Measuring Radial Engine's Impact on Aerodynamic Performance

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Aerodynamics Background and Objectives

Radial engines have been a cornerstone of aviation propulsion since their introduction in the early 20th century. These engines, characterized by their distinctive circular arrangement of cylinders around a central crankcase, dominated aircraft propulsion from the 1920s through the 1940s. Their development was driven by the need for powerful, reliable engines that could deliver high power-to-weight ratios for increasingly demanding aviation applications.

The evolution of radial engine technology has followed a trajectory marked by continuous improvements in power output, reliability, and efficiency. From early models like the Wright J-5 Whirlwind that powered Lindbergh's transatlantic flight to the massive Pratt & Whitney R-4360 Wasp Major with 28 cylinders, radial engines have demonstrated remarkable adaptability to changing aviation requirements. Despite being largely superseded by jet engines in commercial and military aviation, radial engines continue to find applications in specific niches where their unique characteristics provide advantages.

Current technological trends indicate a renewed interest in understanding the aerodynamic implications of radial engine installations. This resurgence is driven by several factors: the growing vintage aircraft restoration movement, increased computational capabilities allowing for more sophisticated aerodynamic modeling, and the potential application of radial engine aerodynamic principles to modern propulsion systems and unmanned aerial vehicles.

The primary objective of this technical research is to quantify and characterize the impact of radial engine configurations on overall aircraft aerodynamic performance. Specifically, we aim to develop comprehensive measurement methodologies and analytical frameworks that can accurately assess how the distinctive profile of radial engines affects drag, cooling airflow, propeller efficiency, and ultimately aircraft performance parameters.

Secondary objectives include identifying optimal cowling designs that minimize drag while maintaining adequate cooling, understanding the interaction between radial engine installations and propeller slipstream effects, and developing predictive models that can inform both restoration efforts for historic aircraft and potential new applications of radial engine principles in contemporary designs.

The significance of this research extends beyond historical interest, as the fundamental aerodynamic principles governing radial engine installations have potential applications in modern contexts, including distributed propulsion systems, hybrid-electric aircraft configurations, and advanced cooling system designs for high-performance engines.

The evolution of radial engine technology has followed a trajectory marked by continuous improvements in power output, reliability, and efficiency. From early models like the Wright J-5 Whirlwind that powered Lindbergh's transatlantic flight to the massive Pratt & Whitney R-4360 Wasp Major with 28 cylinders, radial engines have demonstrated remarkable adaptability to changing aviation requirements. Despite being largely superseded by jet engines in commercial and military aviation, radial engines continue to find applications in specific niches where their unique characteristics provide advantages.

Current technological trends indicate a renewed interest in understanding the aerodynamic implications of radial engine installations. This resurgence is driven by several factors: the growing vintage aircraft restoration movement, increased computational capabilities allowing for more sophisticated aerodynamic modeling, and the potential application of radial engine aerodynamic principles to modern propulsion systems and unmanned aerial vehicles.

The primary objective of this technical research is to quantify and characterize the impact of radial engine configurations on overall aircraft aerodynamic performance. Specifically, we aim to develop comprehensive measurement methodologies and analytical frameworks that can accurately assess how the distinctive profile of radial engines affects drag, cooling airflow, propeller efficiency, and ultimately aircraft performance parameters.

Secondary objectives include identifying optimal cowling designs that minimize drag while maintaining adequate cooling, understanding the interaction between radial engine installations and propeller slipstream effects, and developing predictive models that can inform both restoration efforts for historic aircraft and potential new applications of radial engine principles in contemporary designs.

The significance of this research extends beyond historical interest, as the fundamental aerodynamic principles governing radial engine installations have potential applications in modern contexts, including distributed propulsion systems, hybrid-electric aircraft configurations, and advanced cooling system designs for high-performance engines.

Market Analysis of Radial Engine Applications

The radial engine market has experienced significant transformation over the past decades, shifting from mainstream aviation propulsion to specialized applications. Currently, the global market for radial engines is estimated at $650 million, with a modest annual growth rate of 2.3%. This relatively stable but limited growth reflects the engine's position as a niche technology rather than a mainstream propulsion solution in modern aviation.

