Repair Cycle Time Optimization For Minimizing Down Time In Industry

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Repair Cycle Time Background and Objectives

Repair Cycle Time (RCT) has emerged as a critical metric in industrial operations, representing the total time required to restore equipment or systems to full functionality after a failure or scheduled maintenance. The evolution of RCT management can be traced back to the early manufacturing systems of the 20th century, where downtime was often accepted as an inevitable cost of production. However, with the advent of lean manufacturing principles in the 1950s and 1960s, pioneered by Toyota Production System, industries began recognizing the significant impact of equipment downtime on overall productivity and profitability.

The technological progression in RCT optimization has accelerated dramatically in recent decades. From basic preventive maintenance schedules to condition-based monitoring systems in the 1980s and 1990s, the field has now entered an era of predictive analytics and AI-driven maintenance strategies. This evolution reflects the growing understanding that minimizing repair cycle time directly correlates with maximizing operational efficiency and asset utilization.

Current industry benchmarks indicate that unplanned downtime costs industrial manufacturers an estimated $50 billion annually, with equipment failure being the cause of 42% of this unplanned downtime. These statistics underscore the critical importance of optimizing repair cycles across various industrial sectors, from manufacturing and energy to transportation and healthcare.

The primary objectives of RCT optimization are multifaceted. First, to reduce the mean time to repair (MTTR) through improved diagnostic capabilities, streamlined repair processes, and enhanced resource allocation. Second, to increase overall equipment effectiveness (OEE) by minimizing downtime periods and maximizing productive operational time. Third, to develop predictive maintenance capabilities that can anticipate failures before they occur, thereby transforming reactive repair cycles into proactive maintenance strategies.

Additionally, RCT optimization aims to establish standardized repair procedures that can be consistently applied across different equipment types and operational contexts. This standardization facilitates knowledge transfer, improves repair quality, and reduces variability in repair times. The ultimate goal is to create a systematic approach to equipment maintenance that balances the need for thorough repairs with the operational imperative to minimize downtime.

Looking forward, the trajectory of RCT optimization is increasingly aligned with Industry 4.0 principles, where interconnected systems, real-time data analytics, and machine learning algorithms work in concert to create self-diagnosing and potentially self-healing industrial systems. This represents the next frontier in the ongoing evolution of repair cycle time management and its critical role in industrial efficiency.

The technological progression in RCT optimization has accelerated dramatically in recent decades. From basic preventive maintenance schedules to condition-based monitoring systems in the 1980s and 1990s, the field has now entered an era of predictive analytics and AI-driven maintenance strategies. This evolution reflects the growing understanding that minimizing repair cycle time directly correlates with maximizing operational efficiency and asset utilization.

Current industry benchmarks indicate that unplanned downtime costs industrial manufacturers an estimated $50 billion annually, with equipment failure being the cause of 42% of this unplanned downtime. These statistics underscore the critical importance of optimizing repair cycles across various industrial sectors, from manufacturing and energy to transportation and healthcare.

The primary objectives of RCT optimization are multifaceted. First, to reduce the mean time to repair (MTTR) through improved diagnostic capabilities, streamlined repair processes, and enhanced resource allocation. Second, to increase overall equipment effectiveness (OEE) by minimizing downtime periods and maximizing productive operational time. Third, to develop predictive maintenance capabilities that can anticipate failures before they occur, thereby transforming reactive repair cycles into proactive maintenance strategies.

Additionally, RCT optimization aims to establish standardized repair procedures that can be consistently applied across different equipment types and operational contexts. This standardization facilitates knowledge transfer, improves repair quality, and reduces variability in repair times. The ultimate goal is to create a systematic approach to equipment maintenance that balances the need for thorough repairs with the operational imperative to minimize downtime.

Looking forward, the trajectory of RCT optimization is increasingly aligned with Industry 4.0 principles, where interconnected systems, real-time data analytics, and machine learning algorithms work in concert to create self-diagnosing and potentially self-healing industrial systems. This represents the next frontier in the ongoing evolution of repair cycle time management and its critical role in industrial efficiency.

Market Demand for Downtime Reduction Solutions

The global market for downtime reduction solutions is experiencing significant growth, driven by the increasing recognition of the substantial financial impact of equipment failures and production interruptions. According to recent industry analyses, manufacturing companies lose approximately 800 hours annually due to unplanned downtime, translating to between 5% and 20% of their productive capacity. This loss represents a compelling economic incentive for organizations to invest in solutions that minimize repair cycle times.

The demand for repair cycle time optimization technologies spans across multiple industrial sectors, with particularly strong interest from automotive manufacturing, aerospace, semiconductor production, and heavy machinery industries. These sectors are characterized by high-value equipment where downtime costs can exceed thousands of dollars per minute, creating an urgent business case for implementation of advanced repair optimization systems.

Market research indicates that the industrial maintenance management software market, which includes repair cycle optimization solutions, is growing at a compound annual growth rate of 10.3%, expected to reach $14.9 billion by 2026. This growth trajectory reflects the increasing prioritization of operational efficiency and asset performance management among industrial enterprises worldwide.

