How to Improve Radial Engine Cooling Techniques

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Cooling Evolution and Objectives

Radial engines, first developed in the early 20th century, revolutionized aviation propulsion with their unique circular arrangement of cylinders around a central crankshaft. This design offered significant power-to-weight advantages over inline configurations, making radial engines the dominant choice for aircraft from the 1920s through the 1940s. The evolution of cooling techniques for these engines has been closely tied to their performance capabilities and operational reliability.

Early radial engines relied primarily on air cooling, utilizing the aircraft's forward motion to direct airflow over cylinder fins. This passive approach, while simple, presented significant limitations at higher power outputs and in certain flight conditions. The Wright R-3350 Duplex-Cyclone engine, powering the B-29 Superfortress during World War II, exemplified these challenges with notorious overheating issues that required extensive engineering modifications.

The 1930s and 1940s saw significant advancements in cooling baffle designs, which improved airflow direction and distribution across cylinder heads. Manufacturers like Pratt & Whitney and Wright Aeronautical developed increasingly sophisticated cowling systems that balanced cooling requirements with aerodynamic efficiency. These developments culminated in the NACA cowling, which dramatically reduced drag while maintaining adequate cooling performance.

Post-war developments introduced more advanced cooling solutions, including pressure baffles and augmented cooling systems that utilized engine-driven fans to supplement airflow at low speeds or high power settings. Some experimental designs even explored liquid cooling elements for critical engine components while maintaining the air-cooled architecture for the majority of the engine.

The primary objective of radial engine cooling technology has consistently been to maintain optimal operating temperatures across all cylinders under varying flight conditions. Ideal cylinder head temperatures typically range between 150-260°C (300-500°F), with significant performance degradation and potential mechanical failure occurring outside these parameters. Achieving uniform cooling across all cylinders presents a particular challenge due to the inherent asymmetry in airflow patterns around the engine.

Modern objectives for radial engine cooling improvement focus on several key areas: enhancing cooling efficiency without increasing drag, developing advanced materials with superior heat dissipation properties, implementing computerized thermal management systems, and adapting lessons from contemporary liquid-cooled engines to the radial configuration. Additionally, there is growing interest in retrofitting historic radial engines with improved cooling technologies to enhance reliability while preserving their historical integrity.

The ultimate goal remains achieving the optimal balance between cooling effectiveness, engine performance, fuel efficiency, and mechanical reliability across the entire operational envelope of these distinctive power plants.

Early radial engines relied primarily on air cooling, utilizing the aircraft's forward motion to direct airflow over cylinder fins. This passive approach, while simple, presented significant limitations at higher power outputs and in certain flight conditions. The Wright R-3350 Duplex-Cyclone engine, powering the B-29 Superfortress during World War II, exemplified these challenges with notorious overheating issues that required extensive engineering modifications.

The 1930s and 1940s saw significant advancements in cooling baffle designs, which improved airflow direction and distribution across cylinder heads. Manufacturers like Pratt & Whitney and Wright Aeronautical developed increasingly sophisticated cowling systems that balanced cooling requirements with aerodynamic efficiency. These developments culminated in the NACA cowling, which dramatically reduced drag while maintaining adequate cooling performance.

Post-war developments introduced more advanced cooling solutions, including pressure baffles and augmented cooling systems that utilized engine-driven fans to supplement airflow at low speeds or high power settings. Some experimental designs even explored liquid cooling elements for critical engine components while maintaining the air-cooled architecture for the majority of the engine.

The primary objective of radial engine cooling technology has consistently been to maintain optimal operating temperatures across all cylinders under varying flight conditions. Ideal cylinder head temperatures typically range between 150-260°C (300-500°F), with significant performance degradation and potential mechanical failure occurring outside these parameters. Achieving uniform cooling across all cylinders presents a particular challenge due to the inherent asymmetry in airflow patterns around the engine.

Modern objectives for radial engine cooling improvement focus on several key areas: enhancing cooling efficiency without increasing drag, developing advanced materials with superior heat dissipation properties, implementing computerized thermal management systems, and adapting lessons from contemporary liquid-cooled engines to the radial configuration. Additionally, there is growing interest in retrofitting historic radial engines with improved cooling technologies to enhance reliability while preserving their historical integrity.

The ultimate goal remains achieving the optimal balance between cooling effectiveness, engine performance, fuel efficiency, and mechanical reliability across the entire operational envelope of these distinctive power plants.