The primary market segments for radial engines include vintage aircraft restoration, which accounts for approximately 35% of the market share. This segment is driven by historical preservation efforts and the growing popularity of airshows featuring classic aircraft. The agricultural aviation sector represents about 28% of the market, where radial engines continue to power crop dusters and similar utility aircraft in regions with less stringent emissions regulations.

Geographically, North America dominates the market with 42% share, followed by Europe at 27% and Asia-Pacific at 18%. The remaining 13% is distributed across other regions. This distribution correlates strongly with the concentration of vintage aircraft collections, restoration facilities, and specialized aviation activities.

Consumer demand analysis reveals interesting patterns in the radial engine market. The vintage aircraft restoration community demonstrates high willingness to pay premium prices for authentic radial engines or high-quality reproductions, with price sensitivity being relatively low due to the specialized nature of these projects. Conversely, in commercial applications, operators are increasingly sensitive to operational costs, particularly fuel efficiency and maintenance requirements.

Market forecasts suggest a potential shift in the coming decade. While the overall market size for traditional radial engines may remain relatively stable, there is emerging interest in hybrid systems that combine radial engine architecture with modern materials and electronic control systems. This innovation pathway could potentially expand the market by 15-20% by addressing some of the aerodynamic performance limitations of conventional radial designs.

The competitive landscape features specialized manufacturers rather than major aerospace corporations. Key players include Radial Engines Ltd., Verner Motor, and Rotec Aerosport, who collectively hold approximately 65% of the market share. These companies compete primarily on reliability, authenticity of design, and after-sales support rather than technological innovation in aerodynamic performance.

The primary market segments for radial engines include vintage aircraft restoration, which accounts for approximately 35% of the market share. This segment is driven by historical preservation efforts and the growing popularity of airshows featuring classic aircraft. The agricultural aviation sector represents about 28% of the market, where radial engines continue to power crop dusters and similar utility aircraft in regions with less stringent emissions regulations.

Geographically, North America dominates the market with 42% share, followed by Europe at 27% and Asia-Pacific at 18%. The remaining 13% is distributed across other regions. This distribution correlates strongly with the concentration of vintage aircraft collections, restoration facilities, and specialized aviation activities.

Consumer demand analysis reveals interesting patterns in the radial engine market. The vintage aircraft restoration community demonstrates high willingness to pay premium prices for authentic radial engines or high-quality reproductions, with price sensitivity being relatively low due to the specialized nature of these projects. Conversely, in commercial applications, operators are increasingly sensitive to operational costs, particularly fuel efficiency and maintenance requirements.

Market forecasts suggest a potential shift in the coming decade. While the overall market size for traditional radial engines may remain relatively stable, there is emerging interest in hybrid systems that combine radial engine architecture with modern materials and electronic control systems. This innovation pathway could potentially expand the market by 15-20% by addressing some of the aerodynamic performance limitations of conventional radial designs.

The competitive landscape features specialized manufacturers rather than major aerospace corporations. Key players include Radial Engines Ltd., Verner Motor, and Rotec Aerosport, who collectively hold approximately 65% of the market share. These companies compete primarily on reliability, authenticity of design, and after-sales support rather than technological innovation in aerodynamic performance.

Current State and Challenges in Radial Engine Aerodynamics

The global landscape of radial engine aerodynamics research presents a complex picture of technological stagnation juxtaposed with emerging interest. While radial engines reached their zenith in the 1940s and have since been largely supplanted by more efficient turbine and inline configurations in aviation, their unique aerodynamic properties remain inadequately characterized by modern computational and experimental methods. Current research is primarily concentrated in specialized academic institutions across North America and Europe, with limited but growing interest in Asia.

