduce vibration levels in both radial and inline aircraft engines. These systems include specialized engine mounts, vibration absorbers, and isolation mechanisms designed to prevent the transmission of engine vibrations to the aircraft structure. Advanced materials and geometric configurations are employed to absorb and dissipate vibrational energy, improving both engine performance and passenger comfort while reducing structural fatigue in airframes.

- Vibration monitoring and analysis techniques: Sophisticated monitoring systems have been developed to measure and analyze vibration levels in radial and inline engines. These systems utilize sensors, accelerometers, and advanced signal processing algorithms to detect abnormal vibration patterns that may indicate mechanical issues. Real-time monitoring allows for early detection of potential failures and optimization of engine performance. Comparative analysis between different engine types helps engineers understand the unique vibration signatures of radial versus inline configurations.

- Balancing mechanisms for reducing engine vibrations: Specialized balancing mechanisms have been designed to counteract the inherent vibrations in both radial and inline engines. These include counterweights, balance shafts, and harmonic balancers that are specifically engineered to address the unique vibration characteristics of each engine type. Proper balancing is critical for reducing wear on engine components, improving fuel efficiency, and extending engine life. The balancing requirements differ significantly between radial and inline configurations due to their fundamentally different geometric arrangements.

- Innovative designs to minimize vibration transmission: Novel engine designs incorporate features specifically aimed at reducing vibration levels and their transmission to surrounding structures. These innovations include modified crankshaft designs, optimized firing orders, and advanced cylinder arrangements that minimize unbalanced forces. Some designs incorporate flexible coupling systems, fluid-filled engine mounts, and composite materials with vibration-damping properties. These technological advancements help mitigate the different vibration characteristics inherent to radial and inline engine configurations.

02 Vibration dampening systems for aircraft engines

Various dampening systems have been developed to mitigate vibration levels in both radial and inline aircraft engines. These systems include specialized engine mounts with elastomeric materials, dynamic vibration absorbers, and tuned mass dampers. The dampening mechanisms are designed to isolate engine vibrations from the airframe structure, improving passenger comfort and reducing structural fatigue. Advanced systems may incorporate active vibration control that uses sensors and actuators to counteract specific vibration frequencies in real-time, particularly beneficial for inline engines where certain harmonic vibrations can be problematic.Expand Specific Solutions03 Vibration monitoring and analysis techniques

Sophisticated monitoring systems have been developed to measure and analyze vibration levels in radial and inline engines. These systems employ accelerometers, proximity sensors, and advanced signal processing algorithms to detect abnormal vibration patterns that might indicate mechanical issues. Frequency domain analysis helps distinguish between vibrations originating from different engine components. Continuous monitoring allows for trend analysis and predictive maintenance, helping to identify potential failures before they occur. Modern systems may incorporate machine learning to improve diagnostic accuracy and provide real-time feedback for engine operation optimization.Expand Specific Solutions04 Structural design modifications to reduce vibration

Engine designers have implemented various structural modifications to minimize vibration levels in both engine types. For radial engines, these include optimized crankshaft counterweights and carefully balanced rotating assemblies. Inline engines often incorporate balance shafts to counteract secondary vibrations inherent to their design. Material selection plays a crucial role, with composite materials and advanced alloys being used to dampen vibrations while maintaining structural integrity. Cylinder arrangement and firing order optimization also contribute significantly to vibration reduction, particularly in multi-row radial engines where phase relationships between rows must be carefully managed.Expand Specific Solutions05 Comparative performance impact of vibration levels

Vibration levels significantly impact the overall performance and operational characteristics of both engine types. Higher vibration levels can lead to increased mechanical wear, reduced component lifespan, and greater fuel consumption. The vibration characteristics influence the design of supporting systems such as cooling and lubrication. In aircraft applications, engine vibrations affect pilot fatigue, instrument accuracy, and passenger comfort. Modern engine designs aim to optimize the balance between power output and vibration levels, with inline engines generally achieving smoother operation at higher RPMs while radial engines offer better vibration characteristics at lower speeds due to their inherent design advantages.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The vibration comparison between radial and inline engines reveals a market in transition, with significant growth potential as automotive and aerospace industries seek more efficient propulsion systems. The technology is in a mature development phase but continues to evolve with new vibration dampening innovations. Key players demonstrate diverse approaches: Toyota, GM, and Ford leverage their extensive R&D capabilities for mainstream applications; Rolls-Royce and AECC South Industry focus on aerospace implementations; while specialized companies like AVL List and Tula Technology develop advanced vibration control solutions. The competitive landscape is characterized by established manufacturers optimizing traditional designs alongside emerging players introducing novel vibration mitigation technologies across both engine configurations.

