Measuring Radial Engine's Efficiency in Energy Consumption

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Efficiency Background and Objectives

Radial engines have been a cornerstone of aviation propulsion since their introduction in the early 20th century. These engines, characterized by their distinctive circular arrangement of cylinders around a central crankshaft, dominated aircraft propulsion until the advent of jet engines. The historical evolution of radial engines reflects a continuous pursuit of improved efficiency, reliability, and power-to-weight ratios, particularly in energy consumption metrics.

The measurement of radial engine efficiency has evolved significantly over the decades. Initially, simple metrics such as brake-specific fuel consumption (BSFC) were the primary indicators. However, as engineering precision advanced, more sophisticated parameters including thermal efficiency, volumetric efficiency, and mechanical efficiency became standard evaluation criteria. This evolution in measurement methodologies has paralleled the technological advancement of the engines themselves.

Current global energy challenges and environmental concerns have renewed interest in optimizing all forms of mechanical propulsion, including legacy technologies like radial engines. While these engines are no longer mainstream in aviation, they continue to find applications in specialized sectors such as vintage aircraft restoration, certain industrial applications, and as educational platforms for engineering principles. This persistent relevance necessitates continued refinement of efficiency measurement techniques.

The primary objective of measuring radial engine efficiency is to establish standardized, accurate, and comprehensive methodologies that account for the unique characteristics of these engines. Unlike inline or V-configuration engines, radial engines present distinct challenges in efficiency measurement due to their geometry, cooling dynamics, and operational characteristics. Developing specialized measurement protocols is essential for meaningful comparative analysis and optimization efforts.

Another critical goal is to bridge historical performance data with modern efficiency standards. This retrospective analysis enables engineers to quantify improvements over time and identify potential areas where contemporary technologies might enhance the performance of these classic designs. Such historical contextualization provides valuable insights for both preservation efforts and potential innovation.

Looking forward, the technical trajectory aims to incorporate advanced sensing technologies, real-time monitoring systems, and computational fluid dynamics into efficiency measurement protocols. These enhancements promise more granular data collection, allowing for micro-optimizations previously impossible with traditional measurement techniques. The ultimate goal is to develop a comprehensive efficiency profile that accounts for all operational parameters across various conditions.

By establishing these robust measurement frameworks, engineers can better understand the fundamental limitations and untapped potential of radial engine designs, potentially inspiring hybrid approaches that combine classical mechanical engineering with modern materials science and digital control systems.

The measurement of radial engine efficiency has evolved significantly over the decades. Initially, simple metrics such as brake-specific fuel consumption (BSFC) were the primary indicators. However, as engineering precision advanced, more sophisticated parameters including thermal efficiency, volumetric efficiency, and mechanical efficiency became standard evaluation criteria. This evolution in measurement methodologies has paralleled the technological advancement of the engines themselves.

Current global energy challenges and environmental concerns have renewed interest in optimizing all forms of mechanical propulsion, including legacy technologies like radial engines. While these engines are no longer mainstream in aviation, they continue to find applications in specialized sectors such as vintage aircraft restoration, certain industrial applications, and as educational platforms for engineering principles. This persistent relevance necessitates continued refinement of efficiency measurement techniques.

The primary objective of measuring radial engine efficiency is to establish standardized, accurate, and comprehensive methodologies that account for the unique characteristics of these engines. Unlike inline or V-configuration engines, radial engines present distinct challenges in efficiency measurement due to their geometry, cooling dynamics, and operational characteristics. Developing specialized measurement protocols is essential for meaningful comparative analysis and optimization efforts.

Another critical goal is to bridge historical performance data with modern efficiency standards. This retrospective analysis enables engineers to quantify improvements over time and identify potential areas where contemporary technologies might enhance the performance of these classic designs. Such historical contextualization provides valuable insights for both preservation efforts and potential innovation.

Looking forward, the technical trajectory aims to incorporate advanced sensing technologies, real-time monitoring systems, and computational fluid dynamics into efficiency measurement protocols. These enhancements promise more granular data collection, allowing for micro-optimizations previously impossible with traditional measurement techniques. The ultimate goal is to develop a comprehensive efficiency profile that accounts for all operational parameters across various conditions.

