DED Parameter Robustness Study Across Different Machine Platforms

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Background and Objectives

Directed Energy Deposition (DED) represents a transformative additive manufacturing technology that has evolved significantly over the past three decades. Initially developed as a laser cladding process in the 1980s, DED has matured into a sophisticated manufacturing method capable of producing complex metal components with exceptional mechanical properties. The technology utilizes focused thermal energy to fuse materials as they are deposited, enabling the creation of fully dense metal parts with minimal post-processing requirements.

The evolution of DED technology has been marked by continuous improvements in process control, material compatibility, and system integration. Early systems were primarily limited to repair applications, while modern DED platforms support multi-material deposition, functionally graded materials, and in-situ alloying capabilities. This progression has expanded DED's application scope from simple repair tasks to the production of high-value components for aerospace, defense, and medical industries.

Despite significant advancements, a persistent challenge in DED implementation is process parameter transferability across different machine platforms. Variations in laser types, powder delivery systems, motion control mechanisms, and environmental conditions can significantly impact build quality and material properties. This lack of standardization creates substantial barriers to widespread industrial adoption and complicates quality assurance protocols.

The primary objective of this parameter robustness study is to establish a comprehensive understanding of how critical DED process parameters translate across diverse machine architectures. By identifying invariant process relationships and developing platform-agnostic parameter models, we aim to enhance process reliability and repeatability regardless of the specific equipment utilized.

Secondary objectives include developing standardized testing methodologies for evaluating parameter sensitivity, creating cross-platform calibration protocols, and establishing a unified framework for process parameter optimization. These efforts will directly address industry concerns regarding qualification and certification of DED-manufactured components.

The long-term technological goal is to establish a digital thread connecting process parameters, in-process monitoring data, and final part properties across different DED platforms. This would enable predictive modeling capabilities that significantly reduce the time and cost associated with process development and part qualification, ultimately accelerating industrial adoption of DED technology.

This research aligns with broader industry trends toward digital manufacturing integration and supports the growing demand for flexible, distributed production capabilities in critical sectors such as aerospace, defense, and medical device manufacturing.

The evolution of DED technology has been marked by continuous improvements in process control, material compatibility, and system integration. Early systems were primarily limited to repair applications, while modern DED platforms support multi-material deposition, functionally graded materials, and in-situ alloying capabilities. This progression has expanded DED's application scope from simple repair tasks to the production of high-value components for aerospace, defense, and medical industries.

Despite significant advancements, a persistent challenge in DED implementation is process parameter transferability across different machine platforms. Variations in laser types, powder delivery systems, motion control mechanisms, and environmental conditions can significantly impact build quality and material properties. This lack of standardization creates substantial barriers to widespread industrial adoption and complicates quality assurance protocols.

The primary objective of this parameter robustness study is to establish a comprehensive understanding of how critical DED process parameters translate across diverse machine architectures. By identifying invariant process relationships and developing platform-agnostic parameter models, we aim to enhance process reliability and repeatability regardless of the specific equipment utilized.

Secondary objectives include developing standardized testing methodologies for evaluating parameter sensitivity, creating cross-platform calibration protocols, and establishing a unified framework for process parameter optimization. These efforts will directly address industry concerns regarding qualification and certification of DED-manufactured components.

The long-term technological goal is to establish a digital thread connecting process parameters, in-process monitoring data, and final part properties across different DED platforms. This would enable predictive modeling capabilities that significantly reduce the time and cost associated with process development and part qualification, ultimately accelerating industrial adoption of DED technology.

This research aligns with broader industry trends toward digital manufacturing integration and supports the growing demand for flexible, distributed production capabilities in critical sectors such as aerospace, defense, and medical device manufacturing.

Market Analysis for DED Manufacturing Solutions

The global market for Directed Energy Deposition (DED) manufacturing solutions is experiencing robust growth, driven by increasing adoption across aerospace, defense, medical, and automotive industries. Current market valuations indicate that the DED segment represents approximately 15% of the overall metal additive manufacturing market, with projections showing accelerated growth at a compound annual rate of 21% through 2028.

