Best Practices For DED Repair Of Aeroengine Turbine Blades

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Repair Technology Background and Objectives

Directed Energy Deposition (DED) technology has evolved significantly over the past three decades, transforming from experimental additive manufacturing processes to sophisticated repair solutions for high-value components. The aerospace industry, particularly the aeroengine sector, has been a primary driver of this evolution due to the critical nature of turbine blade performance and the substantial costs associated with component replacement. DED repair technology emerged as a response to the increasing demand for sustainable maintenance practices and the need to extend the service life of complex, expensive turbine components.

The historical progression of DED technology began with rudimentary laser cladding systems in the 1990s, advancing through various iterations of powder-fed and wire-fed systems. By the early 2000s, the integration of computer numerical control (CNC) with laser deposition technologies marked a significant milestone, enabling more precise material application and expanding repair capabilities. The subsequent development of multi-axis robotic systems further enhanced the adaptability of DED processes to complex geometries characteristic of turbine blades.

Current technological objectives for DED repair of aeroengine turbine blades center on several key areas. First, achieving microstructural consistency between deposited material and the substrate is paramount for ensuring mechanical integrity and performance under extreme operating conditions. Second, minimizing heat-affected zones and residual stresses remains a critical challenge that directly impacts component fatigue life and dimensional stability.

Process parameter optimization represents another significant objective, focusing on establishing standardized protocols for different alloy systems commonly used in turbine blade manufacturing, such as nickel-based superalloys, titanium alloys, and advanced intermetallics. This includes determining optimal laser power densities, deposition rates, and thermal management strategies to ensure consistent repair quality.

The integration of in-situ monitoring and closed-loop control systems constitutes a forward-looking objective, aimed at real-time quality assurance and adaptive process control. These systems utilize various sensing technologies to detect and correct process anomalies during deposition, significantly reducing repair variability and enhancing reproducibility.

From a broader perspective, the industry aims to establish comprehensive certification pathways for DED-repaired components, addressing the stringent regulatory requirements of aerospace applications. This involves developing robust testing methodologies, non-destructive evaluation techniques, and performance validation protocols specific to repaired turbine blades.

The ultimate goal of DED repair technology development is to create a sustainable, economically viable alternative to component replacement, capable of restoring turbine blades to their original performance specifications while maintaining or even enhancing their durability under extreme operating conditions. This aligns with the aerospace industry's increasing focus on sustainability, cost reduction, and resource efficiency.

The historical progression of DED technology began with rudimentary laser cladding systems in the 1990s, advancing through various iterations of powder-fed and wire-fed systems. By the early 2000s, the integration of computer numerical control (CNC) with laser deposition technologies marked a significant milestone, enabling more precise material application and expanding repair capabilities. The subsequent development of multi-axis robotic systems further enhanced the adaptability of DED processes to complex geometries characteristic of turbine blades.

Current technological objectives for DED repair of aeroengine turbine blades center on several key areas. First, achieving microstructural consistency between deposited material and the substrate is paramount for ensuring mechanical integrity and performance under extreme operating conditions. Second, minimizing heat-affected zones and residual stresses remains a critical challenge that directly impacts component fatigue life and dimensional stability.

Process parameter optimization represents another significant objective, focusing on establishing standardized protocols for different alloy systems commonly used in turbine blade manufacturing, such as nickel-based superalloys, titanium alloys, and advanced intermetallics. This includes determining optimal laser power densities, deposition rates, and thermal management strategies to ensure consistent repair quality.

The integration of in-situ monitoring and closed-loop control systems constitutes a forward-looking objective, aimed at real-time quality assurance and adaptive process control. These systems utilize various sensing technologies to detect and correct process anomalies during deposition, significantly reducing repair variability and enhancing reproducibility.

From a broader perspective, the industry aims to establish comprehensive certification pathways for DED-repaired components, addressing the stringent regulatory requirements of aerospace applications. This involves developing robust testing methodologies, non-destructive evaluation techniques, and performance validation protocols specific to repaired turbine blades.

