Validation Metrics for Radial Engine Environmental Impact

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Environmental Metrics Background and Objectives

Radial engines, with their distinctive star-shaped cylinder arrangement, have been a cornerstone of aviation propulsion since their introduction in the early 20th century. Initially developed to provide higher power-to-weight ratios compared to inline engines, these powerplants dominated military and commercial aviation until the advent of jet engines in the mid-20th century. Despite their declining prominence in aviation, radial engines continue to find applications in specialized sectors, including vintage aircraft restoration, certain industrial applications, and as educational platforms for engineering studies.

The environmental impact assessment of radial engines has historically been overlooked, as these engines were developed during eras when emissions standards and environmental considerations were not primary design factors. With growing global emphasis on sustainable technologies and stringent emissions regulations, there emerges a critical need to establish comprehensive validation metrics specifically tailored for evaluating the environmental footprint of radial engines.

Current environmental assessment frameworks predominantly focus on modern propulsion systems, creating a significant gap in methodologies applicable to radial engine technology. This technical gap has resulted in inconsistent evaluation approaches and limited comparative data regarding the ecological impact of these engines across their operational lifecycle.

The primary objective of this technical research is to develop a standardized set of validation metrics that accurately quantify the environmental impact of radial engines. These metrics aim to encompass emissions profiles (including carbon monoxide, nitrogen oxides, unburned hydrocarbons, and particulate matter), fuel efficiency parameters across various operational conditions, noise pollution characteristics unique to radial configuration, and lifecycle assessment factors including manufacturing impact and end-of-life considerations.

Additionally, this research seeks to establish baseline environmental performance data for various radial engine configurations, enabling meaningful comparisons with alternative propulsion technologies. By creating these benchmarks, stakeholders can make informed decisions regarding the continued use, modification, or replacement of radial engines in existing applications.

The development of these validation metrics will facilitate the potential modernization of radial engine designs through targeted environmental improvements. This approach acknowledges the historical significance and continuing specialized applications of radial engines while addressing contemporary environmental imperatives. Furthermore, these metrics will support regulatory bodies in developing appropriate standards for vintage and specialized aircraft utilizing radial engine technology.

Through comprehensive technical analysis and systematic metric development, this research aims to bridge the gap between historical engineering achievements represented by radial engines and modern environmental sustainability requirements, potentially extending the viable service life of these distinctive powerplants in appropriate applications.

The environmental impact assessment of radial engines has historically been overlooked, as these engines were developed during eras when emissions standards and environmental considerations were not primary design factors. With growing global emphasis on sustainable technologies and stringent emissions regulations, there emerges a critical need to establish comprehensive validation metrics specifically tailored for evaluating the environmental footprint of radial engines.

Current environmental assessment frameworks predominantly focus on modern propulsion systems, creating a significant gap in methodologies applicable to radial engine technology. This technical gap has resulted in inconsistent evaluation approaches and limited comparative data regarding the ecological impact of these engines across their operational lifecycle.

The primary objective of this technical research is to develop a standardized set of validation metrics that accurately quantify the environmental impact of radial engines. These metrics aim to encompass emissions profiles (including carbon monoxide, nitrogen oxides, unburned hydrocarbons, and particulate matter), fuel efficiency parameters across various operational conditions, noise pollution characteristics unique to radial configuration, and lifecycle assessment factors including manufacturing impact and end-of-life considerations.

Additionally, this research seeks to establish baseline environmental performance data for various radial engine configurations, enabling meaningful comparisons with alternative propulsion technologies. By creating these benchmarks, stakeholders can make informed decisions regarding the continued use, modification, or replacement of radial engines in existing applications.

The development of these validation metrics will facilitate the potential modernization of radial engine designs through targeted environmental improvements. This approach acknowledges the historical significance and continuing specialized applications of radial engines while addressing contemporary environmental imperatives. Furthermore, these metrics will support regulatory bodies in developing appropriate standards for vintage and specialized aircraft utilizing radial engine technology.

Through comprehensive technical analysis and systematic metric development, this research aims to bridge the gap between historical engineering achievements represented by radial engines and modern environmental sustainability requirements, potentially extending the viable service life of these distinctive powerplants in appropriate applications.

