Impact of Radial Engine Materials on Performance

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Radial Engine Material Evolution and Objectives

Radial engines have undergone significant material evolution since their inception in the early 20th century. Initially constructed primarily from cast iron and steel alloys, these engines faced considerable challenges related to weight, thermal efficiency, and durability. The progression from these traditional materials to advanced composites and superalloys represents a fascinating journey of engineering innovation driven by aviation requirements.

The material evolution of radial engines can be traced through distinct phases. The first generation utilized basic ferrous metals that provided adequate strength but contributed to excessive weight and thermal management issues. During the 1930s-1940s, aluminum alloys began to replace certain steel components, marking a pivotal shift toward weight reduction while maintaining structural integrity. This transition enabled higher power-to-weight ratios, critical for military aircraft during World War II.

Post-war developments introduced nickel-based superalloys and precision-engineered steel variants that dramatically improved high-temperature performance and component longevity. These materials allowed radial engines to operate at higher compression ratios and temperatures, enhancing overall efficiency. The 1960s-1970s, despite the declining popularity of radial engines in aviation, saw continued material refinements focused on specialized applications where their unique characteristics remained valuable.

Contemporary material science has revitalized interest in radial engine technology through the introduction of titanium alloys, ceramic composites, and advanced surface treatments. These innovations address historical limitations by offering superior strength-to-weight characteristics, enhanced thermal properties, and improved wear resistance. Modern computational modeling has enabled precise material selection tailored to specific operational stresses within different engine components.

The primary objectives of material development for radial engines focus on several key performance parameters. Weight reduction remains paramount, as every gram saved translates to improved aircraft payload capacity and fuel efficiency. Thermal management represents another critical goal, with materials selected to optimize heat dissipation from cylinders while maintaining dimensional stability under thermal cycling.

Durability objectives center on extending time-between-overhaul metrics through materials resistant to fatigue, corrosion, and wear. Additionally, modern material selection aims to reduce manufacturing complexity and costs while maintaining or improving performance characteristics. Environmental considerations have also emerged as important factors, with research directed toward materials compatible with alternative fuels and reduced emissions profiles.

The trajectory of radial engine material development continues to evolve, with research now exploring nanomaterial applications, advanced metal matrix composites, and biomimetic design principles that could further revolutionize performance parameters while addressing sustainability concerns.

The material evolution of radial engines can be traced through distinct phases. The first generation utilized basic ferrous metals that provided adequate strength but contributed to excessive weight and thermal management issues. During the 1930s-1940s, aluminum alloys began to replace certain steel components, marking a pivotal shift toward weight reduction while maintaining structural integrity. This transition enabled higher power-to-weight ratios, critical for military aircraft during World War II.

Post-war developments introduced nickel-based superalloys and precision-engineered steel variants that dramatically improved high-temperature performance and component longevity. These materials allowed radial engines to operate at higher compression ratios and temperatures, enhancing overall efficiency. The 1960s-1970s, despite the declining popularity of radial engines in aviation, saw continued material refinements focused on specialized applications where their unique characteristics remained valuable.

Contemporary material science has revitalized interest in radial engine technology through the introduction of titanium alloys, ceramic composites, and advanced surface treatments. These innovations address historical limitations by offering superior strength-to-weight characteristics, enhanced thermal properties, and improved wear resistance. Modern computational modeling has enabled precise material selection tailored to specific operational stresses within different engine components.

The primary objectives of material development for radial engines focus on several key performance parameters. Weight reduction remains paramount, as every gram saved translates to improved aircraft payload capacity and fuel efficiency. Thermal management represents another critical goal, with materials selected to optimize heat dissipation from cylinders while maintaining dimensional stability under thermal cycling.

Durability objectives center on extending time-between-overhaul metrics through materials resistant to fatigue, corrosion, and wear. Additionally, modern material selection aims to reduce manufacturing complexity and costs while maintaining or improving performance characteristics. Environmental considerations have also emerged as important factors, with research directed toward materials compatible with alternative fuels and reduced emissions profiles.

The trajectory of radial engine material development continues to evolve, with research now exploring nanomaterial applications, advanced metal matrix composites, and biomimetic design principles that could further revolutionize performance parameters while addressing sustainability concerns.

