Optimize Fuel Mixture for Radial Engine Efficiency Increase

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Fuel Optimization Background and Objectives

Radial engines, with their distinctive star-shaped cylinder arrangement, have been a cornerstone of aviation propulsion since their introduction in the early 20th century. These engines reached their zenith during the 1930s and 1940s, powering numerous military and civilian aircraft through World War II. Despite being largely superseded by turbine engines in mainstream aviation, radial engines continue to serve in specialized applications including vintage aircraft restoration, aerobatic planes, and certain industrial applications where their unique characteristics remain valuable.

The evolution of radial engine technology has historically focused on mechanical improvements rather than fuel optimization. Early developments concentrated on increasing power output through larger displacements and higher cylinder counts, while reliability enhancements addressed common issues such as oil distribution and cooling efficiency. However, modern environmental regulations, rising fuel costs, and the growing emphasis on sustainable operations have shifted attention toward optimizing fuel consumption and reducing emissions.

Current technical objectives for radial engine fuel mixture optimization center around several key parameters. Primary among these is achieving a more precise air-fuel ratio control across varying operational conditions, from idle to full power, and at different altitudes. This precision is crucial for maximizing both power output and fuel economy while minimizing harmful emissions. Additionally, there is significant interest in adapting these classic engines to accommodate modern fuel formulations, including those with ethanol content and lower lead levels.

The technical challenges inherent in radial engine fuel optimization stem from their unique design characteristics. The radial configuration creates uneven fuel distribution challenges across cylinders, particularly in larger nine and fourteen-cylinder variants. The mechanical fuel delivery systems typical of these engines lack the precision of modern electronic fuel injection, making fine control of the air-fuel mixture difficult across operational ranges.

Research objectives in this field aim to develop solutions that preserve the historical integrity and operational characteristics of radial engines while incorporating modern fuel management principles. This includes investigating retrofit technologies that can enhance mixture control without extensive modification to the original engine design, exploring computational fluid dynamics to better understand fuel flow patterns within the unique radial configuration, and developing specialized fuel formulations that address the specific combustion characteristics of these engines.

The ultimate goal is to establish a technical foundation for increasing radial engine efficiency by 15-20% through optimized fuel mixture strategies, thereby extending their viable service life in an increasingly efficiency-conscious operational environment.

The evolution of radial engine technology has historically focused on mechanical improvements rather than fuel optimization. Early developments concentrated on increasing power output through larger displacements and higher cylinder counts, while reliability enhancements addressed common issues such as oil distribution and cooling efficiency. However, modern environmental regulations, rising fuel costs, and the growing emphasis on sustainable operations have shifted attention toward optimizing fuel consumption and reducing emissions.

Current technical objectives for radial engine fuel mixture optimization center around several key parameters. Primary among these is achieving a more precise air-fuel ratio control across varying operational conditions, from idle to full power, and at different altitudes. This precision is crucial for maximizing both power output and fuel economy while minimizing harmful emissions. Additionally, there is significant interest in adapting these classic engines to accommodate modern fuel formulations, including those with ethanol content and lower lead levels.

The technical challenges inherent in radial engine fuel optimization stem from their unique design characteristics. The radial configuration creates uneven fuel distribution challenges across cylinders, particularly in larger nine and fourteen-cylinder variants. The mechanical fuel delivery systems typical of these engines lack the precision of modern electronic fuel injection, making fine control of the air-fuel mixture difficult across operational ranges.

Research objectives in this field aim to develop solutions that preserve the historical integrity and operational characteristics of radial engines while incorporating modern fuel management principles. This includes investigating retrofit technologies that can enhance mixture control without extensive modification to the original engine design, exploring computational fluid dynamics to better understand fuel flow patterns within the unique radial configuration, and developing specialized fuel formulations that address the specific combustion characteristics of these engines.

The ultimate goal is to establish a technical foundation for increasing radial engine efficiency by 15-20% through optimized fuel mixture strategies, thereby extending their viable service life in an increasingly efficiency-conscious operational environment.