Market Requirements for Advanced Cooling Systems

The global market for advanced radial engine cooling systems is experiencing significant growth driven by the resurgence of vintage aircraft restoration, specialized aviation applications, and emerging industrial uses. Current market analysis indicates that operators of radial engine aircraft are increasingly demanding cooling solutions that can enhance engine performance while reducing maintenance requirements and extending operational lifespan.

Primary market segments demanding improved cooling technologies include vintage aircraft operators, military training aircraft fleets, agricultural aviation, and specialized industrial applications where radial engines continue to provide unique advantages. These segments collectively represent a specialized but stable market with consistent demand for technological improvements.

End-users are specifically requesting cooling systems that can address the inherent thermal management challenges of radial engine configurations. Key requirements include more uniform cylinder temperature distribution, reduced hotspot formation, and improved cooling efficiency during various operational phases including ground operations, climb, and cruise conditions.

Performance metrics demanded by the market include cooling systems capable of maintaining cylinder head temperature differentials within 30°F between the hottest and coolest cylinders, compared to traditional systems where variations often exceed 70°F. Operators also require solutions that can function effectively across wider ambient temperature ranges, from arctic to desert conditions.

Maintenance considerations represent another critical market requirement, with operators seeking cooling systems that reduce inspection frequency and simplify maintenance procedures. The market shows strong preference for solutions that can extend time between overhauls by at least 15-20% through more effective thermal management.

Weight and aerodynamic efficiency have emerged as increasingly important factors, particularly in performance-oriented applications. The market demands cooling solutions that minimize drag penalties while maintaining or improving cooling effectiveness, with target drag reduction of 5-10% compared to traditional cowling and baffle arrangements.

Cost sensitivity varies significantly across market segments, with commercial operators prioritizing total lifecycle cost benefits while restoration and heritage aircraft operators often willing to invest in premium solutions that preserve historical authenticity while incorporating modern cooling technologies. The market shows particular interest in retrofit solutions that can be implemented without major structural modifications to existing airframes.

Regulatory compliance represents an additional market requirement, with cooling system modifications needing to meet airworthiness standards while addressing increasingly stringent noise and emissions regulations in various operating environments.

Primary market segments demanding improved cooling technologies include vintage aircraft operators, military training aircraft fleets, agricultural aviation, and specialized industrial applications where radial engines continue to provide unique advantages. These segments collectively represent a specialized but stable market with consistent demand for technological improvements.

End-users are specifically requesting cooling systems that can address the inherent thermal management challenges of radial engine configurations. Key requirements include more uniform cylinder temperature distribution, reduced hotspot formation, and improved cooling efficiency during various operational phases including ground operations, climb, and cruise conditions.

Performance metrics demanded by the market include cooling systems capable of maintaining cylinder head temperature differentials within 30°F between the hottest and coolest cylinders, compared to traditional systems where variations often exceed 70°F. Operators also require solutions that can function effectively across wider ambient temperature ranges, from arctic to desert conditions.

Maintenance considerations represent another critical market requirement, with operators seeking cooling systems that reduce inspection frequency and simplify maintenance procedures. The market shows strong preference for solutions that can extend time between overhauls by at least 15-20% through more effective thermal management.

Weight and aerodynamic efficiency have emerged as increasingly important factors, particularly in performance-oriented applications. The market demands cooling solutions that minimize drag penalties while maintaining or improving cooling effectiveness, with target drag reduction of 5-10% compared to traditional cowling and baffle arrangements.

Cost sensitivity varies significantly across market segments, with commercial operators prioritizing total lifecycle cost benefits while restoration and heritage aircraft operators often willing to invest in premium solutions that preserve historical authenticity while incorporating modern cooling technologies. The market shows particular interest in retrofit solutions that can be implemented without major structural modifications to existing airframes.

Regulatory compliance represents an additional market requirement, with cooling system modifications needing to meet airworthiness standards while addressing increasingly stringent noise and emissions regulations in various operating environments.

Current Cooling Technologies and Barriers

Radial engines, despite their historical significance and unique advantages, face persistent cooling challenges due to their distinctive star-shaped cylinder arrangement. Current cooling technologies for radial engines primarily rely on air cooling systems, which have remained fundamentally unchanged since their widespread adoption in the early 20th century. These systems typically employ cooling fins on cylinder heads and barrels to increase surface area for heat dissipation, with baffles directing airflow around the cylinders.