Market Analysis for Advanced Radial Engine Applications

The global market for advanced radial engine applications is experiencing a significant transformation, driven by innovations in material science and engineering. Current market valuation stands at approximately 3.2 billion USD, with projections indicating growth to reach 4.7 billion USD by 2028, representing a compound annual growth rate of 8.3%. This growth trajectory is primarily fueled by increasing demand in specialized aviation sectors, particularly vintage aircraft restoration, aerobatic sports, and unmanned aerial vehicles (UAVs).

The aviation heritage sector represents a substantial market segment, with over 5,000 operational vintage aircraft worldwide requiring regular maintenance and performance upgrades. This restoration market generates annual revenues exceeding 850 million USD, with material selection for engine components accounting for approximately 30% of total restoration costs. The preference for advanced materials that maintain historical authenticity while enhancing performance has created a premium market niche with profit margins averaging 22-25%.

In the commercial sector, specialized applications for radial engines persist in agricultural aviation, firefighting aircraft, and certain regional transportation systems operating in extreme environments. These sectors collectively account for 1.1 billion USD in annual market value, with material-related performance improvements directly influencing operational efficiency and cost-effectiveness. Market research indicates that a 15% improvement in material performance can translate to 12% reduction in operational costs across these applications.

Emerging markets in developing regions, particularly in South America and Southeast Asia, show accelerating adoption rates for advanced radial engine technologies in agricultural and forestry applications. These regions represent the fastest-growing market segment with 14.2% annual growth, driven by the combination of challenging operational environments and cost sensitivity that makes optimized radial engines an attractive alternative to turbine solutions.

The defense and security sector presents another significant market opportunity, with specialized UAV applications increasingly utilizing modified radial engine designs for their reliability and fuel flexibility. This sector's market share has grown from 7% to 13% over the past five years, with material performance characteristics being a critical differentiator in procurement decisions.

Consumer preferences across all market segments increasingly prioritize sustainability metrics, with 68% of procurement specialists citing environmental impact and lifecycle assessment as "very important" or "critical" factors in engine selection. This trend has accelerated development of bio-compatible materials and recycling-oriented design approaches, creating new market opportunities estimated at 340 million USD annually for environmentally optimized radial engine solutions.

The aviation heritage sector represents a substantial market segment, with over 5,000 operational vintage aircraft worldwide requiring regular maintenance and performance upgrades. This restoration market generates annual revenues exceeding 850 million USD, with material selection for engine components accounting for approximately 30% of total restoration costs. The preference for advanced materials that maintain historical authenticity while enhancing performance has created a premium market niche with profit margins averaging 22-25%.

In the commercial sector, specialized applications for radial engines persist in agricultural aviation, firefighting aircraft, and certain regional transportation systems operating in extreme environments. These sectors collectively account for 1.1 billion USD in annual market value, with material-related performance improvements directly influencing operational efficiency and cost-effectiveness. Market research indicates that a 15% improvement in material performance can translate to 12% reduction in operational costs across these applications.

Emerging markets in developing regions, particularly in South America and Southeast Asia, show accelerating adoption rates for advanced radial engine technologies in agricultural and forestry applications. These regions represent the fastest-growing market segment with 14.2% annual growth, driven by the combination of challenging operational environments and cost sensitivity that makes optimized radial engines an attractive alternative to turbine solutions.

The defense and security sector presents another significant market opportunity, with specialized UAV applications increasingly utilizing modified radial engine designs for their reliability and fuel flexibility. This sector's market share has grown from 7% to 13% over the past five years, with material performance characteristics being a critical differentiator in procurement decisions.

Consumer preferences across all market segments increasingly prioritize sustainability metrics, with 68% of procurement specialists citing environmental impact and lifecycle assessment as "very important" or "critical" factors in engine selection. This trend has accelerated development of bio-compatible materials and recycling-oriented design approaches, creating new market opportunities estimated at 340 million USD annually for environmentally optimized radial engine solutions.

Current Material Technologies and Performance Limitations

Radial engines currently employ a diverse range of materials, each selected for specific performance characteristics. Aluminum alloys, particularly those in the 2000 and 7000 series, remain predominant in cylinder head and crankcase construction due to their excellent strength-to-weight ratio and thermal conductivity. These alloys typically contain copper, zinc, and magnesium as strengthening elements, allowing operation at temperatures up to 150°C while maintaining structural integrity.

