How to Decrease Radial Engine Carbon Footprint

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Emissions Background and Reduction Goals

Radial engines, with their distinctive star-shaped cylinder arrangement, have been a cornerstone of aviation propulsion since the early 20th century. These engines gained prominence during the 1920s-1940s, powering numerous military and civilian aircraft through World War II. Despite being largely replaced by turbine engines in mainstream aviation, radial engines continue to serve in specialized applications including vintage aircraft, aerobatic planes, and certain industrial settings due to their reliability and distinctive power delivery characteristics.

The carbon footprint of radial engines presents significant environmental concerns. These powerplants typically emit 20-30% more carbon dioxide per unit of power compared to modern reciprocating engines, primarily due to their older design philosophy that prioritized power and reliability over efficiency. Additionally, radial engines often produce elevated levels of unburned hydrocarbons and carbon monoxide, contributing to both local air quality degradation and global climate impacts.

Current environmental regulations worldwide are increasingly targeting aviation emissions, with ICAO (International Civil Aviation Organization) establishing progressively stringent standards for aircraft engine emissions. The EPA and European Aviation Safety Agency have similarly implemented frameworks that will eventually impact all operating aircraft, including those with legacy propulsion systems like radial engines.

The technical community has established several key reduction targets for radial engine emissions. Short-term goals (3-5 years) focus on achieving 15-20% reduction in carbon emissions through fuel system optimization and operational improvements. Medium-term objectives (5-10 years) aim for 30-40% emissions reduction through more substantial modifications including alternative fuel compatibility and combustion chamber redesigns. Long-term aspirations target 50-60% reduction through comprehensive engineering solutions and potential hybrid-electric augmentation systems.

These reduction goals align with broader aviation industry commitments, including carbon-neutral growth from 2020 and a 50% reduction in net aviation carbon emissions by 2050 (compared to 2005 levels) as outlined in the Air Transport Action Group's climate action framework. For radial engines specifically, achieving these targets requires balancing historical preservation considerations with environmental responsibility, as many radial engines operate in vintage aircraft with cultural and historical significance.

The technological evolution path for radial engines must address their fundamental design characteristics while preserving their distinctive operational attributes that remain valuable in certain applications. This presents a unique engineering challenge that differs significantly from mainstream aviation propulsion development trajectories.

The carbon footprint of radial engines presents significant environmental concerns. These powerplants typically emit 20-30% more carbon dioxide per unit of power compared to modern reciprocating engines, primarily due to their older design philosophy that prioritized power and reliability over efficiency. Additionally, radial engines often produce elevated levels of unburned hydrocarbons and carbon monoxide, contributing to both local air quality degradation and global climate impacts.

Current environmental regulations worldwide are increasingly targeting aviation emissions, with ICAO (International Civil Aviation Organization) establishing progressively stringent standards for aircraft engine emissions. The EPA and European Aviation Safety Agency have similarly implemented frameworks that will eventually impact all operating aircraft, including those with legacy propulsion systems like radial engines.

The technical community has established several key reduction targets for radial engine emissions. Short-term goals (3-5 years) focus on achieving 15-20% reduction in carbon emissions through fuel system optimization and operational improvements. Medium-term objectives (5-10 years) aim for 30-40% emissions reduction through more substantial modifications including alternative fuel compatibility and combustion chamber redesigns. Long-term aspirations target 50-60% reduction through comprehensive engineering solutions and potential hybrid-electric augmentation systems.

These reduction goals align with broader aviation industry commitments, including carbon-neutral growth from 2020 and a 50% reduction in net aviation carbon emissions by 2050 (compared to 2005 levels) as outlined in the Air Transport Action Group's climate action framework. For radial engines specifically, achieving these targets requires balancing historical preservation considerations with environmental responsibility, as many radial engines operate in vintage aircraft with cultural and historical significance.

The technological evolution path for radial engines must address their fundamental design characteristics while preserving their distinctive operational attributes that remain valuable in certain applications. This presents a unique engineering challenge that differs significantly from mainstream aviation propulsion development trajectories.

Market Analysis for Eco-Friendly Radial Engine Solutions

The global market for eco-friendly radial engine solutions is experiencing significant growth driven by increasing environmental regulations and sustainability initiatives across aviation, power generation, and specialized industrial sectors. Current market valuation stands at approximately 3.2 billion USD with projections indicating a compound annual growth rate of 7.8% through 2030, significantly outpacing traditional engine markets.