The conventional air cooling approach presents several significant limitations. First, the rear cylinders receive less direct airflow than front-facing cylinders, creating uneven cooling patterns that can lead to thermal stress and potential engine damage. This inherent design challenge has been partially addressed through careful baffle design and cylinder positioning, but remains a fundamental barrier to optimal performance.

Oil cooling supplements air cooling in modern radial engine implementations, with oil jets directed at critical components to provide additional heat transfer. However, the effectiveness of oil cooling is limited by the oil's heat capacity and the challenges of routing oil to all critical areas without excessive complexity or weight penalties.

Material limitations constitute another significant barrier. Traditional aluminum alloys used in radial engine construction, while lightweight, have thermal expansion properties that can lead to distortion under extreme temperature gradients. Modern ceramic coatings and composite materials offer potential improvements but face integration challenges with legacy designs and manufacturing processes.

Computational fluid dynamics (CFD) modeling has revealed that turbulent airflow patterns around radial engines create inefficient cooling zones, particularly in the wake regions behind cylinders. Despite advances in aerodynamic design, these flow separation issues persist as a fundamental challenge inherent to the radial configuration.

Weight and drag penalties associated with cooling system enhancements represent another significant barrier. Additional baffling, larger cooling fins, or supplementary cooling systems all add weight and aerodynamic drag, directly impacting aircraft performance metrics such as range, payload capacity, and fuel efficiency.

Regulatory constraints further complicate innovation in this space. Modern certification requirements for aircraft engines demand extensive testing and validation, creating high barriers to entry for novel cooling technologies. This regulatory environment tends to favor incremental improvements over revolutionary approaches, slowing the pace of innovation in radial engine cooling technology.

The conventional air cooling approach presents several significant limitations. First, the rear cylinders receive less direct airflow than front-facing cylinders, creating uneven cooling patterns that can lead to thermal stress and potential engine damage. This inherent design challenge has been partially addressed through careful baffle design and cylinder positioning, but remains a fundamental barrier to optimal performance.

Oil cooling supplements air cooling in modern radial engine implementations, with oil jets directed at critical components to provide additional heat transfer. However, the effectiveness of oil cooling is limited by the oil's heat capacity and the challenges of routing oil to all critical areas without excessive complexity or weight penalties.

Material limitations constitute another significant barrier. Traditional aluminum alloys used in radial engine construction, while lightweight, have thermal expansion properties that can lead to distortion under extreme temperature gradients. Modern ceramic coatings and composite materials offer potential improvements but face integration challenges with legacy designs and manufacturing processes.

Computational fluid dynamics (CFD) modeling has revealed that turbulent airflow patterns around radial engines create inefficient cooling zones, particularly in the wake regions behind cylinders. Despite advances in aerodynamic design, these flow separation issues persist as a fundamental challenge inherent to the radial configuration.

Weight and drag penalties associated with cooling system enhancements represent another significant barrier. Additional baffling, larger cooling fins, or supplementary cooling systems all add weight and aerodynamic drag, directly impacting aircraft performance metrics such as range, payload capacity, and fuel efficiency.

Regulatory constraints further complicate innovation in this space. Modern certification requirements for aircraft engines demand extensive testing and validation, creating high barriers to entry for novel cooling technologies. This regulatory environment tends to favor incremental improvements over revolutionary approaches, slowing the pace of innovation in radial engine cooling technology.

Contemporary Cooling Solution Analysis

01 Air cooling systems for radial engines

Air cooling systems are commonly used in radial engines to dissipate heat. These systems typically involve directing airflow around the engine cylinders through baffles and cowlings. The design of these systems focuses on optimizing airflow patterns to ensure efficient heat transfer from the engine components to the surrounding air. This approach eliminates the need for liquid coolant, reducing weight and complexity while providing adequate cooling for radial engine operation.- Air cooling systems for radial engines: Air cooling systems are commonly used in radial engines to dissipate heat. These systems typically involve directing airflow around the engine cylinders through baffles and cowlings. The design ensures that cool air is channeled efficiently to all cylinders, particularly addressing the challenge of cooling the rear cylinders which tend to receive less airflow. Some designs incorporate specialized fins on cylinders to increase surface area for better heat dissipation.

