Radial Engine vs Opposed-Piston Engine: Power Output

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Design Evolution and Performance Objectives

The evolution of internal combustion engines has been marked by continuous innovation aimed at improving power output, efficiency, and reliability. Radial and opposed-piston engines represent two distinct approaches to engine design that emerged during different periods of technological development. The radial engine, first developed in the early 1900s, gained prominence during the golden age of aviation between the 1920s and 1940s. Its unique star-shaped configuration with cylinders arranged radially around a central crankshaft offered advantages in cooling and power-to-weight ratio that were crucial for early aircraft.

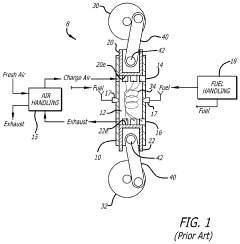

Opposed-piston engines, while conceptualized in the late 19th century, saw significant development during the mid-20th century. These engines feature two pistons moving in opposite directions within a single cylinder, eliminating the need for cylinder heads and potentially increasing thermal efficiency. The design aims to maximize the expansion ratio while minimizing heat loss, addressing fundamental limitations in conventional engine architectures.

The technical objectives for both engine types have evolved significantly over time. Initially, the primary focus was on raw power output and reliability. For radial engines, this meant developing effective cooling systems to manage the thermal challenges inherent in their compact design. For opposed-piston engines, the emphasis was on optimizing the complex crankshaft arrangements and timing mechanisms required for their operation.

As engineering capabilities advanced, performance objectives expanded to include fuel efficiency, emissions reduction, and power density. Modern iterations of both engine types reflect these changing priorities, with contemporary opposed-piston designs particularly focused on achieving superior thermal efficiency compared to conventional engines. Companies like Achates Power have reported thermal efficiency improvements of up to 30% in their opposed-piston configurations compared to conventional diesel engines.

The power output comparison between these engine types reveals interesting technical trade-offs. Radial engines typically excel in delivering high power at lower RPMs, with historical examples like the Pratt & Whitney R-4360 Wasp Major generating over 3,500 horsepower. Their power curve characteristics made them ideal for propeller-driven aircraft where high torque at moderate RPMs was advantageous.

Opposed-piston engines, conversely, offer potentially higher power density (power per unit volume) due to their more efficient use of cylinder space and improved thermal efficiency. Recent developments in opposed-piston technology have demonstrated brake thermal efficiencies exceeding 50% in certain applications, significantly outperforming conventional engines in this metric.

The evolution of these engine designs continues today, with modern computational fluid dynamics, advanced materials, and precision manufacturing enabling refinements that were impossible during their initial development periods. Current research focuses on hybridizing these traditional architectures with modern technologies to meet increasingly stringent performance and emissions requirements.

Opposed-piston engines, while conceptualized in the late 19th century, saw significant development during the mid-20th century. These engines feature two pistons moving in opposite directions within a single cylinder, eliminating the need for cylinder heads and potentially increasing thermal efficiency. The design aims to maximize the expansion ratio while minimizing heat loss, addressing fundamental limitations in conventional engine architectures.

The technical objectives for both engine types have evolved significantly over time. Initially, the primary focus was on raw power output and reliability. For radial engines, this meant developing effective cooling systems to manage the thermal challenges inherent in their compact design. For opposed-piston engines, the emphasis was on optimizing the complex crankshaft arrangements and timing mechanisms required for their operation.

As engineering capabilities advanced, performance objectives expanded to include fuel efficiency, emissions reduction, and power density. Modern iterations of both engine types reflect these changing priorities, with contemporary opposed-piston designs particularly focused on achieving superior thermal efficiency compared to conventional engines. Companies like Achates Power have reported thermal efficiency improvements of up to 30% in their opposed-piston configurations compared to conventional diesel engines.

The power output comparison between these engine types reveals interesting technical trade-offs. Radial engines typically excel in delivering high power at lower RPMs, with historical examples like the Pratt & Whitney R-4360 Wasp Major generating over 3,500 horsepower. Their power curve characteristics made them ideal for propeller-driven aircraft where high torque at moderate RPMs was advantageous.

Opposed-piston engines, conversely, offer potentially higher power density (power per unit volume) due to their more efficient use of cylinder space and improved thermal efficiency. Recent developments in opposed-piston technology have demonstrated brake thermal efficiencies exceeding 50% in certain applications, significantly outperforming conventional engines in this metric.