Customer requirements in this market segment are evolving toward more sophisticated, predictive capabilities. While traditional reactive maintenance approaches focused simply on reducing mean time to repair (MTTR), today's market demands intelligent systems that can predict failures before they occur, automatically dispatch appropriate resources, and optimize repair sequences to minimize overall downtime impact.

Regional analysis reveals varying levels of market maturity. North American and Western European markets demonstrate higher adoption rates of advanced repair cycle optimization technologies, while rapidly industrializing regions in Asia-Pacific show the highest growth potential, with manufacturing hubs in China, India, and Southeast Asia increasingly investing in downtime reduction solutions.

The COVID-19 pandemic has accelerated market demand, as labor shortages and remote work requirements have highlighted the value of automated repair optimization systems. This has created a notable shift toward solutions that incorporate remote diagnostics, augmented reality-assisted repairs, and AI-driven decision support tools that can function effectively even with reduced on-site personnel.

Customer willingness to invest in these solutions correlates strongly with the demonstrable return on investment, with most enterprises expecting payback periods of less than 18 months for significant downtime reduction implementations. This economic reality is shaping product development in the space, with vendors increasingly focusing on quantifiable business outcomes rather than technical specifications alone.

The demand for repair cycle time optimization technologies spans across multiple industrial sectors, with particularly strong interest from automotive manufacturing, aerospace, semiconductor production, and heavy machinery industries. These sectors are characterized by high-value equipment where downtime costs can exceed thousands of dollars per minute, creating an urgent business case for implementation of advanced repair optimization systems.

Market research indicates that the industrial maintenance management software market, which includes repair cycle optimization solutions, is growing at a compound annual growth rate of 10.3%, expected to reach $14.9 billion by 2026. This growth trajectory reflects the increasing prioritization of operational efficiency and asset performance management among industrial enterprises worldwide.

Customer requirements in this market segment are evolving toward more sophisticated, predictive capabilities. While traditional reactive maintenance approaches focused simply on reducing mean time to repair (MTTR), today's market demands intelligent systems that can predict failures before they occur, automatically dispatch appropriate resources, and optimize repair sequences to minimize overall downtime impact.

Regional analysis reveals varying levels of market maturity. North American and Western European markets demonstrate higher adoption rates of advanced repair cycle optimization technologies, while rapidly industrializing regions in Asia-Pacific show the highest growth potential, with manufacturing hubs in China, India, and Southeast Asia increasingly investing in downtime reduction solutions.

The COVID-19 pandemic has accelerated market demand, as labor shortages and remote work requirements have highlighted the value of automated repair optimization systems. This has created a notable shift toward solutions that incorporate remote diagnostics, augmented reality-assisted repairs, and AI-driven decision support tools that can function effectively even with reduced on-site personnel.

Customer willingness to invest in these solutions correlates strongly with the demonstrable return on investment, with most enterprises expecting payback periods of less than 18 months for significant downtime reduction implementations. This economic reality is shaping product development in the space, with vendors increasingly focusing on quantifiable business outcomes rather than technical specifications alone.

Current Repair Cycle Challenges and Constraints

The current repair cycle in industrial settings faces numerous challenges that significantly impact operational efficiency and overall productivity. One of the primary constraints is the lack of standardized repair procedures across different equipment types and manufacturing environments. This inconsistency leads to variable repair times, unpredictable resource allocation, and difficulty in establishing reliable maintenance schedules. Without standardization, technicians often rely on individual expertise rather than documented best practices, resulting in repair quality variations and extended downtime periods.

Diagnostic inefficiencies represent another major challenge in the repair cycle. Traditional diagnostic approaches frequently involve time-consuming trial-and-error methods, particularly for complex equipment with multiple potential failure points. The absence of advanced diagnostic tools and technologies in many industrial settings further exacerbates this issue, leading to prolonged equipment assessment phases that constitute a significant portion of total downtime.

Parts availability and supply chain constraints critically impact repair cycle times across industries. Many facilities experience extended waiting periods for critical components, especially for specialized or legacy equipment. This situation is compounded by inventory management challenges, where organizations struggle to balance the costs of maintaining extensive spare parts inventories against the risk of extended downtime due to parts unavailability.

Resource allocation presents persistent difficulties in optimizing repair cycles. Skilled maintenance personnel are often in short supply, creating bottlenecks in the repair process when multiple equipment failures occur simultaneously. This shortage is particularly acute for specialized equipment requiring specific technical expertise. Additionally, the scheduling of maintenance activities frequently conflicts with production demands, creating tension between short-term production goals and long-term equipment reliability needs.

Documentation and knowledge management deficiencies further complicate repair processes. Many organizations lack comprehensive repair histories, equipment performance data, and failure analysis records that could inform more efficient maintenance strategies. This information gap prevents the implementation of data-driven approaches to repair cycle optimization and limits the ability to predict and prevent future failures.

Technological integration barriers represent a significant constraint in modernizing repair cycles. Legacy equipment often lacks the sensors and connectivity required for condition monitoring and predictive maintenance approaches. The integration of new monitoring technologies with existing systems frequently presents compatibility challenges, requiring substantial investment and specialized expertise that may not be readily available within the organization.