Market Demand Analysis for Eco-Friendly Radial Engines

The global market for eco-friendly radial engines is experiencing significant growth driven by increasing environmental regulations and sustainability initiatives across various industries. Current market analysis indicates a strong shift towards greener propulsion technologies, with radial engines being reconsidered for their potential efficiency improvements when modernized with eco-friendly innovations.

Aviation represents the primary market segment, where smaller aircraft operators and vintage aircraft restorers seek environmentally compliant power solutions that maintain the distinctive characteristics of radial engines. This niche market values the unique power-to-weight ratio and reliability of radial configurations while demanding reduced emissions and improved fuel efficiency to meet modern standards.

The agricultural and industrial sectors constitute emerging markets for eco-friendly radial engines, particularly in regions with less developed infrastructure where the simplicity and serviceability of radial designs provide operational advantages. Market research shows growing interest in hybrid radial engine systems that combine traditional mechanical reliability with cleaner combustion technologies.

Consumer demand patterns reveal three key drivers: regulatory compliance, operational cost reduction, and corporate sustainability goals. Regulatory pressures, particularly in Europe and North America, have established increasingly stringent emission standards that conventional radial engines cannot meet without significant modifications. This regulatory landscape has created a market gap for validated eco-friendly alternatives.

Cost considerations form the second major demand factor, with fuel representing a substantial operational expense. Market surveys indicate operators are willing to invest in premium eco-friendly engine technology when demonstrable fuel savings can provide return on investment within 3-5 years. This economic calculation has become more favorable as carbon taxation schemes expand globally.

The third demand driver comes from corporate sustainability commitments, with many commercial operators pledging carbon neutrality within defined timeframes. These organizations require validated metrics to substantiate environmental claims, creating demand for standardized environmental impact assessment methodologies specific to radial engine applications.

Market forecasts suggest the eco-friendly radial engine segment will grow as validation metrics become standardized and widely accepted. The current fragmentation in environmental impact measurement approaches has created market uncertainty, with potential customers hesitating due to difficulties in comparing competing technologies. This highlights the critical need for industry-accepted validation metrics that can accurately quantify environmental improvements in radial engine designs.

Aviation represents the primary market segment, where smaller aircraft operators and vintage aircraft restorers seek environmentally compliant power solutions that maintain the distinctive characteristics of radial engines. This niche market values the unique power-to-weight ratio and reliability of radial configurations while demanding reduced emissions and improved fuel efficiency to meet modern standards.

The agricultural and industrial sectors constitute emerging markets for eco-friendly radial engines, particularly in regions with less developed infrastructure where the simplicity and serviceability of radial designs provide operational advantages. Market research shows growing interest in hybrid radial engine systems that combine traditional mechanical reliability with cleaner combustion technologies.

Consumer demand patterns reveal three key drivers: regulatory compliance, operational cost reduction, and corporate sustainability goals. Regulatory pressures, particularly in Europe and North America, have established increasingly stringent emission standards that conventional radial engines cannot meet without significant modifications. This regulatory landscape has created a market gap for validated eco-friendly alternatives.

Cost considerations form the second major demand factor, with fuel representing a substantial operational expense. Market surveys indicate operators are willing to invest in premium eco-friendly engine technology when demonstrable fuel savings can provide return on investment within 3-5 years. This economic calculation has become more favorable as carbon taxation schemes expand globally.

The third demand driver comes from corporate sustainability commitments, with many commercial operators pledging carbon neutrality within defined timeframes. These organizations require validated metrics to substantiate environmental claims, creating demand for standardized environmental impact assessment methodologies specific to radial engine applications.

Market forecasts suggest the eco-friendly radial engine segment will grow as validation metrics become standardized and widely accepted. The current fragmentation in environmental impact measurement approaches has created market uncertainty, with potential customers hesitating due to difficulties in comparing competing technologies. This highlights the critical need for industry-accepted validation metrics that can accurately quantify environmental improvements in radial engine designs.

