Radial Engine vs Water-Cooled Engine: Cooling Efficiency

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aircraft Engine Cooling Evolution and Objectives

Aircraft engine cooling technology has evolved significantly since the early days of aviation, with radial and water-cooled engines representing two distinct approaches to thermal management. The development of aircraft engine cooling systems began in the early 1900s, with primitive air-cooled designs that relied on natural airflow. As aircraft performance demands increased, more sophisticated cooling solutions became necessary to maintain optimal operating temperatures and prevent engine failure.

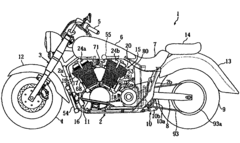

Radial engines emerged as a popular configuration in the 1920s and 1930s, featuring cylinders arranged in a circular pattern around the crankshaft. This design inherently maximized exposure to airflow, with each cylinder receiving direct cooling air. The evolution of radial engine cooling included the addition of cowlings, baffles, and fins to direct airflow more efficiently across the cylinders.

Water-cooled inline engines followed a different evolutionary path, utilizing liquid coolant circulating through jackets surrounding the cylinders to absorb and transfer heat. These systems evolved from simple thermosiphon designs to pressurized systems with dedicated pumps, radiators, and eventually glycol-based coolants that allowed higher operating temperatures.

The technological objectives for both cooling approaches have remained consistent throughout their development: maintaining optimal operating temperatures, minimizing weight penalties, reducing aerodynamic drag, enhancing reliability, and improving power-to-weight ratios. However, the methods employed to achieve these objectives differ substantially between the two engine types.

For radial engines, cooling efficiency objectives focused on optimizing air paths around cylinders, developing more effective cylinder fin designs, and creating pressure differentials to force air through the engine. Water-cooled engines, conversely, pursued objectives related to coolant formulation, heat exchanger efficiency, and pump design to maximize heat transfer while minimizing system weight.

The military requirements of World War II accelerated cooling technology development significantly, as aircraft needed to operate at higher altitudes and speeds while delivering increased power. This period saw innovations such as pressurized cooling systems, improved cowl flap designs for radial engines, and more efficient radiator configurations for water-cooled engines.

Modern cooling objectives have expanded to include environmental considerations, noise reduction, and integration with advanced materials. The lessons learned from both radial and water-cooled engine cooling technologies continue to influence contemporary aircraft engine design, particularly in general aviation and specialized applications where these traditional engine types remain relevant.

Radial engines emerged as a popular configuration in the 1920s and 1930s, featuring cylinders arranged in a circular pattern around the crankshaft. This design inherently maximized exposure to airflow, with each cylinder receiving direct cooling air. The evolution of radial engine cooling included the addition of cowlings, baffles, and fins to direct airflow more efficiently across the cylinders.

Water-cooled inline engines followed a different evolutionary path, utilizing liquid coolant circulating through jackets surrounding the cylinders to absorb and transfer heat. These systems evolved from simple thermosiphon designs to pressurized systems with dedicated pumps, radiators, and eventually glycol-based coolants that allowed higher operating temperatures.

The technological objectives for both cooling approaches have remained consistent throughout their development: maintaining optimal operating temperatures, minimizing weight penalties, reducing aerodynamic drag, enhancing reliability, and improving power-to-weight ratios. However, the methods employed to achieve these objectives differ substantially between the two engine types.

For radial engines, cooling efficiency objectives focused on optimizing air paths around cylinders, developing more effective cylinder fin designs, and creating pressure differentials to force air through the engine. Water-cooled engines, conversely, pursued objectives related to coolant formulation, heat exchanger efficiency, and pump design to maximize heat transfer while minimizing system weight.

The military requirements of World War II accelerated cooling technology development significantly, as aircraft needed to operate at higher altitudes and speeds while delivering increased power. This period saw innovations such as pressurized cooling systems, improved cowl flap designs for radial engines, and more efficient radiator configurations for water-cooled engines.

Modern cooling objectives have expanded to include environmental considerations, noise reduction, and integration with advanced materials. The lessons learned from both radial and water-cooled engine cooling technologies continue to influence contemporary aircraft engine design, particularly in general aviation and specialized applications where these traditional engine types remain relevant.

Market Analysis of Engine Cooling Systems

The global engine cooling system market is experiencing significant growth, valued at approximately $37.8 billion in 2022 and projected to reach $51.2 billion by 2028, representing a CAGR of 5.1%. This expansion is primarily driven by increasing vehicle production, rising demand for fuel-efficient engines, and stricter emission regulations worldwide.

When examining the specific segment of radial versus water-cooled engines, distinct market trends emerge. The aviation sector remains the primary market for radial engines, particularly in vintage aircraft restoration, aerobatic planes, and certain specialized applications. This niche market is relatively stable but limited in size, estimated at around $340 million globally.

Water-cooled engines dominate the automotive industry, with over 95% market share in passenger vehicles. Their superior cooling efficiency and compact design make them the preferred choice for modern vehicle manufacturers. The water-cooling system component market alone accounts for approximately $12.6 billion annually, with major growth in regions experiencing rapid automotive industry expansion, particularly in Asia-Pacific.