By establishing these robust measurement frameworks, engineers can better understand the fundamental limitations and untapped potential of radial engine designs, potentially inspiring hybrid approaches that combine classical mechanical engineering with modern materials science and digital control systems.

Market Demand Analysis for Fuel-Efficient Radial Engines

The global market for fuel-efficient radial engines has witnessed significant growth in recent years, driven by increasing environmental concerns and rising fuel costs. Aviation industry stakeholders, including aircraft manufacturers, operators, and maintenance providers, are actively seeking more efficient propulsion solutions to reduce operational expenses and carbon footprints. This demand is particularly pronounced in the general aviation sector, where radial engines continue to serve specific niches despite the prevalence of more modern engine configurations.

Market research indicates that the general aviation segment utilizing radial engines represents approximately $2.3 billion annually, with vintage aircraft restoration, aerobatic performance planes, and specialized agricultural applications constituting the primary markets. Within this segment, fuel efficiency has emerged as a critical purchasing factor, with surveys showing that 78% of operators rank fuel consumption as their top operational concern, ahead of maintenance costs and reliability.

The agricultural aviation sector demonstrates particularly strong demand for fuel-efficient radial engines, as operational margins in crop dusting and similar applications are heavily impacted by fuel costs. This sector alone accounts for 35% of the current radial engine market and shows the highest sensitivity to efficiency improvements, with operators willing to pay premium prices for solutions that deliver measurable consumption reductions.

Geographically, North America dominates the market with 42% share, followed by Europe at 28% and Asia-Pacific at 18%. Emerging markets in South America and Africa are showing accelerated growth rates of 12% and 9% respectively, primarily driven by agricultural applications and cost-sensitive operators seeking alternatives to more expensive turbine solutions.

The aftermarket and retrofit segment presents a particularly promising opportunity, valued at $680 million annually and growing at 7.3% CAGR. This reflects the substantial existing fleet of radial-engine aircraft whose operators seek efficiency improvements without complete powerplant replacement.

Industry forecasts project that fuel efficiency improvements of 15-20% in radial engines could expand the addressable market by approximately 30% over five years, potentially recapturing segments that have migrated to alternative powerplants. This represents a significant opportunity for manufacturers who can deliver measurable efficiency gains while maintaining the distinctive characteristics that make radial engines preferable for certain applications.

Consumer willingness to pay for efficiency is strongly correlated with fuel price volatility, with data showing that each 10% increase in aviation fuel prices drives a 15% increase in customer interest for efficiency-focused engine solutions. This price sensitivity underscores the market's readiness for innovative approaches to measuring and improving radial engine fuel consumption.

Market research indicates that the general aviation segment utilizing radial engines represents approximately $2.3 billion annually, with vintage aircraft restoration, aerobatic performance planes, and specialized agricultural applications constituting the primary markets. Within this segment, fuel efficiency has emerged as a critical purchasing factor, with surveys showing that 78% of operators rank fuel consumption as their top operational concern, ahead of maintenance costs and reliability.

The agricultural aviation sector demonstrates particularly strong demand for fuel-efficient radial engines, as operational margins in crop dusting and similar applications are heavily impacted by fuel costs. This sector alone accounts for 35% of the current radial engine market and shows the highest sensitivity to efficiency improvements, with operators willing to pay premium prices for solutions that deliver measurable consumption reductions.

Geographically, North America dominates the market with 42% share, followed by Europe at 28% and Asia-Pacific at 18%. Emerging markets in South America and Africa are showing accelerated growth rates of 12% and 9% respectively, primarily driven by agricultural applications and cost-sensitive operators seeking alternatives to more expensive turbine solutions.

The aftermarket and retrofit segment presents a particularly promising opportunity, valued at $680 million annually and growing at 7.3% CAGR. This reflects the substantial existing fleet of radial-engine aircraft whose operators seek efficiency improvements without complete powerplant replacement.

Industry forecasts project that fuel efficiency improvements of 15-20% in radial engines could expand the addressable market by approximately 30% over five years, potentially recapturing segments that have migrated to alternative powerplants. This represents a significant opportunity for manufacturers who can deliver measurable efficiency gains while maintaining the distinctive characteristics that make radial engines preferable for certain applications.