Financial constraints ultimately limit many organizations' ability to implement optimal repair strategies. Budget restrictions often force maintenance departments to adopt reactive rather than proactive approaches, prioritizing immediate fixes over system improvements that could reduce downtime in the long term. This short-term financial perspective creates a cycle where repair inefficiencies persist due to underinvestment in the tools, technologies, and training that could address the fundamental challenges in the repair cycle.

Diagnostic inefficiencies represent another major challenge in the repair cycle. Traditional diagnostic approaches frequently involve time-consuming trial-and-error methods, particularly for complex equipment with multiple potential failure points. The absence of advanced diagnostic tools and technologies in many industrial settings further exacerbates this issue, leading to prolonged equipment assessment phases that constitute a significant portion of total downtime.

Parts availability and supply chain constraints critically impact repair cycle times across industries. Many facilities experience extended waiting periods for critical components, especially for specialized or legacy equipment. This situation is compounded by inventory management challenges, where organizations struggle to balance the costs of maintaining extensive spare parts inventories against the risk of extended downtime due to parts unavailability.

Resource allocation presents persistent difficulties in optimizing repair cycles. Skilled maintenance personnel are often in short supply, creating bottlenecks in the repair process when multiple equipment failures occur simultaneously. This shortage is particularly acute for specialized equipment requiring specific technical expertise. Additionally, the scheduling of maintenance activities frequently conflicts with production demands, creating tension between short-term production goals and long-term equipment reliability needs.

Documentation and knowledge management deficiencies further complicate repair processes. Many organizations lack comprehensive repair histories, equipment performance data, and failure analysis records that could inform more efficient maintenance strategies. This information gap prevents the implementation of data-driven approaches to repair cycle optimization and limits the ability to predict and prevent future failures.

Technological integration barriers represent a significant constraint in modernizing repair cycles. Legacy equipment often lacks the sensors and connectivity required for condition monitoring and predictive maintenance approaches. The integration of new monitoring technologies with existing systems frequently presents compatibility challenges, requiring substantial investment and specialized expertise that may not be readily available within the organization.

Financial constraints ultimately limit many organizations' ability to implement optimal repair strategies. Budget restrictions often force maintenance departments to adopt reactive rather than proactive approaches, prioritizing immediate fixes over system improvements that could reduce downtime in the long term. This short-term financial perspective creates a cycle where repair inefficiencies persist due to underinvestment in the tools, technologies, and training that could address the fundamental challenges in the repair cycle.

Current Methodologies for Repair Cycle Time Reduction

01 Predictive maintenance systems for downtime reduction

Predictive maintenance systems utilize data analytics and machine learning algorithms to anticipate equipment failures before they occur. By monitoring equipment performance metrics and analyzing historical data, these systems can identify patterns that precede failures, allowing maintenance to be scheduled during planned downtime rather than experiencing unexpected breakdowns. This approach significantly reduces repair cycle time and optimizes overall equipment effectiveness by minimizing unplanned downtime.- Predictive maintenance systems for downtime reduction: Predictive maintenance systems utilize data analytics and machine learning algorithms to anticipate equipment failures before they occur. By monitoring equipment performance parameters and analyzing historical data, these systems can predict when maintenance is needed, allowing for scheduled interventions before critical failures. This approach significantly reduces unexpected downtime, optimizes repair cycle times, and extends equipment lifespan through timely maintenance actions.

- Real-time monitoring and diagnostic systems: Real-time monitoring systems continuously track equipment performance and operational parameters to quickly identify anomalies or potential issues. These systems employ sensors and IoT devices to collect data that is analyzed through diagnostic algorithms to detect early signs of malfunction. By enabling immediate identification of problems, maintenance teams can respond rapidly, significantly reducing diagnostic time and overall equipment downtime while optimizing the repair cycle.

- Automated maintenance scheduling and resource allocation: Automated maintenance scheduling systems optimize repair cycle times by efficiently allocating resources based on equipment priority, maintenance requirements, and available personnel. These systems use algorithms to determine the optimal timing for maintenance activities, coordinate spare parts availability, and assign qualified technicians. By streamlining the scheduling process and ensuring all necessary resources are available when needed, organizations can minimize equipment downtime and improve overall operational efficiency.

- Integrated maintenance management systems: Integrated maintenance management systems combine various aspects of maintenance operations into a unified platform, including inventory management, work order processing, and maintenance history tracking. These comprehensive systems provide a holistic view of maintenance activities, enabling better coordination between departments and more efficient repair processes. By centralizing maintenance information and automating workflows, organizations can reduce administrative delays, improve communication, and ultimately decrease equipment downtime.

- Advanced repair techniques and standardized procedures: Implementing advanced repair techniques and standardized maintenance procedures helps reduce repair cycle times and equipment downtime. These approaches include modular replacement strategies, standardized troubleshooting protocols, and specialized repair tools designed for quick component access and replacement. By establishing clear repair procedures and training technicians in efficient methods, organizations can ensure consistent repair quality while minimizing the time equipment remains out of service.