Regional analysis reveals interesting patterns in cooling system preferences. North America and Europe show strong markets for both technologies, with water-cooled systems dominating commercial applications while radial engine cooling systems maintain presence in specialty aviation and historical restoration sectors. The Asia-Pacific region, particularly China and India, demonstrates the fastest growth rate at 7.3% annually for water-cooling technologies due to expanding automotive manufacturing.

Market segmentation by application shows that commercial aviation strongly favors water-cooled engines for new aircraft, while military applications maintain some demand for radial engine technology in specific use cases where their unique cooling characteristics provide tactical advantages. The automotive sector almost exclusively utilizes water-cooled systems, with air-cooled engines (a different technology than radial engines) maintaining minimal market share in specialized vehicles.

Consumer preferences increasingly prioritize fuel efficiency and environmental performance, driving innovation in cooling system design. This trend benefits water-cooled engines, which typically offer superior thermal management capabilities. However, a small but dedicated market segment values the mechanical simplicity and distinctive characteristics of radial engines, supporting continued niche production and aftermarket services estimated at $85 million annually.

When examining the specific segment of radial versus water-cooled engines, distinct market trends emerge. The aviation sector remains the primary market for radial engines, particularly in vintage aircraft restoration, aerobatic planes, and certain specialized applications. This niche market is relatively stable but limited in size, estimated at around $340 million globally.

Water-cooled engines dominate the automotive industry, with over 95% market share in passenger vehicles. Their superior cooling efficiency and compact design make them the preferred choice for modern vehicle manufacturers. The water-cooling system component market alone accounts for approximately $12.6 billion annually, with major growth in regions experiencing rapid automotive industry expansion, particularly in Asia-Pacific.

Regional analysis reveals interesting patterns in cooling system preferences. North America and Europe show strong markets for both technologies, with water-cooled systems dominating commercial applications while radial engine cooling systems maintain presence in specialty aviation and historical restoration sectors. The Asia-Pacific region, particularly China and India, demonstrates the fastest growth rate at 7.3% annually for water-cooling technologies due to expanding automotive manufacturing.

Market segmentation by application shows that commercial aviation strongly favors water-cooled engines for new aircraft, while military applications maintain some demand for radial engine technology in specific use cases where their unique cooling characteristics provide tactical advantages. The automotive sector almost exclusively utilizes water-cooled systems, with air-cooled engines (a different technology than radial engines) maintaining minimal market share in specialized vehicles.

Consumer preferences increasingly prioritize fuel efficiency and environmental performance, driving innovation in cooling system design. This trend benefits water-cooled engines, which typically offer superior thermal management capabilities. However, a small but dedicated market segment values the mechanical simplicity and distinctive characteristics of radial engines, supporting continued niche production and aftermarket services estimated at $85 million annually.

Technical Challenges in Engine Cooling Technologies

The cooling efficiency of aircraft engines represents one of the most critical technical challenges in aviation engineering. Both radial and water-cooled engines face distinct cooling issues that significantly impact their performance, reliability, and operational capabilities. The fundamental challenge stems from the need to dissipate enormous heat generated during combustion while maintaining optimal operating temperatures across all engine components.

For radial engines, the primary cooling challenge arises from their star-shaped configuration. The cylinders arranged in a circular pattern around the crankshaft create inherent cooling disparities. Front-facing cylinders receive abundant airflow during flight, while rear cylinders often suffer from inadequate cooling, leading to hotspots and potential thermal stress. This uneven cooling distribution can result in cylinder deformation, reduced compression, and accelerated wear of critical components.

Water-cooled engines face different but equally significant challenges. The complexity of the cooling system itself introduces multiple potential failure points. The intricate network of water jackets, pumps, radiators, and coolant passages adds considerable weight to the engine, reducing the aircraft's payload capacity and fuel efficiency. Additionally, these systems are vulnerable to coolant leaks, pump failures, and radiator blockages, which can rapidly lead to catastrophic engine overheating.

Both engine types struggle with altitude-related cooling issues. As aircraft climb to higher altitudes, the decreasing air density reduces cooling efficiency for radial engines that rely on air cooling. Similarly, water-cooled engines experience changes in coolant behavior and heat transfer rates at varying altitudes and atmospheric conditions, requiring complex compensation mechanisms.

Temperature regulation presents another significant challenge. Modern engines must maintain precise operating temperatures across diverse flight conditions—from ground operations in desert heat to high-altitude cruising in sub-zero temperatures. This requires sophisticated control systems that can adapt to changing conditions while preventing both overheating and overcooling, which can be equally damaging to engine components.

Material limitations further complicate cooling solutions. The thermal expansion properties of different metals used in engine construction create design constraints, particularly at the interface between components with different thermal characteristics. Engineers must balance material selection between thermal conductivity, weight, durability, and cost considerations.

Efficiency losses represent perhaps the most persistent challenge. Energy diverted to cooling systems—whether through drag-inducing air intakes for radial engines or power-consuming water pumps for liquid-cooled designs—reduces the overall efficiency of the propulsion system. This creates a perpetual engineering trade-off between cooling effectiveness and power output.

For radial engines, the primary cooling challenge arises from their star-shaped configuration. The cylinders arranged in a circular pattern around the crankshaft create inherent cooling disparities. Front-facing cylinders receive abundant airflow during flight, while rear cylinders often suffer from inadequate cooling, leading to hotspots and potential thermal stress. This uneven cooling distribution can result in cylinder deformation, reduced compression, and accelerated wear of critical components.