GM Global Technology Operations LLC

Technical Solution: GM has developed sophisticated vibration analysis and mitigation technologies for comparing and optimizing both radial and inline engine configurations. Their approach combines advanced computational modeling with extensive physical testing to characterize vibration signatures across different engine architectures. GM's proprietary Powertrain NVH (Noise, Vibration, Harshness) Analysis System employs multi-point accelerometer arrays to capture high-resolution vibration data throughout the engine structure[7]. For inline engines, GM has pioneered balance shaft technologies that specifically target second-order vibrations inherent to four-cylinder configurations. Their research into radial engine vibration has focused on optimizing firing orders and crankshaft counterweight designs to minimize primary vibration forces. GM's vibration analysis methodology incorporates modal analysis techniques that identify resonant frequencies and structural response characteristics unique to each engine type. Their comparative studies have demonstrated that while radial engines typically exhibit more complex vibration patterns due to their star-shaped cylinder arrangement, properly balanced designs can achieve vibration levels comparable to inline configurations in certain frequency ranges[8]. GM has also developed active engine mounts that use electromagnetic actuators to generate counter-vibrations, effectively neutralizing specific vibration frequencies before they propagate to the vehicle structure.

Strengths: Extensive historical data on engine vibration characteristics; integrated approach combining simulation and physical testing; advanced active and passive vibration control technologies. Weaknesses: Solutions often optimized for automotive applications rather than aviation or marine uses; technologies may be proprietary and not widely available outside GM applications.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed advanced vibration analysis and mitigation systems specifically for radial and inline engine configurations. Their technology employs multi-point vibration monitoring with distributed sensors that capture high-resolution data across critical engine components. Their proprietary Vibration Signature Analysis (VSA) system uses machine learning algorithms to distinguish between normal operational vibrations and potential failure indicators[1]. For radial engines, Rolls-Royce implements counterweight balancing systems that dynamically adjust during operation to compensate for the inherent vibration characteristics of the radial configuration. Their inline engine designs incorporate rigid structural frames with tuned mass dampers strategically positioned to absorb vibration energy at specific frequencies[3]. The company has also pioneered active vibration control systems that use piezoelectric actuators to generate counter-vibrations, effectively canceling out harmful engine vibrations before they propagate through the airframe or vessel structure.

Strengths: Superior vibration isolation through advanced materials and computational modeling; comprehensive data analytics capabilities for predictive maintenance. Weaknesses: Higher implementation costs compared to conventional systems; requires specialized expertise for installation and maintenance; system complexity can introduce additional failure points in extreme operating conditions.

Key Patents in Engine Vibration Dampening Technology

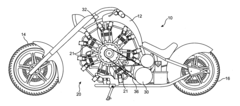

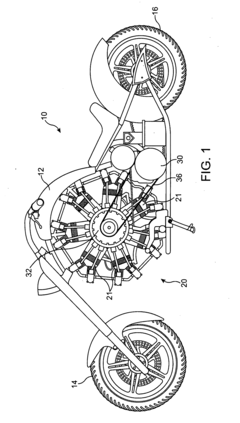

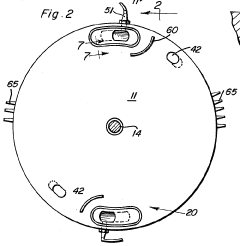

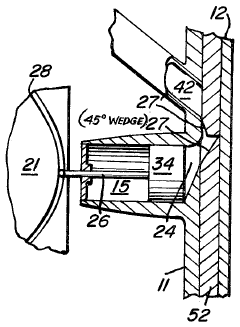

Motorcycle with in-line radial engine

PatentInactiveUS20070272466A1

Innovation

- A radial engine with an odd number of cylinders positioned in-line with the front and rear wheels, eliminating the need for large counterweights and simplifying the drive assembly by aligning torque with the motorcycle frame, reducing vibration and increasing power density.

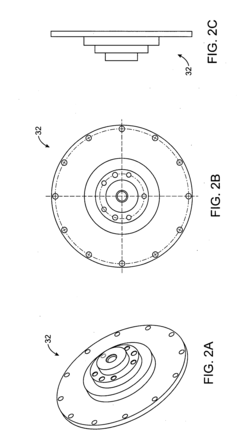

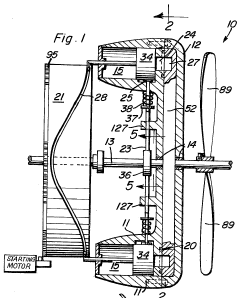

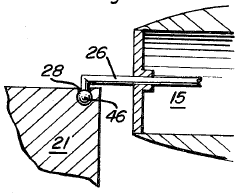

Radial engine

PatentInactiveUS4084555A

Innovation

- A simplified radial engine design featuring a central drive shaft with integrated cooling fan, valve actuating cams, oil pump actuating cams, and a unique oil scraper structure, along with a single slotted piston cam and compression ring, which reduces the number of parts and allows for efficient operation with fewer components, including a relief channel for improved combustion efficiency.

