DED For Composite-To-Metal Repair Interfaces: Challenges And Solutions

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Repair Technology Background and Objectives

Directed Energy Deposition (DED) technology has emerged as a revolutionary approach in the field of advanced manufacturing and repair processes. Originating in the 1990s as a specialized additive manufacturing technique, DED has evolved significantly over the past three decades, transitioning from experimental applications to becoming an integral part of industrial repair strategies. The technology's evolution has been characterized by continuous improvements in precision, material compatibility, and process control systems.

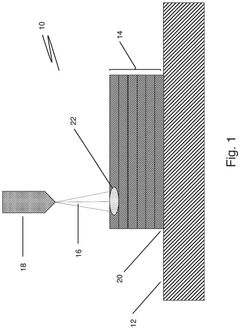

The fundamental principle of DED involves the focused deposition of materials through a nozzle, where they are simultaneously melted by a high-energy source such as a laser, electron beam, or plasma arc. This process creates a melt pool on the substrate surface, allowing for the controlled addition of material to repair damaged components or build new structures. The technology's development trajectory has been shaped by increasing demands for more efficient repair solutions in high-value industries including aerospace, defense, and energy sectors.

In the context of composite-to-metal repair interfaces, DED technology addresses a critical gap in traditional repair methodologies. Conventional repair techniques often struggle with the inherent challenges of joining dissimilar materials, particularly at the interface between composite structures and metallic components. These interfaces represent complex engineering challenges due to differences in thermal properties, mechanical behavior, and chemical compatibility between the constituent materials.

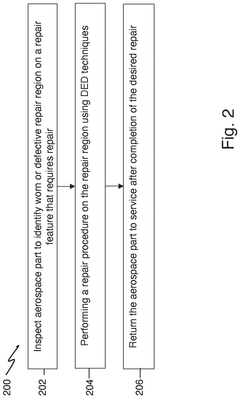

The primary technical objective of DED for composite-to-metal repair interfaces is to develop robust methodologies that ensure structural integrity while maintaining or enhancing the performance characteristics of the original components. This includes achieving strong metallurgical bonding at the interface, minimizing heat-affected zones, controlling residual stresses, and ensuring dimensional accuracy of the repaired section.

Secondary objectives include optimizing process parameters to accommodate the unique challenges presented by different material combinations, developing real-time monitoring systems for quality assurance, and establishing standardized procedures for qualification and certification of repairs. These objectives align with broader industry trends toward more sustainable manufacturing practices, as effective repair technologies can significantly extend component lifecycles and reduce material waste.

The evolution of DED technology is increasingly focused on addressing the specific challenges of composite-to-metal interfaces, with research efforts directed toward understanding the complex physical and chemical interactions that occur during the deposition process. Recent technological advancements have enabled more precise control over energy input, material feed rates, and atmospheric conditions, all of which are critical factors in achieving high-quality repairs at material interfaces.

Looking forward, the trajectory of DED technology development is expected to continue toward more sophisticated multi-material capabilities, enhanced process monitoring and control systems, and greater integration with computational modeling to predict and optimize repair outcomes.

The fundamental principle of DED involves the focused deposition of materials through a nozzle, where they are simultaneously melted by a high-energy source such as a laser, electron beam, or plasma arc. This process creates a melt pool on the substrate surface, allowing for the controlled addition of material to repair damaged components or build new structures. The technology's development trajectory has been shaped by increasing demands for more efficient repair solutions in high-value industries including aerospace, defense, and energy sectors.

In the context of composite-to-metal repair interfaces, DED technology addresses a critical gap in traditional repair methodologies. Conventional repair techniques often struggle with the inherent challenges of joining dissimilar materials, particularly at the interface between composite structures and metallic components. These interfaces represent complex engineering challenges due to differences in thermal properties, mechanical behavior, and chemical compatibility between the constituent materials.

The primary technical objective of DED for composite-to-metal repair interfaces is to develop robust methodologies that ensure structural integrity while maintaining or enhancing the performance characteristics of the original components. This includes achieving strong metallurgical bonding at the interface, minimizing heat-affected zones, controlling residual stresses, and ensuring dimensional accuracy of the repaired section.