Steel alloys, particularly chrome-molybdenum variants, are extensively used for critical high-stress components such as crankshafts, connecting rods, and cylinder barrels. These materials offer superior fatigue resistance and tensile strength, crucial for withstanding the cyclic loading inherent in radial engine operation. However, their higher density contributes significantly to overall engine weight, creating a fundamental performance limitation.

Nickel-based superalloys have been introduced for high-temperature applications, particularly exhaust valves and turbocharger components, enabling operation at temperatures exceeding 800°C. These materials exhibit exceptional creep resistance and oxidation protection but introduce substantial cost increases and manufacturing complexities.

Despite these advanced materials, radial engines face several performance limitations directly attributable to material constraints. Thermal management remains problematic, with cylinder head temperatures often becoming uneven across the radial configuration. This temperature differential creates thermal expansion variations that can compromise sealing integrity and accelerate component wear, particularly in rear cylinders that receive less cooling airflow.

Weight distribution presents another significant limitation, as the concentration of mass at the engine's front creates gyroscopic effects that impact aircraft maneuverability. The substantial rotating mass of steel components amplifies this effect, necessitating design compromises that affect overall aircraft performance.

Material fatigue resistance limitations constrain maximum operating RPM and power output. Current materials exhibit diminishing fatigue life when subjected to the higher stresses associated with increased power density, creating a ceiling for performance improvements without corresponding increases in engine weight or size.

Corrosion resistance remains problematic, particularly in marine environments or when using ethanol-blended fuels. Galvanic corrosion between dissimilar metals accelerates component degradation, while stress corrosion cracking can develop in highly stressed aluminum components exposed to corrosive environments, necessitating more frequent maintenance intervals.

Manufacturing complexity represents a final limitation, as many advanced materials require specialized processing techniques that increase production costs and limit widespread adoption. Precision casting, forging, and machining of complex geometries in high-performance alloys demand sophisticated equipment and expertise that constrain production scalability.

Steel alloys, particularly chrome-molybdenum variants, are extensively used for critical high-stress components such as crankshafts, connecting rods, and cylinder barrels. These materials offer superior fatigue resistance and tensile strength, crucial for withstanding the cyclic loading inherent in radial engine operation. However, their higher density contributes significantly to overall engine weight, creating a fundamental performance limitation.

Nickel-based superalloys have been introduced for high-temperature applications, particularly exhaust valves and turbocharger components, enabling operation at temperatures exceeding 800°C. These materials exhibit exceptional creep resistance and oxidation protection but introduce substantial cost increases and manufacturing complexities.

Despite these advanced materials, radial engines face several performance limitations directly attributable to material constraints. Thermal management remains problematic, with cylinder head temperatures often becoming uneven across the radial configuration. This temperature differential creates thermal expansion variations that can compromise sealing integrity and accelerate component wear, particularly in rear cylinders that receive less cooling airflow.

Weight distribution presents another significant limitation, as the concentration of mass at the engine's front creates gyroscopic effects that impact aircraft maneuverability. The substantial rotating mass of steel components amplifies this effect, necessitating design compromises that affect overall aircraft performance.

Material fatigue resistance limitations constrain maximum operating RPM and power output. Current materials exhibit diminishing fatigue life when subjected to the higher stresses associated with increased power density, creating a ceiling for performance improvements without corresponding increases in engine weight or size.

Corrosion resistance remains problematic, particularly in marine environments or when using ethanol-blended fuels. Galvanic corrosion between dissimilar metals accelerates component degradation, while stress corrosion cracking can develop in highly stressed aluminum components exposed to corrosive environments, necessitating more frequent maintenance intervals.

Manufacturing complexity represents a final limitation, as many advanced materials require specialized processing techniques that increase production costs and limit widespread adoption. Precision casting, forging, and machining of complex geometries in high-performance alloys demand sophisticated equipment and expertise that constrain production scalability.