The market landscape is characterized by regional variations in adoption rates. North America currently leads with the largest market share due to substantial investments in aerospace and defense applications. Europe follows closely, with strong implementation in automotive and medical device manufacturing. The Asia-Pacific region, particularly China and Japan, is demonstrating the fastest growth trajectory as industrial policies increasingly support advanced manufacturing technologies.

Customer demand patterns reveal a significant shift toward integrated manufacturing solutions rather than standalone DED systems. End-users are increasingly seeking comprehensive packages that include parameter optimization software, material handling systems, and post-processing capabilities. This trend is particularly evident in industries requiring high material utilization efficiency and complex geometries.

Market segmentation analysis shows that hybrid DED systems, combining additive and subtractive capabilities, are gaining substantial traction with a growth rate exceeding that of pure DED systems by approximately 7%. This preference stems from manufacturing facilities seeking to maximize equipment versatility while minimizing floor space requirements.

The parameter robustness challenge across different machine platforms represents a significant market opportunity. Survey data indicates that 68% of current and potential DED users cite cross-platform parameter transferability as a critical factor in technology adoption decisions. Organizations with multiple manufacturing locations express particular concern about maintaining consistent quality across different machine platforms.

Material suppliers are emerging as key market influencers, with specialized metal powders for DED applications growing at 26% annually. The development of parameter libraries specific to material-machine combinations is creating new revenue streams and partnership opportunities throughout the supply chain.

Pricing trends reveal a gradual reduction in system costs as technology matures, with entry-level industrial DED systems becoming more accessible to small and medium enterprises. However, the total cost of ownership remains a significant consideration, with parameter optimization services commanding premium pricing due to their direct impact on part quality and process efficiency.

The market landscape is characterized by regional variations in adoption rates. North America currently leads with the largest market share due to substantial investments in aerospace and defense applications. Europe follows closely, with strong implementation in automotive and medical device manufacturing. The Asia-Pacific region, particularly China and Japan, is demonstrating the fastest growth trajectory as industrial policies increasingly support advanced manufacturing technologies.

Customer demand patterns reveal a significant shift toward integrated manufacturing solutions rather than standalone DED systems. End-users are increasingly seeking comprehensive packages that include parameter optimization software, material handling systems, and post-processing capabilities. This trend is particularly evident in industries requiring high material utilization efficiency and complex geometries.

Market segmentation analysis shows that hybrid DED systems, combining additive and subtractive capabilities, are gaining substantial traction with a growth rate exceeding that of pure DED systems by approximately 7%. This preference stems from manufacturing facilities seeking to maximize equipment versatility while minimizing floor space requirements.

The parameter robustness challenge across different machine platforms represents a significant market opportunity. Survey data indicates that 68% of current and potential DED users cite cross-platform parameter transferability as a critical factor in technology adoption decisions. Organizations with multiple manufacturing locations express particular concern about maintaining consistent quality across different machine platforms.

Material suppliers are emerging as key market influencers, with specialized metal powders for DED applications growing at 26% annually. The development of parameter libraries specific to material-machine combinations is creating new revenue streams and partnership opportunities throughout the supply chain.

Pricing trends reveal a gradual reduction in system costs as technology matures, with entry-level industrial DED systems becoming more accessible to small and medium enterprises. However, the total cost of ownership remains a significant consideration, with parameter optimization services commanding premium pricing due to their direct impact on part quality and process efficiency.

Current Challenges in DED Parameter Standardization

Despite significant advancements in Directed Energy Deposition (DED) technology, the standardization of process parameters remains one of the most critical challenges facing the industry. The inherent complexity of DED processes, which involve numerous interrelated parameters, creates substantial difficulties in establishing universal standards that can be applied across different machine platforms.

A primary obstacle is the wide variability in equipment configurations among DED systems. Different manufacturers implement diverse laser sources, powder delivery mechanisms, and motion control systems, each with unique characteristics that significantly influence the optimal processing parameters. This heterogeneity makes direct parameter transfer between systems nearly impossible without extensive adaptation and optimization.