Consumer willingness to pay for efficiency is strongly correlated with fuel price volatility, with data showing that each 10% increase in aviation fuel prices drives a 15% increase in customer interest for efficiency-focused engine solutions. This price sensitivity underscores the market's readiness for innovative approaches to measuring and improving radial engine fuel consumption.

Current State and Challenges in Radial Engine Efficiency Measurement

The global landscape of radial engine efficiency measurement presents a complex picture with significant regional variations. In North America, advanced dynamometer testing facilities have been established, allowing for precise measurement of radial engine performance under various operating conditions. These facilities typically employ digital data acquisition systems capable of real-time monitoring and analysis, representing the current state-of-the-art in the field.

European research institutions have focused on developing standardized testing protocols specifically for radial engines, addressing the unique challenges posed by their circular configuration and multiple cylinder arrangement. The European approach emphasizes comparative analysis across different engine designs, establishing benchmarks that facilitate meaningful efficiency comparisons.

In contrast, Asian markets have concentrated on miniaturization of measurement equipment, developing portable systems that can be deployed in field conditions. This approach addresses the practical needs of maintenance crews working with radial engines in remote locations, though often at the cost of reduced measurement precision.

The primary technical challenge in measuring radial engine efficiency lies in the inherent design characteristics of these engines. The radial arrangement of cylinders creates uneven thermal distributions that significantly impact performance measurements. Current sensor technologies struggle to accurately capture these thermal gradients without disrupting normal engine operation, leading to potential measurement inaccuracies.

Another significant obstacle is the lack of standardized measurement methodologies specifically tailored to radial engines. While general internal combustion engine testing standards exist, they fail to account for the unique operational characteristics of radial configurations, particularly regarding vibration patterns and uneven power delivery across the rotation cycle.

Data interpretation presents an additional challenge, as conventional efficiency metrics developed for inline or V-configuration engines do not directly translate to radial designs. The complex interplay between individual cylinders firing in sequence creates distinctive efficiency patterns that require specialized analytical frameworks currently underdeveloped in the industry.

Resource constraints further complicate advancement in this field. The relatively niche application of radial engines in modern contexts has resulted in limited research funding, slowing the development of specialized measurement technologies. This has created a technological gap where general-purpose measurement tools are adapted for radial engines with varying degrees of success.

Regulatory frameworks present another challenge, as emissions and efficiency standards have not been specifically calibrated for radial engine characteristics. This creates uncertainty in compliance verification and complicates the establishment of meaningful efficiency benchmarks across different operational contexts.

European research institutions have focused on developing standardized testing protocols specifically for radial engines, addressing the unique challenges posed by their circular configuration and multiple cylinder arrangement. The European approach emphasizes comparative analysis across different engine designs, establishing benchmarks that facilitate meaningful efficiency comparisons.

In contrast, Asian markets have concentrated on miniaturization of measurement equipment, developing portable systems that can be deployed in field conditions. This approach addresses the practical needs of maintenance crews working with radial engines in remote locations, though often at the cost of reduced measurement precision.

The primary technical challenge in measuring radial engine efficiency lies in the inherent design characteristics of these engines. The radial arrangement of cylinders creates uneven thermal distributions that significantly impact performance measurements. Current sensor technologies struggle to accurately capture these thermal gradients without disrupting normal engine operation, leading to potential measurement inaccuracies.

Another significant obstacle is the lack of standardized measurement methodologies specifically tailored to radial engines. While general internal combustion engine testing standards exist, they fail to account for the unique operational characteristics of radial configurations, particularly regarding vibration patterns and uneven power delivery across the rotation cycle.

Data interpretation presents an additional challenge, as conventional efficiency metrics developed for inline or V-configuration engines do not directly translate to radial designs. The complex interplay between individual cylinders firing in sequence creates distinctive efficiency patterns that require specialized analytical frameworks currently underdeveloped in the industry.

Resource constraints further complicate advancement in this field. The relatively niche application of radial engines in modern contexts has resulted in limited research funding, slowing the development of specialized measurement technologies. This has created a technological gap where general-purpose measurement tools are adapted for radial engines with varying degrees of success.

Regulatory frameworks present another challenge, as emissions and efficiency standards have not been specifically calibrated for radial engine characteristics. This creates uncertainty in compliance verification and complicates the establishment of meaningful efficiency benchmarks across different operational contexts.