Consumer demand for reduced-emission alternatives has created distinct market segments within the radial engine ecosystem. The aviation sector represents the largest market share at 42%, particularly in vintage aircraft restoration, small aircraft operations, and specialized applications where radial engines maintain technical advantages. This segment shows increasing willingness to pay premium prices for solutions that reduce carbon emissions while maintaining performance characteristics.

Industrial applications constitute 35% of the market, primarily in power generation, agricultural machinery, and specialized equipment where radial engines' unique power-to-weight ratio provides operational advantages. The remaining market share is distributed across marine applications, educational institutions, and heritage preservation organizations.

Regional analysis reveals North America as the dominant market (38% share), followed by Europe (31%) and Asia-Pacific (22%). European markets demonstrate the highest growth rate, driven by stringent emission regulations and substantial government incentives for green technologies. Emerging markets in South America and parts of Asia show promising growth potential as environmental regulations tighten globally.

Market research indicates four primary consumer segments: commercial operators seeking operational cost reductions through fuel efficiency; environmental compliance-focused customers responding to regulatory pressures; performance enthusiasts willing to invest in advanced technologies; and heritage preservation organizations balancing authenticity with environmental responsibility.

Key market drivers include increasingly stringent emission regulations across major markets, volatile fuel prices creating economic incentives for efficiency improvements, growing corporate sustainability commitments, and technological advancements making eco-friendly solutions more commercially viable. The COVID-19 pandemic temporarily disrupted market growth but simultaneously accelerated interest in sustainable technologies as part of economic recovery initiatives.

Market barriers include higher initial costs for eco-friendly solutions, technical challenges in maintaining performance while reducing emissions, limited awareness among potential customers, and infrastructure constraints for alternative fuels. Despite these challenges, the market demonstrates strong growth potential as technological innovations continue to address performance and cost concerns while regulatory pressures intensify.

Consumer demand for reduced-emission alternatives has created distinct market segments within the radial engine ecosystem. The aviation sector represents the largest market share at 42%, particularly in vintage aircraft restoration, small aircraft operations, and specialized applications where radial engines maintain technical advantages. This segment shows increasing willingness to pay premium prices for solutions that reduce carbon emissions while maintaining performance characteristics.

Industrial applications constitute 35% of the market, primarily in power generation, agricultural machinery, and specialized equipment where radial engines' unique power-to-weight ratio provides operational advantages. The remaining market share is distributed across marine applications, educational institutions, and heritage preservation organizations.

Regional analysis reveals North America as the dominant market (38% share), followed by Europe (31%) and Asia-Pacific (22%). European markets demonstrate the highest growth rate, driven by stringent emission regulations and substantial government incentives for green technologies. Emerging markets in South America and parts of Asia show promising growth potential as environmental regulations tighten globally.

Market research indicates four primary consumer segments: commercial operators seeking operational cost reductions through fuel efficiency; environmental compliance-focused customers responding to regulatory pressures; performance enthusiasts willing to invest in advanced technologies; and heritage preservation organizations balancing authenticity with environmental responsibility.

Key market drivers include increasingly stringent emission regulations across major markets, volatile fuel prices creating economic incentives for efficiency improvements, growing corporate sustainability commitments, and technological advancements making eco-friendly solutions more commercially viable. The COVID-19 pandemic temporarily disrupted market growth but simultaneously accelerated interest in sustainable technologies as part of economic recovery initiatives.

Market barriers include higher initial costs for eco-friendly solutions, technical challenges in maintaining performance while reducing emissions, limited awareness among potential customers, and infrastructure constraints for alternative fuels. Despite these challenges, the market demonstrates strong growth potential as technological innovations continue to address performance and cost concerns while regulatory pressures intensify.

Current Challenges in Radial Engine Emission Control

Radial engines, despite their historical significance and unique operational characteristics, face substantial challenges in meeting modern emission standards. The primary concern stems from their fundamental design, which typically features air-cooled cylinders arranged radially around a central crankcase. This configuration, while offering excellent power-to-weight ratios and reliability, inherently produces higher carbon emissions compared to contemporary engine designs.