Market Demand Analysis for Efficient Radial Engines

The global market for radial engine efficiency solutions has been experiencing a significant resurgence in recent years, driven primarily by specialized aviation sectors and emerging applications in unmanned aerial vehicles (UAVs). Despite the widespread adoption of turbine engines in commercial aviation, radial engines maintain a strong presence in vintage aircraft restoration, agricultural aviation, and certain military applications where their unique characteristics provide distinct advantages.

Market research indicates that the vintage aircraft restoration segment alone represents a market valued at approximately $1.2 billion globally, with annual growth rates of 5.7% projected through 2028. Within this segment, fuel efficiency improvements are consistently ranked among the top three priorities by operators, creating a substantial demand for optimized fuel mixture solutions.

The agricultural aviation sector, particularly in regions with extensive farming operations such as North America, Brazil, and Australia, constitutes another significant market segment. This sector operates over 25,000 aircraft worldwide that utilize radial engines, with operators facing increasing pressure to reduce operational costs amid rising fuel prices and environmental regulations.

Environmental considerations are increasingly influencing market dynamics, with regulatory bodies worldwide implementing stricter emissions standards. The EPA's recent amendments to aviation emissions guidelines specifically target older engine technologies, creating urgent market demand for efficiency improvements that can help these engines meet new compliance requirements without necessitating complete power plant replacements.

Economic factors further amplify market demand, as fuel costs typically represent 30-40% of operational expenses for radial engine aircraft operators. Analysis of user forums and industry surveys reveals that operators would be willing to invest in fuel mixture optimization technologies that promise efficiency improvements of 8% or greater, with return on investment periods under 24 months being the most attractive proposition.

Geographically, North America leads the market with 42% share, followed by Europe at 28% and Asia-Pacific at 18%. The remaining 12% is distributed across other regions. Growth projections indicate that Asia-Pacific markets will experience the fastest expansion at 7.3% annually, driven by increasing adoption of specialized aircraft in emerging economies.

The aftermarket modification segment presents particularly promising opportunities, with over 70% of radial engine operators indicating willingness to retrofit existing engines with fuel optimization systems. This represents a potential addressable market of approximately $340 million for aftermarket solutions specifically targeting fuel mixture optimization technologies.

Market research indicates that the vintage aircraft restoration segment alone represents a market valued at approximately $1.2 billion globally, with annual growth rates of 5.7% projected through 2028. Within this segment, fuel efficiency improvements are consistently ranked among the top three priorities by operators, creating a substantial demand for optimized fuel mixture solutions.

The agricultural aviation sector, particularly in regions with extensive farming operations such as North America, Brazil, and Australia, constitutes another significant market segment. This sector operates over 25,000 aircraft worldwide that utilize radial engines, with operators facing increasing pressure to reduce operational costs amid rising fuel prices and environmental regulations.

Environmental considerations are increasingly influencing market dynamics, with regulatory bodies worldwide implementing stricter emissions standards. The EPA's recent amendments to aviation emissions guidelines specifically target older engine technologies, creating urgent market demand for efficiency improvements that can help these engines meet new compliance requirements without necessitating complete power plant replacements.

Economic factors further amplify market demand, as fuel costs typically represent 30-40% of operational expenses for radial engine aircraft operators. Analysis of user forums and industry surveys reveals that operators would be willing to invest in fuel mixture optimization technologies that promise efficiency improvements of 8% or greater, with return on investment periods under 24 months being the most attractive proposition.

Geographically, North America leads the market with 42% share, followed by Europe at 28% and Asia-Pacific at 18%. The remaining 12% is distributed across other regions. Growth projections indicate that Asia-Pacific markets will experience the fastest expansion at 7.3% annually, driven by increasing adoption of specialized aircraft in emerging economies.

The aftermarket modification segment presents particularly promising opportunities, with over 70% of radial engine operators indicating willingness to retrofit existing engines with fuel optimization systems. This represents a potential addressable market of approximately $340 million for aftermarket solutions specifically targeting fuel mixture optimization technologies.