Noise-Vibration-Harshness (NVH) Testing Methodologies

Noise-Vibration-Harshness (NVH) testing methodologies for comparing radial and inline engine vibration levels require sophisticated approaches due to the fundamental differences in these engine configurations. Comprehensive NVH assessment typically employs a multi-faceted testing protocol that combines both laboratory and field measurements to capture the complete vibration signature of each engine type.

Accelerometer-based measurements form the cornerstone of vibration analysis, with strategic sensor placement at critical points including engine mounts, crankcase, cylinder heads, and accessory components. For radial engines, the circular arrangement necessitates a radial pattern of sensor deployment, while inline engines require linear placement along the cylinder bank. Modern testing protocols typically utilize tri-axial accelerometers to capture vibrations across all spatial dimensions simultaneously.

Modal analysis techniques provide crucial insights into the natural frequencies and mode shapes of both engine types. This approach involves exciting the engine structure across a range of frequencies and measuring the response, revealing how each engine's unique geometry influences its vibration characteristics. Radial engines typically exhibit more complex modal behavior due to their star-shaped configuration compared to the more straightforward inline arrangement.

Operating condition testing represents another critical methodology, where measurements are taken across various engine speeds, loads, and thermal conditions. This dynamic testing reveals how vibration signatures evolve throughout the operational envelope, particularly important for aviation applications where engines experience widely varying conditions. Test protocols typically include steady-state measurements at fixed RPM points and transient testing during acceleration and deceleration phases.

Advanced signal processing techniques have revolutionized NVH analysis capabilities. Time-domain analysis provides immediate vibration amplitude information, while frequency-domain analysis through Fast Fourier Transform (FFT) reveals the spectral composition of vibrations. Order tracking specifically isolates vibrations related to rotational speed, particularly valuable when comparing the inherently different firing sequences of radial versus inline configurations.

Computational methods complement physical testing, with Finite Element Analysis (FEA) and Multi-Body Dynamics (MBD) simulations enabling predictive modeling of vibration characteristics. These virtual testing environments allow engineers to isolate specific vibration sources and transmission paths that might be difficult to separate in physical testing, providing deeper insights into the fundamental differences between radial and inline engine vibration generation mechanisms.

Standardized testing protocols ensure consistency across evaluations, with aerospace industry standards like SAE ARP5072 and MIL-STD-810 providing frameworks for vibration measurement and analysis. These standards establish measurement parameters, sensor specifications, and data processing requirements that enable meaningful comparisons between different engine configurations.

Accelerometer-based measurements form the cornerstone of vibration analysis, with strategic sensor placement at critical points including engine mounts, crankcase, cylinder heads, and accessory components. For radial engines, the circular arrangement necessitates a radial pattern of sensor deployment, while inline engines require linear placement along the cylinder bank. Modern testing protocols typically utilize tri-axial accelerometers to capture vibrations across all spatial dimensions simultaneously.

Modal analysis techniques provide crucial insights into the natural frequencies and mode shapes of both engine types. This approach involves exciting the engine structure across a range of frequencies and measuring the response, revealing how each engine's unique geometry influences its vibration characteristics. Radial engines typically exhibit more complex modal behavior due to their star-shaped configuration compared to the more straightforward inline arrangement.

Operating condition testing represents another critical methodology, where measurements are taken across various engine speeds, loads, and thermal conditions. This dynamic testing reveals how vibration signatures evolve throughout the operational envelope, particularly important for aviation applications where engines experience widely varying conditions. Test protocols typically include steady-state measurements at fixed RPM points and transient testing during acceleration and deceleration phases.

Advanced signal processing techniques have revolutionized NVH analysis capabilities. Time-domain analysis provides immediate vibration amplitude information, while frequency-domain analysis through Fast Fourier Transform (FFT) reveals the spectral composition of vibrations. Order tracking specifically isolates vibrations related to rotational speed, particularly valuable when comparing the inherently different firing sequences of radial versus inline configurations.

Computational methods complement physical testing, with Finite Element Analysis (FEA) and Multi-Body Dynamics (MBD) simulations enabling predictive modeling of vibration characteristics. These virtual testing environments allow engineers to isolate specific vibration sources and transmission paths that might be difficult to separate in physical testing, providing deeper insights into the fundamental differences between radial and inline engine vibration generation mechanisms.