02 Real-time monitoring and diagnostic systems

Real-time monitoring and diagnostic systems continuously track equipment performance and operational parameters to detect anomalies or deviations from normal operating conditions. These systems employ sensors, IoT devices, and advanced analytics to provide immediate alerts when potential issues are detected. By enabling rapid response to emerging problems, these systems help minimize repair cycle time and reduce the duration of downtime events, allowing for more efficient maintenance scheduling and resource allocation.Expand Specific Solutions03 Automated repair workflow management

Automated repair workflow management systems streamline the maintenance process by coordinating tasks, resources, and personnel. These systems automatically generate work orders, assign technicians based on expertise and availability, track repair progress, and manage spare parts inventory. By eliminating manual coordination and administrative delays, these systems optimize the repair cycle time, reduce equipment downtime, and improve overall maintenance efficiency.Expand Specific Solutions04 Integrated maintenance scheduling optimization

Integrated maintenance scheduling optimization systems use advanced algorithms to determine the optimal timing for preventive and corrective maintenance activities. These systems consider multiple factors including production schedules, resource availability, equipment criticality, and failure probability to create maintenance schedules that minimize overall downtime impact. By coordinating maintenance activities across multiple equipment units and optimizing the sequence of repair tasks, these systems significantly reduce repair cycle times and improve operational efficiency.Expand Specific Solutions05 Knowledge-based decision support systems

Knowledge-based decision support systems leverage historical repair data, expert knowledge, and best practices to guide maintenance personnel through complex troubleshooting and repair processes. These systems provide technicians with step-by-step procedures, technical documentation, and diagnostic guidance based on equipment symptoms and historical failure patterns. By reducing diagnostic time and minimizing trial-and-error approaches, these systems optimize repair cycle time and reduce equipment downtime while improving first-time fix rates.Expand Specific Solutions

Key Industry Players in Maintenance Optimization

Repair Cycle Time Optimization for minimizing downtime in industry is currently in a growth phase, with an expanding market driven by Industry 4.0 initiatives. The global market for maintenance optimization solutions is estimated at $3-5 billion, growing at 10-15% annually. Technologically, the field shows varying maturity levels across different sectors. Leading players like IBM, ABB Research, and Volkswagen AG have developed advanced predictive maintenance systems using AI and machine learning, while companies like Fujitsu and Caterpillar focus on integrated maintenance management platforms. Chinese entities including Sinopec and State Grid are investing heavily in reliability-centered maintenance approaches, particularly for critical infrastructure. Academic institutions like Beihang University and Xi'an Jiaotong University contribute significant research in optimization algorithms and failure prediction models.

International Business Machines Corp.

Technical Solution: IBM has developed the Maximo Asset Performance Management (APM) suite specifically targeting repair cycle optimization through AI-powered predictive maintenance. Their solution leverages machine learning algorithms that analyze operational data, maintenance records, and environmental factors to predict equipment failures with up to 95% accuracy. IBM's approach includes a unique "repair impact simulator" that models the consequences of different maintenance strategies on production throughput and financial outcomes. The system features an intelligent work order prioritization engine that optimizes technician dispatching based on criticality, skills required, parts availability, and geographic proximity. IBM's platform incorporates natural language processing capabilities that extract insights from unstructured maintenance logs and technician notes, identifying recurring issues and effective repair procedures. Their solution also includes a cognitive assistant that provides technicians with contextual information and step-by-step guidance during repairs, reducing execution time by approximately 20-30%.

Strengths: Advanced AI and analytics capabilities; extensive integration options with enterprise systems; strong cloud infrastructure; comprehensive data security features. Weaknesses: Higher complexity requiring specialized implementation expertise; significant data preparation requirements; potential challenges integrating with legacy operational technology systems.

ABB Research Ltd.

Technical Solution: ABB has developed the ABB Ability Asset Performance Management suite that focuses on optimizing repair cycles through a combination of condition monitoring, predictive analytics, and digital workflow management. Their solution employs a multi-layered approach that starts with smart sensors collecting real-time equipment data, progresses through edge computing for local analysis, and culminates in cloud-based optimization algorithms. ABB's system features an advanced anomaly detection engine that identifies subtle changes in equipment behavior that precede failures, providing longer lead times for maintenance planning. Their platform includes a sophisticated repair scheduling optimizer that considers production schedules, spare parts logistics, technician availability, and interdependencies between equipment to minimize overall downtime. ABB's approach incorporates collaborative robotics for inspection and maintenance tasks in hazardous environments, reducing safety-related delays by up to 40%. The system also features a knowledge management component that captures repair procedures and outcomes, creating a continuously improving repository of maintenance best practices.

Strengths: Extensive industrial automation expertise; excellent integration with control systems; strong domain knowledge across multiple industries; robust hardware-software integration. Weaknesses: Solutions can be capital-intensive; implementation complexity in brownfield environments; may require specialized skills for configuration and maintenance.