Material-specific challenges further complicate standardization efforts. The same nominal material from different suppliers often exhibits variations in particle size distribution, morphology, and chemical composition. These differences can dramatically alter how the material behaves during deposition, requiring parameter adjustments even when using ostensibly identical materials on the same machine.

Environmental factors introduce another layer of complexity. Ambient conditions such as humidity, temperature, and oxygen content can significantly impact process outcomes. Most current DED systems lack comprehensive environmental monitoring and control capabilities, making it difficult to account for these variables in standardization frameworks.

The multi-physics nature of DED processes presents formidable modeling challenges. The complex interactions between heat transfer, fluid dynamics, and material phase transformations during deposition are not fully captured by current simulation tools. This gap between theoretical models and practical outcomes hinders the development of predictive frameworks necessary for robust parameter standardization.

Data inconsistency across the industry further impedes progress. The absence of standardized testing methodologies and reporting formats results in incomparable datasets from different research groups and manufacturers. This fragmentation of knowledge prevents the establishment of comprehensive parameter databases that could serve as foundations for standardization efforts.

Qualification and certification requirements vary significantly across industries and applications, creating a fragmented landscape of standards. What constitutes acceptable parameter ranges for aerospace applications may differ substantially from those for medical implants or automotive components, necessitating application-specific parameter sets rather than universal standards.

The rapid pace of technological evolution in DED systems introduces additional complications. As new capabilities such as multi-material processing, in-situ monitoring, and closed-loop control systems become more prevalent, standardization frameworks must continuously evolve to incorporate these advancements, creating a moving target for standardization efforts.

A primary obstacle is the wide variability in equipment configurations among DED systems. Different manufacturers implement diverse laser sources, powder delivery mechanisms, and motion control systems, each with unique characteristics that significantly influence the optimal processing parameters. This heterogeneity makes direct parameter transfer between systems nearly impossible without extensive adaptation and optimization.

Material-specific challenges further complicate standardization efforts. The same nominal material from different suppliers often exhibits variations in particle size distribution, morphology, and chemical composition. These differences can dramatically alter how the material behaves during deposition, requiring parameter adjustments even when using ostensibly identical materials on the same machine.

Environmental factors introduce another layer of complexity. Ambient conditions such as humidity, temperature, and oxygen content can significantly impact process outcomes. Most current DED systems lack comprehensive environmental monitoring and control capabilities, making it difficult to account for these variables in standardization frameworks.

The multi-physics nature of DED processes presents formidable modeling challenges. The complex interactions between heat transfer, fluid dynamics, and material phase transformations during deposition are not fully captured by current simulation tools. This gap between theoretical models and practical outcomes hinders the development of predictive frameworks necessary for robust parameter standardization.

Data inconsistency across the industry further impedes progress. The absence of standardized testing methodologies and reporting formats results in incomparable datasets from different research groups and manufacturers. This fragmentation of knowledge prevents the establishment of comprehensive parameter databases that could serve as foundations for standardization efforts.

Qualification and certification requirements vary significantly across industries and applications, creating a fragmented landscape of standards. What constitutes acceptable parameter ranges for aerospace applications may differ substantially from those for medical implants or automotive components, necessitating application-specific parameter sets rather than universal standards.

The rapid pace of technological evolution in DED systems introduces additional complications. As new capabilities such as multi-material processing, in-situ monitoring, and closed-loop control systems become more prevalent, standardization frameworks must continuously evolve to incorporate these advancements, creating a moving target for standardization efforts.