The ultimate goal of DED repair technology development is to create a sustainable, economically viable alternative to component replacement, capable of restoring turbine blades to their original performance specifications while maintaining or even enhancing their durability under extreme operating conditions. This aligns with the aerospace industry's increasing focus on sustainability, cost reduction, and resource efficiency.

Market Analysis for Aeroengine Turbine Blade Repair

The global market for aeroengine turbine blade repair is experiencing robust growth, driven by the increasing demand for cost-effective maintenance solutions in the aviation industry. Currently valued at approximately 3.2 billion USD, this market is projected to grow at a compound annual growth rate of 6.8% through 2028, according to recent industry analyses.

The primary market drivers include the aging fleet of commercial and military aircraft worldwide, with over 25,000 commercial aircraft currently in service having an average age of 11 years. This aging fleet requires more frequent maintenance and repair operations, particularly for critical components like turbine blades that experience extreme thermal and mechanical stresses during operation.

Geographically, North America dominates the market with approximately 38% share, followed by Europe (27%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth due to expanding aviation sectors and increasing domestic manufacturing capabilities for aerospace components.

By end-user segment, commercial aviation accounts for the largest market share at 65%, followed by military aviation at 28% and general aviation at 7%. The commercial segment's dominance is attributed to the larger fleet size and stricter maintenance schedules imposed by aviation authorities.

The economic benefits of DED repair for turbine blades present a compelling value proposition. New turbine blades can cost between $8,000 to $50,000 per piece depending on complexity and materials, while DED repair typically costs 30-50% of replacement cost. This significant cost advantage is driving market adoption, especially as airlines and operators face increasing pressure to reduce maintenance costs and extend component lifecycles.

Market analysis indicates that repair services offering faster turnaround times command premium pricing, with operators willing to pay 15-20% more for expedited services that minimize aircraft downtime. Each day of aircraft grounding costs operators between $25,000 to $150,000 depending on aircraft type, making rapid repair capabilities a critical competitive advantage.

Environmental regulations are also influencing market dynamics, with sustainability initiatives favoring repair over replacement. DED repair processes typically reduce carbon footprint by 60-70% compared to manufacturing new components, aligning with the aviation industry's growing focus on environmental sustainability and circular economy principles.

The primary market drivers include the aging fleet of commercial and military aircraft worldwide, with over 25,000 commercial aircraft currently in service having an average age of 11 years. This aging fleet requires more frequent maintenance and repair operations, particularly for critical components like turbine blades that experience extreme thermal and mechanical stresses during operation.

Geographically, North America dominates the market with approximately 38% share, followed by Europe (27%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth due to expanding aviation sectors and increasing domestic manufacturing capabilities for aerospace components.

By end-user segment, commercial aviation accounts for the largest market share at 65%, followed by military aviation at 28% and general aviation at 7%. The commercial segment's dominance is attributed to the larger fleet size and stricter maintenance schedules imposed by aviation authorities.

The economic benefits of DED repair for turbine blades present a compelling value proposition. New turbine blades can cost between $8,000 to $50,000 per piece depending on complexity and materials, while DED repair typically costs 30-50% of replacement cost. This significant cost advantage is driving market adoption, especially as airlines and operators face increasing pressure to reduce maintenance costs and extend component lifecycles.

Market analysis indicates that repair services offering faster turnaround times command premium pricing, with operators willing to pay 15-20% more for expedited services that minimize aircraft downtime. Each day of aircraft grounding costs operators between $25,000 to $150,000 depending on aircraft type, making rapid repair capabilities a critical competitive advantage.

Environmental regulations are also influencing market dynamics, with sustainability initiatives favoring repair over replacement. DED repair processes typically reduce carbon footprint by 60-70% compared to manufacturing new components, aligning with the aviation industry's growing focus on environmental sustainability and circular economy principles.