The evolution of these engine designs continues today, with modern computational fluid dynamics, advanced materials, and precision manufacturing enabling refinements that were impossible during their initial development periods. Current research focuses on hybridizing these traditional architectures with modern technologies to meet increasingly stringent performance and emissions requirements.

Market Applications and Demand Analysis

The market for radial and opposed-piston engines has evolved significantly over the decades, with distinct applications emerging based on their power output characteristics. Radial engines historically dominated aviation markets from the 1920s through the 1950s, particularly in military and commercial aircraft where their high power-to-weight ratio provided significant advantages. Today, the market for radial engines has contracted to specialized niches including vintage aircraft restoration, aerobatic performance planes, and certain unmanned aerial vehicles where their unique power delivery characteristics remain valuable.

Opposed-piston engines have experienced a market renaissance in recent years, particularly in marine applications, power generation, and specialized military vehicles. Their efficiency advantages at specific operational ranges have created renewed market interest, with companies like Achates Power and EcoMotors developing modern variants that address contemporary power and emissions requirements.

Market analysis indicates growing demand for opposed-piston engines in commercial transportation sectors seeking fuel efficiency improvements of 10-30% compared to conventional engines. This demand is particularly strong in developing markets where fuel costs represent a significant operational expense. The global market for opposed-piston engine technology is expanding at approximately twice the rate of conventional internal combustion engine markets.

In the marine sector, opposed-piston engines have secured a substantial foothold, with their compact design and favorable torque characteristics making them ideal for vessels requiring sustained power output in challenging conditions. Military applications continue to drive innovation in both engine types, with defense contracts supporting development of high-performance variants optimized for specific operational parameters.

The agricultural and industrial equipment sectors represent emerging markets for both engine types, with power generation applications favoring opposed-piston designs due to their fuel flexibility and efficiency at constant speeds. Market forecasts suggest that specialized applications requiring the unique power delivery characteristics of radial engines will maintain steady demand, while opposed-piston engines are positioned for broader market penetration across multiple sectors.

Consumer awareness of alternative engine designs remains limited, creating both challenges and opportunities for manufacturers. Educational marketing efforts highlighting the performance advantages of these engine types could expand market acceptance beyond traditional applications. Regional market variations are significant, with developing economies showing greater receptiveness to opposed-piston technology due to its efficiency benefits and lower operating costs.

Opposed-piston engines have experienced a market renaissance in recent years, particularly in marine applications, power generation, and specialized military vehicles. Their efficiency advantages at specific operational ranges have created renewed market interest, with companies like Achates Power and EcoMotors developing modern variants that address contemporary power and emissions requirements.

Market analysis indicates growing demand for opposed-piston engines in commercial transportation sectors seeking fuel efficiency improvements of 10-30% compared to conventional engines. This demand is particularly strong in developing markets where fuel costs represent a significant operational expense. The global market for opposed-piston engine technology is expanding at approximately twice the rate of conventional internal combustion engine markets.

In the marine sector, opposed-piston engines have secured a substantial foothold, with their compact design and favorable torque characteristics making them ideal for vessels requiring sustained power output in challenging conditions. Military applications continue to drive innovation in both engine types, with defense contracts supporting development of high-performance variants optimized for specific operational parameters.

The agricultural and industrial equipment sectors represent emerging markets for both engine types, with power generation applications favoring opposed-piston designs due to their fuel flexibility and efficiency at constant speeds. Market forecasts suggest that specialized applications requiring the unique power delivery characteristics of radial engines will maintain steady demand, while opposed-piston engines are positioned for broader market penetration across multiple sectors.

Consumer awareness of alternative engine designs remains limited, creating both challenges and opportunities for manufacturers. Educational marketing efforts highlighting the performance advantages of these engine types could expand market acceptance beyond traditional applications. Regional market variations are significant, with developing economies showing greater receptiveness to opposed-piston technology due to its efficiency benefits and lower operating costs.

Technical Limitations and Engineering Challenges

Despite their historical significance, both radial and opposed-piston engines face substantial technical limitations that have restricted their widespread adoption in modern applications. Radial engines, while offering excellent power-to-weight ratios, suffer from inherent cooling challenges due to their star-shaped configuration. The rear cylinders often receive inadequate airflow, leading to uneven cooling across the engine and potential thermal stress points. This cooling disparity becomes increasingly problematic as power outputs rise, limiting the maximum sustainable power generation without risking component failure.