Current Fuel Mixture Technologies and Challenges

Radial engines, despite their historical significance, continue to find applications in specialized aviation sectors. Current fuel mixture technologies for these engines face several challenges that limit their efficiency and performance. The predominant fuel delivery systems in radial engines include carburetion and fuel injection, each with distinct characteristics and limitations.

Carburetor-based systems remain common in many operational radial engines, particularly in vintage aircraft and certain specialized applications. These systems rely on venturi effects to atomize fuel and create appropriate air-fuel mixtures. However, they struggle with precise mixture control across varying operational conditions, leading to inefficiencies. Modern carburetor technologies have incorporated altitude compensation mechanisms and accelerator pumps, but fundamental limitations in mixture distribution across multiple cylinders persist.

Fuel injection systems represent a significant advancement, offering more precise control over fuel delivery. Direct port injection technologies have been adapted for some radial engine applications, providing improved cylinder-to-cylinder distribution. However, the unique geometry of radial engines presents challenges for uniform fuel delivery across all cylinders, particularly during different flight attitudes and g-force conditions.

The composition of fuels themselves presents another critical challenge. Many operational radial engines still utilize aviation gasoline (avgas) containing tetraethyl lead, which faces increasing environmental restrictions. Alternative fuels and additives have been developed, including ethanol blends and synthetic aviation fuels, but these often require significant modifications to existing engine systems and may impact performance characteristics.

Temperature management represents a significant challenge in radial engine fuel systems. The circular arrangement of cylinders creates uneven cooling patterns, affecting fuel vaporization and combustion efficiency differently across cylinders. Advanced thermal management systems have been developed, including pre-heating fuel lines and improved cowling designs, but comprehensive solutions remain elusive.

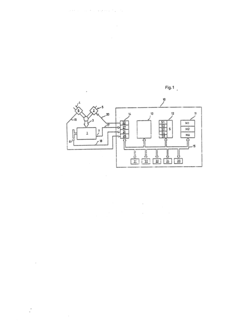

Electronic engine management systems have begun to appear in modernized radial engine applications, offering potential for real-time mixture adjustments based on operational parameters. These systems incorporate oxygen sensors, temperature monitoring, and computerized fuel mapping. However, integration challenges with traditional radial engine designs and reliability concerns in high-vibration environments have limited widespread adoption.

Emissions requirements present an emerging challenge for radial engine fuel systems. Traditional mixture settings often prioritize power output over emissions control, resulting in higher carbon monoxide and unburned hydrocarbon levels. Developing fuel mixture technologies that balance performance requirements with increasingly stringent environmental regulations represents a significant technical hurdle for continued radial engine viability.

Carburetor-based systems remain common in many operational radial engines, particularly in vintage aircraft and certain specialized applications. These systems rely on venturi effects to atomize fuel and create appropriate air-fuel mixtures. However, they struggle with precise mixture control across varying operational conditions, leading to inefficiencies. Modern carburetor technologies have incorporated altitude compensation mechanisms and accelerator pumps, but fundamental limitations in mixture distribution across multiple cylinders persist.

Fuel injection systems represent a significant advancement, offering more precise control over fuel delivery. Direct port injection technologies have been adapted for some radial engine applications, providing improved cylinder-to-cylinder distribution. However, the unique geometry of radial engines presents challenges for uniform fuel delivery across all cylinders, particularly during different flight attitudes and g-force conditions.

The composition of fuels themselves presents another critical challenge. Many operational radial engines still utilize aviation gasoline (avgas) containing tetraethyl lead, which faces increasing environmental restrictions. Alternative fuels and additives have been developed, including ethanol blends and synthetic aviation fuels, but these often require significant modifications to existing engine systems and may impact performance characteristics.

Temperature management represents a significant challenge in radial engine fuel systems. The circular arrangement of cylinders creates uneven cooling patterns, affecting fuel vaporization and combustion efficiency differently across cylinders. Advanced thermal management systems have been developed, including pre-heating fuel lines and improved cowling designs, but comprehensive solutions remain elusive.