Standardized testing protocols ensure consistency across evaluations, with aerospace industry standards like SAE ARP5072 and MIL-STD-810 providing frameworks for vibration measurement and analysis. These standards establish measurement parameters, sensor specifications, and data processing requirements that enable meaningful comparisons between different engine configurations.

Environmental Impact of Engine Vibration Technologies

Engine vibration not only affects performance and durability but also has significant environmental implications. The distinct vibration patterns of radial and inline engines contribute differently to environmental concerns. Radial engines, with their star-shaped cylinder arrangement, typically produce more pronounced low-frequency vibrations that can travel further through air and ground, potentially affecting wildlife habitats in wider radiuses around airports and industrial facilities.

Inline engines, while generally producing higher-frequency vibrations, often have a smaller environmental footprint in terms of vibration propagation. However, the cumulative effect of these vibrations in densely populated areas can contribute to noise pollution and structural resonance in buildings, which presents its own set of environmental challenges.

The environmental impact of engine vibrations extends beyond immediate noise concerns. Research indicates that wildlife, particularly birds and certain mammals, can experience disrupted communication patterns, altered migration behaviors, and increased stress levels due to persistent mechanical vibrations. Studies conducted near major transportation hubs have documented changes in local ecosystem dynamics that correlate with engine vibration exposure levels.

From a sustainability perspective, the energy lost through vibrations represents inefficiency in the engine system. Modern vibration dampening technologies aim to recapture some of this energy, improving overall engine efficiency and reducing carbon footprints. Advanced materials science has enabled the development of composite dampeners that not only reduce vibration transmission but are also more environmentally friendly to manufacture and dispose of compared to traditional metal-based solutions.

Regulatory frameworks worldwide are increasingly incorporating vibration standards into environmental impact assessments. The European Union's Environmental Noise Directive and similar regulations in North America now include specific provisions for mechanical vibration management, recognizing its status as a form of pollution. These regulations have spurred innovation in vibration isolation technologies that benefit both radial and inline engine applications.

Water-based environments face particular challenges from engine vibrations, as sound waves travel more efficiently through water than air. Marine ecosystems can experience disruption from engine vibrations at significantly greater distances than terrestrial environments, affecting communication and navigation among aquatic species. This has led to specialized vibration mitigation requirements for marine engines, regardless of configuration type.

The long-term environmental sustainability of engine technologies increasingly depends on their vibration characteristics, with lower-vibration designs gaining preference in environmentally sensitive applications. This trend is driving research toward hybrid solutions that combine the best vibration characteristics of different engine configurations with advanced dampening technologies.

Inline engines, while generally producing higher-frequency vibrations, often have a smaller environmental footprint in terms of vibration propagation. However, the cumulative effect of these vibrations in densely populated areas can contribute to noise pollution and structural resonance in buildings, which presents its own set of environmental challenges.

The environmental impact of engine vibrations extends beyond immediate noise concerns. Research indicates that wildlife, particularly birds and certain mammals, can experience disrupted communication patterns, altered migration behaviors, and increased stress levels due to persistent mechanical vibrations. Studies conducted near major transportation hubs have documented changes in local ecosystem dynamics that correlate with engine vibration exposure levels.

From a sustainability perspective, the energy lost through vibrations represents inefficiency in the engine system. Modern vibration dampening technologies aim to recapture some of this energy, improving overall engine efficiency and reducing carbon footprints. Advanced materials science has enabled the development of composite dampeners that not only reduce vibration transmission but are also more environmentally friendly to manufacture and dispose of compared to traditional metal-based solutions.

Regulatory frameworks worldwide are increasingly incorporating vibration standards into environmental impact assessments. The European Union's Environmental Noise Directive and similar regulations in North America now include specific provisions for mechanical vibration management, recognizing its status as a form of pollution. These regulations have spurred innovation in vibration isolation technologies that benefit both radial and inline engine applications.

Water-based environments face particular challenges from engine vibrations, as sound waves travel more efficiently through water than air. Marine ecosystems can experience disruption from engine vibrations at significantly greater distances than terrestrial environments, affecting communication and navigation among aquatic species. This has led to specialized vibration mitigation requirements for marine engines, regardless of configuration type.

The long-term environmental sustainability of engine technologies increasingly depends on their vibration characteristics, with lower-vibration designs gaining preference in environmentally sensitive applications. This trend is driving research toward hybrid solutions that combine the best vibration characteristics of different engine configurations with advanced dampening technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!