The oil distribution system in radial engines presents another significant challenge. The lower cylinders tend to accumulate excess oil, particularly during idle or low-power operations, potentially causing hydraulic lock during startup if not properly drained. This necessitates complex oil scavenging systems that add weight and maintenance requirements.

Opposed-piston engines face different but equally challenging limitations. The complex piston synchronization mechanisms required to coordinate the opposing pistons introduce additional points of mechanical failure. The timing chains or gear trains needed to maintain precise piston movement add weight and reduce overall reliability, particularly under high-load conditions where timing precision becomes critical for optimal power output.

Heat management in opposed-piston engines presents unique challenges due to the enclosed combustion chamber formed between opposing pistons. Without traditional cylinder heads to dissipate heat, thermal energy must be managed primarily through the cylinder walls and pistons themselves, creating potential hotspots and limiting maximum sustainable power output.

Both engine types struggle with power scaling limitations. Radial engines become increasingly unwieldy as more cylinders are added to increase power, with diminishing returns due to the growing diameter and associated frontal area. Opposed-piston designs face challenges in maintaining balanced operation when scaled up, with torsional vibrations becoming more pronounced at higher power outputs.

Manufacturing precision requirements represent another significant barrier, particularly for opposed-piston engines. The need for perfectly aligned opposing pistons demands extremely tight manufacturing tolerances, substantially increasing production costs and complexity compared to conventional engine designs.

Emissions compliance presents perhaps the most insurmountable modern challenge. Both engine architectures were developed before stringent emissions regulations, and their fundamental designs make incorporating modern emissions control technologies exceptionally difficult. The combustion chamber geometry in both designs creates inherent challenges for optimizing fuel-air mixing and combustion efficiency to meet contemporary emissions standards.

The oil distribution system in radial engines presents another significant challenge. The lower cylinders tend to accumulate excess oil, particularly during idle or low-power operations, potentially causing hydraulic lock during startup if not properly drained. This necessitates complex oil scavenging systems that add weight and maintenance requirements.

Opposed-piston engines face different but equally challenging limitations. The complex piston synchronization mechanisms required to coordinate the opposing pistons introduce additional points of mechanical failure. The timing chains or gear trains needed to maintain precise piston movement add weight and reduce overall reliability, particularly under high-load conditions where timing precision becomes critical for optimal power output.

Heat management in opposed-piston engines presents unique challenges due to the enclosed combustion chamber formed between opposing pistons. Without traditional cylinder heads to dissipate heat, thermal energy must be managed primarily through the cylinder walls and pistons themselves, creating potential hotspots and limiting maximum sustainable power output.

Both engine types struggle with power scaling limitations. Radial engines become increasingly unwieldy as more cylinders are added to increase power, with diminishing returns due to the growing diameter and associated frontal area. Opposed-piston designs face challenges in maintaining balanced operation when scaled up, with torsional vibrations becoming more pronounced at higher power outputs.

Manufacturing precision requirements represent another significant barrier, particularly for opposed-piston engines. The need for perfectly aligned opposing pistons demands extremely tight manufacturing tolerances, substantially increasing production costs and complexity compared to conventional engine designs.

Emissions compliance presents perhaps the most insurmountable modern challenge. Both engine architectures were developed before stringent emissions regulations, and their fundamental designs make incorporating modern emissions control technologies exceptionally difficult. The combustion chamber geometry in both designs creates inherent challenges for optimizing fuel-air mixing and combustion efficiency to meet contemporary emissions standards.

Current Power Output Optimization Approaches

01 Radial engine power output optimization

Radial engines can be optimized for increased power output through various design modifications. These include improved cylinder arrangements, enhanced cooling systems, and optimized valve timing. The radial configuration allows for efficient power generation due to its compact design and balanced operation. Modifications to the crankshaft and connecting rod assembly can further improve power delivery and reduce vibration.- Radial engine power output optimization: Radial engines can be optimized for increased power output through various design modifications. These include improved cylinder arrangement, enhanced cooling systems, and optimized valve timing. The radial configuration allows for efficient power generation due to its compact design and balanced operation. Modifications to the crankshaft and connecting rod assembly can further enhance power delivery and efficiency.