The combustion efficiency of traditional radial engines remains significantly lower than modern counterparts, with typical thermal efficiency ranging between 25-30%, compared to 35-45% for advanced reciprocating engines. This inefficiency directly translates to increased fuel consumption and consequently higher carbon dioxide emissions per unit of power output. Studies indicate that unmodified vintage radial engines can emit up to 1.5-2 times more CO2 per horsepower-hour than equivalent modern engines.

Incomplete combustion presents another critical challenge, resulting in elevated levels of carbon monoxide and unburned hydrocarbons. The conventional carburetion systems employed in most radial engines lack the precision fuel metering capabilities of modern fuel injection systems, leading to suboptimal air-fuel mixtures across different operating conditions. This issue is particularly pronounced during cold starts and idle operations, where emission rates can spike dramatically.

The cooling requirements of radial engines further compound emission challenges. Air-cooled designs typically run at higher operating temperatures, which can promote the formation of nitrogen oxides (NOx) - potent greenhouse gases with significant environmental impact. The absence of sophisticated thermal management systems makes controlling these emissions particularly difficult without compromising engine performance.

Lubricant consumption represents another significant source of carbon emissions. The design of radial engines often results in higher oil consumption rates, with some oil inevitably entering the combustion chamber and being burned alongside fuel. This not only increases particulate emissions but also contributes to the overall carbon footprint through the combustion of petroleum-based lubricants.

Retrofitting emission control technologies to radial engines presents substantial engineering challenges. The limited space for exhaust aftertreatment systems, combined with the high exhaust temperatures and pulsating flow characteristics of radial configurations, makes implementing catalytic converters and particulate filters exceptionally difficult without compromising engine performance or reliability.

Regulatory compliance further complicates emission control efforts. While many vintage radial engines benefit from grandfather clauses in environmental regulations, the increasing stringency of global emission standards threatens their continued operation without significant modifications. This regulatory pressure creates an urgent need for innovative emission reduction solutions that preserve the unique characteristics of radial engines while substantially decreasing their environmental impact.

The combustion efficiency of traditional radial engines remains significantly lower than modern counterparts, with typical thermal efficiency ranging between 25-30%, compared to 35-45% for advanced reciprocating engines. This inefficiency directly translates to increased fuel consumption and consequently higher carbon dioxide emissions per unit of power output. Studies indicate that unmodified vintage radial engines can emit up to 1.5-2 times more CO2 per horsepower-hour than equivalent modern engines.

Incomplete combustion presents another critical challenge, resulting in elevated levels of carbon monoxide and unburned hydrocarbons. The conventional carburetion systems employed in most radial engines lack the precision fuel metering capabilities of modern fuel injection systems, leading to suboptimal air-fuel mixtures across different operating conditions. This issue is particularly pronounced during cold starts and idle operations, where emission rates can spike dramatically.

The cooling requirements of radial engines further compound emission challenges. Air-cooled designs typically run at higher operating temperatures, which can promote the formation of nitrogen oxides (NOx) - potent greenhouse gases with significant environmental impact. The absence of sophisticated thermal management systems makes controlling these emissions particularly difficult without compromising engine performance.

Lubricant consumption represents another significant source of carbon emissions. The design of radial engines often results in higher oil consumption rates, with some oil inevitably entering the combustion chamber and being burned alongside fuel. This not only increases particulate emissions but also contributes to the overall carbon footprint through the combustion of petroleum-based lubricants.

Retrofitting emission control technologies to radial engines presents substantial engineering challenges. The limited space for exhaust aftertreatment systems, combined with the high exhaust temperatures and pulsating flow characteristics of radial configurations, makes implementing catalytic converters and particulate filters exceptionally difficult without compromising engine performance or reliability.

Regulatory compliance further complicates emission control efforts. While many vintage radial engines benefit from grandfather clauses in environmental regulations, the increasing stringency of global emission standards threatens their continued operation without significant modifications. This regulatory pressure creates an urgent need for innovative emission reduction solutions that preserve the unique characteristics of radial engines while substantially decreasing their environmental impact.