Secondary objectives include optimizing process parameters to accommodate the unique challenges presented by different material combinations, developing real-time monitoring systems for quality assurance, and establishing standardized procedures for qualification and certification of repairs. These objectives align with broader industry trends toward more sustainable manufacturing practices, as effective repair technologies can significantly extend component lifecycles and reduce material waste.

The evolution of DED technology is increasingly focused on addressing the specific challenges of composite-to-metal interfaces, with research efforts directed toward understanding the complex physical and chemical interactions that occur during the deposition process. Recent technological advancements have enabled more precise control over energy input, material feed rates, and atmospheric conditions, all of which are critical factors in achieving high-quality repairs at material interfaces.

Looking forward, the trajectory of DED technology development is expected to continue toward more sophisticated multi-material capabilities, enhanced process monitoring and control systems, and greater integration with computational modeling to predict and optimize repair outcomes.

Market Analysis for Composite-Metal Interface Repair Solutions

The global market for composite-to-metal repair interfaces is experiencing significant growth, driven by increasing adoption of composite materials across aerospace, automotive, marine, and energy sectors. Current market valuation stands at approximately $2.3 billion, with projections indicating a compound annual growth rate of 7.8% through 2028, potentially reaching $3.5 billion by that time.

Aerospace remains the dominant application segment, accounting for nearly 42% of the market share. This dominance stems from the critical need for lightweight yet durable structures in aircraft manufacturing, where composite-to-metal interfaces are essential for structural integrity. The commercial aviation sector's recovery post-pandemic has further accelerated demand, with major manufacturers increasing production rates of composite-intensive aircraft models.

The automotive industry represents the fastest-growing segment, with a projected growth rate of 9.2% annually. This surge is primarily attributed to the electric vehicle revolution, where weight reduction is paramount for extending battery range. Premium automotive manufacturers are increasingly incorporating composite components bonded to traditional metal structures, creating substantial demand for advanced repair solutions.

Defense applications constitute another significant market segment, valued at approximately $580 million. Military aircraft, naval vessels, and ground vehicles utilize composite-metal hybrid structures for their superior performance characteristics, creating steady demand for specialized repair technologies.

Regionally, North America leads the market with a 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate of 10.3% annually, driven by rapid industrialization in China and India, along with expanding aerospace and automotive manufacturing bases.

The market landscape features a mix of large OEMs offering proprietary repair solutions and specialized service providers. Key market players include Henkel AG, 3M Company, Sika AG, and Huntsman Corporation in the materials segment, alongside service providers like AAR Corp and Lufthansa Technik. These companies are increasingly investing in research and development to address the technical challenges associated with composite-to-metal interface repairs.

Customer demand is primarily focused on repair solutions that can restore original strength properties while minimizing downtime and costs. There is growing interest in field-deployable repair technologies that can be implemented outside specialized facilities, particularly in aerospace MRO operations and remote industrial applications.

Aerospace remains the dominant application segment, accounting for nearly 42% of the market share. This dominance stems from the critical need for lightweight yet durable structures in aircraft manufacturing, where composite-to-metal interfaces are essential for structural integrity. The commercial aviation sector's recovery post-pandemic has further accelerated demand, with major manufacturers increasing production rates of composite-intensive aircraft models.

The automotive industry represents the fastest-growing segment, with a projected growth rate of 9.2% annually. This surge is primarily attributed to the electric vehicle revolution, where weight reduction is paramount for extending battery range. Premium automotive manufacturers are increasingly incorporating composite components bonded to traditional metal structures, creating substantial demand for advanced repair solutions.

Defense applications constitute another significant market segment, valued at approximately $580 million. Military aircraft, naval vessels, and ground vehicles utilize composite-metal hybrid structures for their superior performance characteristics, creating steady demand for specialized repair technologies.

Regionally, North America leads the market with a 38% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate of 10.3% annually, driven by rapid industrialization in China and India, along with expanding aerospace and automotive manufacturing bases.