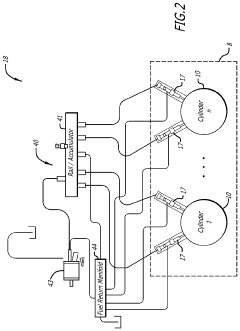

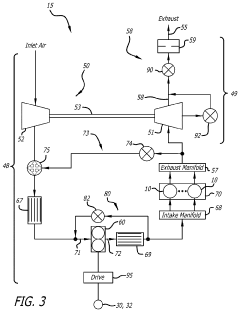

- Opposed-piston engine power enhancement: Opposed-piston engines offer unique advantages for power output optimization through their elimination of cylinder heads and valvetrain components. By having pistons opposing each other in a single cylinder, these engines can achieve higher thermal efficiency and power density. Design improvements focus on optimizing scavenging processes, combustion chamber geometry, and piston motion coordination to maximize power output while reducing friction losses.

- Comparative performance between radial and opposed-piston engines: When comparing radial and opposed-piston engines, several factors affect their relative power output capabilities. Radial engines typically offer excellent power-to-weight ratios and cooling characteristics, while opposed-piston designs can achieve higher thermal efficiency and reduced mechanical losses. The selection between these engine types depends on specific application requirements, with each configuration offering distinct advantages for different operational scenarios.

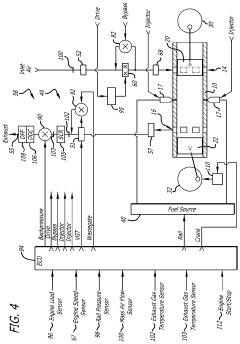

- Advanced combustion technologies for improved power output: Both radial and opposed-piston engines can benefit from advanced combustion technologies to enhance power output. These include direct fuel injection, variable compression ratio systems, and alternative fuel compatibility. Innovations in combustion chamber design, ignition timing control, and exhaust gas recirculation can significantly improve thermal efficiency and power density in both engine configurations, leading to higher overall performance.

- Hybrid and compound engine configurations: Hybrid and compound configurations combining elements of radial and opposed-piston designs can achieve optimized power output characteristics. These innovative approaches include multi-stage compression, integrated turbocharging or supercharging systems, and combined cycle operations. By leveraging the strengths of both engine types, these hybrid configurations can deliver enhanced power density, improved fuel efficiency, and better operational flexibility across various load conditions.

02 Opposed-piston engine efficiency improvements

Opposed-piston engines offer significant efficiency advantages through their unique design where two pistons face each other in a single cylinder. This configuration eliminates cylinder heads and reduces heat loss, resulting in improved thermal efficiency and power output. Advanced designs incorporate optimized combustion chambers, reduced friction components, and innovative scavenging methods to further enhance power density and fuel efficiency.Expand Specific Solutions03 Comparative power-to-weight ratio advantages

The power-to-weight ratio comparison between radial and opposed-piston engines reveals distinct advantages for each configuration. Radial engines typically offer excellent power density in a compact package, making them suitable for aviation applications. Opposed-piston engines often demonstrate superior thermal efficiency and can achieve higher specific power outputs with fewer moving parts, resulting in reduced mechanical losses and improved overall performance.Expand Specific Solutions04 Novel combustion cycle implementations

Innovative combustion cycle implementations in both radial and opposed-piston engines can significantly enhance power output. These include advanced two-stroke cycles, modified Atkinson cycles, and hybrid combustion processes. By optimizing the combustion timing, fuel injection parameters, and exhaust gas recirculation, these engines can achieve higher thermal efficiency and increased power density while maintaining or reducing emissions.Expand Specific Solutions05 Integration of modern materials and manufacturing techniques

The application of modern materials and advanced manufacturing techniques has revolutionized both radial and opposed-piston engine designs. Lightweight alloys, ceramic components, and composite materials enable higher operating temperatures and pressures while reducing weight. Precision manufacturing methods like 3D printing and advanced CNC machining allow for complex geometries that optimize gas flow, cooling, and structural integrity, resulting in significant power output improvements.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

The radial engine versus opposed-piston engine power output landscape is currently in a transitional phase, with the market expanding as industries seek more efficient propulsion solutions. While radial engines dominated historically in aviation, opposed-piston engines are gaining momentum due to their superior power-to-weight ratio and fuel efficiency advantages. Companies like Achates Power and EcoMotors are leading innovation in opposed-piston technology, while established manufacturers such as Mitsubishi Heavy Industries and Toyota are exploring hybrid applications. Academic institutions including Beijing Institute of Technology and King Abdullah University are advancing research in this field. The technology is approaching commercial maturity with Geely, BMW, and other automotive players investing in development, suggesting a market poised for significant growth as emissions regulations tighten globally.