Water-cooled engines face different but equally significant challenges. The complexity of the cooling system itself introduces multiple potential failure points. The intricate network of water jackets, pumps, radiators, and coolant passages adds considerable weight to the engine, reducing the aircraft's payload capacity and fuel efficiency. Additionally, these systems are vulnerable to coolant leaks, pump failures, and radiator blockages, which can rapidly lead to catastrophic engine overheating.

Both engine types struggle with altitude-related cooling issues. As aircraft climb to higher altitudes, the decreasing air density reduces cooling efficiency for radial engines that rely on air cooling. Similarly, water-cooled engines experience changes in coolant behavior and heat transfer rates at varying altitudes and atmospheric conditions, requiring complex compensation mechanisms.

Temperature regulation presents another significant challenge. Modern engines must maintain precise operating temperatures across diverse flight conditions—from ground operations in desert heat to high-altitude cruising in sub-zero temperatures. This requires sophisticated control systems that can adapt to changing conditions while preventing both overheating and overcooling, which can be equally damaging to engine components.

Material limitations further complicate cooling solutions. The thermal expansion properties of different metals used in engine construction create design constraints, particularly at the interface between components with different thermal characteristics. Engineers must balance material selection between thermal conductivity, weight, durability, and cost considerations.

Efficiency losses represent perhaps the most persistent challenge. Energy diverted to cooling systems—whether through drag-inducing air intakes for radial engines or power-consuming water pumps for liquid-cooled designs—reduces the overall efficiency of the propulsion system. This creates a perpetual engineering trade-off between cooling effectiveness and power output.

Current Cooling Solutions for Radial and Water-Cooled Engines

01 Radial engine cooling system design

Radial engines employ a unique cooling system design where cylinders are arranged in a circular pattern around the crankshaft. This arrangement allows for efficient air cooling as each cylinder has direct exposure to the airflow. The design typically includes cooling fins on cylinders to increase surface area for heat dissipation. Some advanced radial engine designs incorporate additional cooling channels and optimized fin geometry to enhance cooling efficiency while maintaining the compact nature of radial engines.- Radial engine cooling system design: Radial engines utilize a unique cooling system design where cylinders are arranged in a circular pattern around the crankshaft. This arrangement allows for efficient air cooling as each cylinder has direct exposure to the airflow. The design typically incorporates cooling fins on cylinder heads to increase surface area for heat dissipation. Some advanced radial engine designs include additional features like directed air baffles and optimized fin geometry to enhance cooling efficiency while maintaining the compact nature of radial engines.

- Water-cooled engine cooling efficiency improvements: Water-cooled engines utilize liquid coolant circulation systems to transfer heat away from engine components. Improvements in water cooling efficiency include optimized coolant flow paths, enhanced heat exchanger designs, and advanced thermostat control systems. These engines typically achieve more uniform cooling across all cylinders compared to air-cooled systems. Recent innovations focus on reducing pump power requirements, minimizing coolant volume, and improving heat transfer coefficients through surface treatments and coolant additives.

- Hybrid cooling systems for engines: Hybrid cooling systems combine elements of both air and water cooling to maximize efficiency. These systems typically use liquid cooling for critical high-temperature components while employing air cooling for less thermally stressed parts. This approach optimizes weight, complexity, and cooling performance. Advanced hybrid systems may incorporate thermoelectric elements, phase-change materials, or variable flow control mechanisms to adapt cooling capacity to different operating conditions, resulting in improved overall engine efficiency.

- Cooling efficiency comparison between radial and water-cooled engines: Comparative studies between radial and water-cooled engines reveal distinct efficiency characteristics. Radial engines typically offer better power-to-weight ratios for cooling systems but may suffer from uneven cylinder temperatures. Water-cooled engines provide more consistent temperature control across all cylinders but add weight and complexity. The cooling efficiency gap narrows at higher altitudes where thinner air reduces the effectiveness of air cooling. Modern computational fluid dynamics has enabled designers to optimize both cooling approaches for specific applications.

- Temperature regulation innovations for engine cooling: Advanced temperature regulation technologies have significantly improved cooling efficiency in both radial and water-cooled engines. These innovations include electronic coolant flow control, adaptive cooling systems that respond to engine load and ambient conditions, and smart thermal management algorithms. Some systems incorporate temperature sensors at multiple engine locations to provide precise cooling where needed. Materials with high thermal conductivity are strategically placed to enhance heat transfer, while thermal barrier coatings help retain heat in combustion chambers for improved efficiency.