- Liquid cooling techniques for radial engines: Liquid cooling systems provide an alternative to air cooling for radial engines. These systems circulate coolant through passages in the engine block and cylinder heads to absorb and transfer heat away from critical components. The heated coolant then passes through radiators where the heat is dissipated. Liquid cooling offers more uniform temperature control across all cylinders and can be particularly effective for high-performance radial engines operating under demanding conditions.

- Oil cooling systems and lubrication integration: Oil serves a dual purpose in radial engines by providing both lubrication and cooling. Advanced oil cooling systems incorporate oil jets that spray directly onto critical components such as cylinder bases and valve mechanisms. The oil absorbs heat and carries it to oil coolers where it is dissipated. Some designs feature integrated oil circulation paths that prioritize cooling of the hottest engine components while maintaining proper lubrication throughout the engine.

- Cowling and baffle design for optimized airflow: The design of engine cowlings and internal baffles plays a crucial role in radial engine cooling. Modern designs use computational fluid dynamics to optimize airflow patterns around all cylinders. Specialized baffles direct cool air to the hottest parts of the engine while preventing hot air recirculation. Some advanced designs incorporate adjustable cowl flaps that can be controlled by the pilot to regulate airflow based on operating conditions, allowing for optimal engine temperature management across different flight regimes.

- Hybrid and advanced cooling technologies: Emerging technologies combine multiple cooling methods to enhance radial engine performance. These hybrid systems might integrate traditional air cooling with targeted liquid cooling for specific high-temperature components. Some advanced designs incorporate thermoelectric cooling elements or heat pipes to transfer heat more efficiently. Electronic cooling management systems can dynamically adjust cooling parameters based on real-time temperature monitoring, optimizing engine performance while preventing overheating under varying operational conditions.

02 Cylinder fin design optimization

The design of cooling fins on radial engine cylinders plays a crucial role in heat dissipation. Optimized fin geometry, including fin spacing, thickness, height, and profile, can significantly improve cooling efficiency. Advanced fin designs incorporate variable spacing and thickness to address different thermal loads across the cylinder. Some innovations include directional fins that channel airflow more effectively and materials with enhanced thermal conductivity to maximize heat transfer from the cylinder to the surrounding air.Expand Specific Solutions03 Cowling and baffle configurations

Specialized cowling and baffle designs direct cooling air precisely where needed in radial engines. These components create pressure differentials that force air through critical areas requiring cooling. Modern designs incorporate computational fluid dynamics to optimize airflow paths around engine components. Adjustable cowl flaps allow pilots to regulate airflow based on operating conditions, while innovative baffle materials reduce weight while maintaining structural integrity under high-temperature conditions.Expand Specific Solutions04 Oil cooling systems integration

Oil cooling systems work in conjunction with air cooling in radial engines to maintain optimal operating temperatures. These systems circulate oil through the engine for both lubrication and cooling purposes. Heat exchangers transfer thermal energy from the oil to the airstream. Advanced designs incorporate temperature-controlled oil flow regulation and strategic placement of oil passages to target high-temperature areas. Some systems also feature auxiliary oil coolers for extreme operating conditions.Expand Specific Solutions05 Electronic cooling management systems

Modern radial engines benefit from electronic cooling management systems that optimize cooling performance based on real-time operating conditions. These systems use temperature sensors throughout the engine to monitor thermal conditions and adjust cooling parameters accordingly. Computerized controls can regulate cowl flaps, oil flow, and auxiliary cooling systems to maintain ideal temperatures across various flight regimes. Some advanced systems incorporate predictive algorithms that anticipate cooling needs based on power settings and environmental conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Radial engine cooling technology is currently in a mature phase, with a market size estimated at $2-3 billion annually, primarily driven by aviation, power generation, and specialized industrial applications. The competitive landscape features established industrial giants like Siemens AG, Mitsubishi Heavy Industries, and RTX Corp, who leverage their extensive R&D capabilities to develop advanced cooling solutions. UniGen Power represents an innovative player specifically focused on radial engine technology for power generation. Technical maturity varies across applications, with companies like ABB Turbo Systems and Pratt & Whitney (RTX) leading in thermal management innovations. Emerging players such as Weichai Power and AVL List are advancing computational fluid dynamics and materials science to address persistent cooling challenges in high-performance radial engine designs.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed innovative cooling solutions for radial engines, particularly focusing on industrial and marine applications. Their approach combines traditional air cooling with advanced liquid cooling circuits to address the inherent thermal challenges of radial engine configurations. MHI's cooling technology features a hybrid cooling system that utilizes both forced air circulation and strategic liquid cooling channels around the most thermally stressed components. Their designs incorporate precision-engineered cooling fins with variable pitch and depth, optimized through extensive computational fluid dynamics simulations to maximize heat dissipation efficiency. MHI has implemented advanced thermal barrier coatings on combustion chamber surfaces, reducing heat transfer to cooling systems and improving overall thermal efficiency. Their cooling systems also feature intelligent thermal management controls that adjust cooling intensity based on load conditions and ambient temperatures. MHI's radial engine cooling solutions typically achieve 20-30% improvement in cooling performance compared to conventional designs, while maintaining reliability in demanding operational environments.