Current DED Repair Challenges in Aerospace Industry

The aerospace industry faces significant challenges in implementing Directed Energy Deposition (DED) repair techniques for aeroengine turbine blades. One of the primary obstacles is achieving consistent material properties across the repaired regions. The high-temperature operating environment of turbine blades demands exceptional material integrity, yet current DED processes often struggle to maintain uniform microstructure throughout the repair zone, leading to potential weak points that could compromise blade performance under extreme conditions.

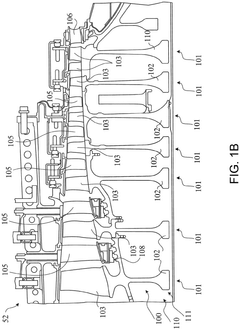

Geometric accuracy presents another substantial challenge. Turbine blades feature complex geometries with thin edges, cooling channels, and intricate surface features. Current DED systems have limitations in reproducing these precise geometries, particularly when dealing with thin-walled sections where heat management becomes critical. The dimensional tolerance requirements for aerospace components are exceptionally stringent, often in the range of ±0.05mm, which pushes the boundaries of current DED capabilities.

Heat management during the repair process constitutes a significant technical hurdle. The localized high-temperature input from DED processes can induce thermal stresses, distortion, and unwanted microstructural changes in the base material. This is particularly problematic for nickel-based superalloys commonly used in turbine blades, as these materials are highly susceptible to heat-affected zone cracking and recrystallization phenomena that can degrade mechanical properties.

Surface finish quality remains below aerospace requirements in many DED applications. Post-processing operations are invariably needed, which adds complexity, cost, and time to the repair cycle. The industry standard typically requires surface roughness values of Ra < 0.8μm for aerodynamic surfaces, which is challenging to achieve directly through current DED processes that often produce surfaces with Ra values between 5-20μm.

Qualification and certification frameworks represent perhaps the most significant non-technical barrier. The aerospace industry operates under rigorous certification requirements, and the variable nature of repair processes makes standardization difficult. Current regulatory frameworks were largely developed for traditional manufacturing methods, creating a certification gap for additive repair technologies like DED. The lack of industry-wide accepted standards specifically for DED repair processes slows adoption despite technical advancements.

Material compatibility issues arise when attempting to repair advanced alloys. Many modern turbine blades utilize single-crystal superalloys or contain protective coatings that are difficult to match with DED processes. The challenge lies in developing parameter sets that can effectively bond with these specialized materials while maintaining their unique properties, particularly directional solidification characteristics critical for high-temperature performance.

AI-based process monitoring and control systems remain in early development stages, limiting the ability to implement real-time quality assurance during repairs. This gap in process validation technology increases the risk of undetected defects and contributes to higher rejection rates of repaired components.

Geometric accuracy presents another substantial challenge. Turbine blades feature complex geometries with thin edges, cooling channels, and intricate surface features. Current DED systems have limitations in reproducing these precise geometries, particularly when dealing with thin-walled sections where heat management becomes critical. The dimensional tolerance requirements for aerospace components are exceptionally stringent, often in the range of ±0.05mm, which pushes the boundaries of current DED capabilities.

Heat management during the repair process constitutes a significant technical hurdle. The localized high-temperature input from DED processes can induce thermal stresses, distortion, and unwanted microstructural changes in the base material. This is particularly problematic for nickel-based superalloys commonly used in turbine blades, as these materials are highly susceptible to heat-affected zone cracking and recrystallization phenomena that can degrade mechanical properties.

Surface finish quality remains below aerospace requirements in many DED applications. Post-processing operations are invariably needed, which adds complexity, cost, and time to the repair cycle. The industry standard typically requires surface roughness values of Ra < 0.8μm for aerodynamic surfaces, which is challenging to achieve directly through current DED processes that often produce surfaces with Ra values between 5-20μm.