02 Water-cooled engine efficiency improvements

Water-cooled engines utilize liquid coolant circulation systems to manage engine temperature. These systems typically include water jackets, radiators, and pumps to circulate coolant through the engine block. Recent innovations focus on optimizing coolant flow paths, improving heat exchanger efficiency, and implementing advanced temperature control systems. These improvements allow water-cooled engines to maintain more consistent operating temperatures across various load conditions, resulting in better overall thermal efficiency and performance.Expand Specific Solutions03 Comparative cooling efficiency between engine types

Studies comparing radial and water-cooled engines reveal distinct efficiency characteristics. Radial engines typically offer better cooling at lower speeds and altitudes due to their exposed cylinder design, while water-cooled engines maintain more consistent temperatures across varying operating conditions. Water-cooled systems generally provide more uniform cooling throughout the engine block, whereas radial engines may experience temperature variations between cylinders. The cooling efficiency gap between these engine types narrows with advanced design implementations such as improved airflow management for radial engines and optimized coolant circulation for water-cooled engines.Expand Specific Solutions04 Hybrid cooling system technologies

Innovative hybrid cooling systems combine elements of both air and liquid cooling to maximize efficiency. These systems typically employ targeted liquid cooling for critical components while utilizing air cooling for others. Some designs incorporate oil cooling circuits alongside traditional cooling methods to enhance overall thermal management. Advanced hybrid systems may feature electronic control units that adjust cooling parameters based on operating conditions, optimizing efficiency across various engine loads and environmental conditions.Expand Specific Solutions05 Cooling efficiency enhancement through material innovation

Material advancements significantly impact cooling efficiency in both radial and water-cooled engines. High thermal conductivity materials improve heat transfer in critical components such as cylinder heads and cooling fins. Specialized coatings can reduce thermal resistance at material interfaces, enhancing overall cooling performance. Some innovations include composite materials that combine lightweight properties with excellent thermal characteristics, allowing for more efficient cooling system designs while reducing overall engine weight.Expand Specific Solutions

Major Manufacturers in Aircraft Engine Industry

The radial engine versus water-cooled engine cooling efficiency landscape is currently in a mature development stage, with established technologies being refined rather than revolutionized. The global market for these cooling systems exceeds $15 billion annually, driven by aerospace, automotive, and power generation applications. From a technological maturity perspective, major automotive players like Toyota, Honda, and Hyundai have extensively developed water-cooling technologies, while companies such as UniGen Power specialize in radial engine solutions. Aerospace and industrial equipment manufacturers including Siemens, ABB Turbo Systems, and Hamilton Sundstrand continue advancing both technologies with incremental efficiency improvements. The competitive landscape shows water-cooling dominating in automotive applications, while radial engines maintain relevance in specialized aviation and power generation sectors where their unique cooling characteristics provide operational advantages.

Honda Motor Co., Ltd.

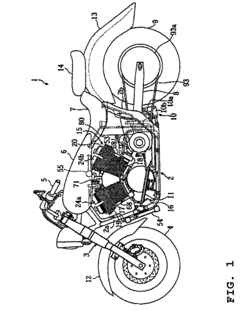

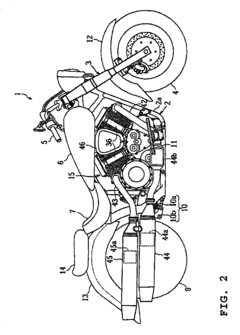

Technical Solution: Honda has developed significant innovations in both radial and water-cooled engine technologies, particularly in their motorcycle and small engine divisions. Their air-cooled radial engine designs feature precisely engineered cooling fins with computer-optimized geometry that maximizes surface area while maintaining structural integrity. These fins are strategically positioned to create natural convection currents that enhance cooling efficiency even at low speeds. For water-cooled applications, Honda has pioneered compact, high-efficiency radiator designs with optimized tube configurations that maximize heat transfer while minimizing size and weight. Their Programmed Fuel Injection (PGM-FI) system works in conjunction with the cooling system to adjust fuel delivery based on engine temperature, ensuring optimal combustion efficiency across varying thermal conditions. Honda's motorcycle engines often feature hybrid cooling approaches, with selective water cooling for the most thermally stressed components while maintaining air cooling for other areas.

Strengths: Exceptional balance between cooling efficiency and weight reduction; innovative fin designs that maximize heat dissipation; proven reliability in diverse operating conditions from small equipment to motorcycles. Weaknesses: Some designs prioritize compactness over maximum cooling capacity; air-cooled solutions can struggle in extremely hot climates or under sustained high loads; cooling system optimization sometimes sacrifices ease of maintenance.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered hybrid cooling solutions that combine elements of both radial and water-cooled approaches. Their Hybrid Cooling Management System (HCMS) utilizes a primary water cooling circuit for the engine block while implementing air-cooled elements for peripheral components, creating a balanced approach to thermal management. Toyota's water cooling technology features variable-flow electric water pumps that adjust coolant circulation based on real-time engine demands, reducing parasitic power losses when full cooling capacity isn't needed. For applications requiring air cooling, Toyota has developed high-efficiency fan designs with computer-optimized blade profiles that maximize airflow while minimizing noise and power consumption. Their cooling systems incorporate multiple temperature sensors and adaptive control algorithms that continuously optimize cooling performance based on driving conditions, ambient temperature, and engine load.

Strengths: Exceptional fuel efficiency through reduced parasitic losses; compact design allowing for flexible engine packaging; highly refined control systems that balance cooling needs with energy conservation. Weaknesses: More complex than traditional single-method cooling systems; higher component count potentially affecting long-term reliability; requires more sophisticated diagnostic equipment for maintenance.