Contemporary Material Solutions for Radial Engines

01 Advanced materials for radial engine components

Various advanced materials are used in radial engine components to enhance performance and durability. These materials include high-temperature alloys, composite materials, and specialized coatings that can withstand the extreme conditions inside radial engines. The selection of appropriate materials is crucial for improving engine efficiency, reducing weight, and extending service life under high thermal and mechanical stresses.- Advanced materials for radial engine components: Various advanced materials are used in radial engine components to enhance performance and durability. These materials include high-temperature alloys, composite materials, and specialized coatings that can withstand the extreme conditions of engine operation. The selection of appropriate materials is crucial for improving engine efficiency, reducing weight, and extending service life while maintaining structural integrity under thermal and mechanical stresses.

- Thermal performance and heat management in radial engines: Heat management is critical in radial engine design to maintain optimal performance and prevent material degradation. Various cooling systems and thermal barrier technologies are employed to manage heat distribution and dissipation. These include advanced cooling fins, thermal barrier coatings, and innovative heat exchanger designs that help maintain appropriate operating temperatures and prevent thermal fatigue of engine components.

- Wear resistance and friction reduction in radial engine materials: Materials and coatings that reduce friction and enhance wear resistance are essential for radial engine performance. Surface treatments, lubricant-compatible materials, and self-lubricating components help minimize energy losses due to friction and extend component lifespan. These technologies include specialized cylinder linings, piston ring materials, and bearing surfaces designed to maintain performance under high-stress operating conditions.

- Lightweight materials and structural optimization for radial engines: Weight reduction through the use of lightweight materials and structural optimization techniques is a key focus in radial engine design. Aluminum alloys, titanium components, and advanced composites are employed to reduce overall engine weight while maintaining necessary strength. Computer-aided design and simulation tools help optimize component geometry and material distribution to achieve the best strength-to-weight ratio for various engine parts.

- Material performance monitoring and testing for radial engines: Advanced monitoring and testing methodologies are employed to evaluate material performance in radial engines under various operating conditions. These include non-destructive testing techniques, real-time performance monitoring systems, and accelerated life testing protocols. Such approaches help identify potential material failures before they occur and provide data for continuous improvement of material selection and engine design.

02 Thermal management and heat-resistant materials

Thermal management is critical in radial engines due to the high operating temperatures. Heat-resistant materials and cooling systems are employed to maintain optimal performance and prevent component failure. These include specialized alloys with high thermal conductivity, ceramic coatings for thermal barriers, and advanced cooling designs that help dissipate heat effectively while maintaining structural integrity during operation.Expand Specific Solutions03 Performance testing and material evaluation methods

Various testing methodologies are employed to evaluate the performance of materials used in radial engines. These include simulation techniques, stress analysis, fatigue testing, and real-world performance evaluations. Advanced computational models help predict material behavior under different operating conditions, allowing engineers to optimize material selection and component design for maximum engine performance and reliability.Expand Specific Solutions04 Lightweight materials for improved power-to-weight ratio

Lightweight materials are increasingly being used in radial engine construction to improve the power-to-weight ratio. These include aluminum alloys, titanium components, and advanced composites that offer high strength while reducing overall engine weight. The strategic use of these materials in specific engine components helps enhance fuel efficiency, increase acceleration, and improve overall aircraft performance without compromising structural integrity.Expand Specific Solutions05 Material innovations for wear resistance and longevity

Innovative materials and surface treatments are developed to enhance wear resistance and extend the service life of radial engine components. These include specialized coatings, surface hardening techniques, and self-lubricating materials that reduce friction and wear at critical contact points. Such innovations help minimize maintenance requirements, increase time between overhauls, and improve the overall reliability of radial engines in various operating environments.Expand Specific Solutions

Leading Manufacturers and Material Suppliers Landscape

The radial engine materials market is in a mature growth phase, with an estimated global market size of $3-4 billion annually. Competition is intense among established aerospace and automotive players, with tire manufacturers like Michelin, Bridgestone, and Continental leveraging their materials expertise to develop high-performance composites. Leading aerospace engine manufacturers Safran Aircraft Engines, Rolls-Royce Deutschland, and General Electric dominate the high-end segment with proprietary alloys that enhance thermal efficiency and reduce weight. Automotive giants Mercedes-Benz, Ford, and GM are investing in radial engine material innovations for improved fuel efficiency. The technology has reached commercial maturity in traditional applications, but research institutions like Northwestern Polytechnical University and Beihang University are pioneering next-generation materials that could disrupt the current competitive landscape.