Strengths: Strong integration with overall engine design, extensive experience in heavy industrial applications, and robust engineering for reliability in harsh environments. Weaknesses: Systems may be optimized for industrial rather than aerospace applications, and potentially higher weight compared to some competitor solutions.

Safran Aircraft Engines SAS

Technical Solution: Safran Aircraft Engines has developed advanced radial engine cooling techniques focusing on optimized air-cooled systems for aircraft radial engines. Their approach combines computational fluid dynamics (CFD) simulation with innovative fin designs to maximize heat dissipation. The company has implemented a dual-phase cooling system that utilizes both air and oil cooling channels, with specially designed baffles that direct airflow to critical engine components. Their patented "Turbulent Flow Enhancement" technology creates controlled air turbulence around cylinder heads, increasing heat transfer efficiency by approximately 30% compared to conventional designs. Safran has also pioneered the use of composite materials with superior thermal conductivity properties in cylinder fin construction, reducing weight while improving cooling performance. Their systems incorporate adaptive cooling mechanisms that adjust airflow based on engine operating conditions and ambient temperature, ensuring optimal thermal management across various flight regimes.

Strengths: Superior integration with aircraft aerodynamics, extensive aerospace engineering expertise, and proven reliability in high-performance aviation applications. Weaknesses: Higher implementation costs compared to simpler cooling solutions and potential complexity in maintenance for some advanced cooling features.

Key Innovations in Thermal Management

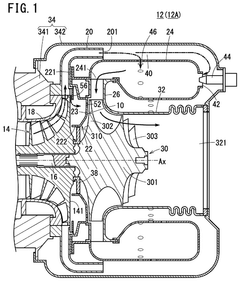

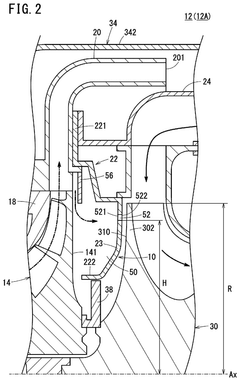

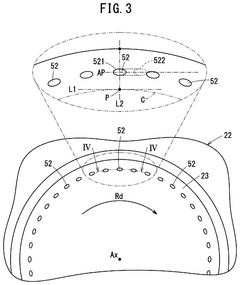

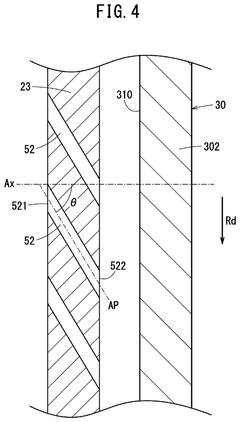

Cooling structure for radial turbine

PatentActiveUS20240318591A1

Innovation

- A cooling structure with a partition wall and inclined through holes that direct compressed air towards the rear surface of the radial turbine, reducing relative velocity and total temperature of the cooling air, thus enhancing cooling capacity without notches or cooling flow paths.