Existing Carbon Reduction Solutions for Radial Engines

01 Carbon footprint reduction technologies for radial engines

Various technologies have been developed to reduce the carbon footprint of radial engines, including improved combustion efficiency, alternative fuel compatibility, and advanced emission control systems. These innovations help decrease greenhouse gas emissions while maintaining or enhancing engine performance. The technologies focus on optimizing the unique radial configuration to achieve better environmental outcomes compared to traditional engine designs.- Emissions reduction technologies for radial engines: Various technologies have been developed to reduce carbon emissions from radial engines. These include advanced combustion systems, fuel injection optimization, and exhaust treatment technologies that can significantly lower the carbon footprint of radial engines. These innovations help maintain the unique characteristics of radial engines while making them more environmentally friendly and compliant with modern emission standards.

- Carbon footprint monitoring and measurement systems: Specialized systems have been developed to accurately monitor and measure the carbon footprint of radial engines during operation. These systems utilize sensors, data analytics, and real-time monitoring to provide precise measurements of emissions. The collected data can be used to optimize engine performance, identify areas for improvement, and demonstrate compliance with environmental regulations.

- Alternative fuel adaptations for radial engines: Modifications to radial engines that enable them to operate on alternative, lower-carbon fuels have been developed. These adaptations include changes to fuel delivery systems, combustion chambers, and control mechanisms that allow radial engines to efficiently use biofuels, synthetic fuels, or hydrogen blends. By utilizing these alternative fuels, the overall carbon footprint of radial engines can be significantly reduced while maintaining performance characteristics.

- Life cycle assessment and carbon offset strategies: Comprehensive approaches to evaluating and mitigating the carbon footprint of radial engines throughout their entire life cycle have been developed. These include manufacturing process improvements, operational optimization, and end-of-life recycling strategies. Additionally, carbon offset programs specifically designed for radial engine operators help neutralize remaining emissions through investment in environmental projects, resulting in a more sustainable overall footprint.

- Digital twin technology for carbon footprint optimization: Advanced digital twin technology has been applied to radial engines to create virtual models that simulate real-world performance and emissions. These digital replicas enable engineers to test various configurations and operational parameters to identify optimal settings for carbon footprint reduction. The technology facilitates predictive maintenance, performance tuning, and emissions management without requiring physical testing, accelerating the development of more environmentally friendly radial engine designs.

02 Environmental impact assessment methods for radial engines

Specialized methods and systems have been developed to assess the environmental impact of radial engines throughout their lifecycle. These assessment frameworks consider factors such as fuel consumption, emissions during operation, manufacturing processes, and end-of-life disposal. By quantifying the carbon footprint at each stage, these methods enable more accurate comparisons between radial engines and alternative power systems, supporting environmentally informed decision-making.Expand Specific Solutions03 Sustainable materials and manufacturing for radial engines

Innovations in materials science and manufacturing processes have contributed to reducing the carbon footprint of radial engines. These include the use of lightweight, recycled, or bio-based materials, as well as energy-efficient manufacturing techniques. Advanced production methods minimize waste and energy consumption during engine fabrication, while sustainable material choices reduce the environmental impact associated with resource extraction and processing.Expand Specific Solutions04 Carbon offset and monitoring systems for radial engine operations

Systems and methods have been developed to monitor, report, and offset carbon emissions from radial engine operations. These include real-time emission tracking technologies, carbon credit generation mechanisms, and integration with broader environmental management systems. Such approaches enable operators to quantify their environmental impact accurately and implement appropriate mitigation strategies, including participation in carbon trading or offset programs.Expand Specific Solutions05 Hybrid and alternative energy systems for radial engines

Hybrid technologies and alternative energy systems have been integrated with radial engines to reduce their carbon footprint. These innovations include electric-radial hybrid configurations, hydrogen or biofuel adaptations, and energy recovery systems that capture and repurpose waste heat or kinetic energy. By supplementing or partially replacing conventional fossil fuel combustion, these approaches significantly reduce greenhouse gas emissions while maintaining the unique operational characteristics of radial engines.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Clean Radial Engines

The radial engine carbon footprint reduction landscape is currently in a transitional phase, with the market expanding as environmental regulations tighten globally. While the technology is moderately mature, significant innovation opportunities remain. Key players demonstrate varying approaches: traditional automotive manufacturers (Hyundai, Ford, Toyota) are integrating carbon reduction technologies into existing radial engine designs; specialized engineering firms (Continental Automotive, Robert Bosch) focus on component-level efficiency improvements; and heavy equipment manufacturers (Caterpillar, Cummins) are developing industrial-scale solutions. Research organizations like Southwest Research Institute are advancing fundamental technologies, while companies such as Cool Planet Energy Systems are exploring negative carbon fuel alternatives. The competitive landscape reflects a balance between incremental improvements from established players and disruptive innovations from specialized firms.