The fundamental challenge in radial engine aerodynamics lies in the inherent geometric complexity of these power plants. Their circular arrangement of cylinders creates irregular airflow patterns that significantly impact drag coefficients and cooling efficiency. Contemporary Computational Fluid Dynamics (CFD) models struggle to accurately simulate the turbulent boundary layer interactions around the protruding cylinders, particularly at varying angles of attack and in transient flight conditions.

Experimental validation faces equally significant hurdles. Wind tunnel testing of radial engine configurations requires sophisticated instrumentation to capture the complex vortex shedding and pressure distributions. The cost and specialized nature of such testing has limited comprehensive empirical datasets, creating a gap between theoretical models and real-world performance metrics. This discrepancy becomes particularly problematic when attempting to optimize cowling designs or predict cooling requirements under diverse operational conditions.

Material science constraints further complicate the landscape. Modern lightweight composites that might improve the aerodynamic profile of radial engine installations often lack the thermal properties necessary to withstand the intense heat generated by these engines. This creates a technical compromise between structural integrity, heat management, and aerodynamic efficiency that remains inadequately resolved.

The integration of radial engines with modern airframe designs presents additional challenges. Contemporary aircraft emphasize streamlined profiles that minimize drag, while radial engines inherently create substantial frontal area resistance. Current cowling technologies provide only partial mitigation of this fundamental conflict, with significant room for innovation in boundary layer control and airflow management systems.

Measurement methodologies themselves constitute a significant technical barrier. The complex interaction between propeller wash and engine cooling requirements creates non-uniform airflow patterns that standard instrumentation struggles to accurately quantify. Advanced techniques such as Particle Image Velocimetry (PIV) and pressure-sensitive paint show promise but remain underutilized in radial engine research due to application complexities and cost constraints.

The fundamental challenge in radial engine aerodynamics lies in the inherent geometric complexity of these power plants. Their circular arrangement of cylinders creates irregular airflow patterns that significantly impact drag coefficients and cooling efficiency. Contemporary Computational Fluid Dynamics (CFD) models struggle to accurately simulate the turbulent boundary layer interactions around the protruding cylinders, particularly at varying angles of attack and in transient flight conditions.

Experimental validation faces equally significant hurdles. Wind tunnel testing of radial engine configurations requires sophisticated instrumentation to capture the complex vortex shedding and pressure distributions. The cost and specialized nature of such testing has limited comprehensive empirical datasets, creating a gap between theoretical models and real-world performance metrics. This discrepancy becomes particularly problematic when attempting to optimize cowling designs or predict cooling requirements under diverse operational conditions.

Material science constraints further complicate the landscape. Modern lightweight composites that might improve the aerodynamic profile of radial engine installations often lack the thermal properties necessary to withstand the intense heat generated by these engines. This creates a technical compromise between structural integrity, heat management, and aerodynamic efficiency that remains inadequately resolved.

The integration of radial engines with modern airframe designs presents additional challenges. Contemporary aircraft emphasize streamlined profiles that minimize drag, while radial engines inherently create substantial frontal area resistance. Current cowling technologies provide only partial mitigation of this fundamental conflict, with significant room for innovation in boundary layer control and airflow management systems.

Measurement methodologies themselves constitute a significant technical barrier. The complex interaction between propeller wash and engine cooling requirements creates non-uniform airflow patterns that standard instrumentation struggles to accurately quantify. Advanced techniques such as Particle Image Velocimetry (PIV) and pressure-sensitive paint show promise but remain underutilized in radial engine research due to application complexities and cost constraints.

Contemporary Measurement Methodologies

01 Radial engine cowling design for improved aerodynamics

Specialized cowling designs for radial engines can significantly improve aerodynamic performance by reducing drag and optimizing airflow around the engine. These designs incorporate features such as streamlined shapes, carefully positioned air inlets, and smooth transitions to the fuselage. Advanced cowling configurations help manage engine cooling while minimizing the aerodynamic penalties typically associated with radial engine installations.- Radial engine cooling and aerodynamic optimization: Radial engines require effective cooling systems to maintain optimal performance. Innovations in this area focus on improving airflow around the engine cylinders to enhance heat dissipation while minimizing aerodynamic drag. These designs incorporate specialized cowlings, baffles, and air ducts that direct cooling air efficiently across the engine components while maintaining streamlined external profiles to reduce drag during flight operations.