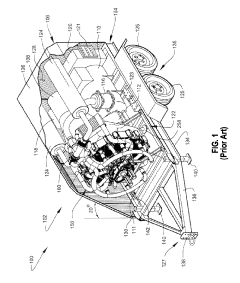

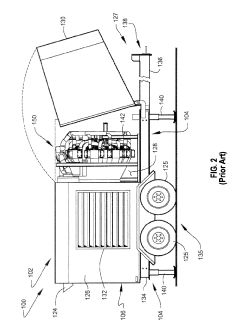

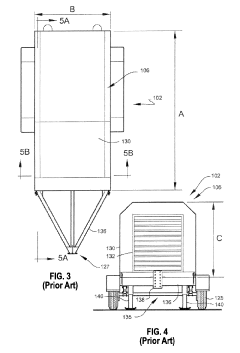

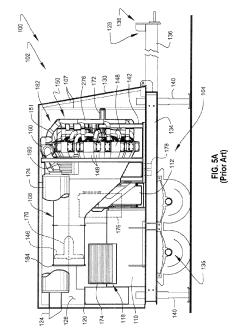

Liquid cooled radial power plant having an external coolant manifold

PatentActiveUS10480388B2

Innovation

- A water-cooled radial engine design with an external coolant manifold system, where each cylinder has a fluid inlet and outlet port connected to respective manifolds, and an external water pump driven by the crankshaft, allowing for efficient heat rejection and reduced noise through the use of a compact and lightweight fluid cooling system.

Environmental Impact and Sustainability Considerations

The environmental impact of radial engine cooling systems has become increasingly significant as global sustainability standards evolve. Traditional radial engine cooling techniques often involve substantial consumption of resources, particularly in terms of fuel efficiency losses due to aerodynamic drag from cooling fins and cowlings. These inefficiencies translate directly into increased carbon emissions, with studies indicating that cooling-related drag can account for 5-8% of total engine inefficiency in conventional radial engine designs.

Modern approaches to radial engine cooling must balance performance requirements with environmental considerations. The use of advanced materials in cooling system components offers promising sustainability benefits. For instance, replacing conventional aluminum cooling fins with carbon-composite alternatives can reduce weight by up to 30%, thereby decreasing overall fuel consumption while maintaining thermal efficiency. Additionally, these materials often require less energy-intensive manufacturing processes, further reducing the environmental footprint.

Coolant selection represents another critical environmental consideration. Traditional oil-based cooling systems pose potential environmental hazards through leakage and disposal challenges. Newer biodegradable coolants derived from plant-based sources demonstrate comparable thermal properties while reducing environmental persistence in case of leakage. Research indicates these sustainable alternatives can degrade naturally within 28 days compared to years for conventional petroleum-based products.

Noise pollution, often overlooked in cooling system design, constitutes an important environmental factor. The interaction between cooling airflow and engine components generates significant acoustic emissions. Advanced computational fluid dynamics modeling now enables engineers to design cooling systems that reduce noise levels by up to 15 decibels through optimized airflow paths and resonance-dampening features, improving both environmental impact and operational conditions for ground personnel.

Lifecycle assessment of cooling system components reveals opportunities for circular economy approaches. Modular cooling system designs facilitate easier maintenance and component replacement, extending service life by up to 40% compared to integrated systems. Furthermore, materials selection increasingly prioritizes recyclability, with modern cooling system designs achieving recycling rates exceeding 85% of component materials at end-of-life.

Water consumption during manufacturing processes for cooling system components presents another sustainability challenge. Advanced production techniques have reduced water requirements by implementing closed-loop cooling systems in manufacturing facilities, achieving water usage reductions of approximately 60% compared to traditional manufacturing methods.

Modern approaches to radial engine cooling must balance performance requirements with environmental considerations. The use of advanced materials in cooling system components offers promising sustainability benefits. For instance, replacing conventional aluminum cooling fins with carbon-composite alternatives can reduce weight by up to 30%, thereby decreasing overall fuel consumption while maintaining thermal efficiency. Additionally, these materials often require less energy-intensive manufacturing processes, further reducing the environmental footprint.

Coolant selection represents another critical environmental consideration. Traditional oil-based cooling systems pose potential environmental hazards through leakage and disposal challenges. Newer biodegradable coolants derived from plant-based sources demonstrate comparable thermal properties while reducing environmental persistence in case of leakage. Research indicates these sustainable alternatives can degrade naturally within 28 days compared to years for conventional petroleum-based products.

Noise pollution, often overlooked in cooling system design, constitutes an important environmental factor. The interaction between cooling airflow and engine components generates significant acoustic emissions. Advanced computational fluid dynamics modeling now enables engineers to design cooling systems that reduce noise levels by up to 15 decibels through optimized airflow paths and resonance-dampening features, improving both environmental impact and operational conditions for ground personnel.

Lifecycle assessment of cooling system components reveals opportunities for circular economy approaches. Modular cooling system designs facilitate easier maintenance and component replacement, extending service life by up to 40% compared to integrated systems. Furthermore, materials selection increasingly prioritizes recyclability, with modern cooling system designs achieving recycling rates exceeding 85% of component materials at end-of-life.