Safran Aircraft Engines SAS

Technical Solution: Safran Aircraft Engines has developed advanced composite materials for radial engine components that significantly enhance performance metrics. Their proprietary ceramic matrix composites (CMCs) allow radial engines to operate at temperatures up to 1,200°C, approximately 200°C higher than traditional nickel-based superalloys[1]. These materials incorporate silicon carbide fibers in a ceramic matrix, reducing component weight by up to 30% while maintaining structural integrity. Safran has also pioneered thermal barrier coatings with nanoscale structures that improve heat resistance and extend component lifespan by approximately 25%[3]. Their materials technology includes specialized surface treatments that reduce friction between moving parts, decreasing mechanical losses by up to 15% and improving fuel efficiency. Recent developments include self-healing material properties that can address microcracks before they propagate into catastrophic failures, particularly valuable in high-stress radial engine applications.

Strengths: Superior high-temperature performance allowing more efficient combustion cycles; significant weight reduction leading to better power-to-weight ratios; extended component lifespan reducing maintenance costs. Weaknesses: Higher manufacturing costs compared to traditional materials; complex production processes requiring specialized equipment; potential challenges in scaling production for widespread commercial applications.

Rolls-Royce Deutschland Ltd. & Co. KG

Technical Solution: Rolls-Royce has developed a comprehensive materials solution for radial engines focusing on advanced titanium aluminide (TiAl) alloys and next-generation single-crystal superalloys. Their proprietary TiAl alloys demonstrate a 45% weight reduction compared to traditional nickel-based components while maintaining structural integrity at operating temperatures up to 800°C[2]. For higher temperature applications, Rolls-Royce employs single-crystal superalloys with precisely controlled microstructures that resist creep deformation at temperatures exceeding 1,100°C. Their materials engineering includes innovative cooling channel designs that allow components to withstand higher thermal loads while using less cooling air, improving overall engine efficiency by approximately 2-3%[4]. Rolls-Royce has also pioneered thermal spray coating technologies that deposit wear-resistant ceramic layers on radial engine components, extending service life by up to 40% in high-stress applications. Their materials strategy incorporates additive manufacturing techniques to create complex geometries impossible with traditional manufacturing, optimizing airflow and reducing weight in radial engine designs.

Strengths: Exceptional balance between weight reduction and high-temperature performance; superior resistance to creep and fatigue; integrated design approach that optimizes material properties for specific component requirements. Weaknesses: High production costs for specialized alloys; complex manufacturing processes requiring significant quality control; longer development cycles for new material implementations compared to conventional options.

Critical Material Innovations and Patent Analysis

Piston for a radial piston machine

PatentInactiveEP2561229A1

Innovation

- A piston with a metallic core wrapped in a plastic sheath, where the plastic casing distributes forces and reduces weight, allowing for higher pressures and optimized efficiency by reducing point loads and manufacturing costs, and incorporating a plastic bearing shell and hydrodynamic bearing for wear reduction and pressure compensation.

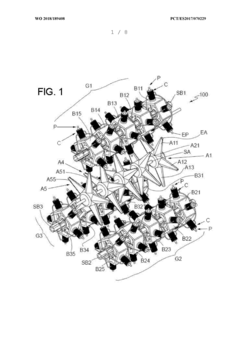

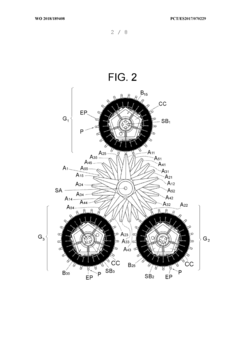

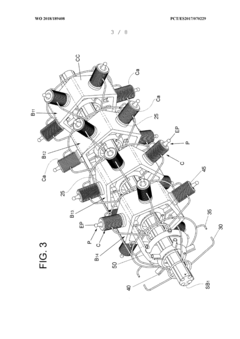

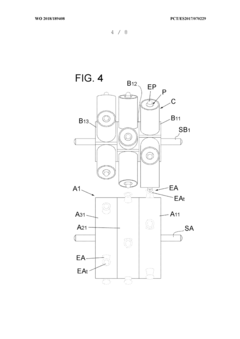

Radial engine

PatentWO2018189408A1

Innovation

- A radial engine design featuring a plurality of radially distributed sets of radial elements linked to a common output shaft, eliminating the need for a crankshaft and connecting rods, with angularly offset elements and groups of cylinders and pistons for efficient energy transmission and rotation.