Qualification and certification frameworks represent perhaps the most significant non-technical barrier. The aerospace industry operates under rigorous certification requirements, and the variable nature of repair processes makes standardization difficult. Current regulatory frameworks were largely developed for traditional manufacturing methods, creating a certification gap for additive repair technologies like DED. The lack of industry-wide accepted standards specifically for DED repair processes slows adoption despite technical advancements.

Material compatibility issues arise when attempting to repair advanced alloys. Many modern turbine blades utilize single-crystal superalloys or contain protective coatings that are difficult to match with DED processes. The challenge lies in developing parameter sets that can effectively bond with these specialized materials while maintaining their unique properties, particularly directional solidification characteristics critical for high-temperature performance.

AI-based process monitoring and control systems remain in early development stages, limiting the ability to implement real-time quality assurance during repairs. This gap in process validation technology increases the risk of undetected defects and contributes to higher rejection rates of repaired components.

State-of-the-Art DED Repair Solutions

01 Process parameters optimization for DED repair quality

Optimizing process parameters such as laser power, scanning speed, powder feed rate, and layer thickness is crucial for achieving high-quality repairs using Directed Energy Deposition technology. Proper parameter selection helps control microstructure formation, minimize defects like porosity and cracks, and ensure strong metallurgical bonding between the substrate and deposited material. Advanced parameter optimization techniques can significantly improve the mechanical properties and overall repair quality.- Process parameters optimization for DED repair quality: Optimizing process parameters is crucial for achieving high-quality repairs using Directed Energy Deposition technology. Parameters such as laser power, powder feed rate, scanning speed, and layer thickness significantly impact the microstructure, mechanical properties, and overall repair quality. Proper calibration and control of these parameters help minimize defects like porosity and cracks while ensuring good bonding between the substrate and deposited material.

- Microstructure control and characterization in DED repairs: The microstructure of DED-repaired components directly influences repair quality. Advanced characterization techniques are employed to analyze grain structure, phase composition, and defect distribution in repaired zones. Controlling cooling rates and thermal gradients during deposition helps achieve desired microstructural features. Post-processing heat treatments can further refine the microstructure to enhance mechanical properties and ensure repair durability.

- Non-destructive testing and quality assurance for DED repairs: Quality assurance of DED repairs involves various non-destructive testing methods to verify repair integrity. Techniques such as ultrasonic testing, X-ray computed tomography, and infrared thermography are used to detect internal defects, lack of fusion, and other anomalies. In-process monitoring systems provide real-time feedback on deposition quality, allowing for immediate adjustments to process parameters to maintain repair quality standards.

- Material compatibility and powder characteristics for DED repair: The quality of DED repairs is heavily influenced by the compatibility between substrate and repair materials, as well as powder characteristics. Factors such as powder particle size distribution, morphology, flowability, and chemical composition affect deposition quality. Specialized powder formulations are developed to enhance material bonding, reduce thermal stresses, and minimize defects at the interface between the substrate and deposited material, resulting in superior repair quality.

- Post-processing treatments for enhanced DED repair quality: Post-processing treatments are essential for optimizing the quality of DED repairs. Techniques such as hot isostatic pressing, heat treatment, and surface finishing are applied to reduce porosity, relieve residual stresses, and improve surface quality. Machining operations are often necessary to achieve dimensional accuracy and surface finish requirements. These post-processing steps significantly enhance the mechanical properties, fatigue resistance, and overall performance of DED-repaired components.