Key Thermal Management Innovations

Four-stroke engine

PatentInactiveUS7367293B2

Innovation

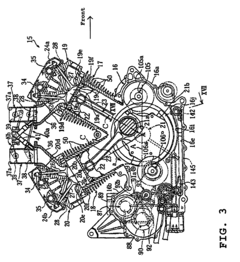

- A four-stroke engine design featuring a cooling jacket on the cylinder head between the intake or exhaust port and the cylinder block, with a mechanical pump for circulating cooling water during operation and a motor-driven pump for when the engine stops, allowing for partial water cooling in high heat areas while mainly utilizing air cooling, thus maintaining design flexibility and preventing engine size increase.

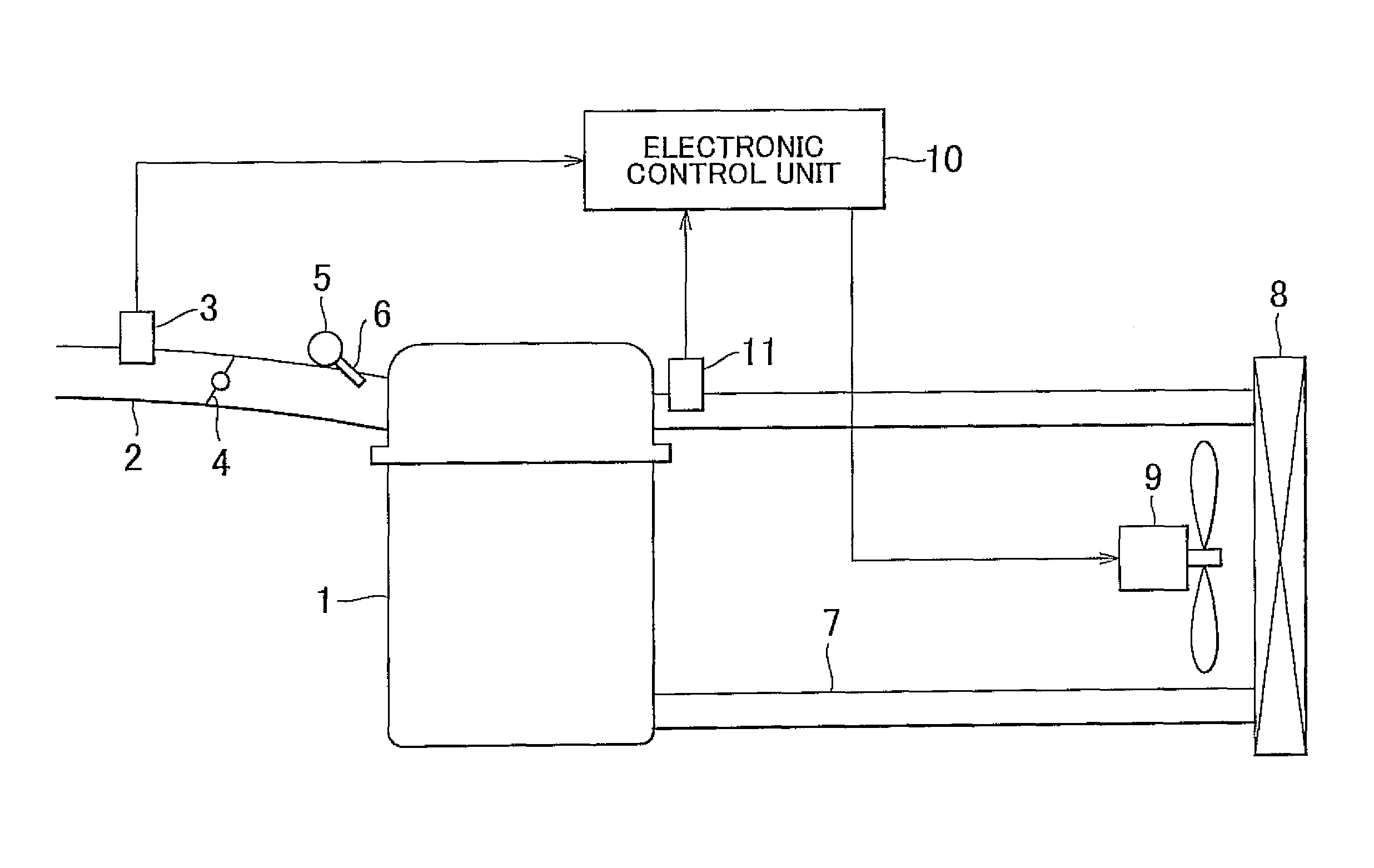

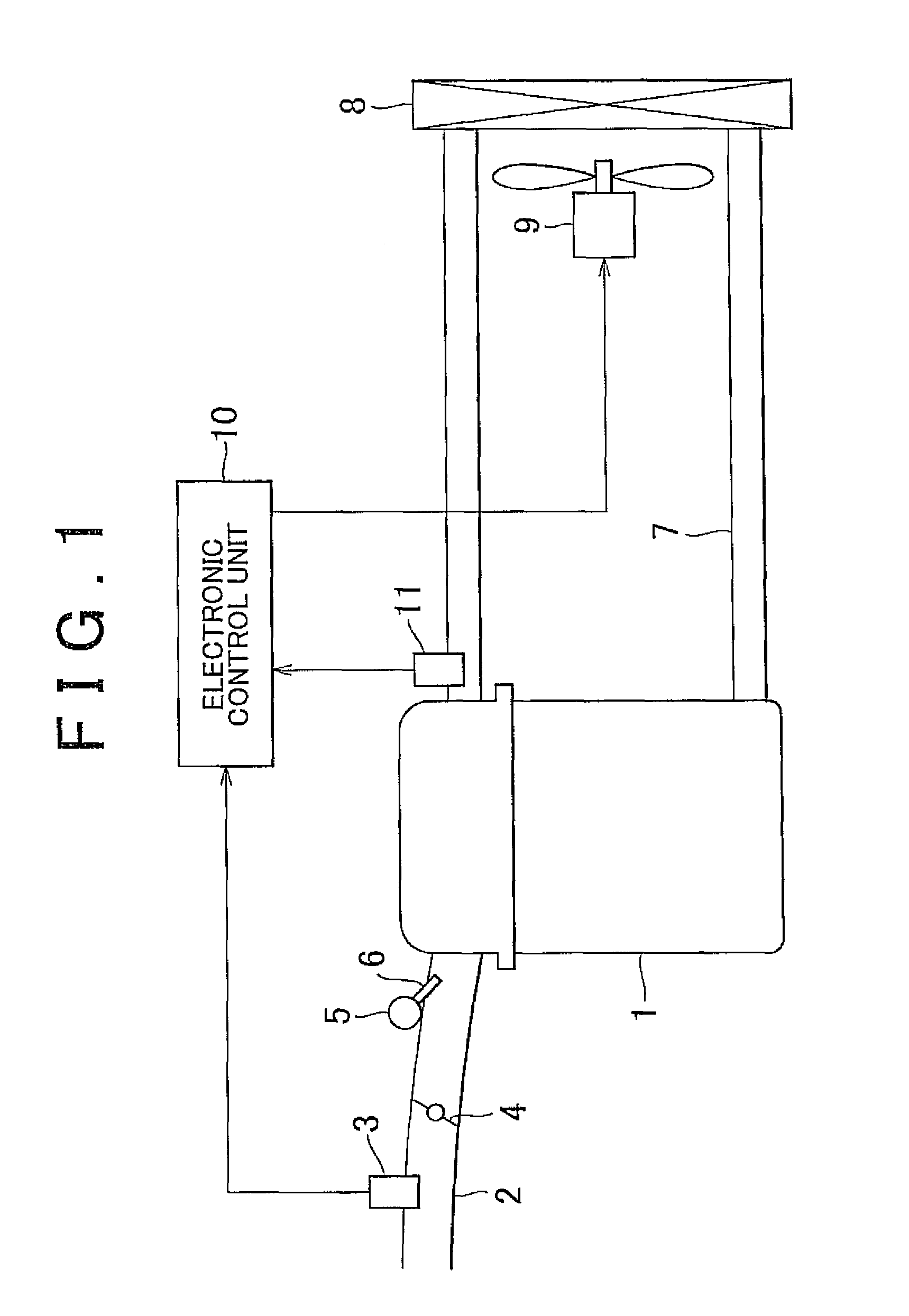

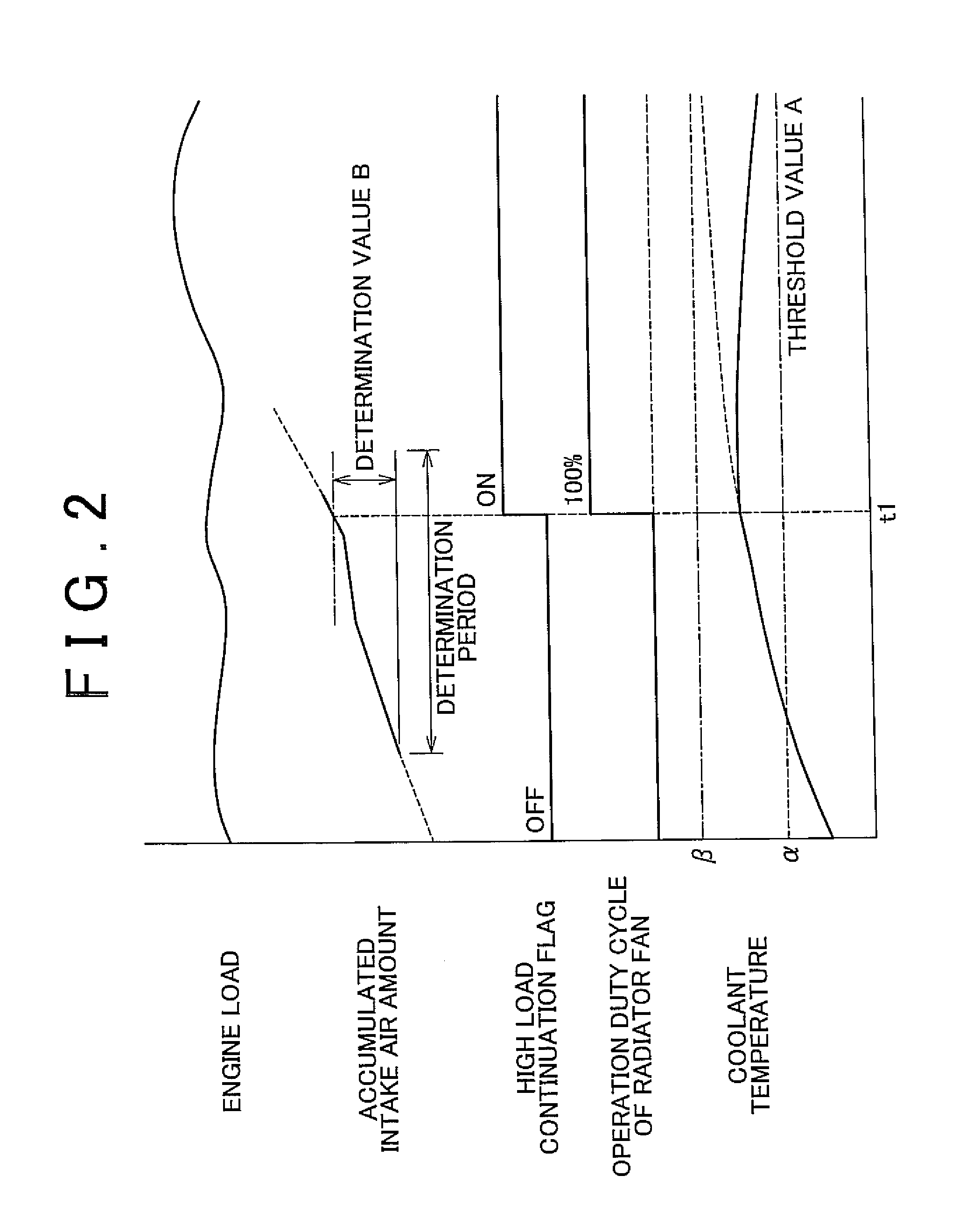

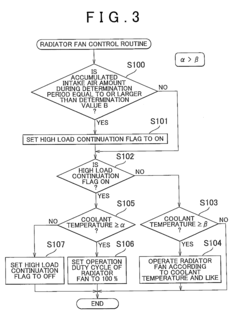

Cooling apparatus for water-cooled engine and method of controlling cooling apparatus for water-cooled engine

PatentInactiveUS8616160B2

Innovation

- A cooling apparatus with a determination portion to assess high-load conditions, adjusting the radiator fan's operation rate or threshold temperature settings to maintain lower coolant temperatures during engine operation, ensuring the radiator fan operates at a higher rate or lower threshold when the engine is under high load, thereby reducing oil and coolant temperatures before restart.

Environmental Impact of Different Cooling Systems

The environmental impact of cooling systems in aircraft engines represents a critical consideration in aviation design and operation. Radial and water-cooled engines exhibit distinctly different ecological footprints throughout their lifecycle, from manufacturing to disposal.