Current Validation Metrics Status and Challenges

The validation metrics for assessing radial engine environmental impact currently face significant challenges across both technical and regulatory domains. Globally, there exists a fragmented landscape of validation methodologies, with different regions employing varied standards and protocols. This inconsistency creates substantial difficulties for manufacturers attempting to validate their radial engine designs across international markets.

Current metrics primarily focus on traditional pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter. However, these metrics were largely developed for linear engine configurations and fail to account for the unique combustion dynamics and thermal characteristics of radial engines. This fundamental mismatch results in validation procedures that either overestimate or underestimate the actual environmental impact of these specialized engine designs.

The instrumentation and measurement technologies employed in validation processes present another significant challenge. Many existing sensor systems lack the precision required to accurately capture the distinctive emission patterns of radial engines, particularly during transient operational states. This technical limitation undermines the reliability of collected data and subsequently affects the validity of environmental impact assessments.

Computational models used for predictive validation also demonstrate considerable shortcomings. Current simulation frameworks typically employ assumptions based on conventional engine geometries, leading to systematic errors when applied to radial configurations. The complex airflow patterns and heat distribution characteristics unique to radial engines remain inadequately represented in standard modeling approaches.

Lifecycle assessment metrics represent another problematic area. Present validation methodologies often focus narrowly on operational emissions while neglecting the comprehensive environmental footprint including manufacturing processes, material selection, and end-of-life considerations. This narrow scope fails to capture the true environmental impact of radial engines across their complete lifecycle.

Regulatory frameworks worldwide have not kept pace with technological developments in radial engine design. Many jurisdictions continue to apply outdated validation protocols that do not reflect recent advances in engine efficiency and emission control technologies. This regulatory lag creates significant barriers to innovation and market entry for improved radial engine designs with potentially lower environmental impacts.

The economic feasibility of comprehensive validation processes poses an additional challenge, particularly for smaller manufacturers. The high costs associated with rigorous environmental testing create market disparities, where only larger companies can afford thorough validation procedures, potentially stifling innovation from smaller market participants.

Current metrics primarily focus on traditional pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter. However, these metrics were largely developed for linear engine configurations and fail to account for the unique combustion dynamics and thermal characteristics of radial engines. This fundamental mismatch results in validation procedures that either overestimate or underestimate the actual environmental impact of these specialized engine designs.

The instrumentation and measurement technologies employed in validation processes present another significant challenge. Many existing sensor systems lack the precision required to accurately capture the distinctive emission patterns of radial engines, particularly during transient operational states. This technical limitation undermines the reliability of collected data and subsequently affects the validity of environmental impact assessments.

Computational models used for predictive validation also demonstrate considerable shortcomings. Current simulation frameworks typically employ assumptions based on conventional engine geometries, leading to systematic errors when applied to radial configurations. The complex airflow patterns and heat distribution characteristics unique to radial engines remain inadequately represented in standard modeling approaches.

Lifecycle assessment metrics represent another problematic area. Present validation methodologies often focus narrowly on operational emissions while neglecting the comprehensive environmental footprint including manufacturing processes, material selection, and end-of-life considerations. This narrow scope fails to capture the true environmental impact of radial engines across their complete lifecycle.

Regulatory frameworks worldwide have not kept pace with technological developments in radial engine design. Many jurisdictions continue to apply outdated validation protocols that do not reflect recent advances in engine efficiency and emission control technologies. This regulatory lag creates significant barriers to innovation and market entry for improved radial engine designs with potentially lower environmental impacts.

The economic feasibility of comprehensive validation processes poses an additional challenge, particularly for smaller manufacturers. The high costs associated with rigorous environmental testing create market disparities, where only larger companies can afford thorough validation procedures, potentially stifling innovation from smaller market participants.