02 Material selection and compatibility for DED repairs

The selection of appropriate repair materials that are compatible with the substrate is essential for successful DED repairs. Material compatibility affects the metallurgical bonding, thermal expansion behavior, and mechanical properties of the repaired component. Using powders with specific particle size distributions, chemical compositions, and flow characteristics can enhance deposition quality. Proper material selection helps prevent issues such as cracking, delamination, and residual stress accumulation at the interface between the substrate and deposited material.Expand Specific Solutions03 Post-processing treatments to enhance repair quality

Various post-processing treatments can significantly improve the quality of DED repairs. Heat treatments such as annealing, solution treatment, and aging can optimize microstructure and relieve residual stresses. Surface finishing operations including machining, grinding, and polishing can enhance dimensional accuracy and surface quality. Hot isostatic pressing (HIP) can be employed to eliminate internal porosity. These post-processing steps are essential for achieving desired mechanical properties and ensuring the repaired components meet performance requirements.Expand Specific Solutions04 Quality monitoring and control systems for DED repairs

Advanced monitoring and control systems are implemented to ensure high-quality DED repairs. In-situ monitoring techniques using thermal cameras, pyrometers, and high-speed imaging can detect defects during the deposition process. Machine learning algorithms can analyze real-time data to make process adjustments. Closed-loop control systems can automatically modify process parameters based on feedback from sensors. These monitoring and control systems help maintain consistent repair quality and reduce the likelihood of defects.Expand Specific Solutions05 Microstructure and mechanical property evaluation of DED repairs

Comprehensive evaluation of microstructure and mechanical properties is critical for assessing DED repair quality. Techniques such as optical microscopy, scanning electron microscopy, and X-ray diffraction are used to analyze grain structure, phase composition, and defect distribution. Mechanical testing including tensile, fatigue, and hardness tests helps determine the structural integrity of repairs. Non-destructive testing methods such as ultrasonic testing and computed tomography can identify internal defects without damaging the repaired component. These evaluation methods ensure that repaired parts meet or exceed the performance requirements of the original components.Expand Specific Solutions

Leading Companies in Aeroengine Repair Technologies

The Directed Energy Deposition (DED) repair market for aeroengine turbine blades is in a growth phase, with increasing adoption across the aerospace industry. Major players like RTX Corp., Pratt & Whitney, GE, and Safran Aircraft Engines are leading technological advancements, while MTU Aero Engines and Siemens Energy are developing specialized repair capabilities. The market is characterized by varying levels of technical maturity, with Western companies demonstrating higher technology readiness levels compared to emerging competitors from China such as AECC Aviation Power and AVIC Shenyang Liming. Research institutions including Fraunhofer-Gesellschaft, Beihang University, and Shanghai Jiao Tong University are contributing to technological innovation through collaborative industry partnerships, driving the market toward standardization and broader implementation.

RTX Corp.

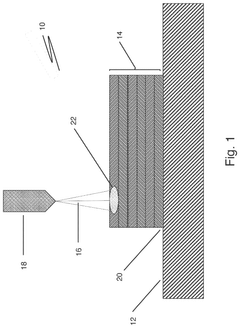

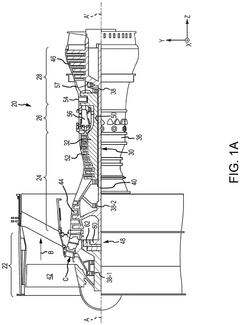

Technical Solution: RTX Corporation (formerly Raytheon Technologies) has developed an advanced Directed Energy Deposition (DED) repair system for aeroengine turbine blades that integrates laser powder DED with sophisticated process monitoring. Their approach utilizes a closed-loop control system that continuously monitors melt pool characteristics through multiple sensors, allowing real-time adjustments to laser power, powder feed rate, and deposition path[1]. RTX's proprietary software incorporates machine learning algorithms to predict optimal process parameters based on blade geometry and damage assessment. The system employs a five-axis motion platform that enables complex deposition strategies for tip repairs, airfoil reconstruction, and cooling hole restoration[3]. Their process includes automated pre-repair inspection using blue light scanning technology that creates a digital twin of the damaged component, allowing precise material addition only where needed.