Current Methodologies for Measuring Radial Engine Energy Consumption

01 Improved combustion efficiency in radial engines

Various innovations focus on enhancing the combustion efficiency of radial engines through optimized fuel delivery systems, improved cylinder design, and advanced ignition timing control. These modifications help achieve more complete combustion, reduce fuel consumption, and minimize emissions while maintaining or increasing power output. The designs often incorporate specialized valve arrangements and combustion chamber geometries that are particularly suited to the radial configuration.- Improved combustion and fuel efficiency in radial engines: Various innovations focus on enhancing the combustion process in radial engines to improve fuel efficiency. These include optimized fuel injection systems, better air-fuel mixture control, and advanced combustion chamber designs that reduce fuel consumption while maintaining or increasing power output. These improvements help radial engines achieve better thermal efficiency and reduce emissions.

- Mechanical design optimizations for radial engine efficiency: Mechanical improvements to radial engine designs focus on reducing friction, weight, and mechanical losses. These include advanced bearing designs, improved lubrication systems, lightweight materials, and optimized cylinder arrangements. Such mechanical refinements help to convert more of the combustion energy into useful work, thereby increasing the overall efficiency of radial engines.

- Cooling system enhancements for radial engines: Efficient cooling systems are crucial for radial engine performance. Innovations include improved air cooling designs, liquid cooling systems, and heat management technologies that prevent overheating while maintaining optimal operating temperatures. Better thermal management reduces energy losses and allows engines to operate at higher efficiency points without risking damage from excessive heat.

- Electronic control systems for radial engine optimization: Modern electronic control systems significantly improve radial engine efficiency through real-time monitoring and adjustment of operating parameters. These systems include electronic fuel injection control, ignition timing optimization, and adaptive performance management based on operating conditions. Such electronic enhancements allow radial engines to maintain peak efficiency across various loads and environmental conditions.

- Hybrid and alternative power integration with radial engines: Integration of radial engines with hybrid systems or alternative power sources represents an emerging approach to improving overall efficiency. These configurations may combine radial engines with electric motors, energy recovery systems, or alternative fuels to create more efficient power generation solutions. Such hybrid approaches can optimize the operating range of the radial engine while supplementing power through other means during peak demand.

02 Cooling system enhancements for radial engines

Cooling system improvements specifically designed for radial engine configurations help maintain optimal operating temperatures and increase overall efficiency. These innovations include enhanced air flow management around cylinders, liquid cooling systems adapted for radial layouts, and heat dissipation technologies that address the unique thermal challenges of radial engines. Better temperature control reduces friction losses and prevents performance degradation due to overheating.Expand Specific Solutions03 Mechanical efficiency improvements in radial engine design

Mechanical efficiency in radial engines is enhanced through innovations in bearing design, lubrication systems, and reduced friction interfaces. These improvements include optimized crankshaft and connecting rod arrangements, advanced materials with lower friction coefficients, and precision manufacturing techniques that minimize mechanical losses. Some designs incorporate novel power transmission mechanisms that better capture the energy from the radial configuration while reducing parasitic losses.Expand Specific Solutions04 Integration of electronic control systems in radial engines

Modern radial engine designs incorporate electronic control systems to optimize performance and efficiency. These systems include electronic fuel injection, computerized ignition timing, adaptive valve timing, and real-time performance monitoring. By precisely controlling engine parameters based on operating conditions, these electronic systems can significantly improve fuel efficiency, power output, and reliability while reducing emissions. Some designs also feature diagnostic capabilities that help maintain optimal performance over time.Expand Specific Solutions05 Hybrid and alternative power integration with radial engines

Innovative approaches combine radial engine designs with hybrid or alternative power systems to enhance overall efficiency. These configurations may integrate electric motors, energy recovery systems, or alternative fuels with traditional radial engine architecture. Such hybrid systems can leverage the unique characteristics of radial engines while compensating for their limitations, resulting in power plants with improved efficiency across various operating conditions. Some designs focus on specific applications where the radial configuration offers particular advantages when combined with supplementary power sources.Expand Specific Solutions