Current Validation Methodologies and Standards

01 Emissions reduction technologies for radial engines

Various technologies have been developed to reduce the environmental impact of radial engines by minimizing harmful emissions. These include advanced combustion control systems, catalytic converters specifically designed for radial engine configurations, and fuel injection systems that optimize the air-fuel mixture. These technologies help radial engines meet increasingly stringent environmental regulations while maintaining performance characteristics.- Emissions reduction technologies for radial engines: Various technologies have been developed to reduce the environmental impact of radial engines by minimizing harmful emissions. These include advanced combustion control systems, catalytic converters specifically designed for radial engine configurations, and fuel injection systems that optimize the air-fuel mixture. These technologies help radial engines meet increasingly stringent environmental regulations while maintaining performance characteristics.

- Alternative fuel adaptations for radial engines: Modifications to radial engines allowing them to operate on alternative, more environmentally friendly fuels represent a significant approach to reducing their environmental footprint. These adaptations include systems for using biofuels, hydrogen, or synthetic fuels in traditional radial engine designs. Such fuel flexibility helps reduce dependency on fossil fuels and can significantly lower carbon emissions while extending the viability of radial engine technology in a carbon-constrained future.

- Lifecycle assessment and environmental monitoring systems: Environmental impact monitoring systems specifically designed for radial engines help track and analyze their ecological footprint throughout their operational lifecycle. These systems include sensors that monitor emissions in real-time, data analytics platforms that process environmental performance metrics, and lifecycle assessment tools that evaluate the total environmental impact from manufacturing through disposal. Such comprehensive monitoring enables more informed decisions about engine operation, maintenance, and eventual replacement.

- Noise and vibration reduction technologies: Technologies focused on reducing the noise and vibration pollution associated with radial engines represent an important aspect of minimizing their environmental impact. These include advanced muffler designs, vibration dampening systems, acoustic insulation materials, and redesigned engine mounts. By addressing noise pollution, these innovations help radial engines operate in environmentally sensitive areas while improving comfort for operators and reducing disturbance to wildlife and communities.

- Efficiency improvements and heat recovery systems: Innovations focused on improving the overall efficiency of radial engines help reduce their environmental impact by decreasing fuel consumption and associated emissions. These include advanced cooling systems that maintain optimal operating temperatures, waste heat recovery mechanisms that capture and repurpose thermal energy, lightweight materials that reduce overall weight, and optimized lubrication systems. Such efficiency improvements directly translate to reduced resource consumption and lower environmental impact throughout the engine's operational life.

02 Alternative fuel adaptations for radial engines

Modifications to radial engines allowing them to operate on alternative, more environmentally friendly fuels represent a significant approach to reducing their environmental footprint. These adaptations include systems for using biofuels, hydrogen, or synthetic fuels in traditional radial engine designs. Such fuel flexibility helps reduce dependency on fossil fuels and can significantly lower carbon emissions while extending the viability of radial engine technology in a carbon-constrained future.Expand Specific Solutions03 Lifecycle assessment and environmental monitoring systems

Environmental impact monitoring systems specifically designed for radial engines help track and analyze their ecological footprint throughout their operational lifecycle. These systems incorporate sensors and data analytics to measure emissions, fuel efficiency, and other environmental parameters in real-time. The collected data enables operators to optimize engine performance for minimal environmental impact and provides valuable information for future design improvements.Expand Specific Solutions04 Noise and vibration reduction technologies

Specialized technologies have been developed to address the noise and vibration pollution associated with radial engines. These include advanced muffler designs, vibration dampening systems, and acoustic insulation materials specifically engineered for the unique configuration of radial engines. By reducing noise and vibration, these technologies mitigate not only environmental noise pollution but also improve the durability and efficiency of the engine, indirectly contributing to reduced resource consumption over its operational life.Expand Specific Solutions05 Efficiency optimization and heat recovery systems

Innovations in radial engine design focus on improving overall efficiency and incorporating heat recovery systems to minimize wasted energy. These include advanced cooling systems that capture and repurpose thermal energy, lightweight materials that reduce overall weight and improve power-to-weight ratios, and computerized engine management systems that continuously optimize performance parameters. By maximizing efficiency, these technologies reduce fuel consumption and associated emissions while maintaining or improving engine performance.Expand Specific Solutions