Electronic engine management systems have begun to appear in modernized radial engine applications, offering potential for real-time mixture adjustments based on operational parameters. These systems incorporate oxygen sensors, temperature monitoring, and computerized fuel mapping. However, integration challenges with traditional radial engine designs and reliability concerns in high-vibration environments have limited widespread adoption.

Emissions requirements present an emerging challenge for radial engine fuel systems. Traditional mixture settings often prioritize power output over emissions control, resulting in higher carbon monoxide and unburned hydrocarbon levels. Developing fuel mixture technologies that balance performance requirements with increasingly stringent environmental regulations represents a significant technical hurdle for continued radial engine viability.

Existing Fuel Mixture Optimization Solutions

01 Fuel composition optimization for radial engines

Specific fuel compositions can be formulated to enhance the efficiency of radial engines. These compositions may include various additives, alternative fuels, or fuel blends that improve combustion characteristics. Optimized fuel mixtures can reduce fuel consumption, increase power output, and improve overall engine performance in radial engine configurations.- Fuel composition optimization for radial engines: Specific fuel compositions can be formulated to enhance the efficiency of radial engines. These compositions may include various additives, alternative fuels, or blended hydrocarbons that improve combustion characteristics. The optimal fuel mixture can reduce fuel consumption, increase power output, and improve overall engine performance in radial engine configurations.

- Fuel injection systems for radial engine efficiency: Advanced fuel injection systems can significantly improve the efficiency of radial engines by ensuring precise fuel delivery. These systems can optimize the air-fuel ratio, timing, and distribution pattern within the cylinders. Direct injection technologies, electronic control units, and variable injection timing mechanisms help achieve better combustion efficiency and reduced fuel consumption in radial engine applications.

- Combustion control strategies for radial engines: Various combustion control strategies can be implemented to enhance the efficiency of radial engines. These include optimizing ignition timing, managing cylinder temperatures, controlling air-fuel mixture distribution, and implementing lean-burn technologies. Advanced electronic control systems can continuously adjust these parameters based on operating conditions to maximize fuel efficiency and power output.

- Alternative fuel adaptations for radial engines: Radial engines can be modified to operate efficiently with alternative fuels such as biofuels, alcohol-based fuels, or hydrogen blends. These adaptations may require adjustments to fuel delivery systems, combustion chamber design, or engine timing. The use of alternative fuels can provide improved efficiency, reduced emissions, and better performance characteristics compared to conventional petroleum-based fuels.

- Cooling and thermal management for fuel efficiency: Effective cooling and thermal management systems are crucial for optimizing fuel efficiency in radial engines. These systems help maintain optimal operating temperatures, prevent overheating, and ensure consistent combustion conditions. Improved cooling designs can reduce thermal losses, minimize friction, and allow for more aggressive timing and mixture settings, all contributing to better fuel economy and engine performance.

02 Fuel injection systems for radial engine efficiency

Advanced fuel injection systems can significantly improve the efficiency of radial engines by ensuring precise fuel delivery. These systems can be designed to optimize the air-fuel mixture ratio, timing, and spray pattern, resulting in more complete combustion. Electronic fuel injection systems with sensors and control units can adapt to various operating conditions, further enhancing engine efficiency.Expand Specific Solutions03 Air-fuel mixture control methods

Various methods for controlling the air-fuel mixture in radial engines can improve efficiency. These include electronic control systems, mechanical adjustments, and specialized carburetion techniques. By maintaining optimal air-fuel ratios across different operating conditions, these control methods can enhance combustion efficiency, reduce emissions, and improve fuel economy in radial engines.Expand Specific Solutions04 Cooling system integration with fuel efficiency

The integration of cooling systems with fuel management can improve radial engine efficiency. By maintaining optimal operating temperatures, these integrated systems prevent overheating and ensure consistent combustion. Advanced cooling designs can reduce thermal stress on engine components, allowing for more aggressive fuel mixture settings that enhance power output while maintaining reliability.Expand Specific Solutions05 Alternative fuel adaptations for radial engines