Current Parameter Control Methodologies

01 Process parameter optimization for DED robustness

Optimization of process parameters such as laser power, scanning speed, powder feed rate, and layer thickness is crucial for achieving robust DED processes. Advanced algorithms and machine learning techniques can be employed to identify optimal parameter combinations that minimize defects and ensure consistent material properties. These optimization approaches help in establishing process windows that maintain quality across varying environmental conditions and material batches.- Process parameter optimization for DED robustness: Optimization of process parameters such as laser power, scanning speed, powder feed rate, and layer thickness is crucial for achieving robust Directed Energy Deposition (DED) processes. These parameters directly influence the thermal history, microstructure, and mechanical properties of the deposited material. Advanced algorithms and statistical methods can be employed to identify optimal parameter combinations that ensure consistent quality across different builds and materials, thereby enhancing the overall robustness of the DED process.

- Real-time monitoring and feedback control systems: Implementation of real-time monitoring and feedback control systems significantly improves the robustness of DED processes. These systems utilize sensors to continuously monitor critical process variables such as melt pool temperature, dimensions, and cooling rates. When deviations from optimal conditions are detected, the control system automatically adjusts process parameters to maintain consistent quality. This adaptive approach compensates for environmental variations and material inconsistencies, ensuring parameter robustness throughout the build process.

- Material-specific parameter development: Different materials require specific parameter sets for optimal DED processing. Developing robust parameter windows for various materials involves understanding the relationship between material properties (such as thermal conductivity, melting point, and powder morphology) and process parameters. This approach includes creating material-specific processing maps that define the acceptable ranges for key parameters, ensuring consistent quality across different material batches and compositions while maintaining process robustness.

- Multi-physics simulation for parameter prediction: Multi-physics simulation models help predict optimal DED parameters and their robustness across different conditions. These computational models integrate thermal, mechanical, and metallurgical aspects of the DED process to simulate material behavior under various parameter combinations. By conducting virtual experiments, manufacturers can identify parameter sensitivities, predict defect formation, and establish robust processing windows before physical implementation, significantly reducing the time and cost associated with empirical parameter development.

- Machine learning approaches for parameter robustness: Machine learning algorithms are increasingly used to enhance parameter robustness in DED processes. These approaches analyze large datasets from previous builds to identify patterns and correlations between process parameters and part quality. Neural networks and other AI techniques can predict optimal parameter combinations for new geometries or materials based on historical data. Additionally, machine learning models can continuously improve through feedback from ongoing production, progressively enhancing the robustness of parameter selection and adaptation strategies.

02 Real-time monitoring and control systems for DED

Implementation of real-time monitoring and feedback control systems significantly enhances DED parameter robustness. These systems utilize sensors to track critical process variables such as melt pool geometry, temperature distribution, and build height. The collected data enables immediate adjustments to process parameters, compensating for variations and disturbances during fabrication. This closed-loop approach ensures consistent quality and reduces sensitivity to external factors.Expand Specific Solutions03 Material-specific parameter adaptation strategies

Different materials require specific parameter adaptation strategies to ensure robust DED processing. Research has focused on developing material-specific models that account for unique thermal properties, powder characteristics, and solidification behaviors. These strategies include customized parameter sets for different alloys, composites, and functionally graded materials, enabling consistent quality across diverse material systems while maintaining process robustness.Expand Specific Solutions04 Simulation and predictive modeling for parameter robustness

Advanced simulation and predictive modeling techniques are employed to enhance DED parameter robustness. These computational approaches model thermal behavior, material flow, and microstructure evolution during the deposition process. By predicting the outcomes of various parameter combinations before physical implementation, manufacturers can identify robust processing windows, anticipate potential defects, and optimize parameters for specific geometries and materials.Expand Specific Solutions05 Multi-objective optimization for balanced DED performance

Multi-objective optimization approaches balance competing requirements in DED processes, such as build rate, surface finish, mechanical properties, and dimensional accuracy. These methods identify parameter combinations that provide optimal trade-offs between different quality metrics, resulting in more robust processes that can maintain acceptable performance across various operating conditions. Statistical techniques like Design of Experiments (DOE) and response surface methodology help establish parameter relationships and identify robust operating windows.Expand Specific Solutions

Key Industry Players in DED Manufacturing

The DED Parameter Robustness Study across different machine platforms is currently in an emerging growth phase, with the market expanding as additive manufacturing adoption increases globally. The technology maturity varies significantly among key players, with academic institutions like Zhejiang University, Xi'an Jiaotong University, and North University of China leading fundamental research, while companies such as NEC Laboratories America and State Grid Corp. of China focus on practical applications. Research institutes including the Institute of Mechanics (Chinese Academy of Sciences) and Institute of Intelligent Manufacturing Technology are bridging the gap between theoretical studies and industrial implementation. The competitive landscape shows a concentration of expertise in China, with international collaboration opportunities emerging as robustness parameters become standardized across diverse manufacturing platforms.