Key Industry Players in Radial Engine Validation

The radial engine environmental impact validation metrics market is in a growth phase, with increasing focus on sustainability driving demand. The market size is expanding as automotive and aerospace industries adopt stricter emission standards. Technologically, the field shows varying maturity levels across players. Major automotive manufacturers like Toyota, Hyundai, and Ford are leading with advanced validation systems, while specialized companies such as AVL List and Cryoshelter are developing innovative measurement technologies. Research institutions like Southeast University and aerospace entities including Pratt & Whitney Canada are contributing significant technical advancements. The competitive landscape features traditional automotive giants competing with specialized engineering firms and research organizations to establish industry standards for environmental impact assessment of radial engine technologies.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corporation has established the Comprehensive Environmental Impact Validation System (CEIVS) for radial engine configurations, focusing on holistic assessment methodologies. Their approach integrates laboratory testing with extensive field validation across diverse operating conditions. Toyota's metrics framework employs a multi-dimensional assessment matrix that evaluates both direct emissions (regulated pollutants) and indirect environmental impacts throughout the engine lifecycle. Their validation protocol incorporates specialized test cycles designed to capture the unique operational characteristics of radial engines, including cold-start emissions, transient response, and steady-state performance. The CEIVS methodology utilizes advanced analytics to correlate emissions data with engine operating parameters, enabling precise identification of optimization opportunities. Toyota has also developed specific correction factors for altitude, temperature, and humidity variations that ensure consistent environmental impact assessments across different geographical regions and climatic conditions. Their system includes comparative lifecycle assessment capabilities that quantify environmental improvements relative to previous generation technologies and competitive alternatives.

Strengths: Exceptionally comprehensive approach that addresses both direct and indirect environmental impacts; strong integration with Toyota's broader environmental management systems; extensive validation across diverse operating conditions and geographical regions. Weaknesses: System complexity requires significant resources to implement fully; primarily optimized for automotive applications with adaptation needed for other sectors; higher implementation costs compared to more focused validation approaches.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies has developed the Radial Engine Environmental Performance System (REEPS), a comprehensive validation framework specifically designed for assessing the environmental impact of radial engines across multiple applications. Their approach integrates both laboratory testing and real-world operational data collection through a network of embedded sensors and telemetry systems. The REEPS methodology employs a multi-parameter assessment that includes traditional emissions measurements (NOx, CO, HC, PM) alongside broader environmental indicators such as noise generation, vibration characteristics, and thermal efficiency metrics. Ford's system incorporates specialized test cycles that simulate various operational scenarios while accounting for the unique combustion dynamics of radial engine configurations. Their validation protocol includes comparative benchmarking against baseline technologies to quantify relative environmental improvements. The company has also developed predictive modeling capabilities that allow for virtual testing of design modifications before physical prototyping, accelerating the optimization process while reducing development costs and environmental impact during the testing phase.

Strengths: Comprehensive approach that extends beyond emissions to include multiple environmental impact factors; strong integration with product development processes; robust data analytics capabilities that support continuous improvement. Weaknesses: System complexity requires significant expertise to implement effectively; primarily developed for automotive applications with adaptation needed for other sectors; higher initial investment compared to simpler validation approaches.

Critical Technologies for Environmental Impact Measurement

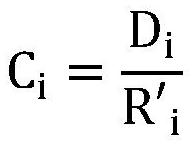

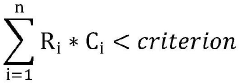

Calculation method of environmental impact coefficient and determination method of radioactivity acceptance criteria

PatentActiveCN112434405B

Innovation

- By calculating the environmental impact coefficient, we determine the representative nuclides and their groupings of radionuclides in serious accidents at nuclear power plants, analyze their reference release amounts and consequences, formulate radioactive acceptance criteria for serious accidents at nuclear power plants, and ensure that the design objectives comply with the "Nuclear Power Plant Design" Safety Regulations to mitigate radioactive consequences.

Regulatory Compliance and Certification Requirements

Regulatory frameworks governing radial engine emissions have evolved significantly over the past decades, with increasingly stringent standards being implemented worldwide. The International Civil Aviation Organization (ICAO) has established comprehensive environmental protection standards through Annex 16, which specifically addresses aircraft engine emissions. These standards set clear limits for nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (UHC), and smoke, requiring manufacturers to validate compliance through standardized testing protocols. For radial engines specifically, these requirements present unique challenges due to their distinctive combustion characteristics and historical design origins.