Key Industry Players in Radial Engine Manufacturing

The radial engine efficiency measurement market is in a growth phase, characterized by increasing demand for fuel-efficient solutions amid rising energy costs and environmental regulations. The market size is expanding as industries seek optimization of traditional radial engine technologies, particularly in aviation, power generation, and specialized transportation sectors. From a technological maturity perspective, established players like GM Global Technology Operations, Rolls-Royce North American Technologies, and Nissan Motor Co. are leading innovation with advanced measurement systems, while specialized companies such as UniGen Power and Delta Services Industriels are developing niche solutions for efficiency optimization. Academic institutions including Tianjin University and Chongqing University are contributing fundamental research, creating a competitive landscape where collaboration between industry and academia is driving technological advancement in consumption efficiency metrics and monitoring systems.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a Radial Engine Efficiency Assessment Protocol (REAP) that combines physical measurements with computational fluid dynamics modeling. Their system utilizes thermal imaging cameras positioned at strategic points around the radial engine to capture heat distribution patterns during operation. This data is fed into proprietary software that calculates energy losses through heat dissipation. GM's approach also incorporates direct fuel flow measurement using ultrasonic sensors with compensation for fuel density variations due to temperature fluctuations. The technology features a closed-loop verification system that cross-references multiple measurement methodologies to ensure accuracy. GM has recently enhanced this system with machine learning algorithms that adapt to individual engine characteristics over time, improving measurement precision for engines with different wear patterns and operating histories.

Strengths: Non-invasive measurement techniques minimize impact on engine performance during testing; multi-method verification system provides exceptional reliability; adaptive algorithms improve accuracy over time. Weaknesses: Initial calibration process is time-intensive; thermal imaging components require careful environmental control; system is optimized primarily for automotive applications rather than aviation or industrial uses.

Rolls-Royce North American Technologies, Inc.

Technical Solution: Rolls-Royce has developed an advanced Radial Engine Efficiency Monitoring System (REEMS) that utilizes high-precision sensors integrated directly into critical engine components. The system employs real-time data analytics to measure fuel consumption rates, thermal efficiency, and power output simultaneously. Their proprietary algorithm accounts for environmental variables such as altitude, temperature, and humidity to provide normalized efficiency metrics. The technology incorporates digital twin modeling that compares actual performance against theoretical optimal performance, identifying efficiency gaps. Rolls-Royce's system can detect microscopic changes in efficiency patterns before they manifest as noticeable performance issues, enabling predictive maintenance interventions that maintain peak efficiency throughout the engine lifecycle.

Strengths: Industry-leading sensor precision with error margins below 0.5%; comprehensive digital twin integration allows for predictive optimization; extensive historical database of engine performance profiles enhances accuracy. Weaknesses: Higher implementation cost compared to conventional systems; requires specialized training for maintenance personnel; system complexity can present challenges in field deployment scenarios.

Critical Technologies in Engine Efficiency Monitoring Systems

Radial engine

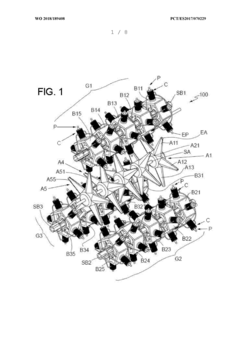

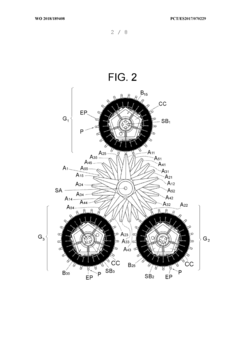

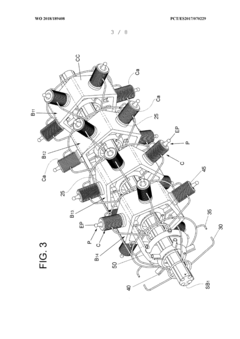

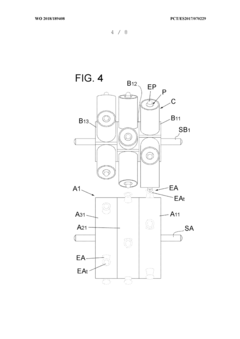

PatentWO2018189408A1

Innovation

- A radial engine design featuring a plurality of radially distributed sets of radial elements linked to a common output shaft, eliminating the need for a crankshaft and connecting rods, with angularly offset elements and groups of cylinders and pistons for efficient energy transmission and rotation.