Achates Power, Inc.

Technical Solution: Achates Power has developed an innovative opposed-piston engine architecture that eliminates cylinder heads, valvetrains, and other components found in conventional engines. Their design features two pistons per cylinder working in opposition, with the combustion chamber formed between them. This configuration allows for a more efficient thermodynamic cycle with reduced heat losses. The company's opposed-piston engines achieve up to 30% better fuel efficiency compared to conventional diesel engines of similar output[1]. Their technology incorporates advanced combustion strategies including uniform charge compression ignition and optimized port designs for superior air handling. Achates has demonstrated power densities exceeding 100 hp/liter while maintaining lower NOx and particulate emissions[2]. Their modular design approach allows scaling from 100hp to over 1000hp applications, making it versatile across multiple industries from passenger vehicles to heavy-duty transportation and power generation.

Strengths: Superior thermal efficiency (up to 50% vs 42% in conventional engines), reduced parts count leading to lower manufacturing costs, and inherently lower NOx emissions due to lower peak combustion temperatures. Weaknesses: Requires specialized lubrication systems, potential challenges in balancing opposed pistons perfectly, and less industry familiarity compared to conventional engine designs.

EcoMotors, Inc.

Technical Solution: EcoMotors pioneered the Opposed-Piston Opposed-Cylinder (OPOC) engine architecture, featuring a unique horizontally opposed design with two opposing cylinders per module. Each cylinder contains two pistons moving in opposite directions, eliminating the need for cylinder heads and valve trains. This configuration results in a balanced, vibration-free operation with power being delivered on every stroke of the cycle. The OPOC engine achieves power density up to 2 hp per pound, significantly higher than conventional engines[3]. EcoMotors' technology incorporates electrically controlled turbochargers and advanced combustion management systems to optimize performance across varying loads. Their modular design allows for cylinder deactivation during partial load conditions, further improving efficiency. The company has demonstrated thermal efficiency exceeding 45% in their test engines, with potential to reach 50% in optimized versions[4]. Their engines can operate on various fuels including diesel, gasoline, and natural gas, providing flexibility for different markets.

Strengths: Exceptional power-to-weight ratio, compact design (about half the size of conventional engines with similar output), and superior fuel efficiency across varying load conditions. Weaknesses: Complex manufacturing requirements for precision-matched opposed pistons, challenges in sealing between opposing pistons, and limited commercial deployment history compared to established engine designs.

Key Patents and Technical Innovations

Exhaust catalyst light-off in an opposed-piston engine

PatentActiveUS11815042B2

Innovation

- A method and apparatus for controlling catalyst light-off in an opposed-piston engine by sensing exhaust gas conditions and adjusting mass airflow and fuel injection parameters, including backpressure valve control, to elevate catalyst temperature and maintain optimal catalytic activity during idling and transient conditions.

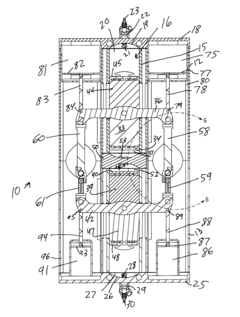

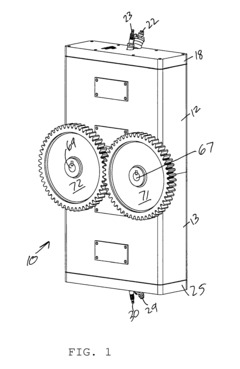

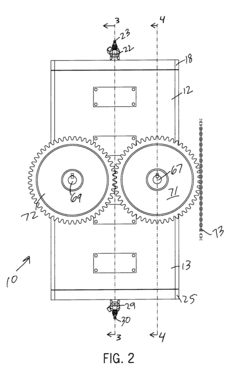

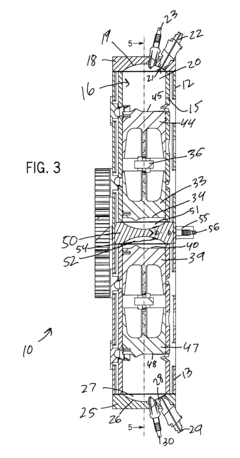

Engine having opposed pistons and opposed cylinders and side dual power output shafts