Strengths: Superior process control through multi-sensor monitoring enables consistent metallurgical properties across repairs. The automated inspection and adaptive control system reduces operator dependency and increases repeatability. Weaknesses: The complex system requires significant capital investment and specialized training. The proprietary nature of their software and parameter sets creates vendor lock-in for maintenance operations.

MTU Aero Engines AG

Technical Solution: MTU Aero Engines has pioneered a hybrid DED repair methodology specifically optimized for high-pressure turbine blades in aeroengines. Their approach combines laser-based DED with conventional welding techniques in a staged process. The system first applies a precision DED layer to establish the base geometry and metallurgical bond, followed by conventional welding for bulk material addition where appropriate[2]. MTU's process incorporates pre-heating and controlled cooling cycles managed through an integrated thermal management system that maintains the substrate within optimal temperature ranges to minimize heat-affected zone issues. Their proprietary powder formulations are specifically engineered to match the superalloy compositions of modern turbine blades while improving weldability characteristics[4]. The process includes post-deposition heat treatment protocols that are customized based on material composition analysis performed during the initial inspection phase. MTU has also developed specialized fixturing systems that compensate for thermal distortion during the repair process.

Strengths: The hybrid approach optimizes cost efficiency by using DED only where precision is critical, reducing overall repair costs. Their material-specific process parameters result in excellent microstructural properties and fatigue resistance. Weaknesses: The multi-step process increases repair time compared to fully automated solutions. The system requires careful operator oversight during transitions between deposition methods.

Critical Patents and Research in DED Repair Techniques

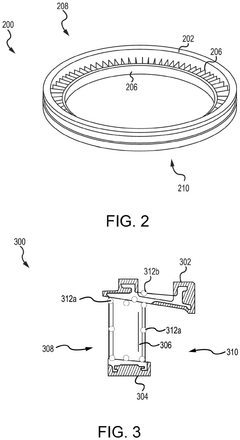

Engineered microstructure for enhanced performance during directed energy deposition repair process

PatentPendingUS20250242410A1

Innovation

- A directed energy deposition (DED) process is used to control the microstructure of each repair layer by adjusting parameters like powder feed rate, energy intensity, traversal rate, and auxiliary heating/cooling, ensuring each layer has a pre-determined microstructure to meet specific structural and functional needs.

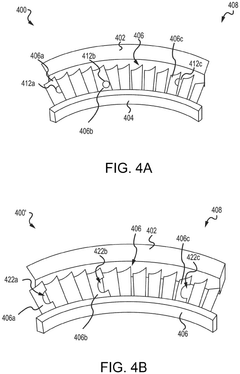

Localized rework using directed energy deposition

PatentPendingEP4491849A1

Innovation

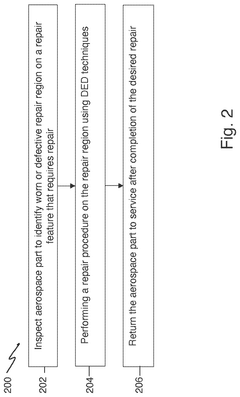

- A method utilizing directed energy deposition (DED) additive manufacturing for localized repairs of stator vanes, involving defect analysis, removal of standardized portions to form scallops, and rebuilding with minimal heat input to restore the components to their original size and shape, followed by blending to smooth the edges.

Material Science Advancements for High-Temperature Applications

The evolution of material science for high-temperature applications has been pivotal in advancing Directed Energy Deposition (DED) repair techniques for aeroengine turbine blades. Recent developments in superalloys, particularly nickel-based variants with enhanced creep resistance and thermal stability, have significantly improved the performance of repaired components under extreme operating conditions.

Thermal barrier coatings (TBCs) have undergone substantial refinement, with new ceramic formulations incorporating rare earth elements that demonstrate superior resistance to thermal cycling and oxidation. These advanced TBCs enable repaired turbine blades to withstand temperatures exceeding 1200°C while maintaining structural integrity, a critical requirement for modern high-efficiency engines.