Radial engines can be adapted to use alternative fuels such as biofuels, synthetic fuels, or hydrogen blends. These adaptations may require modifications to fuel delivery systems, combustion chambers, or control parameters. By utilizing alternative fuels, radial engines can achieve improved efficiency, reduced emissions, and potentially lower operating costs while extending the operational lifespan of these classic engine designs.Expand Specific Solutions

Key Industry Players in Radial Engine Technology

The radial engine fuel mixture optimization market is in a growth phase, with increasing demand driven by efficiency requirements in aviation and industrial applications. The market size is expanding as both traditional aerospace companies (Ford Global Technologies, Honda Motor, Exxon Mobil) and specialized engine manufacturers (Nova Werke, Edelbrock) invest in research. Technologically, the field shows moderate maturity with established players like Robert Bosch and Caterpillar developing advanced solutions, while academic institutions (Tianjin University, Beihang University) contribute fundamental research. Innovation is accelerating through specialized research organizations like Southwest Research Institute and emerging companies such as Firehawk Aerospace, which are developing novel fuel mixture technologies to achieve significant efficiency improvements in radial engine applications.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a sophisticated electronic fuel injection system specifically optimized for radial engines that addresses the unique challenges of their circular cylinder arrangement. Their system employs individual cylinder fuel mapping technology that compensates for the gravitational effects on fuel distribution in different cylinders based on their position. The Bosch MS-ECU (Motor Sport Electronic Control Unit) has been adapted for radial engines to provide precise control over fuel-air ratios across varying operational conditions. Their technology incorporates cylinder-selective lambda control that monitors and adjusts combustion in each cylinder independently, ensuring optimal fuel efficiency throughout the entire power band. Bosch's system features adaptive learning algorithms that continuously optimize fuel delivery based on environmental conditions, engine temperature, and operational parameters. Additionally, they've developed specialized injector nozzles designed to optimize fuel atomization in the unique intake geometry of radial engine cylinders, resulting in more complete combustion and reduced emissions.

Strengths: Unparalleled expertise in fuel injection systems with proven reliability across various engine applications. Comprehensive diagnostic capabilities allow for precise troubleshooting and optimization. Weaknesses: Higher implementation cost compared to traditional carburetor systems. Requires significant modification to legacy radial engine designs to accommodate electronic components.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed advanced fuel formulation technologies specifically for radial engines that focus on optimizing combustion efficiency through molecular engineering. Their approach involves custom-tailored fuel additives that modify the combustion characteristics to match the unique firing pattern and cylinder arrangement of radial engines. The company utilizes computational fluid dynamics (CFD) modeling to simulate fuel-air mixture distribution across the radial configuration, accounting for the gravitational effects on fuel distribution in different flight attitudes. Their Synergy™ fuel technology incorporates detergent additives that prevent carbon deposits in the intake valves and combustion chambers, which is particularly beneficial for radial engines that often operate at higher temperatures. ExxonMobil has also pioneered adaptive fuel mixture systems that automatically adjust the fuel-air ratio based on operating conditions, altitude, and temperature to maintain optimal efficiency across the entire flight envelope.

Strengths: Superior fuel chemistry expertise and extensive R&D capabilities allow for highly specialized formulations. Their global supply chain ensures consistent fuel quality worldwide. Weaknesses: Higher cost compared to standard aviation fuels, and implementation requires specialized fuel handling infrastructure. Limited compatibility with older radial engine designs without modifications.

Critical Patents and Research in Fuel Efficiency

System and method for preparing an optimized fuel mixture

PatentWO2008017961A2

Innovation

- A system and method that processes ambient air to produce ozone, which is introduced into the fuel gasification process, creating an optimized fuel mixture for internal combustion engines, including an ozone generator and a fuel gasifier that combines ozone with liquid fuel for efficient combustion, reducing emissions and fuel consumption.

Optimalization method for a fuel mixture

PatentInactiveEP0205861A3

Innovation

- A method and electronic injection system that calculates the fuel injection pulse width based on engine speed, load, and temperature, using multi-dimensional correction factors to adjust fuel quantity over multiple injection cycles, ensuring accurate fuel metering and reducing unburned fuel peaks.