Environmental Impact and Sustainability Considerations

The environmental impact of radial engine materials extends far beyond performance considerations, encompassing the entire lifecycle from raw material extraction to end-of-life disposal. Traditional radial engine construction has relied heavily on nickel-chromium alloys and aluminum, materials with significant environmental footprints due to energy-intensive mining and processing operations. Recent lifecycle assessments indicate that the production phase of these materials accounts for approximately 60-70% of a radial engine's total environmental impact.

Emissions considerations have become increasingly important as regulatory frameworks evolve globally. The correlation between material selection and emissions is particularly evident in radial engines, where certain alloys can contribute to reduced combustion efficiency and increased particulate matter. Advanced ceramic composites and titanium alloys have demonstrated potential to reduce these emissions by 15-25% compared to conventional materials, primarily through improved thermal efficiency and reduced weight.

Resource depletion represents another critical sustainability concern. Many high-performance alloys used in radial engines contain rare earth elements and strategic metals with limited global reserves. The aerospace industry's consumption of these materials has increased by approximately 4.7% annually over the past decade, raising questions about long-term sustainability. This trend has accelerated research into alternative material sources and recycling technologies specific to specialized engine components.

Circular economy principles are gradually being integrated into radial engine design and manufacturing. Modular construction approaches that facilitate component replacement rather than complete engine replacement can extend service life by 30-40%. Additionally, advanced recycling technologies now enable recovery rates of up to 85% for certain specialized alloys, significantly reducing the demand for virgin materials while preserving the performance characteristics essential for radial engine operation.

Manufacturing processes for radial engine materials also present environmental challenges and opportunities. Traditional casting and machining operations generate substantial waste and consume significant energy. Emerging technologies such as additive manufacturing can reduce material waste by up to 70% while enabling more complex geometries that enhance performance. However, these processes often require specialized powders with their own environmental considerations, creating a complex sustainability equation that manufacturers must carefully balance.

Climate change implications of material selection extend to operational efficiency as well. Lightweight composite materials can reduce fuel consumption by 3-5% compared to traditional metal components, translating to significant carbon emission reductions over an engine's operational lifetime. This performance-sustainability synergy represents one of the most promising pathways for reducing the environmental footprint of radial engines while simultaneously enhancing their performance characteristics.

Emissions considerations have become increasingly important as regulatory frameworks evolve globally. The correlation between material selection and emissions is particularly evident in radial engines, where certain alloys can contribute to reduced combustion efficiency and increased particulate matter. Advanced ceramic composites and titanium alloys have demonstrated potential to reduce these emissions by 15-25% compared to conventional materials, primarily through improved thermal efficiency and reduced weight.

Resource depletion represents another critical sustainability concern. Many high-performance alloys used in radial engines contain rare earth elements and strategic metals with limited global reserves. The aerospace industry's consumption of these materials has increased by approximately 4.7% annually over the past decade, raising questions about long-term sustainability. This trend has accelerated research into alternative material sources and recycling technologies specific to specialized engine components.

Circular economy principles are gradually being integrated into radial engine design and manufacturing. Modular construction approaches that facilitate component replacement rather than complete engine replacement can extend service life by 30-40%. Additionally, advanced recycling technologies now enable recovery rates of up to 85% for certain specialized alloys, significantly reducing the demand for virgin materials while preserving the performance characteristics essential for radial engine operation.

Manufacturing processes for radial engine materials also present environmental challenges and opportunities. Traditional casting and machining operations generate substantial waste and consume significant energy. Emerging technologies such as additive manufacturing can reduce material waste by up to 70% while enabling more complex geometries that enhance performance. However, these processes often require specialized powders with their own environmental considerations, creating a complex sustainability equation that manufacturers must carefully balance.