Critical Technologies for Minimizing Equipment Downtime

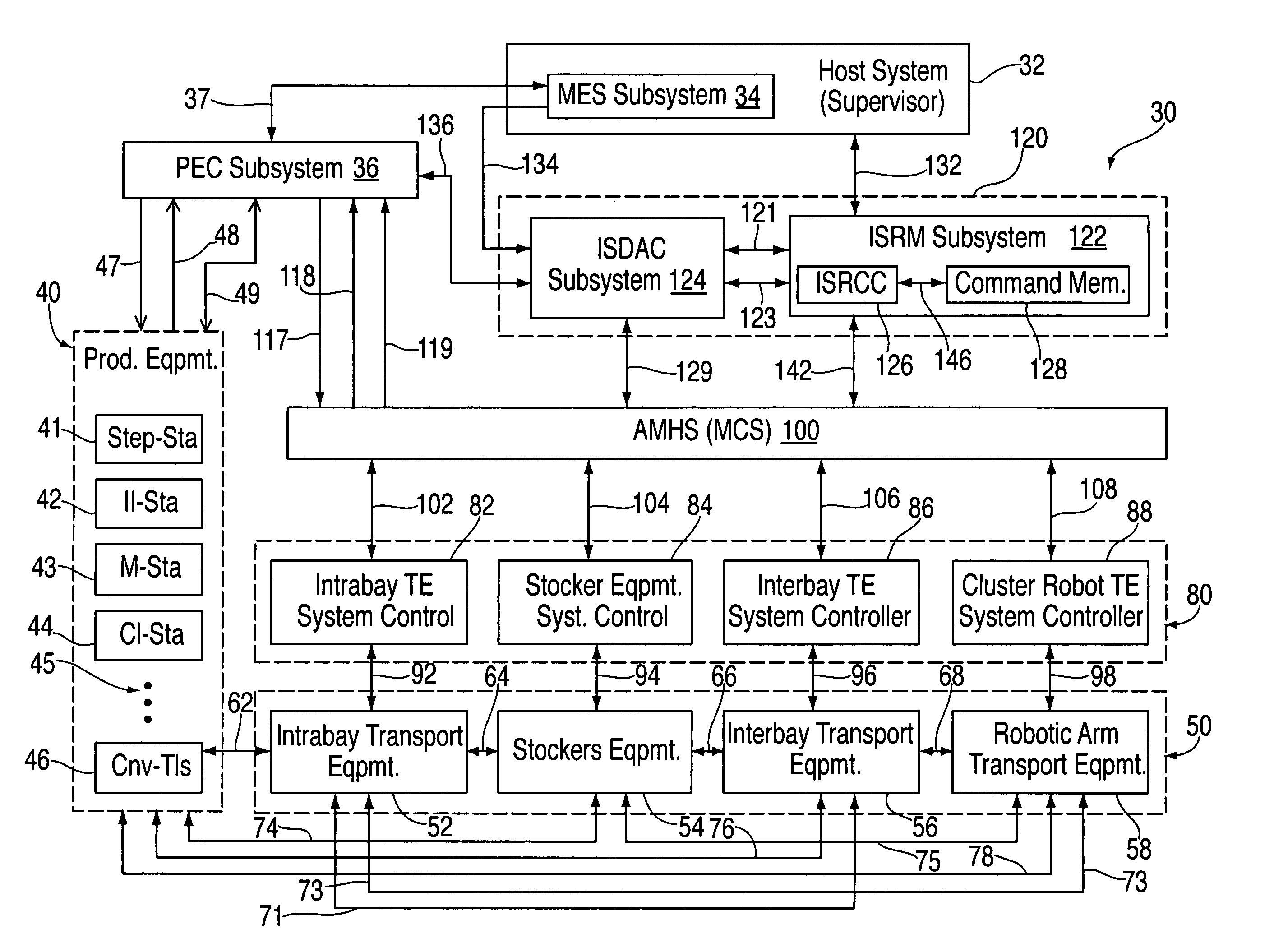

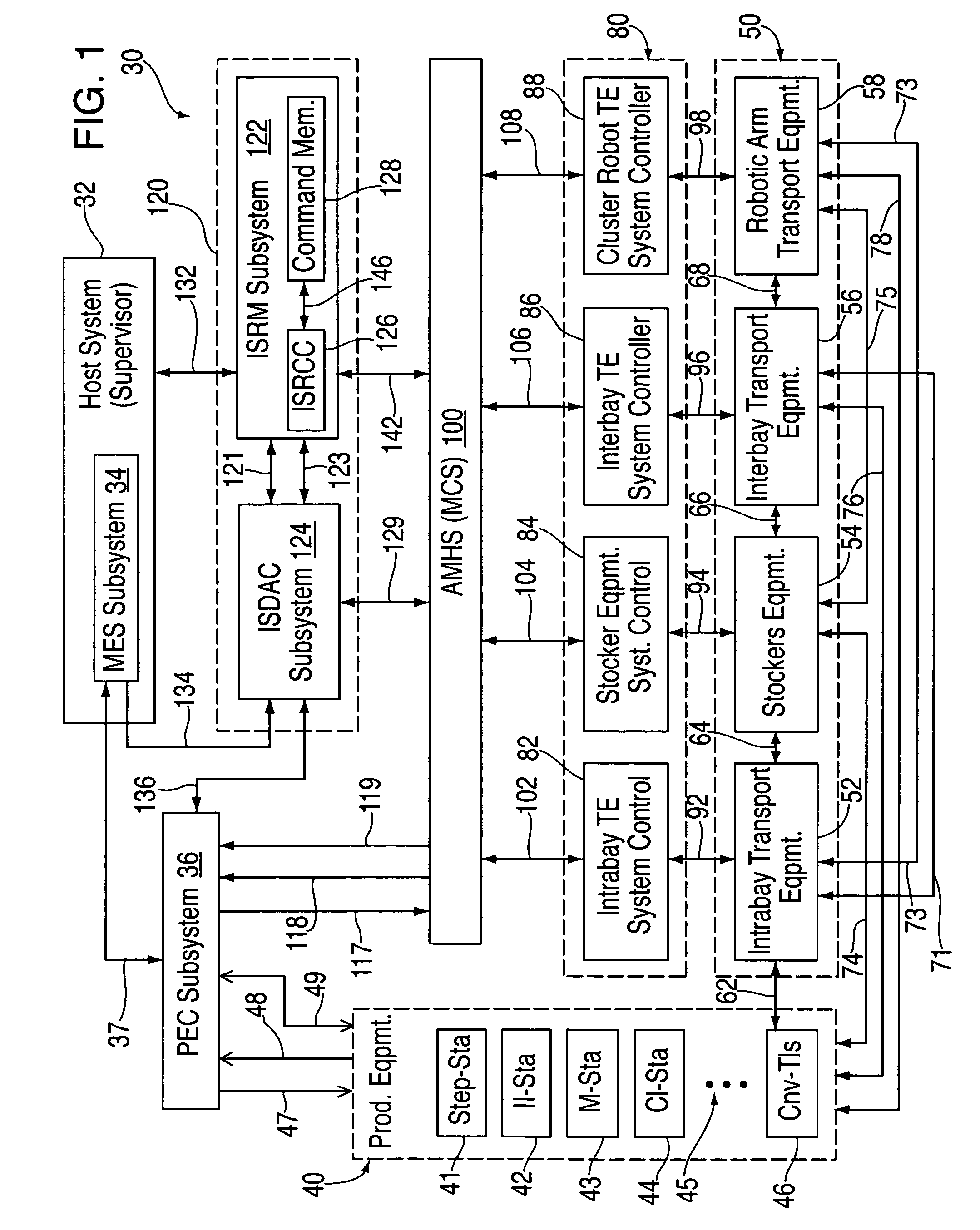

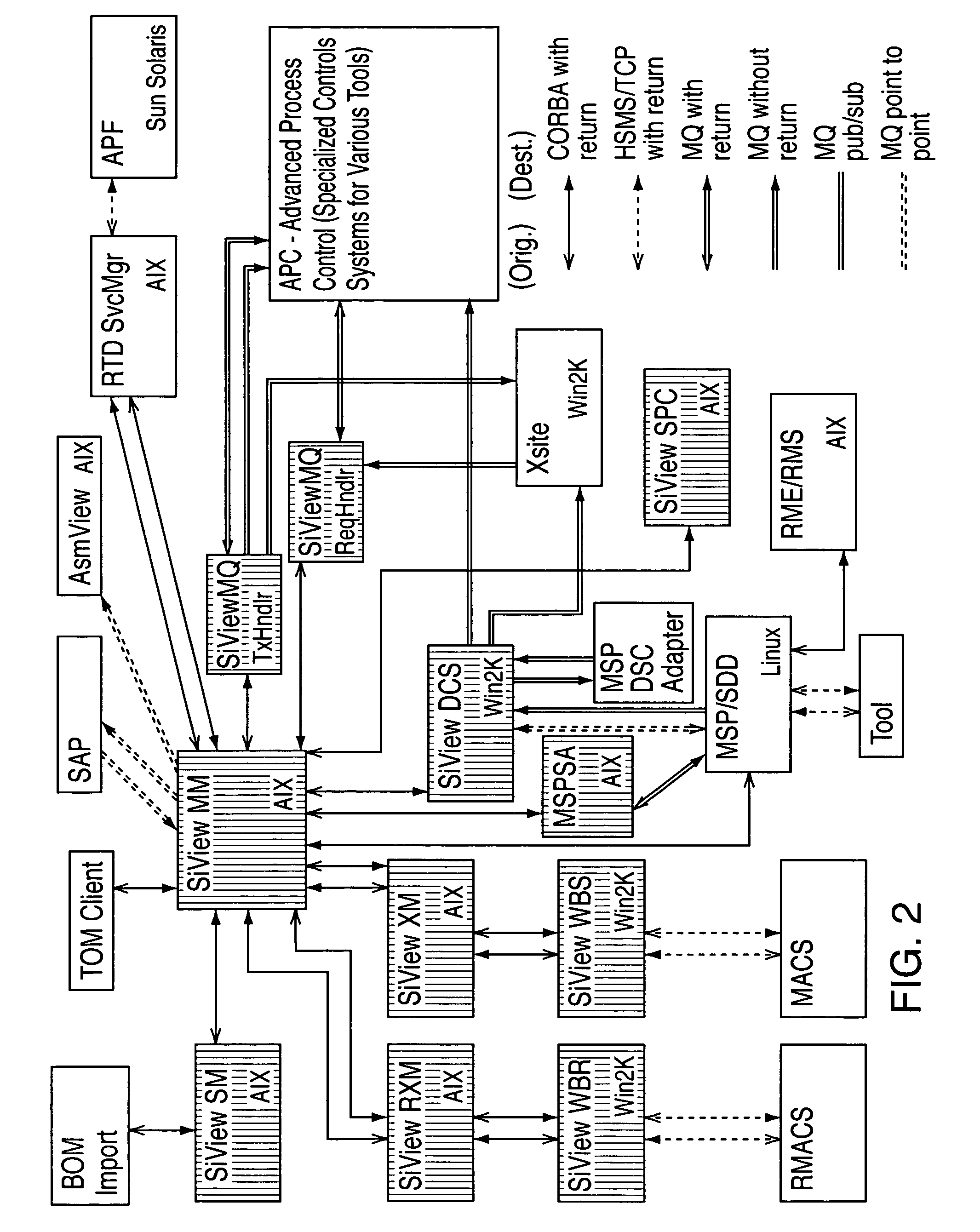

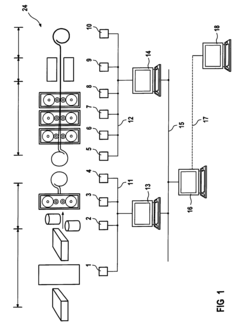

Method and system for automating issue resolution in manufacturing execution and material control systems

PatentInactiveUS7440932B2

Innovation

- The implementation of a supervisory issue resolution (ISR) system that automatically detects and responds to error conditions by coordinating corrective actions across multiple automated manufacturing systems, including error recognition, command generation, and logging, reducing the need for manual intervention and minimizing downtime.

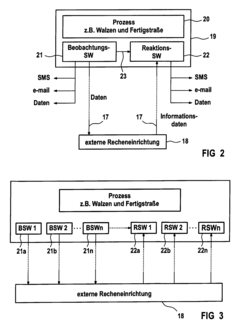

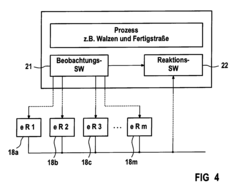

Method of monitoring the operation and/or the product of an industrial installation

PatentInactiveEP1363177A2

Innovation

- A method involving cyclic data acquisition by observation software, transmission to external computing devices for analysis, and implementation of interventions by reaction software to rectify operational and product-related issues, leveraging external know-how for rapid problem resolution.

Economic Impact of Downtime Reduction Strategies

The economic implications of downtime in industrial settings extend far beyond the immediate loss of production. Studies indicate that unplanned downtime costs industrial manufacturers approximately $50 billion annually, with some facilities experiencing losses of up to $260,000 per hour. Implementing effective repair cycle time optimization strategies can significantly reduce these financial impacts through multiple economic mechanisms.