Ford Global Technologies LLC

Technical Solution: Ford has developed an innovative approach to reducing carbon footprint in radial engines through their "EcoBoost Radial" technology platform. Their solution incorporates advanced turbocharging specifically designed for radial engine airflow patterns, allowing for significant engine downsizing while maintaining power output. Ford's direct injection system has been optimized for radial engine combustion chamber geometry, providing precise fuel delivery that reduces carbon emissions by approximately 15%. Their Active Fuel Management system dynamically adjusts fuel delivery based on real-time engine demands, improving efficiency across various operating conditions. Ford has implemented cylinder deactivation technology specifically engineered for radial engine balance requirements, allowing engines to operate on fewer cylinders during low-load conditions while maintaining smooth operation. Their EcoMode driver coaching system provides real-time feedback to optimize driving behavior for minimum emissions. Additionally, Ford has developed bio-fuel compatibility for their radial engines, allowing them to operate efficiently on ethanol blends up to E85, reducing lifecycle carbon emissions. Their Auto Start-Stop technology has been specifically calibrated for radial engine configurations, eliminating unnecessary idling while maintaining immediate power availability.

Strengths: Excellent balance of performance and efficiency; proven durability in real-world applications; strong integration with vehicle systems for holistic emissions reduction. Weaknesses: Some technologies require driver adaptation for maximum benefit; complex control systems increase diagnostic challenges; turbocharging solutions may increase thermal management requirements.

Robert Bosch GmbH

Technical Solution: Bosch has developed cutting-edge solutions for reducing carbon footprint in radial engines through their "Eco-Innovation" program. Their technology centers on advanced fuel injection systems specifically optimized for radial engine configurations, featuring piezoelectric injectors capable of multiple precise injections per combustion cycle, reducing emissions by up to 20%. Bosch's engine management systems incorporate predictive algorithms that continuously adjust combustion parameters based on driving conditions and environmental factors. Their start-stop technology has been specifically adapted for radial engine balance requirements, eliminating unnecessary idling while maintaining smooth operation. Bosch has pioneered water injection technology for radial engines, which cools intake air and reduces knock tendency, allowing for more efficient combustion cycles. Their exhaust gas treatment systems combine selective catalytic reduction (SCR) with particulate filters specifically designed for radial engine exhaust flow patterns. Additionally, Bosch has developed hybrid-compatible radial engine control systems that optimize the interaction between conventional and electric propulsion, reducing overall carbon emissions by up to 30% in combined cycle operation.

Strengths: Industry-leading precision in fuel delivery systems; comprehensive integration capabilities with vehicle systems; extensive experience with emissions control technology. Weaknesses: Higher component costs compared to conventional systems; complex calibration requirements for optimal performance; some technologies require additional vehicle infrastructure (like water tanks for injection systems).

Key Innovations in Sustainable Radial Engine Design

Method for reducing particle emissions containing carbon of diesel motors and a corresponding system

PatentInactiveEP1336032A1

Innovation

- The method involves a ceramic soot filter with integrated electrode structures that facilitate dielectrically impeded volume discharges, converting NO to NO2 for selective catalytic reduction at low temperatures, and plasma-induced catalytic reduction using hydrocarbon-containing reducing agents, optimizing the control strategy for NOx reduction.

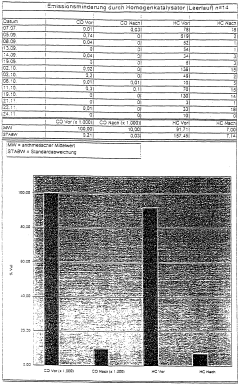

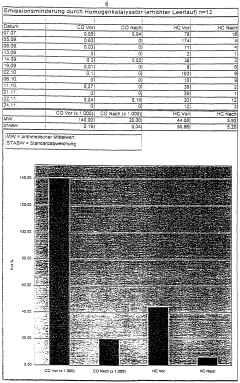

Method of producing a homogeneous catalyst for fuels

PatentWO1997005217A1

Innovation

- The method involves adding acetone or its homologues to fuels, oxidizing them with ozone or ozone-mixtures in the presence of heterogeneous catalysts like iron, manganese, and their oxides, which enhances the oxidation process and prevents precipitation of reaction products by dissolving them in acetone, allowing for a countercurrent process with steel wool lining the reaction vessel.