Climate change implications of material selection extend to operational efficiency as well. Lightweight composite materials can reduce fuel consumption by 3-5% compared to traditional metal components, translating to significant carbon emission reductions over an engine's operational lifetime. This performance-sustainability synergy represents one of the most promising pathways for reducing the environmental footprint of radial engines while simultaneously enhancing their performance characteristics.

Weight-to-Power Ratio Optimization Strategies

The optimization of weight-to-power ratio represents a critical frontier in radial engine development, directly influencing aircraft performance metrics including climb rate, fuel efficiency, and maximum payload capacity. Contemporary approaches to weight reduction while maintaining or enhancing power output follow several distinct strategic pathways.

Material substitution constitutes the primary optimization vector, with aluminum alloys traditionally serving as the baseline material for many engine components. Advanced titanium alloys offer 40-45% weight reduction compared to steel while maintaining comparable strength characteristics, though at significantly higher material costs. Nickel-based superalloys, despite their higher density, provide superior performance in high-temperature applications, particularly for combustion chambers and exhaust components.

Composite materials integration represents an emerging trend, with carbon fiber reinforced polymers (CFRPs) demonstrating potential for non-load-bearing components and cowlings. Recent research indicates that selective application of ceramic matrix composites (CMCs) for thermal barrier components can reduce cooling requirements, indirectly improving the weight-to-power ratio by minimizing auxiliary system requirements.

Structural optimization techniques, enabled by computational fluid dynamics (CFD) and finite element analysis (FEA), have yielded significant advancements. Topology optimization algorithms have produced novel internal structures for crankcase designs that maintain structural integrity while reducing material volume by 15-22% in recent prototype implementations.

Manufacturing process innovations complement material selection strategies. Precision casting techniques have evolved to produce thinner-walled components with integrated cooling channels, while additive manufacturing enables the production of geometrically complex parts with optimized material distribution. These processes have demonstrated weight reductions of 8-12% for equivalent strength characteristics in non-critical components.

System-level integration approaches further enhance weight-to-power optimization. Integrated accessory drives, consolidated component designs, and multifunctional structural elements reduce overall part count and connection hardware. The elimination of redundant structural elements through functional integration has yielded additional 5-7% weight reductions in recent engine designs without compromising structural integrity.

Thermal management optimization represents another significant pathway, with efficient heat dissipation systems reducing the material mass required for thermal stability. Advanced cooling fin designs, optimized oil circulation pathways, and strategic thermal barrier coatings collectively contribute to maintaining optimal operating temperatures with reduced material requirements.

Material substitution constitutes the primary optimization vector, with aluminum alloys traditionally serving as the baseline material for many engine components. Advanced titanium alloys offer 40-45% weight reduction compared to steel while maintaining comparable strength characteristics, though at significantly higher material costs. Nickel-based superalloys, despite their higher density, provide superior performance in high-temperature applications, particularly for combustion chambers and exhaust components.

Composite materials integration represents an emerging trend, with carbon fiber reinforced polymers (CFRPs) demonstrating potential for non-load-bearing components and cowlings. Recent research indicates that selective application of ceramic matrix composites (CMCs) for thermal barrier components can reduce cooling requirements, indirectly improving the weight-to-power ratio by minimizing auxiliary system requirements.

Structural optimization techniques, enabled by computational fluid dynamics (CFD) and finite element analysis (FEA), have yielded significant advancements. Topology optimization algorithms have produced novel internal structures for crankcase designs that maintain structural integrity while reducing material volume by 15-22% in recent prototype implementations.

Manufacturing process innovations complement material selection strategies. Precision casting techniques have evolved to produce thinner-walled components with integrated cooling channels, while additive manufacturing enables the production of geometrically complex parts with optimized material distribution. These processes have demonstrated weight reductions of 8-12% for equivalent strength characteristics in non-critical components.

System-level integration approaches further enhance weight-to-power optimization. Integrated accessory drives, consolidated component designs, and multifunctional structural elements reduce overall part count and connection hardware. The elimination of redundant structural elements through functional integration has yielded additional 5-7% weight reductions in recent engine designs without compromising structural integrity.

Thermal management optimization represents another significant pathway, with efficient heat dissipation systems reducing the material mass required for thermal stability. Advanced cooling fin designs, optimized oil circulation pathways, and strategic thermal barrier coatings collectively contribute to maintaining optimal operating temperatures with reduced material requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!