Single-crystal superalloy development represents another breakthrough, with materials engineered at the atomic level to eliminate grain boundaries—traditionally weak points during thermal cycling. When applied to DED repair processes, these materials help maintain the original microstructural properties of turbine blades, preserving their mechanical performance characteristics after repair interventions.

Powder metallurgy advancements have yielded superior feedstock materials for DED processes, featuring more uniform particle size distribution and chemical homogeneity. These improvements translate directly to higher quality repairs with reduced porosity and improved bonding between the substrate and deposited material, addressing historical challenges in repair durability.

Computational materials science has revolutionized alloy design through high-throughput screening methodologies and machine learning algorithms. These approaches have identified novel compositions with optimized properties specifically for repair applications, balancing weldability concerns with high-temperature performance requirements.

Nano-reinforced superalloys represent an emerging frontier, incorporating carefully engineered nanoparticles to enhance mechanical properties without compromising processability. Early applications in DED repair show promising results, with repaired sections demonstrating improved fatigue resistance compared to conventional materials.

Additive manufacturing-specific material formulations are being developed with tailored solidification characteristics and reduced susceptibility to cracking during rapid cooling cycles typical in DED processes. These specialized materials address the unique challenges of repair environments where thermal management differs significantly from original manufacturing conditions.

Hybrid materials combining metallic and ceramic phases have shown exceptional promise for leading-edge repairs, where erosion resistance must be balanced with thermal performance. These materials create functionally graded structures that can be strategically deployed during the repair process to enhance component longevity in the most demanding sections of turbine blades.

Thermal barrier coatings (TBCs) have undergone substantial refinement, with new ceramic formulations incorporating rare earth elements that demonstrate superior resistance to thermal cycling and oxidation. These advanced TBCs enable repaired turbine blades to withstand temperatures exceeding 1200°C while maintaining structural integrity, a critical requirement for modern high-efficiency engines.

Single-crystal superalloy development represents another breakthrough, with materials engineered at the atomic level to eliminate grain boundaries—traditionally weak points during thermal cycling. When applied to DED repair processes, these materials help maintain the original microstructural properties of turbine blades, preserving their mechanical performance characteristics after repair interventions.

Powder metallurgy advancements have yielded superior feedstock materials for DED processes, featuring more uniform particle size distribution and chemical homogeneity. These improvements translate directly to higher quality repairs with reduced porosity and improved bonding between the substrate and deposited material, addressing historical challenges in repair durability.

Computational materials science has revolutionized alloy design through high-throughput screening methodologies and machine learning algorithms. These approaches have identified novel compositions with optimized properties specifically for repair applications, balancing weldability concerns with high-temperature performance requirements.

Nano-reinforced superalloys represent an emerging frontier, incorporating carefully engineered nanoparticles to enhance mechanical properties without compromising processability. Early applications in DED repair show promising results, with repaired sections demonstrating improved fatigue resistance compared to conventional materials.

Additive manufacturing-specific material formulations are being developed with tailored solidification characteristics and reduced susceptibility to cracking during rapid cooling cycles typical in DED processes. These specialized materials address the unique challenges of repair environments where thermal management differs significantly from original manufacturing conditions.

Hybrid materials combining metallic and ceramic phases have shown exceptional promise for leading-edge repairs, where erosion resistance must be balanced with thermal performance. These materials create functionally graded structures that can be strategically deployed during the repair process to enhance component longevity in the most demanding sections of turbine blades.

Quality Assurance and Certification Standards

Quality assurance and certification standards are paramount in the DED repair of aeroengine turbine blades, as these components operate under extreme conditions where failure could lead to catastrophic consequences. The aerospace industry has established rigorous frameworks to ensure repaired components meet or exceed original specifications.

The primary certification standards governing DED repairs include AS9100 for aerospace quality management systems, which provides specific requirements for aviation, space, and defense organizations. Additionally, NADCAP (National Aerospace and Defense Contractors Accreditation Program) certification is typically required for special processes like additive manufacturing used in aerospace applications.