The market landscape features a mix of large OEMs offering proprietary repair solutions and specialized service providers. Key market players include Henkel AG, 3M Company, Sika AG, and Huntsman Corporation in the materials segment, alongside service providers like AAR Corp and Lufthansa Technik. These companies are increasingly investing in research and development to address the technical challenges associated with composite-to-metal interface repairs.

Customer demand is primarily focused on repair solutions that can restore original strength properties while minimizing downtime and costs. There is growing interest in field-deployable repair technologies that can be implemented outside specialized facilities, particularly in aerospace MRO operations and remote industrial applications.

Technical Challenges in Composite-to-Metal Interfaces

Composite-to-metal interfaces present significant technical challenges due to the fundamental differences in material properties and behavior. The primary challenge stems from the dissimilar nature of these materials - composites being anisotropic with heterogeneous microstructures, while metals exhibit isotropic properties with homogeneous structures. This mismatch creates stress concentrations at the interface during thermal cycling, mechanical loading, and environmental exposure.

Coefficient of thermal expansion (CTE) mismatch represents one of the most critical issues. Metals typically have higher CTEs than composite materials, leading to differential expansion and contraction during temperature fluctuations. This thermal mismatch induces residual stresses at the interface, potentially causing delamination, crack initiation, and propagation under service conditions.

Galvanic corrosion presents another significant challenge when electrically conductive carbon fiber composites contact metals. The electrochemical potential difference between these materials in the presence of an electrolyte (often moisture) accelerates corrosion of the less noble material, compromising the interface integrity over time. This phenomenon is particularly problematic in marine, aerospace, and automotive applications exposed to harsh environments.

Adhesion mechanisms differ substantially between composites and metals. Metals primarily rely on mechanical interlocking and chemical bonding, while composites often require surface preparation to expose fibers and create mechanical anchoring points. Achieving consistent bond strength across the entire interface remains challenging, especially when using Directed Energy Deposition (DED) repair techniques that introduce additional thermal gradients.

Load transfer across the interface presents complex mechanical challenges. The significant stiffness differential between composites and metals creates stress concentrations that can lead to premature failure. Additionally, the anisotropic nature of composites means that load paths and stress distributions are highly directional, complicating interface design and analysis.

Manufacturing and repair processes introduce their own set of challenges. DED techniques, while promising for metal repair, generate high thermal gradients that can damage composite materials through matrix degradation, fiber-matrix debonding, or delamination. Controlling heat input, cooling rates, and residual stress development during DED repair of composite-to-metal interfaces requires sophisticated process control and monitoring systems.

Surface preparation requirements differ significantly between metals and composites, making it difficult to establish a single preparation protocol that optimizes adhesion for both materials simultaneously. This often necessitates multi-step processes that increase complexity, time, and cost of repairs.

Coefficient of thermal expansion (CTE) mismatch represents one of the most critical issues. Metals typically have higher CTEs than composite materials, leading to differential expansion and contraction during temperature fluctuations. This thermal mismatch induces residual stresses at the interface, potentially causing delamination, crack initiation, and propagation under service conditions.

Galvanic corrosion presents another significant challenge when electrically conductive carbon fiber composites contact metals. The electrochemical potential difference between these materials in the presence of an electrolyte (often moisture) accelerates corrosion of the less noble material, compromising the interface integrity over time. This phenomenon is particularly problematic in marine, aerospace, and automotive applications exposed to harsh environments.

Adhesion mechanisms differ substantially between composites and metals. Metals primarily rely on mechanical interlocking and chemical bonding, while composites often require surface preparation to expose fibers and create mechanical anchoring points. Achieving consistent bond strength across the entire interface remains challenging, especially when using Directed Energy Deposition (DED) repair techniques that introduce additional thermal gradients.

Load transfer across the interface presents complex mechanical challenges. The significant stiffness differential between composites and metals creates stress concentrations that can lead to premature failure. Additionally, the anisotropic nature of composites means that load paths and stress distributions are highly directional, complicating interface design and analysis.

Manufacturing and repair processes introduce their own set of challenges. DED techniques, while promising for metal repair, generate high thermal gradients that can damage composite materials through matrix degradation, fiber-matrix debonding, or delamination. Controlling heat input, cooling rates, and residual stress development during DED repair of composite-to-metal interfaces requires sophisticated process control and monitoring systems.