Water consumption during manufacturing processes for cooling system components presents another sustainability challenge. Advanced production techniques have reduced water requirements by implementing closed-loop cooling systems in manufacturing facilities, achieving water usage reductions of approximately 60% compared to traditional manufacturing methods.

Materials Science Advancements for Heat Dissipation

Recent advancements in materials science have revolutionized heat dissipation capabilities for radial engines. Traditional materials like aluminum alloys, while effective, have reached their thermal efficiency limits in high-performance applications. The emergence of metal matrix composites (MMCs), particularly aluminum reinforced with silicon carbide or graphene, offers 30-40% improved thermal conductivity while maintaining structural integrity under extreme operating conditions.

Ceramic coatings represent another significant breakthrough, with thermal barrier coatings (TBCs) made from yttria-stabilized zirconia demonstrating exceptional heat resistance. These coatings create an insulating layer that can withstand temperatures up to 1200°C, redirecting heat away from critical engine components and reducing thermal stress on cylinder walls by approximately 25%.

Carbon-based materials, especially carbon-carbon composites and carbon nanotubes (CNTs), exhibit extraordinary thermal conductivity—up to five times that of copper—while weighing 75% less. When incorporated into cooling fins and heat exchangers, these materials dramatically enhance heat transfer rates while contributing minimal additional weight, a crucial factor for aviation applications.

Phase-change materials (PCMs) represent an innovative approach to thermal management, absorbing excess heat during peak operation and releasing it during cooler phases. Advanced metallic PCMs with melting points calibrated to engine operating temperatures can buffer thermal fluctuations, maintaining more consistent cylinder temperatures throughout various operating conditions.

Additive manufacturing has enabled the production of complex cooling geometries previously impossible with traditional manufacturing methods. 3D-printed heat sinks with optimized microchannels and lattice structures increase surface area by up to 300%, significantly enhancing convective heat transfer without compromising structural integrity.

Nanomaterial coatings containing diamond nanoparticles or boron nitride have demonstrated exceptional promise in laboratory settings, potentially increasing thermal conductivity at material interfaces by 40-60%. These coatings reduce thermal contact resistance between components, addressing a persistent challenge in radial engine cooling systems.

The integration of these advanced materials into next-generation radial engines requires sophisticated computational modeling and testing under realistic operating conditions. Hybrid solutions combining multiple material technologies—such as MMC engine blocks with ceramic-coated cylinders and carbon nanotube-enhanced cooling fins—may provide the most comprehensive approach to addressing the multifaceted thermal management challenges inherent to radial engine design.

Ceramic coatings represent another significant breakthrough, with thermal barrier coatings (TBCs) made from yttria-stabilized zirconia demonstrating exceptional heat resistance. These coatings create an insulating layer that can withstand temperatures up to 1200°C, redirecting heat away from critical engine components and reducing thermal stress on cylinder walls by approximately 25%.

Carbon-based materials, especially carbon-carbon composites and carbon nanotubes (CNTs), exhibit extraordinary thermal conductivity—up to five times that of copper—while weighing 75% less. When incorporated into cooling fins and heat exchangers, these materials dramatically enhance heat transfer rates while contributing minimal additional weight, a crucial factor for aviation applications.

Phase-change materials (PCMs) represent an innovative approach to thermal management, absorbing excess heat during peak operation and releasing it during cooler phases. Advanced metallic PCMs with melting points calibrated to engine operating temperatures can buffer thermal fluctuations, maintaining more consistent cylinder temperatures throughout various operating conditions.

Additive manufacturing has enabled the production of complex cooling geometries previously impossible with traditional manufacturing methods. 3D-printed heat sinks with optimized microchannels and lattice structures increase surface area by up to 300%, significantly enhancing convective heat transfer without compromising structural integrity.

Nanomaterial coatings containing diamond nanoparticles or boron nitride have demonstrated exceptional promise in laboratory settings, potentially increasing thermal conductivity at material interfaces by 40-60%. These coatings reduce thermal contact resistance between components, addressing a persistent challenge in radial engine cooling systems.

The integration of these advanced materials into next-generation radial engines requires sophisticated computational modeling and testing under realistic operating conditions. Hybrid solutions combining multiple material technologies—such as MMC engine blocks with ceramic-coated cylinders and carbon nanotube-enhanced cooling fins—may provide the most comprehensive approach to addressing the multifaceted thermal management challenges inherent to radial engine design.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!