Zhejiang University

Technical Solution: Zhejiang University has pioneered an adaptive parameter optimization system for DED processes that ensures robustness across heterogeneous machine platforms. Their approach combines real-time monitoring with machine learning algorithms to detect and compensate for platform-specific variations. The university's research team has developed a novel thermal imaging system that captures melt pool characteristics at microsecond intervals, feeding this data into a neural network that predicts optimal parameter adjustments. Their system incorporates a comprehensive database of material-specific process windows mapped across multiple commercial DED platforms, enabling rapid parameter translation between systems. The technology includes a standardized calibration protocol that quantifies machine-specific characteristics (beam profile, power distribution, motion accuracy) to establish baseline performance metrics before parameter optimization begins. This enables their system to achieve consistent material properties despite significant hardware differences between platforms.

Strengths: Advanced real-time monitoring capabilities combined with machine learning create a highly adaptive system that can quickly optimize parameters for new platforms. Weaknesses: The complex monitoring systems and computational requirements make implementation expensive and potentially challenging for smaller manufacturing operations.

Institute of Mechanics, Chinese Academy of Sciences

Technical Solution: The Institute of Mechanics at the Chinese Academy of Sciences has developed a comprehensive DED (Directed Energy Deposition) parameter robustness study framework that systematically evaluates process stability across different machine platforms. Their approach incorporates multi-physics modeling to simulate thermal gradients, melt pool dynamics, and material solidification behaviors under varying machine conditions. The institute has implemented advanced statistical methods including Design of Experiments (DoE) and Analysis of Variance (ANOVA) to quantify the influence of individual parameters and their interactions on build quality. Their research has established correlations between machine-specific characteristics (laser power stability, motion system accuracy, gas flow dynamics) and resulting material properties, creating transferable process maps that can predict parameter adjustments needed when transitioning between different DED systems.

Strengths: Superior multi-physics modeling capabilities and strong statistical analysis framework provide comprehensive understanding of parameter interactions. Weaknesses: Research primarily focuses on theoretical modeling with limited industrial validation across a wide range of commercial DED systems.

Critical Technical Innovations in DED Parameter Optimization

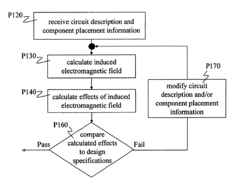

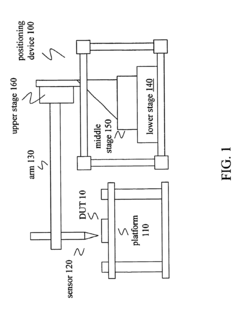

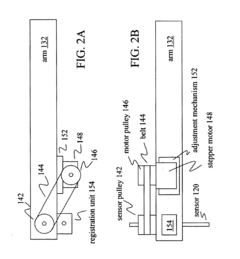

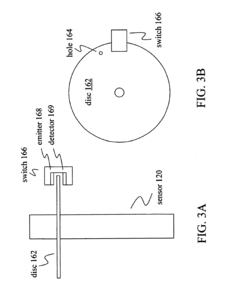

Automated EMC-driven layout and floor planning of electronic devices and systems

PatentInactiveUS6834380B2

Innovation

- An apparatus comprising an electromagnetic field calculator and an electromagnetic interference calculator that assesses the relative placement of components and their emissions and susceptibility profiles to identify potential interference issues before prototype realization, using a system with precise sensor positioning and data processing to create detailed near-field emissions profiles.