Primary cost savings emerge from increased operational availability. When repair cycles are shortened through standardized procedures, predictive maintenance, and improved spare parts management, production equipment returns to service faster. This translates directly to higher production volumes and revenue generation. Companies implementing comprehensive repair cycle optimization programs report availability improvements of 15-25%, resulting in proportional increases in production capacity.

Labor cost optimization represents another substantial economic benefit. Efficient repair processes reduce overtime requirements and eliminate redundant maintenance activities. Organizations utilizing digital workflow management systems for repairs report labor efficiency improvements of 20-30%, allowing skilled technicians to focus on value-adding activities rather than administrative tasks or waiting for parts.

Supply chain economics are similarly transformed through repair cycle optimization. Just-in-time inventory systems for critical repair components can reduce carrying costs by 15-20% while simultaneously decreasing stockout-related downtime. Advanced organizations implementing vendor-managed inventory programs for repair parts report working capital reductions exceeding $1 million for medium-sized manufacturing operations.

Customer satisfaction metrics demonstrate additional economic value. When repair cycles are optimized, production schedules become more reliable, enabling consistent on-time delivery performance. This reliability premium often translates to customer retention and price stability, with studies showing that manufacturers with superior equipment uptime command 5-8% higher average selling prices compared to less reliable competitors.

Energy efficiency improvements frequently accompany repair cycle optimization initiatives. Equipment operating at design specifications after proper repairs consumes less energy than degraded systems. The U.S. Department of Energy estimates that optimized maintenance programs reduce industrial energy consumption by 10-15%, representing significant cost savings in energy-intensive industries.

Return on investment calculations for repair cycle optimization programs typically show payback periods of 6-18 months, with ongoing annual returns of 200-300% on program investments. These compelling economics explain why leading manufacturers increasingly view repair cycle optimization not as a cost center but as a strategic profit driver.

Primary cost savings emerge from increased operational availability. When repair cycles are shortened through standardized procedures, predictive maintenance, and improved spare parts management, production equipment returns to service faster. This translates directly to higher production volumes and revenue generation. Companies implementing comprehensive repair cycle optimization programs report availability improvements of 15-25%, resulting in proportional increases in production capacity.

Labor cost optimization represents another substantial economic benefit. Efficient repair processes reduce overtime requirements and eliminate redundant maintenance activities. Organizations utilizing digital workflow management systems for repairs report labor efficiency improvements of 20-30%, allowing skilled technicians to focus on value-adding activities rather than administrative tasks or waiting for parts.