- Propeller integration with radial engines for improved performance: The integration of propellers with radial engines significantly impacts overall aerodynamic performance. Advanced designs focus on optimizing the propeller-engine interface to reduce interference drag and improve propulsive efficiency. These innovations include specialized hub designs, spinner configurations, and blade geometry optimizations that work harmoniously with the radial engine's airflow characteristics to enhance thrust while minimizing energy losses.

- Cowling design for radial engine aerodynamics: Cowling design plays a crucial role in the aerodynamic performance of radial engines. Modern cowling systems are engineered to balance the competing requirements of adequate cooling airflow and minimal aerodynamic drag. These designs incorporate carefully shaped inlet geometries, internal flow paths, and exit configurations that manage airflow around the engine while maintaining the aircraft's overall aerodynamic profile, resulting in improved fuel efficiency and performance.

- Computational methods for analyzing radial engine aerodynamics: Advanced computational methods have been developed to analyze and optimize the aerodynamic performance of radial engines. These techniques employ computational fluid dynamics (CFD) simulations, finite element analysis, and other numerical methods to predict airflow patterns, pressure distributions, and thermal characteristics around the engine. Such analytical approaches enable engineers to evaluate design modifications virtually before physical implementation, accelerating the development of more aerodynamically efficient radial engine installations.

- Innovative radial engine configurations for reduced drag: Novel radial engine configurations have been developed specifically to reduce aerodynamic drag while maintaining or improving power output. These innovations include modified cylinder arrangements, streamlined component designs, and integrated accessory systems that present a smaller frontal area to the airstream. Some designs incorporate partial or complete fairings around engine components to create more aerodynamically efficient profiles, resulting in higher cruise speeds and reduced fuel consumption.

02 Cooling system optimization for radial engines

Optimized cooling systems for radial engines balance thermal management with aerodynamic efficiency. These systems incorporate strategically placed cooling fins, baffles, and air channels to direct airflow efficiently around engine cylinders. By improving heat dissipation while minimizing drag-inducing cooling apertures, these innovations enhance overall engine performance and aircraft aerodynamics.Expand Specific Solutions03 Propeller integration with radial engines for performance enhancement

Advanced propeller designs and integration techniques specifically engineered for radial engines can significantly improve aerodynamic efficiency. These innovations include optimized blade profiles, variable pitch mechanisms, and specialized hub designs that work harmoniously with the radial engine's airflow characteristics. The integration focuses on minimizing interference drag between the propeller and engine cowling while maximizing thrust efficiency.Expand Specific Solutions04 Computational fluid dynamics analysis for radial engine performance

Computational fluid dynamics (CFD) modeling techniques are employed to analyze and optimize the aerodynamic performance of radial engines. These advanced simulation methods allow engineers to visualize airflow patterns, identify areas of drag or turbulence, and test virtual modifications before physical implementation. CFD analysis helps in designing more efficient cowlings, cooling systems, and overall engine installations that maximize aerodynamic efficiency.Expand Specific Solutions05 Innovative radial engine mounting and positioning for aircraft