The Environmental Protection Agency (EPA) in the United States has adopted these ICAO standards and implemented additional requirements through 40 CFR Part 87, which mandates specific emission certification procedures for aircraft engines. Similarly, the European Union Aviation Safety Agency (EASA) enforces comparable standards through CS-E (Certification Specifications for Engines), with particular attention to environmental impact assessment methodologies. These regulatory frameworks necessitate robust validation metrics that accurately measure and document the environmental performance of radial engines.

Certification processes typically require manufacturers to conduct emissions testing under standardized conditions that simulate various operational scenarios. For radial engines, these tests must account for their unique operating characteristics, including their distinctive power-to-weight ratio and thermal efficiency profiles. The Landing and Take-Off (LTO) cycle serves as the primary reference for emissions measurement, requiring validation across idle, approach, climb-out, and take-off power settings. Each phase demands specific measurement protocols and instrumentation accuracy.

Compliance documentation represents another critical aspect of the certification process. Manufacturers must maintain comprehensive technical files demonstrating adherence to applicable standards, including detailed emissions test reports, measurement uncertainty analyses, and quality assurance documentation. These records must be preserved throughout the engine's service life and made available to regulatory authorities upon request. The validation metrics employed must be traceable to internationally recognized standards and calibration procedures.

Emerging regulatory trends indicate a shift toward lifecycle environmental impact assessment, extending beyond operational emissions to include manufacturing processes and end-of-life disposal considerations. Future certification requirements will likely incorporate carbon footprint analyses covering the entire product lifecycle, requiring manufacturers to develop more comprehensive validation methodologies. Additionally, noise certification requirements under ICAO Annex 16 Volume I establish specific measurement protocols that must be integrated with emissions testing procedures to provide a holistic environmental impact assessment.

International harmonization of certification standards remains an ongoing challenge, with manufacturers often navigating multiple regulatory frameworks when seeking global market access. Mutual recognition agreements between major aviation authorities have streamlined this process somewhat, but significant regional variations persist in implementation and enforcement approaches. These variations necessitate adaptable validation metrics capable of satisfying diverse regulatory requirements while maintaining scientific rigor and comparability.

The Environmental Protection Agency (EPA) in the United States has adopted these ICAO standards and implemented additional requirements through 40 CFR Part 87, which mandates specific emission certification procedures for aircraft engines. Similarly, the European Union Aviation Safety Agency (EASA) enforces comparable standards through CS-E (Certification Specifications for Engines), with particular attention to environmental impact assessment methodologies. These regulatory frameworks necessitate robust validation metrics that accurately measure and document the environmental performance of radial engines.

Certification processes typically require manufacturers to conduct emissions testing under standardized conditions that simulate various operational scenarios. For radial engines, these tests must account for their unique operating characteristics, including their distinctive power-to-weight ratio and thermal efficiency profiles. The Landing and Take-Off (LTO) cycle serves as the primary reference for emissions measurement, requiring validation across idle, approach, climb-out, and take-off power settings. Each phase demands specific measurement protocols and instrumentation accuracy.

Compliance documentation represents another critical aspect of the certification process. Manufacturers must maintain comprehensive technical files demonstrating adherence to applicable standards, including detailed emissions test reports, measurement uncertainty analyses, and quality assurance documentation. These records must be preserved throughout the engine's service life and made available to regulatory authorities upon request. The validation metrics employed must be traceable to internationally recognized standards and calibration procedures.

Emerging regulatory trends indicate a shift toward lifecycle environmental impact assessment, extending beyond operational emissions to include manufacturing processes and end-of-life disposal considerations. Future certification requirements will likely incorporate carbon footprint analyses covering the entire product lifecycle, requiring manufacturers to develop more comprehensive validation methodologies. Additionally, noise certification requirements under ICAO Annex 16 Volume I establish specific measurement protocols that must be integrated with emissions testing procedures to provide a holistic environmental impact assessment.