Radial engines typically utilize air cooling systems that eliminate the need for coolant fluids, thereby reducing the risk of environmental contamination through leaks or improper disposal of potentially harmful chemicals. This advantage is particularly significant in remote or environmentally sensitive areas where maintenance activities could otherwise pose contamination risks. However, radial engines often require higher fuel consumption to maintain optimal operating temperatures, especially during ground operations, resulting in increased carbon emissions per flight hour.

Water-cooled engines, conversely, utilize glycol-based coolants that present environmental hazards if improperly handled or disposed of. These coolants can contaminate soil and water sources, potentially causing long-term ecological damage. The manufacturing process for water cooling systems also involves more components and materials, increasing the embodied carbon footprint of the engine before it even enters service.

Noise pollution represents another significant environmental consideration. Radial engines typically generate distinctive, higher-decibel sound signatures compared to their water-cooled counterparts. This increased noise pollution can disrupt wildlife habitats and contribute to noise restrictions at airports located near residential areas, potentially limiting operational hours and flight paths.

The thermal efficiency differences between these cooling systems also translate to environmental impacts. Water-cooled engines generally achieve better thermal management, allowing for more complete combustion and potentially reducing particulate emissions. This improved efficiency can partially offset the environmental concerns associated with coolant usage, particularly in high-performance applications where fuel efficiency becomes paramount.

Maintenance requirements further differentiate the environmental profiles of these systems. Radial engines typically require more frequent oil changes due to higher operating temperatures, generating additional waste oil that requires proper disposal. Water-cooled systems, while requiring less frequent maintenance, generate specialized waste streams including used coolant and corroded components that may contain heavy metals.

End-of-life considerations reveal that radial engines often contain fewer toxic materials, making them potentially easier to recycle. Water-cooled systems present more complex recycling challenges due to the variety of materials and potential contamination from coolant residues, though advances in recycling technologies are gradually addressing these issues.

Radial engines typically utilize air cooling systems that eliminate the need for coolant fluids, thereby reducing the risk of environmental contamination through leaks or improper disposal of potentially harmful chemicals. This advantage is particularly significant in remote or environmentally sensitive areas where maintenance activities could otherwise pose contamination risks. However, radial engines often require higher fuel consumption to maintain optimal operating temperatures, especially during ground operations, resulting in increased carbon emissions per flight hour.