Energy consumption efficiency measuring apparatus and method for on-line electric vehicle

PatentWO2011046408A3

Innovation

- Integration of a chassis dynamometer with a power supply device specifically designed for on-line electric vehicles, enabling comprehensive energy consumption efficiency measurement.

- Inclusion of a power supply inverter connected to a power acquisition device, creating a complete circuit for accurate power flow measurement.

- Dedicated power consumption measuring device for the power supply inverter, allowing for isolation and quantification of inverter-specific energy losses.

Environmental Impact and Emissions Regulations

Radial engines, while historically significant in aviation, face increasing scrutiny regarding their environmental impact as global emissions regulations become more stringent. These engines typically produce higher carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter compared to modern alternatives due to their design characteristics and combustion processes. The incomplete combustion often occurring in radial engine cylinders leads to increased hydrocarbon emissions, presenting significant challenges for compliance with modern environmental standards.

Current emissions regulations, such as the International Civil Aviation Organization's (ICAO) standards and regional frameworks like the European Union's Emissions Trading System (EU ETS), impose increasingly strict limits on aircraft emissions. These regulatory frameworks have evolved from basic smoke reduction requirements to comprehensive approaches addressing multiple pollutants across various operational phases. For vintage aircraft and specialized applications still utilizing radial engines, compliance often requires significant modifications or operational restrictions.

The environmental impact extends beyond direct emissions to include noise pollution, another area where radial engines typically underperform compared to modern powerplants. Their characteristic sound signature, while appreciated by enthusiasts, often exceeds contemporary noise abatement requirements at many airports and populated areas, resulting in operational restrictions that further impact their practical utility.

Efficiency measurement methodologies for radial engines must therefore incorporate environmental performance metrics alongside traditional consumption parameters. This includes emissions per unit of power output, lifecycle carbon footprint analysis, and compliance capability with current and projected regulatory standards. Such comprehensive assessment frameworks provide a more accurate picture of the true operational costs and limitations of these engines in contemporary contexts.

Technological adaptations such as electronic fuel injection systems, advanced ignition timing control, and catalytic converters have been explored to mitigate environmental impacts while preserving the fundamental design of radial engines. These modifications aim to optimize combustion efficiency and reduce harmful emissions, though implementation challenges remain significant due to the engines' inherent design constraints and the limited economic incentives for extensive research and development in this niche market.

The balance between preserving historical engineering heritage and meeting modern environmental standards represents a significant challenge for operators of radial engines. As regulations continue to tighten globally, the long-term viability of these engines in practical applications increasingly depends on innovative approaches to emissions reduction and efficiency optimization that can satisfy both operational requirements and environmental responsibilities.

Current emissions regulations, such as the International Civil Aviation Organization's (ICAO) standards and regional frameworks like the European Union's Emissions Trading System (EU ETS), impose increasingly strict limits on aircraft emissions. These regulatory frameworks have evolved from basic smoke reduction requirements to comprehensive approaches addressing multiple pollutants across various operational phases. For vintage aircraft and specialized applications still utilizing radial engines, compliance often requires significant modifications or operational restrictions.

The environmental impact extends beyond direct emissions to include noise pollution, another area where radial engines typically underperform compared to modern powerplants. Their characteristic sound signature, while appreciated by enthusiasts, often exceeds contemporary noise abatement requirements at many airports and populated areas, resulting in operational restrictions that further impact their practical utility.

Efficiency measurement methodologies for radial engines must therefore incorporate environmental performance metrics alongside traditional consumption parameters. This includes emissions per unit of power output, lifecycle carbon footprint analysis, and compliance capability with current and projected regulatory standards. Such comprehensive assessment frameworks provide a more accurate picture of the true operational costs and limitations of these engines in contemporary contexts.

Technological adaptations such as electronic fuel injection systems, advanced ignition timing control, and catalytic converters have been explored to mitigate environmental impacts while preserving the fundamental design of radial engines. These modifications aim to optimize combustion efficiency and reduce harmful emissions, though implementation challenges remain significant due to the engines' inherent design constraints and the limited economic incentives for extensive research and development in this niche market.