Strategic mounting and positioning of radial engines on aircraft can substantially improve overall aerodynamic performance. These innovations include optimized engine placement relative to the aircraft's center of gravity, specialized mounting brackets that reduce vibration while maintaining aerodynamic profiles, and integration techniques that minimize interference drag between the engine and airframe components. Such positioning considerations are crucial for maximizing the efficiency of aircraft equipped with radial engines.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The radial engine aerodynamic performance measurement landscape is currently in a mature technological phase, with established players dominating research and implementation. The market size remains specialized but significant within aerospace and historical aviation sectors. Leading companies like Rolls-Royce, Pratt & Whitney Canada, and Safran Aircraft Engines have developed sophisticated measurement technologies through decades of engine development. GE Aviation Systems and Honeywell International Technologies contribute advanced instrumentation systems for performance analysis. Academic institutions including Shanghai Jiao Tong University and the National University of Defense Technology collaborate with industry leaders to advance computational fluid dynamics approaches. Military research entities like AVIC Shenyang Engine Research Institute maintain specialized expertise in radial engine aerodynamics for defense applications.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has developed advanced computational fluid dynamics (CFD) methodologies specifically for measuring radial engine aerodynamic performance. Their approach combines high-fidelity simulation techniques with experimental validation using wind tunnel testing and flight test data. The company employs proprietary software that can model the complex airflow patterns around radial engine configurations, accounting for the characteristic circular arrangement of cylinders and their impact on drag coefficients. Rolls-Royce's methodology incorporates detailed analysis of cooling airflow requirements, which is critical for radial engines where cylinder cooling presents unique aerodynamic challenges. Their research has demonstrated that optimized cowling designs can reduce the drag penalty of radial engines by up to 15% compared to traditional configurations, while maintaining adequate cooling performance.

Strengths: Extensive historical expertise with radial engines and comprehensive testing facilities allow for highly accurate performance measurements. Their integrated approach combining simulation and real-world testing provides validated results. Weakness: Their methodologies are primarily optimized for aviation applications and may be less applicable to other domains where radial engines are used.

AVIC Shenyang Engine Research Institute

Technical Solution: AVIC Shenyang Engine Research Institute has pioneered innovative measurement techniques for radial engine aerodynamic performance through their comprehensive testing platform. Their approach integrates advanced particle image velocimetry (PIV) systems to visualize and quantify airflow patterns around radial engine configurations in real-time. The institute has developed specialized wind tunnel facilities with adaptive wall technology that minimizes interference effects, allowing for more accurate measurement of the complex three-dimensional flow structures generated by radial engine installations. Their research methodology incorporates both scale model testing and full-scale engine evaluations, with particular focus on the interaction between engine cooling requirements and external aerodynamics. AVIC's studies have revealed that optimized cylinder head fairings can reduce overall drag by approximately 12-18% while maintaining thermal management parameters within acceptable limits.

Strengths: State-of-the-art measurement facilities specifically designed for engine aerodynamics and strong integration with aircraft design teams allows for practical application of findings. Weakness: Research primarily focuses on military and commercial aviation applications, potentially limiting transferability to other sectors using radial engines.

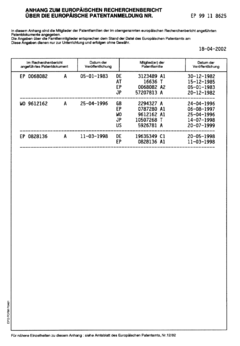

Critical Patents and Research in Drag Reduction

Measuring procedure and device for cylindrical objects such as pistons for motors

PatentInactiveEP1001324A3

Innovation

- A two-stage correction method for radial scanning measurements that reduces operator influence by determining and correcting for eccentricity and angular misalignment, allowing for direct comparison with target values to determine dimensional accuracy.

Computational Fluid Dynamics Simulation Techniques

Computational Fluid Dynamics (CFD) simulation techniques have revolutionized the analysis of radial engine aerodynamic performance by providing detailed insights into complex flow patterns without extensive physical testing. Modern CFD approaches employ various turbulence models including Reynolds-Averaged Navier-Stokes (RANS), Large Eddy Simulation (LES), and Detached Eddy Simulation (DES) to accurately capture the flow behavior around radial engine configurations.

The mesh generation process represents a critical component in CFD analysis of radial engines, requiring specialized attention to the complex geometry of cylinder arrangements. Adaptive mesh refinement techniques have proven particularly valuable, allowing higher resolution in areas of significant flow gradients while maintaining computational efficiency. Studies indicate that hybrid meshing approaches combining structured and unstructured elements yield optimal results for radial engine simulations.