Water-cooled engines, conversely, utilize glycol-based coolants that present environmental hazards if improperly handled or disposed of. These coolants can contaminate soil and water sources, potentially causing long-term ecological damage. The manufacturing process for water cooling systems also involves more components and materials, increasing the embodied carbon footprint of the engine before it even enters service.

Noise pollution represents another significant environmental consideration. Radial engines typically generate distinctive, higher-decibel sound signatures compared to their water-cooled counterparts. This increased noise pollution can disrupt wildlife habitats and contribute to noise restrictions at airports located near residential areas, potentially limiting operational hours and flight paths.

The thermal efficiency differences between these cooling systems also translate to environmental impacts. Water-cooled engines generally achieve better thermal management, allowing for more complete combustion and potentially reducing particulate emissions. This improved efficiency can partially offset the environmental concerns associated with coolant usage, particularly in high-performance applications where fuel efficiency becomes paramount.

Maintenance requirements further differentiate the environmental profiles of these systems. Radial engines typically require more frequent oil changes due to higher operating temperatures, generating additional waste oil that requires proper disposal. Water-cooled systems, while requiring less frequent maintenance, generate specialized waste streams including used coolant and corroded components that may contain heavy metals.

End-of-life considerations reveal that radial engines often contain fewer toxic materials, making them potentially easier to recycle. Water-cooled systems present more complex recycling challenges due to the variety of materials and potential contamination from coolant residues, though advances in recycling technologies are gradually addressing these issues.

Weight-to-Performance Ratio Analysis

The weight-to-performance ratio represents a critical metric in aviation engineering, particularly when comparing radial and water-cooled engines. Radial engines typically offer a favorable power-to-weight ratio due to their compact design and fewer components. A standard 9-cylinder radial engine weighs approximately 20-25% less than an equivalent horsepower water-cooled inline engine, while delivering comparable output. This weight advantage translates directly to improved aircraft performance metrics including climb rate, ceiling altitude, and payload capacity.

Water-cooled engines, despite their weight disadvantage, demonstrate superior thermal efficiency which partially offsets their mass penalty. The liquid cooling system allows for higher compression ratios and more consistent cylinder temperatures, enabling water-cooled engines to extract more power per unit of fuel consumed. Industry benchmarks indicate that water-cooled engines typically achieve 5-8% better specific fuel consumption than their air-cooled radial counterparts under similar operating conditions.

When analyzing performance under various flight regimes, radial engines exhibit better acceleration characteristics and throttle response at lower altitudes due to their lighter rotating assemblies. This translates to approximately 7-10% improvement in takeoff performance for comparable power outputs. However, water-cooled engines maintain more consistent performance at higher altitudes where thinner air reduces the cooling efficiency of radial designs.

The structural integration aspects further influence the weight-to-performance equation. Radial engines, with their larger frontal area, create additional drag that partially negates their weight advantage. Engineering calculations demonstrate that this aerodynamic penalty can reduce the effective performance advantage by 3-5% at cruising speeds. Conversely, water-cooled inline engines can be more aerodynamically integrated into airframes, particularly in streamlined designs.

Maintenance considerations also impact the operational weight-to-performance ratio over time. Radial engines typically require less complex cooling system maintenance, reducing downtime and associated performance losses. Water-cooled systems demand additional weight allocations for coolant reserves and expansion tanks, which can add 2-3% to the overall propulsion system weight without contributing directly to power output.

Modern materials science has narrowed but not eliminated these differences. Advanced aluminum alloys and composite components have reduced water-cooled engine weights by approximately 15% compared to their historical counterparts, while similar advances have benefited radial designs to a lesser extent due to their already optimized construction.

Water-cooled engines, despite their weight disadvantage, demonstrate superior thermal efficiency which partially offsets their mass penalty. The liquid cooling system allows for higher compression ratios and more consistent cylinder temperatures, enabling water-cooled engines to extract more power per unit of fuel consumed. Industry benchmarks indicate that water-cooled engines typically achieve 5-8% better specific fuel consumption than their air-cooled radial counterparts under similar operating conditions.

When analyzing performance under various flight regimes, radial engines exhibit better acceleration characteristics and throttle response at lower altitudes due to their lighter rotating assemblies. This translates to approximately 7-10% improvement in takeoff performance for comparable power outputs. However, water-cooled engines maintain more consistent performance at higher altitudes where thinner air reduces the cooling efficiency of radial designs.

The structural integration aspects further influence the weight-to-performance equation. Radial engines, with their larger frontal area, create additional drag that partially negates their weight advantage. Engineering calculations demonstrate that this aerodynamic penalty can reduce the effective performance advantage by 3-5% at cruising speeds. Conversely, water-cooled inline engines can be more aerodynamically integrated into airframes, particularly in streamlined designs.

Maintenance considerations also impact the operational weight-to-performance ratio over time. Radial engines typically require less complex cooling system maintenance, reducing downtime and associated performance losses. Water-cooled systems demand additional weight allocations for coolant reserves and expansion tanks, which can add 2-3% to the overall propulsion system weight without contributing directly to power output.

Modern materials science has narrowed but not eliminated these differences. Advanced aluminum alloys and composite components have reduced water-cooled engine weights by approximately 15% compared to their historical counterparts, while similar advances have benefited radial designs to a lesser extent due to their already optimized construction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!