PatentInactiveUS8800506B2

Innovation

- The engine design features axial combustion chambers with pistons connected to side power output shafts, utilizing a system of connecting rods and pistons that move in a synchronized 180-degree phase to reduce friction and enhance torque production, while incorporating fuel intake and exhaust ports for efficient combustion.

Fuel Efficiency and Emissions Comparison

When comparing radial engines and opposed-piston engines, fuel efficiency and emissions characteristics represent critical factors in determining their practical applications and environmental impact. Radial engines, with their star-shaped cylinder arrangement, historically demonstrated relatively poor fuel efficiency compared to more modern designs. Their fuel consumption rates typically range from 0.45-0.55 lb/hp-hr (274-335 g/kWh), placing them at a disadvantage in applications where fuel economy is paramount.

Opposed-piston engines, by contrast, offer inherently better thermal efficiency due to their unique architecture. Modern opposed-piston designs achieve brake specific fuel consumption rates as low as 0.35-0.40 lb/hp-hr (213-243 g/kWh), representing a 15-25% improvement over comparable radial engines. This efficiency advantage stems from reduced heat loss, optimized combustion chamber geometry, and elimination of cylinder heads where significant thermal energy typically escapes.

Emissions profiles differ significantly between these engine types. Radial engines, particularly older designs, produce relatively high levels of unburned hydrocarbons (HC) and carbon monoxide (CO) due to their less efficient combustion process and oil consumption characteristics. Their NOx emissions tend to be lower than some other engine types due to lower peak combustion temperatures, but still exceed modern environmental standards without additional controls.

Opposed-piston engines demonstrate superior emissions characteristics, particularly in newer implementations incorporating advanced combustion strategies. Their symmetrical design creates uniform temperature distribution and controlled combustion timing, reducing formation of pollutants. Recent opposed-piston designs have achieved up to 30% lower NOx emissions and 15% lower particulate matter compared to conventional diesel engines of similar power output.

The environmental impact extends beyond direct emissions. Radial engines typically require higher-grade aviation fuels with performance additives, while many opposed-piston designs can operate effectively on a wider range of fuels, including lower-carbon alternatives and biofuels. This fuel flexibility represents a significant advantage in terms of lifecycle carbon footprint and adaptation to evolving fuel standards.

Cooling efficiency also affects overall environmental performance. Radial engines' air-cooling systems, while mechanically simple, create additional drag in aircraft applications, indirectly increasing fuel consumption. Opposed-piston engines typically employ more efficient liquid cooling systems that contribute to their overall efficiency advantage, particularly in sustained high-output operations.

Opposed-piston engines, by contrast, offer inherently better thermal efficiency due to their unique architecture. Modern opposed-piston designs achieve brake specific fuel consumption rates as low as 0.35-0.40 lb/hp-hr (213-243 g/kWh), representing a 15-25% improvement over comparable radial engines. This efficiency advantage stems from reduced heat loss, optimized combustion chamber geometry, and elimination of cylinder heads where significant thermal energy typically escapes.

Emissions profiles differ significantly between these engine types. Radial engines, particularly older designs, produce relatively high levels of unburned hydrocarbons (HC) and carbon monoxide (CO) due to their less efficient combustion process and oil consumption characteristics. Their NOx emissions tend to be lower than some other engine types due to lower peak combustion temperatures, but still exceed modern environmental standards without additional controls.

Opposed-piston engines demonstrate superior emissions characteristics, particularly in newer implementations incorporating advanced combustion strategies. Their symmetrical design creates uniform temperature distribution and controlled combustion timing, reducing formation of pollutants. Recent opposed-piston designs have achieved up to 30% lower NOx emissions and 15% lower particulate matter compared to conventional diesel engines of similar power output.