For turbine blade repairs specifically, manufacturers must adhere to OEM (Original Equipment Manufacturer) specifications and obtain approvals from regulatory bodies such as the FAA (Federal Aviation Administration) in the US, EASA (European Union Aviation Safety Agency) in Europe, or CAAC (Civil Aviation Administration of China) in China. These authorities require extensive documentation and testing to validate repair processes.

Quality assurance for DED-repaired turbine blades involves multiple inspection stages. Pre-repair inspection establishes a baseline condition using techniques such as fluorescent penetrant inspection (FPI), X-ray, and dimensional measurements. In-process monitoring during DED application tracks critical parameters including laser power, powder feed rate, deposition path, and thermal conditions to ensure consistency.

Post-repair quality verification employs both non-destructive and destructive testing methods. Non-destructive techniques include visual inspection, dimensional verification using coordinate measuring machines (CMM), FPI for surface defects, and computed tomography (CT) scanning for internal defects. Destructive testing on representative samples evaluates microstructure, mechanical properties, and fatigue resistance.

Material certification is another critical aspect, requiring full traceability of powder feedstock used in the DED process. Powder must meet strict chemical composition, particle size distribution, and morphology requirements. Documentation must demonstrate proper handling, storage, and batch testing of all materials.

Process validation protocols typically mandate the creation of process qualification records (PQRs) that demonstrate repeatability and reliability. This includes producing test coupons that undergo extensive metallurgical analysis and mechanical testing to verify properties such as tensile strength, yield strength, elongation, hardness, and microstructural characteristics.

The industry is currently moving toward digital certification frameworks that incorporate machine learning for real-time quality monitoring and predictive analytics to identify potential defects before they occur. These advanced systems create digital twins of components that track the entire repair history and performance data throughout the lifecycle.

The primary certification standards governing DED repairs include AS9100 for aerospace quality management systems, which provides specific requirements for aviation, space, and defense organizations. Additionally, NADCAP (National Aerospace and Defense Contractors Accreditation Program) certification is typically required for special processes like additive manufacturing used in aerospace applications.

For turbine blade repairs specifically, manufacturers must adhere to OEM (Original Equipment Manufacturer) specifications and obtain approvals from regulatory bodies such as the FAA (Federal Aviation Administration) in the US, EASA (European Union Aviation Safety Agency) in Europe, or CAAC (Civil Aviation Administration of China) in China. These authorities require extensive documentation and testing to validate repair processes.

Quality assurance for DED-repaired turbine blades involves multiple inspection stages. Pre-repair inspection establishes a baseline condition using techniques such as fluorescent penetrant inspection (FPI), X-ray, and dimensional measurements. In-process monitoring during DED application tracks critical parameters including laser power, powder feed rate, deposition path, and thermal conditions to ensure consistency.

Post-repair quality verification employs both non-destructive and destructive testing methods. Non-destructive techniques include visual inspection, dimensional verification using coordinate measuring machines (CMM), FPI for surface defects, and computed tomography (CT) scanning for internal defects. Destructive testing on representative samples evaluates microstructure, mechanical properties, and fatigue resistance.

Material certification is another critical aspect, requiring full traceability of powder feedstock used in the DED process. Powder must meet strict chemical composition, particle size distribution, and morphology requirements. Documentation must demonstrate proper handling, storage, and batch testing of all materials.

Process validation protocols typically mandate the creation of process qualification records (PQRs) that demonstrate repeatability and reliability. This includes producing test coupons that undergo extensive metallurgical analysis and mechanical testing to verify properties such as tensile strength, yield strength, elongation, hardness, and microstructural characteristics.

The industry is currently moving toward digital certification frameworks that incorporate machine learning for real-time quality monitoring and predictive analytics to identify potential defects before they occur. These advanced systems create digital twins of components that track the entire repair history and performance data throughout the lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!