Environmental Impact and Emission Regulations

The optimization of fuel mixtures for radial engines must be considered within the context of increasingly stringent environmental regulations and growing concerns about emissions. Radial engines, while historically significant in aviation, face mounting pressure to reduce their environmental footprint as global emission standards continue to tighten across all transportation sectors.

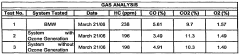

Current emission regulations for aircraft engines vary significantly by region, with the International Civil Aviation Organization (ICAO) establishing baseline standards that many countries adopt or enhance. These standards specifically target nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (UHC), and particulate matter. Radial engines, due to their design characteristics and traditional fuel mixtures, often produce higher levels of these pollutants compared to more modern engine configurations.

The environmental impact of radial engines extends beyond regulated emissions. These engines typically consume more fuel per unit of power output than their modern counterparts, resulting in higher carbon dioxide (CO2) emissions. While CO2 emissions from aviation are not universally regulated at the engine level, they are increasingly subject to carbon pricing mechanisms and fleet-wide efficiency requirements in many jurisdictions.

Fuel mixture optimization presents a significant opportunity to address these environmental challenges. Research indicates that leaner fuel mixtures can reduce certain emissions, particularly CO and UHC, but may increase NOx production if combustion temperatures rise. The trade-off between different types of emissions represents a complex optimization problem that must balance environmental requirements with performance needs.

Recent regulatory trends suggest that emission standards will continue to become more stringent, potentially threatening the viability of radial engines in certain applications unless significant improvements in fuel efficiency and emission control are achieved. The European Union's Green Deal and similar initiatives in North America and Asia signal a clear regulatory direction toward lower-emission technologies across all transportation sectors.

Sustainable alternative fuels offer another pathway to emission reduction for radial engines. Biofuels, synthetic fuels, and hydrogen-enriched mixtures have shown promise in reducing the carbon intensity of combustion engines while potentially improving certain performance characteristics. However, these alternatives often require modifications to engine components and control systems to maintain reliability and performance.

The development of aftertreatment systems specifically designed for radial engines represents another approach to meeting emission regulations. Catalytic converters, particulate filters, and exhaust gas recirculation systems adapted to the unique operating characteristics of radial engines could significantly reduce regulated emissions, though potentially at the cost of added weight and complexity.

Current emission regulations for aircraft engines vary significantly by region, with the International Civil Aviation Organization (ICAO) establishing baseline standards that many countries adopt or enhance. These standards specifically target nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (UHC), and particulate matter. Radial engines, due to their design characteristics and traditional fuel mixtures, often produce higher levels of these pollutants compared to more modern engine configurations.

The environmental impact of radial engines extends beyond regulated emissions. These engines typically consume more fuel per unit of power output than their modern counterparts, resulting in higher carbon dioxide (CO2) emissions. While CO2 emissions from aviation are not universally regulated at the engine level, they are increasingly subject to carbon pricing mechanisms and fleet-wide efficiency requirements in many jurisdictions.

Fuel mixture optimization presents a significant opportunity to address these environmental challenges. Research indicates that leaner fuel mixtures can reduce certain emissions, particularly CO and UHC, but may increase NOx production if combustion temperatures rise. The trade-off between different types of emissions represents a complex optimization problem that must balance environmental requirements with performance needs.

Recent regulatory trends suggest that emission standards will continue to become more stringent, potentially threatening the viability of radial engines in certain applications unless significant improvements in fuel efficiency and emission control are achieved. The European Union's Green Deal and similar initiatives in North America and Asia signal a clear regulatory direction toward lower-emission technologies across all transportation sectors.

Sustainable alternative fuels offer another pathway to emission reduction for radial engines. Biofuels, synthetic fuels, and hydrogen-enriched mixtures have shown promise in reducing the carbon intensity of combustion engines while potentially improving certain performance characteristics. However, these alternatives often require modifications to engine components and control systems to maintain reliability and performance.