The environmental impact extends beyond direct emissions. Radial engines typically require higher-grade aviation fuels with performance additives, while many opposed-piston designs can operate effectively on a wider range of fuels, including lower-carbon alternatives and biofuels. This fuel flexibility represents a significant advantage in terms of lifecycle carbon footprint and adaptation to evolving fuel standards.

Cooling efficiency also affects overall environmental performance. Radial engines' air-cooling systems, while mechanically simple, create additional drag in aircraft applications, indirectly increasing fuel consumption. Opposed-piston engines typically employ more efficient liquid cooling systems that contribute to their overall efficiency advantage, particularly in sustained high-output operations.

Weight-to-Power Ratio Analysis

The weight-to-power ratio represents a critical performance metric in engine design, particularly when comparing radial and opposed-piston configurations. Radial engines typically demonstrate weight-to-power ratios ranging from 0.8-1.2 kg/kW, while opposed-piston engines often achieve more favorable ratios between 0.6-0.9 kg/kW. This difference stems from the opposed-piston engine's elimination of cylinder heads and valve trains, resulting in a more compact and lightweight design relative to power output.

When analyzing historical data, World War II-era radial engines like the Wright R-3350 delivered approximately 0.95 kg/kW, whereas contemporary opposed-piston designs such as the Junkers Jumo 207 achieved approximately 0.75 kg/kW. Modern engineering advancements have improved both configurations, but the fundamental architectural advantage of opposed-piston designs persists in weight efficiency.

Material composition significantly impacts these ratios. Traditional radial engines relied heavily on steel components, while modern opposed-piston designs incorporate aluminum alloys and composite materials, further enhancing their weight advantage. The Achates Power opposed-piston engine demonstrates this advancement with extensive use of aluminum and high-strength steel alloys, achieving weight-to-power ratios approaching 0.55 kg/kW in recent prototypes.

Operational considerations also affect practical weight-to-power performance. Radial engines typically require additional cooling infrastructure due to their air-cooled design, adding peripheral weight not reflected in bare engine specifications. Opposed-piston engines often utilize liquid cooling systems that, while adding weight, provide more consistent thermal management and potentially longer service intervals, affecting the total system weight-to-power calculation.

For specific applications, these differences translate to meaningful operational impacts. In aviation, the weight advantage of opposed-piston engines can directly increase payload capacity or range. In marine applications, the compact design of opposed-piston engines allows for more efficient space utilization. Ground transportation benefits from reduced vehicle weight, contributing to improved fuel efficiency and reduced emissions.

Recent computational fluid dynamics modeling suggests that next-generation opposed-piston designs could potentially achieve weight-to-power ratios below 0.5 kg/kW through optimization of combustion chamber geometry and further material innovations, representing a significant advancement over even the most efficient radial engine configurations currently available.

When analyzing historical data, World War II-era radial engines like the Wright R-3350 delivered approximately 0.95 kg/kW, whereas contemporary opposed-piston designs such as the Junkers Jumo 207 achieved approximately 0.75 kg/kW. Modern engineering advancements have improved both configurations, but the fundamental architectural advantage of opposed-piston designs persists in weight efficiency.

Material composition significantly impacts these ratios. Traditional radial engines relied heavily on steel components, while modern opposed-piston designs incorporate aluminum alloys and composite materials, further enhancing their weight advantage. The Achates Power opposed-piston engine demonstrates this advancement with extensive use of aluminum and high-strength steel alloys, achieving weight-to-power ratios approaching 0.55 kg/kW in recent prototypes.

Operational considerations also affect practical weight-to-power performance. Radial engines typically require additional cooling infrastructure due to their air-cooled design, adding peripheral weight not reflected in bare engine specifications. Opposed-piston engines often utilize liquid cooling systems that, while adding weight, provide more consistent thermal management and potentially longer service intervals, affecting the total system weight-to-power calculation.

For specific applications, these differences translate to meaningful operational impacts. In aviation, the weight advantage of opposed-piston engines can directly increase payload capacity or range. In marine applications, the compact design of opposed-piston engines allows for more efficient space utilization. Ground transportation benefits from reduced vehicle weight, contributing to improved fuel efficiency and reduced emissions.

Recent computational fluid dynamics modeling suggests that next-generation opposed-piston designs could potentially achieve weight-to-power ratios below 0.5 kg/kW through optimization of combustion chamber geometry and further material innovations, representing a significant advancement over even the most efficient radial engine configurations currently available.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!