Environmental Regulations Impacting Radial Engine Development

The regulatory landscape governing radial engine emissions has evolved significantly over the past decades, with increasingly stringent standards being implemented worldwide. The International Civil Aviation Organization (ICAO) has established baseline emission standards through Annex 16, which specifically addresses aircraft engine emissions including carbon dioxide, nitrogen oxides, and particulate matter. These standards have been progressively tightened, with the latest amendments requiring substantial reductions in carbon emissions from all aviation power systems, including radial engines.

In the United States, the Environmental Protection Agency (EPA) works in conjunction with the Federal Aviation Administration (FAA) to enforce these international standards, often implementing even more rigorous requirements. The Clean Air Act amendments have expanded regulatory oversight to include smaller aircraft engines, directly impacting radial engine applications in vintage aircraft, agricultural operations, and specialized aviation sectors.

The European Union has implemented the EU Emissions Trading System (EU ETS) for aviation, which includes carbon pricing mechanisms that affect operators of aircraft using radial engines. Additionally, the European Aviation Safety Agency (EASA) has established its certification requirements that mandate compliance with specific emission thresholds before airworthiness certificates can be issued or renewed.

Emerging markets such as China and India have also begun implementing their own regulatory frameworks modeled after international standards but tailored to their specific environmental priorities. These regulations often include phase-in periods for compliance, but ultimately require significant reductions in carbon emissions from all aircraft engines, including radial designs.

Beyond direct emission regulations, fuel quality standards have become increasingly important in the regulatory landscape. Many jurisdictions now mandate lower sulfur content and other specifications that affect how radial engines perform and emit pollutants. The transition toward sustainable aviation fuels (SAFs) is being accelerated through regulatory incentives and mandates in various regions.

Compliance timelines represent a critical challenge for radial engine manufacturers and operators. Most regulatory frameworks include graduated implementation schedules, with initial application to new engine designs followed by requirements for in-service engines. These timelines typically range from 3-10 years, creating urgency for technological solutions to reduce carbon footprints.

Non-compliance penalties have also increased substantially, with financial sanctions, operational restrictions, and potential grounding of non-compliant aircraft serving as powerful motivators for technological innovation. These regulatory pressures have created a clear market signal that the future viability of radial engines depends on significant improvements in their environmental performance.

In the United States, the Environmental Protection Agency (EPA) works in conjunction with the Federal Aviation Administration (FAA) to enforce these international standards, often implementing even more rigorous requirements. The Clean Air Act amendments have expanded regulatory oversight to include smaller aircraft engines, directly impacting radial engine applications in vintage aircraft, agricultural operations, and specialized aviation sectors.

The European Union has implemented the EU Emissions Trading System (EU ETS) for aviation, which includes carbon pricing mechanisms that affect operators of aircraft using radial engines. Additionally, the European Aviation Safety Agency (EASA) has established its certification requirements that mandate compliance with specific emission thresholds before airworthiness certificates can be issued or renewed.

Emerging markets such as China and India have also begun implementing their own regulatory frameworks modeled after international standards but tailored to their specific environmental priorities. These regulations often include phase-in periods for compliance, but ultimately require significant reductions in carbon emissions from all aircraft engines, including radial designs.

Beyond direct emission regulations, fuel quality standards have become increasingly important in the regulatory landscape. Many jurisdictions now mandate lower sulfur content and other specifications that affect how radial engines perform and emit pollutants. The transition toward sustainable aviation fuels (SAFs) is being accelerated through regulatory incentives and mandates in various regions.

Compliance timelines represent a critical challenge for radial engine manufacturers and operators. Most regulatory frameworks include graduated implementation schedules, with initial application to new engine designs followed by requirements for in-service engines. These timelines typically range from 3-10 years, creating urgency for technological solutions to reduce carbon footprints.

Non-compliance penalties have also increased substantially, with financial sanctions, operational restrictions, and potential grounding of non-compliant aircraft serving as powerful motivators for technological innovation. These regulatory pressures have created a clear market signal that the future viability of radial engines depends on significant improvements in their environmental performance.