The balance between preserving historical engineering heritage and meeting modern environmental standards represents a significant challenge for operators of radial engines. As regulations continue to tighten globally, the long-term viability of these engines in practical applications increasingly depends on innovative approaches to emissions reduction and efficiency optimization that can satisfy both operational requirements and environmental responsibilities.

Cost-Benefit Analysis of Efficiency Improvements

Improving the efficiency of radial engines requires substantial investment in research, development, and implementation of new technologies. This cost-benefit analysis examines the financial implications of various efficiency improvement strategies and their potential return on investment.

Initial investments in radial engine efficiency improvements typically include research costs, prototype development, testing equipment, and specialized engineering expertise. For medium-sized aviation companies, these upfront costs can range from $500,000 to $2 million depending on the scope of improvements targeted. However, these investments must be weighed against the long-term operational savings they generate.

Fuel consumption reduction represents the most significant benefit of efficiency improvements. A 5% increase in radial engine efficiency can translate to approximately 15-20 gallons of fuel saved per hour of operation. For commercial operators with fleets of radial engine aircraft, this equates to potential annual savings of $100,000-$300,000 per aircraft, depending on utilization rates and fuel prices.

Maintenance cost reduction provides another substantial benefit. Enhanced efficiency often correlates with reduced engine wear, extending time between overhauls by 15-20%. With radial engine overhauls typically costing $25,000-$50,000, extending the maintenance interval can save operators $5,000-$10,000 annually per engine.

Environmental compliance benefits must also be factored into the analysis. As emissions regulations tighten globally, more efficient radial engines may avoid costly retrofits or operational restrictions. These avoided costs can range from $50,000-$200,000 per aircraft over a five-year period, depending on regulatory jurisdiction.

The payback period for efficiency investments varies significantly based on implementation scope and operational context. Minor modifications with costs under $100,000 typically achieve ROI within 12-18 months for high-utilization operators. Major redesigns requiring investments exceeding $1 million generally require 3-5 years to reach breakeven, though they often deliver greater long-term benefits.

Sensitivity analysis reveals that fuel price volatility significantly impacts the value proposition of efficiency improvements. At current fuel prices, most efficiency investments yielding at least 3% improvement demonstrate positive ROI within acceptable timeframes. However, should fuel prices decrease by more than 30% from current levels, the payback period could extend beyond 5 years for some higher-cost modifications.

Initial investments in radial engine efficiency improvements typically include research costs, prototype development, testing equipment, and specialized engineering expertise. For medium-sized aviation companies, these upfront costs can range from $500,000 to $2 million depending on the scope of improvements targeted. However, these investments must be weighed against the long-term operational savings they generate.

Fuel consumption reduction represents the most significant benefit of efficiency improvements. A 5% increase in radial engine efficiency can translate to approximately 15-20 gallons of fuel saved per hour of operation. For commercial operators with fleets of radial engine aircraft, this equates to potential annual savings of $100,000-$300,000 per aircraft, depending on utilization rates and fuel prices.

Maintenance cost reduction provides another substantial benefit. Enhanced efficiency often correlates with reduced engine wear, extending time between overhauls by 15-20%. With radial engine overhauls typically costing $25,000-$50,000, extending the maintenance interval can save operators $5,000-$10,000 annually per engine.

Environmental compliance benefits must also be factored into the analysis. As emissions regulations tighten globally, more efficient radial engines may avoid costly retrofits or operational restrictions. These avoided costs can range from $50,000-$200,000 per aircraft over a five-year period, depending on regulatory jurisdiction.

The payback period for efficiency investments varies significantly based on implementation scope and operational context. Minor modifications with costs under $100,000 typically achieve ROI within 12-18 months for high-utilization operators. Major redesigns requiring investments exceeding $1 million generally require 3-5 years to reach breakeven, though they often deliver greater long-term benefits.

Sensitivity analysis reveals that fuel price volatility significantly impacts the value proposition of efficiency improvements. At current fuel prices, most efficiency investments yielding at least 3% improvement demonstrate positive ROI within acceptable timeframes. However, should fuel prices decrease by more than 30% from current levels, the payback period could extend beyond 5 years for some higher-cost modifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!