The development of aftertreatment systems specifically designed for radial engines represents another approach to meeting emission regulations. Catalytic converters, particulate filters, and exhaust gas recirculation systems adapted to the unique operating characteristics of radial engines could significantly reduce regulated emissions, though potentially at the cost of added weight and complexity.

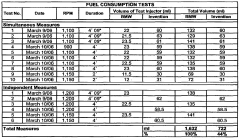

Performance Testing Methodologies and Benchmarks

Effective performance testing methodologies are essential for accurately evaluating fuel mixture optimizations in radial engines. The industry has established several standardized testing protocols that ensure reliable and reproducible results when measuring efficiency improvements. Dynamometer testing represents the primary methodology, allowing engineers to measure torque, power output, and fuel consumption under controlled conditions while systematically varying fuel mixture ratios.

Altitude chamber testing provides critical insights into how optimized fuel mixtures perform across different atmospheric conditions, particularly important for aircraft radial engines that operate at varying altitudes. These specialized chambers can simulate conditions from sea level to 40,000 feet, enabling comprehensive performance mapping across operational envelopes.

Endurance testing protocols typically involve running engines for extended periods (often 100+ hours) at various power settings to evaluate the long-term effects of modified fuel mixtures on engine components and overall efficiency. This methodology helps identify potential issues with valve seats, piston rings, and combustion chamber deposits that might only emerge after prolonged operation.

Thermal efficiency benchmarks serve as key performance indicators, with modern radial engines achieving thermal efficiencies between 25-32% depending on design and application. Leading industry benchmarks include specific fuel consumption (SFC) measurements, typically targeting below 0.45 lb/hp-hr for optimized mixtures in well-maintained radial engines.

Emissions testing has become increasingly important, with standardized procedures measuring CO, HC, NOx and particulate matter across various operational states. The correlation between emissions profiles and fuel mixture ratios provides valuable data for optimization strategies that balance efficiency with environmental considerations.

Computational fluid dynamics (CFD) simulations complement physical testing by modeling combustion dynamics and fuel distribution patterns within cylinders. These virtual benchmarks allow rapid iteration of mixture parameters before committing to hardware testing, significantly accelerating the development cycle while reducing costs.

Comparative benchmark testing against historical data provides context for improvements, with industry databases maintaining performance records for various radial engine models dating back to the 1930s. This historical perspective helps quantify the relative gains achieved through modern fuel mixture optimization techniques compared to original specifications.

Altitude chamber testing provides critical insights into how optimized fuel mixtures perform across different atmospheric conditions, particularly important for aircraft radial engines that operate at varying altitudes. These specialized chambers can simulate conditions from sea level to 40,000 feet, enabling comprehensive performance mapping across operational envelopes.

Endurance testing protocols typically involve running engines for extended periods (often 100+ hours) at various power settings to evaluate the long-term effects of modified fuel mixtures on engine components and overall efficiency. This methodology helps identify potential issues with valve seats, piston rings, and combustion chamber deposits that might only emerge after prolonged operation.

Thermal efficiency benchmarks serve as key performance indicators, with modern radial engines achieving thermal efficiencies between 25-32% depending on design and application. Leading industry benchmarks include specific fuel consumption (SFC) measurements, typically targeting below 0.45 lb/hp-hr for optimized mixtures in well-maintained radial engines.

Emissions testing has become increasingly important, with standardized procedures measuring CO, HC, NOx and particulate matter across various operational states. The correlation between emissions profiles and fuel mixture ratios provides valuable data for optimization strategies that balance efficiency with environmental considerations.

Computational fluid dynamics (CFD) simulations complement physical testing by modeling combustion dynamics and fuel distribution patterns within cylinders. These virtual benchmarks allow rapid iteration of mixture parameters before committing to hardware testing, significantly accelerating the development cycle while reducing costs.

Comparative benchmark testing against historical data provides context for improvements, with industry databases maintaining performance records for various radial engine models dating back to the 1930s. This historical perspective helps quantify the relative gains achieved through modern fuel mixture optimization techniques compared to original specifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!