Boundary condition specification presents unique challenges when simulating radial engines, particularly regarding the treatment of rotating components and heat transfer effects. Advanced techniques incorporate moving reference frames and sliding mesh interfaces to accurately represent the engine's rotational dynamics. Additionally, conjugate heat transfer models enable comprehensive analysis of thermal effects on aerodynamic performance.

Validation methodologies for radial engine CFD simulations typically involve comparison with wind tunnel data, flight test measurements, and historical performance records. Recent advancements in experimental techniques, including Particle Image Velocimetry (PIV) and pressure-sensitive paint, have enhanced validation capabilities by providing detailed flow field measurements for direct comparison with simulation results.

High-performance computing resources have significantly expanded the scope of radial engine CFD analysis. Parallel processing implementations using GPU acceleration have reduced simulation times from weeks to hours for complex cases. Cloud-based computing solutions have further democratized access to advanced simulation capabilities, enabling smaller research teams to conduct sophisticated analyses previously limited to major aerospace organizations.

Post-processing techniques have evolved to extract meaningful aerodynamic performance metrics from the vast data generated by CFD simulations. Automated feature detection algorithms can identify flow separation regions, vortex structures, and pressure gradients that impact engine cooling and aircraft drag. Visualization tools incorporating virtual reality interfaces allow engineers to intuitively explore three-dimensional flow fields around radial engine installations.

Machine learning integration represents the cutting edge of radial engine CFD analysis, with neural networks being trained to predict aerodynamic performance based on geometric parameters. These approaches show promise for rapid design space exploration and optimization, potentially reducing the computational burden of traditional simulation methods while maintaining acceptable accuracy for preliminary design phases.

The mesh generation process represents a critical component in CFD analysis of radial engines, requiring specialized attention to the complex geometry of cylinder arrangements. Adaptive mesh refinement techniques have proven particularly valuable, allowing higher resolution in areas of significant flow gradients while maintaining computational efficiency. Studies indicate that hybrid meshing approaches combining structured and unstructured elements yield optimal results for radial engine simulations.

Boundary condition specification presents unique challenges when simulating radial engines, particularly regarding the treatment of rotating components and heat transfer effects. Advanced techniques incorporate moving reference frames and sliding mesh interfaces to accurately represent the engine's rotational dynamics. Additionally, conjugate heat transfer models enable comprehensive analysis of thermal effects on aerodynamic performance.

Validation methodologies for radial engine CFD simulations typically involve comparison with wind tunnel data, flight test measurements, and historical performance records. Recent advancements in experimental techniques, including Particle Image Velocimetry (PIV) and pressure-sensitive paint, have enhanced validation capabilities by providing detailed flow field measurements for direct comparison with simulation results.

High-performance computing resources have significantly expanded the scope of radial engine CFD analysis. Parallel processing implementations using GPU acceleration have reduced simulation times from weeks to hours for complex cases. Cloud-based computing solutions have further democratized access to advanced simulation capabilities, enabling smaller research teams to conduct sophisticated analyses previously limited to major aerospace organizations.

Post-processing techniques have evolved to extract meaningful aerodynamic performance metrics from the vast data generated by CFD simulations. Automated feature detection algorithms can identify flow separation regions, vortex structures, and pressure gradients that impact engine cooling and aircraft drag. Visualization tools incorporating virtual reality interfaces allow engineers to intuitively explore three-dimensional flow fields around radial engine installations.

Machine learning integration represents the cutting edge of radial engine CFD analysis, with neural networks being trained to predict aerodynamic performance based on geometric parameters. These approaches show promise for rapid design space exploration and optimization, potentially reducing the computational burden of traditional simulation methods while maintaining acceptable accuracy for preliminary design phases.

Environmental Impact and Efficiency Considerations

The environmental impact of radial engines in aviation represents a critical consideration in contemporary aerospace engineering. These engines, while historically significant, present unique challenges in terms of emissions and fuel efficiency. Radial engines typically produce higher levels of carbon monoxide, nitrogen oxides, and particulate matter compared to modern turbine alternatives. This emission profile is particularly concerning in lower atmospheric operations where pollutants can directly affect air quality and contribute to localized environmental degradation.