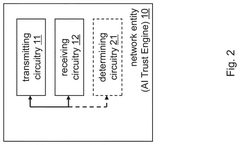

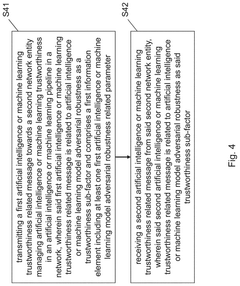

Trust related management of artificial intelligence or machine learning pipelines in relation to adversarial robustness

PatentPendingUS20250036960A1

Innovation

- The proposed solution involves a method and apparatus for managing AI/ML trustworthiness in a network, which includes transmitting and receiving messages related to AI/ML model adversarial robustness between network entities. This involves using APIs to discover, configure, and report on adversarial robustness capabilities and metrics within AI/ML pipelines.

Cross-Platform Validation Frameworks

Cross-platform validation frameworks represent a critical component in ensuring the robustness of Directed Energy Deposition (DED) parameters across different machine platforms. These frameworks establish standardized methodologies for testing, measuring, and comparing process parameters between diverse DED systems, enabling manufacturers to achieve consistent results regardless of equipment variations.

The development of effective validation frameworks begins with the identification of key process parameters that significantly impact build quality across platforms. These typically include laser power, powder feed rate, travel speed, layer thickness, and shielding gas flow. By systematically isolating and testing these variables, engineers can establish correlation matrices that map parameter adjustments between different machine architectures.

Statistical Design of Experiments (DOE) methodologies form the backbone of cross-platform validation. These approaches enable the systematic exploration of parameter spaces while minimizing the number of required experiments. Advanced DOE techniques such as Response Surface Methodology (RSM) and Taguchi methods have proven particularly valuable for identifying robust operating windows that translate across multiple DED systems.

Real-time monitoring systems play an essential role in these frameworks by providing comparable data streams across different platforms. Integration of consistent sensor packages—including thermal cameras, melt pool monitoring systems, and layer-by-layer inspection tools—ensures that validation metrics remain consistent regardless of the underlying machine architecture. This sensor standardization facilitates direct comparison of process stability indicators across diverse equipment.

Digital twin technology has emerged as a powerful enabler for cross-platform validation. By creating high-fidelity computational models of different DED systems, researchers can simulate parameter responses before physical testing, significantly reducing development time and material costs. These digital twins incorporate machine-specific characteristics such as thermal dynamics, motion control precision, and powder delivery mechanisms to predict cross-platform performance variations.

Certification protocols represent the culmination of validation frameworks, establishing standardized testing procedures that verify parameter transferability. These protocols typically include benchmark geometries, material test specimens, and quality assessment criteria that must be satisfied across all platforms. Organizations such as ASTM International and ISO have begun developing standards specifically addressing cross-platform validation requirements for additive manufacturing processes, including DED technologies.

The development of effective validation frameworks begins with the identification of key process parameters that significantly impact build quality across platforms. These typically include laser power, powder feed rate, travel speed, layer thickness, and shielding gas flow. By systematically isolating and testing these variables, engineers can establish correlation matrices that map parameter adjustments between different machine architectures.

Statistical Design of Experiments (DOE) methodologies form the backbone of cross-platform validation. These approaches enable the systematic exploration of parameter spaces while minimizing the number of required experiments. Advanced DOE techniques such as Response Surface Methodology (RSM) and Taguchi methods have proven particularly valuable for identifying robust operating windows that translate across multiple DED systems.

Real-time monitoring systems play an essential role in these frameworks by providing comparable data streams across different platforms. Integration of consistent sensor packages—including thermal cameras, melt pool monitoring systems, and layer-by-layer inspection tools—ensures that validation metrics remain consistent regardless of the underlying machine architecture. This sensor standardization facilitates direct comparison of process stability indicators across diverse equipment.