Supply chain economics are similarly transformed through repair cycle optimization. Just-in-time inventory systems for critical repair components can reduce carrying costs by 15-20% while simultaneously decreasing stockout-related downtime. Advanced organizations implementing vendor-managed inventory programs for repair parts report working capital reductions exceeding $1 million for medium-sized manufacturing operations.

Customer satisfaction metrics demonstrate additional economic value. When repair cycles are optimized, production schedules become more reliable, enabling consistent on-time delivery performance. This reliability premium often translates to customer retention and price stability, with studies showing that manufacturers with superior equipment uptime command 5-8% higher average selling prices compared to less reliable competitors.

Energy efficiency improvements frequently accompany repair cycle optimization initiatives. Equipment operating at design specifications after proper repairs consumes less energy than degraded systems. The U.S. Department of Energy estimates that optimized maintenance programs reduce industrial energy consumption by 10-15%, representing significant cost savings in energy-intensive industries.

Return on investment calculations for repair cycle optimization programs typically show payback periods of 6-18 months, with ongoing annual returns of 200-300% on program investments. These compelling economics explain why leading manufacturers increasingly view repair cycle optimization not as a cost center but as a strategic profit driver.

Predictive Maintenance Integration with Repair Cycles

The integration of predictive maintenance with repair cycles represents a transformative approach to industrial equipment management. By leveraging advanced analytics, machine learning algorithms, and IoT sensor data, organizations can seamlessly connect predictive maintenance insights with repair cycle planning to create a cohesive maintenance strategy. This integration enables maintenance teams to anticipate failures before they occur and schedule repairs during planned downtime, significantly reducing unplanned equipment failures.

Predictive maintenance systems continuously monitor equipment health through real-time data collection from sensors that measure vibration, temperature, pressure, and other critical parameters. These systems analyze patterns and anomalies to identify early warning signs of potential failures. When integrated with repair cycle management, these insights trigger automated scheduling of maintenance activities within optimal repair windows, prioritizing critical equipment and balancing workloads across maintenance teams.

The synchronization between predictive analytics and repair cycles creates a feedback loop that continuously improves maintenance efficiency. As repairs are completed, the system captures data on actual repair times, parts used, and technician performance. This information refines future predictions and optimizes subsequent repair scheduling. Machine learning algorithms progressively enhance their accuracy by correlating predicted failure patterns with actual outcomes, leading to increasingly precise maintenance timing.

Key performance indicators for successful integration include reduced mean time to repair (MTTR), increased mean time between failures (MTBF), and optimized repair cycle times. Organizations implementing this integrated approach typically report 15-30% reductions in downtime and 10-25% improvements in maintenance labor efficiency. The economic impact extends beyond direct maintenance costs to include increased production capacity, improved product quality, and extended equipment lifespan.

Implementation challenges include data integration across disparate systems, sensor deployment strategies, and the development of accurate predictive models for diverse equipment types. Organizations must establish clear protocols for transitioning from predictive alerts to scheduled repair activities, including parts procurement, technician assignment, and production coordination. Change management remains critical, as maintenance teams must adapt from reactive to predictive mindsets.

Future developments in this integration will likely include augmented reality tools for technicians, autonomous maintenance robots for routine tasks, and AI-driven decision support systems that optimize repair scheduling across entire production ecosystems. The convergence of digital twins with predictive maintenance will enable virtual testing of maintenance scenarios before physical implementation, further reducing repair cycle times.

Predictive maintenance systems continuously monitor equipment health through real-time data collection from sensors that measure vibration, temperature, pressure, and other critical parameters. These systems analyze patterns and anomalies to identify early warning signs of potential failures. When integrated with repair cycle management, these insights trigger automated scheduling of maintenance activities within optimal repair windows, prioritizing critical equipment and balancing workloads across maintenance teams.

The synchronization between predictive analytics and repair cycles creates a feedback loop that continuously improves maintenance efficiency. As repairs are completed, the system captures data on actual repair times, parts used, and technician performance. This information refines future predictions and optimizes subsequent repair scheduling. Machine learning algorithms progressively enhance their accuracy by correlating predicted failure patterns with actual outcomes, leading to increasingly precise maintenance timing.

Key performance indicators for successful integration include reduced mean time to repair (MTTR), increased mean time between failures (MTBF), and optimized repair cycle times. Organizations implementing this integrated approach typically report 15-30% reductions in downtime and 10-25% improvements in maintenance labor efficiency. The economic impact extends beyond direct maintenance costs to include increased production capacity, improved product quality, and extended equipment lifespan.

Implementation challenges include data integration across disparate systems, sensor deployment strategies, and the development of accurate predictive models for diverse equipment types. Organizations must establish clear protocols for transitioning from predictive alerts to scheduled repair activities, including parts procurement, technician assignment, and production coordination. Change management remains critical, as maintenance teams must adapt from reactive to predictive mindsets.

Future developments in this integration will likely include augmented reality tools for technicians, autonomous maintenance robots for routine tasks, and AI-driven decision support systems that optimize repair scheduling across entire production ecosystems. The convergence of digital twins with predictive maintenance will enable virtual testing of maintenance scenarios before physical implementation, further reducing repair cycle times.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!