International harmonization of certification standards remains an ongoing challenge, with manufacturers often navigating multiple regulatory frameworks when seeking global market access. Mutual recognition agreements between major aviation authorities have streamlined this process somewhat, but significant regional variations persist in implementation and enforcement approaches. These variations necessitate adaptable validation metrics capable of satisfying diverse regulatory requirements while maintaining scientific rigor and comparability.

Life Cycle Assessment Approaches for Radial Engines

Life Cycle Assessment (LCA) provides a comprehensive framework for evaluating the environmental impacts of radial engines throughout their entire existence. This methodology examines impacts from raw material extraction through manufacturing, operation, maintenance, and eventual disposal or recycling. For radial engines specifically, LCA approaches must account for their unique design characteristics and operational parameters that differ significantly from inline or V-configuration engines.

The ISO 14040 series establishes the foundation for conducting standardized LCAs, offering a four-phase approach: goal and scope definition, inventory analysis, impact assessment, and interpretation. When applying these standards to radial engines, practitioners must develop specialized inventory databases that capture the distinctive materials and manufacturing processes associated with radial engine production, including specialized alloys and complex casting procedures.

Process-based LCA represents the most common approach, tracking material and energy flows through each stage of the radial engine lifecycle. This method excels at identifying environmental hotspots within specific production processes but may struggle with system boundary definition when assessing complex supply chains typical in aviation applications where radial engines are often deployed.

Economic Input-Output LCA (EIO-LCA) offers an alternative by utilizing economic transaction data to estimate environmental impacts across entire industrial sectors. This approach proves valuable for capturing broader supply chain effects but lacks the granular detail needed for engineering-specific improvements in radial engine design.

Hybrid LCA methodologies combine process-based and EIO approaches to leverage their respective strengths. For radial engines, this integration allows for detailed analysis of critical components while maintaining awareness of broader supply chain implications, particularly important when evaluating alternative materials or manufacturing techniques.

Dynamic LCA extends traditional static assessments by incorporating temporal factors, essential for radial engines where operational lifespans often exceed decades. This approach accounts for changing technology landscapes, evolving emission standards, and improvements in maintenance protocols that significantly influence lifetime environmental performance.

Consequential LCA examines broader market effects of radial engine adoption or replacement, considering how changes in production volumes might affect material markets or how performance improvements might alter operational behaviors. This perspective proves particularly valuable when evaluating technology transition pathways in sectors where radial engines remain in service.

The ISO 14040 series establishes the foundation for conducting standardized LCAs, offering a four-phase approach: goal and scope definition, inventory analysis, impact assessment, and interpretation. When applying these standards to radial engines, practitioners must develop specialized inventory databases that capture the distinctive materials and manufacturing processes associated with radial engine production, including specialized alloys and complex casting procedures.

Process-based LCA represents the most common approach, tracking material and energy flows through each stage of the radial engine lifecycle. This method excels at identifying environmental hotspots within specific production processes but may struggle with system boundary definition when assessing complex supply chains typical in aviation applications where radial engines are often deployed.

Economic Input-Output LCA (EIO-LCA) offers an alternative by utilizing economic transaction data to estimate environmental impacts across entire industrial sectors. This approach proves valuable for capturing broader supply chain effects but lacks the granular detail needed for engineering-specific improvements in radial engine design.

Hybrid LCA methodologies combine process-based and EIO approaches to leverage their respective strengths. For radial engines, this integration allows for detailed analysis of critical components while maintaining awareness of broader supply chain implications, particularly important when evaluating alternative materials or manufacturing techniques.

Dynamic LCA extends traditional static assessments by incorporating temporal factors, essential for radial engines where operational lifespans often exceed decades. This approach accounts for changing technology landscapes, evolving emission standards, and improvements in maintenance protocols that significantly influence lifetime environmental performance.

Consequential LCA examines broader market effects of radial engine adoption or replacement, considering how changes in production volumes might affect material markets or how performance improvements might alter operational behaviors. This perspective proves particularly valuable when evaluating technology transition pathways in sectors where radial engines remain in service.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!