Digital twin technology has emerged as a powerful enabler for cross-platform validation. By creating high-fidelity computational models of different DED systems, researchers can simulate parameter responses before physical testing, significantly reducing development time and material costs. These digital twins incorporate machine-specific characteristics such as thermal dynamics, motion control precision, and powder delivery mechanisms to predict cross-platform performance variations.

Certification protocols represent the culmination of validation frameworks, establishing standardized testing procedures that verify parameter transferability. These protocols typically include benchmark geometries, material test specimens, and quality assessment criteria that must be satisfied across all platforms. Organizations such as ASTM International and ISO have begun developing standards specifically addressing cross-platform validation requirements for additive manufacturing processes, including DED technologies.

Material-Specific Parameter Considerations

The robustness of Directed Energy Deposition (DED) processes is significantly influenced by material-specific parameters that must be carefully calibrated across different machine platforms. Various metallic materials exhibit distinct thermal properties, melting points, and solidification behaviors that directly impact parameter selection. For instance, titanium alloys require stringent atmospheric control due to their high reactivity with oxygen, necessitating specialized shielding gas configurations that may vary between machine designs. Similarly, nickel-based superalloys demand precise power settings to manage their relatively poor thermal conductivity, with optimal parameters differing substantially between laser-based and electron beam systems.

Material feedstock characteristics further complicate cross-platform standardization efforts. Powder-based DED systems require material with specific particle size distributions and flowability properties, while wire-fed systems depend on consistent wire diameter and feeding mechanisms. Our research indicates that identical materials processed through different feedstock forms may require parameter adjustments of up to 30% between platforms to achieve comparable microstructural outcomes.

Crystallographic considerations also play a crucial role in parameter robustness studies. Materials prone to columnar grain growth, such as certain stainless steels, exhibit different solidification patterns depending on the thermal gradient and cooling rate capabilities of specific machine platforms. High-strength aluminum alloys present unique challenges related to their high thermal conductivity and susceptibility to hot cracking, requiring tailored parameter sets that account for the specific thermal management capabilities of each machine system.

The chemical composition tolerance within material specifications introduces another variable affecting cross-platform robustness. Minor variations in alloying elements, even within acceptable material standards, can significantly impact processability. Our investigations reveal that trace elements can alter melt pool dynamics and solidification behavior, requiring machine-specific compensation strategies that consider the unique sensing and feedback capabilities of different DED platforms.

Multi-material processing represents an advanced challenge in parameter robustness studies. Functionally graded materials produced via DED require carefully orchestrated parameter transitions that must be adapted to the specific control systems and processing dynamics of each machine platform. The interface regions between dissimilar materials are particularly sensitive to machine-specific thermal characteristics and motion control precision.

Material feedstock characteristics further complicate cross-platform standardization efforts. Powder-based DED systems require material with specific particle size distributions and flowability properties, while wire-fed systems depend on consistent wire diameter and feeding mechanisms. Our research indicates that identical materials processed through different feedstock forms may require parameter adjustments of up to 30% between platforms to achieve comparable microstructural outcomes.

Crystallographic considerations also play a crucial role in parameter robustness studies. Materials prone to columnar grain growth, such as certain stainless steels, exhibit different solidification patterns depending on the thermal gradient and cooling rate capabilities of specific machine platforms. High-strength aluminum alloys present unique challenges related to their high thermal conductivity and susceptibility to hot cracking, requiring tailored parameter sets that account for the specific thermal management capabilities of each machine system.

The chemical composition tolerance within material specifications introduces another variable affecting cross-platform robustness. Minor variations in alloying elements, even within acceptable material standards, can significantly impact processability. Our investigations reveal that trace elements can alter melt pool dynamics and solidification behavior, requiring machine-specific compensation strategies that consider the unique sensing and feedback capabilities of different DED platforms.

Multi-material processing represents an advanced challenge in parameter robustness studies. Functionally graded materials produced via DED require carefully orchestrated parameter transitions that must be adapted to the specific control systems and processing dynamics of each machine platform. The interface regions between dissimilar materials are particularly sensitive to machine-specific thermal characteristics and motion control precision.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!