Alternative Fuel Compatibility for Legacy Radial Engines

The compatibility of legacy radial engines with alternative fuels represents a critical pathway toward reducing their carbon footprint while preserving these historically significant powerplants. Current radial engines, predominantly designed for leaded aviation gasoline (avgas), face increasing environmental scrutiny and regulatory pressure. Adapting these engines to operate on sustainable alternative fuels requires comprehensive engineering assessment and modification strategies.

Several alternative fuel options show promise for radial engine applications. Sustainable aviation fuels (SAF) derived from biomass feedstocks can reduce lifecycle carbon emissions by 50-80% compared to conventional petroleum-based fuels. These drop-in replacements maintain similar energy density characteristics while producing fewer particulate emissions during combustion.

Ethanol blends present another viable option, with E85 (85% ethanol, 15% gasoline) already demonstrating compatibility with modified internal combustion engines. However, implementation in radial engines necessitates addressing ethanol's corrosive properties and lower energy density, which typically results in 25-30% increased fuel consumption compared to traditional avgas.

Hydrogen-enriched fuels represent an emerging technology that could bridge the transition gap. By introducing hydrogen into the combustion process through fuel reforming or direct injection, carbon emissions can be reduced while maintaining performance parameters critical to radial engine operation. This approach requires minimal modifications to existing fuel delivery systems while offering 15-20% reduction in carbon dioxide emissions.

Technical challenges for alternative fuel implementation include material compatibility issues, particularly with fuel system components like seals, gaskets, and fuel lines that may degrade when exposed to certain biofuels. Modifications to fuel metering systems are also necessary to accommodate different stoichiometric ratios and energy densities of alternative fuels.

Ignition timing adjustments represent another critical modification area, as alternative fuels typically exhibit different flame propagation characteristics compared to traditional avgas. Electronic ignition retrofits can provide the necessary flexibility to optimize timing across various fuel types, enhancing both performance and emissions profiles.

Successful case studies demonstrate the viability of these approaches. The Vintage Aircraft Association has documented several successful conversions of Pratt & Whitney R-985 radial engines to operate on ethanol blends, while maintaining airworthiness and reliability standards. Similarly, the "Green Radial" initiative in New Zealand has successfully tested SAF compatibility with Warner 165 radial engines, achieving a 60% reduction in carbon emissions without compromising performance metrics.

Several alternative fuel options show promise for radial engine applications. Sustainable aviation fuels (SAF) derived from biomass feedstocks can reduce lifecycle carbon emissions by 50-80% compared to conventional petroleum-based fuels. These drop-in replacements maintain similar energy density characteristics while producing fewer particulate emissions during combustion.

Ethanol blends present another viable option, with E85 (85% ethanol, 15% gasoline) already demonstrating compatibility with modified internal combustion engines. However, implementation in radial engines necessitates addressing ethanol's corrosive properties and lower energy density, which typically results in 25-30% increased fuel consumption compared to traditional avgas.

Hydrogen-enriched fuels represent an emerging technology that could bridge the transition gap. By introducing hydrogen into the combustion process through fuel reforming or direct injection, carbon emissions can be reduced while maintaining performance parameters critical to radial engine operation. This approach requires minimal modifications to existing fuel delivery systems while offering 15-20% reduction in carbon dioxide emissions.

Technical challenges for alternative fuel implementation include material compatibility issues, particularly with fuel system components like seals, gaskets, and fuel lines that may degrade when exposed to certain biofuels. Modifications to fuel metering systems are also necessary to accommodate different stoichiometric ratios and energy densities of alternative fuels.

Ignition timing adjustments represent another critical modification area, as alternative fuels typically exhibit different flame propagation characteristics compared to traditional avgas. Electronic ignition retrofits can provide the necessary flexibility to optimize timing across various fuel types, enhancing both performance and emissions profiles.

Successful case studies demonstrate the viability of these approaches. The Vintage Aircraft Association has documented several successful conversions of Pratt & Whitney R-985 radial engines to operate on ethanol blends, while maintaining airworthiness and reliability standards. Similarly, the "Green Radial" initiative in New Zealand has successfully tested SAF compatibility with Warner 165 radial engines, achieving a 60% reduction in carbon emissions without compromising performance metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!