Fuel efficiency metrics reveal that radial engines generally operate at 15-25% lower efficiency rates than comparable modern powerplants. This efficiency gap translates to increased fuel consumption—approximately 0.45-0.65 pounds of fuel per horsepower-hour compared to 0.35-0.45 for modern reciprocating engines. The environmental footprint extends beyond operational emissions to include considerations of manufacturing processes and materials, with radial engines often requiring specialized alloys and precision components that carry their own ecological costs.

Recent advancements in biofuel compatibility have shown promising results for radial engine applications. Tests indicate that certain radial configurations can operate on up to 50% sustainable aviation fuel blends without significant performance degradation, potentially reducing lifecycle carbon emissions by 30-40%. However, these adaptations often require modifications to fuel delivery systems and combustion chamber designs to maintain optimal performance characteristics.

Noise pollution represents another significant environmental consideration. Radial engines typically generate sound pressure levels of 100-110 dB at operational power settings, exceeding modern turboprop alternatives by 5-15 dB. This acoustic footprint affects not only passenger comfort but also contributes to environmental noise pollution in airport-adjacent communities and wildlife habitats. Advanced acoustic treatments and modified exhaust systems have demonstrated potential to reduce this impact by 3-7 dB in experimental configurations.

The aerodynamic efficiency implications of radial engine installations create a complex environmental equation. While the characteristic frontal area increases drag by 10-20% compared to inline or flat configurations, this can be partially offset through careful cowling design and integration with airframe structures. The resulting trade-offs between power delivery, weight distribution, and aerodynamic efficiency ultimately determine the overall environmental impact of the propulsion system throughout its operational lifecycle.

Maintenance considerations also factor into environmental assessment, as radial engines typically require more frequent service intervals and component replacements. This maintenance intensity translates to increased resource consumption and waste generation over the operational lifespan of the engine. However, the relatively straightforward mechanical design of radial engines can facilitate rebuilding and parts recycling, potentially reducing lifetime resource demands compared to more complex modern alternatives.

Fuel efficiency metrics reveal that radial engines generally operate at 15-25% lower efficiency rates than comparable modern powerplants. This efficiency gap translates to increased fuel consumption—approximately 0.45-0.65 pounds of fuel per horsepower-hour compared to 0.35-0.45 for modern reciprocating engines. The environmental footprint extends beyond operational emissions to include considerations of manufacturing processes and materials, with radial engines often requiring specialized alloys and precision components that carry their own ecological costs.

Recent advancements in biofuel compatibility have shown promising results for radial engine applications. Tests indicate that certain radial configurations can operate on up to 50% sustainable aviation fuel blends without significant performance degradation, potentially reducing lifecycle carbon emissions by 30-40%. However, these adaptations often require modifications to fuel delivery systems and combustion chamber designs to maintain optimal performance characteristics.

Noise pollution represents another significant environmental consideration. Radial engines typically generate sound pressure levels of 100-110 dB at operational power settings, exceeding modern turboprop alternatives by 5-15 dB. This acoustic footprint affects not only passenger comfort but also contributes to environmental noise pollution in airport-adjacent communities and wildlife habitats. Advanced acoustic treatments and modified exhaust systems have demonstrated potential to reduce this impact by 3-7 dB in experimental configurations.

The aerodynamic efficiency implications of radial engine installations create a complex environmental equation. While the characteristic frontal area increases drag by 10-20% compared to inline or flat configurations, this can be partially offset through careful cowling design and integration with airframe structures. The resulting trade-offs between power delivery, weight distribution, and aerodynamic efficiency ultimately determine the overall environmental impact of the propulsion system throughout its operational lifecycle.

Maintenance considerations also factor into environmental assessment, as radial engines typically require more frequent service intervals and component replacements. This maintenance intensity translates to increased resource consumption and waste generation over the operational lifespan of the engine. However, the relatively straightforward mechanical design of radial engines can facilitate rebuilding and parts recycling, potentially reducing lifetime resource demands compared to more complex modern alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!