Surface preparation requirements differ significantly between metals and composites, making it difficult to establish a single preparation protocol that optimizes adhesion for both materials simultaneously. This often necessitates multi-step processes that increase complexity, time, and cost of repairs.

Current DED Solutions for Composite-Metal Interfaces

01 Interface characterization in DED repair processes

The characterization of interfaces in Directed Energy Deposition repair processes is crucial for ensuring structural integrity. This involves analyzing the microstructural properties, mechanical behavior, and metallurgical bonding at the interface between the substrate and deposited material. Advanced techniques such as electron microscopy, X-ray diffraction, and mechanical testing are employed to evaluate interface quality, identify potential defects, and ensure proper fusion between the original component and the repair material.- Interface characterization in DED repair processes: The interface between the original component and the deposited material in Directed Energy Deposition (DED) repair processes is critical for structural integrity. Advanced characterization techniques are used to analyze the microstructure, composition, and mechanical properties of these interfaces. This includes examining grain structure, phase transformations, and potential defects that may occur at the boundary. Understanding these interface characteristics is essential for ensuring the quality and durability of repaired components.

- Thermal management at DED repair interfaces: Thermal management is crucial during the DED repair process to control the interface quality between the substrate and deposited material. Techniques include preheating the substrate, controlling cooling rates, and implementing specific heat treatment protocols. Proper thermal management helps minimize residual stresses, prevent cracking, and ensure optimal metallurgical bonding at the interface. This approach is particularly important when repairing high-value components where interface integrity directly impacts performance and service life.

- Material compatibility and interface optimization: Ensuring compatibility between the substrate material and the deposited material is essential for creating strong interfaces in DED repairs. This involves selecting appropriate alloy compositions, adjusting process parameters to optimize dilution zones, and developing gradient structures to accommodate differences in material properties. Advanced powder feeding systems and multi-material deposition strategies are employed to create functionally graded interfaces that minimize stress concentrations and enhance overall repair quality.

- Process parameter optimization for interface quality: The quality of DED repair interfaces is highly dependent on process parameters such as laser power, scanning speed, powder feed rate, and layer thickness. Optimization of these parameters through experimental design and modeling helps achieve desired interface properties including minimal porosity, controlled dilution, and appropriate hardness profiles. Real-time monitoring and adaptive control systems are implemented to maintain consistent interface quality throughout the repair process, even when dealing with complex geometries or variable substrate conditions.

- Post-processing treatments for interface enhancement: Various post-processing treatments are applied to enhance the properties of DED repair interfaces. These include heat treatments to relieve residual stresses and homogenize the microstructure, surface finishing operations to improve fatigue resistance, and hot isostatic pressing to eliminate porosity. Some advanced approaches incorporate localized surface treatments such as laser shock peening or ultrasonic impact treatment to induce beneficial compressive stresses at the interface region, thereby improving the mechanical performance and extending the service life of repaired components.

02 Pre-treatment methods for DED repair interfaces

Various pre-treatment methods are employed to prepare surfaces for Directed Energy Deposition repair, enhancing interface quality. These include mechanical cleaning, chemical etching, laser ablation, and plasma treatment to remove oxides, contaminants, and create optimal surface roughness. Pre-heating strategies are also implemented to reduce thermal gradients and residual stresses at the interface. These preparation techniques significantly improve adhesion, reduce defects, and enhance the overall mechanical properties of the repaired component.Expand Specific Solutions03 Post-processing treatments for DED repair interfaces

Post-processing treatments are essential for optimizing the properties of DED repair interfaces. These include heat treatments to relieve residual stresses, homogenize microstructure, and improve mechanical properties. Surface finishing techniques such as machining, grinding, and polishing are applied to achieve dimensional accuracy and surface quality. Additional treatments like shot peening and hot isostatic pressing can further enhance fatigue resistance and eliminate porosity at the interface region, resulting in superior repair quality and extended component life.Expand Specific Solutions04 Process parameter optimization for DED repair interfaces

Optimizing process parameters is critical for achieving high-quality interfaces in DED repairs. Key parameters include laser power, scanning speed, powder feed rate, and layer thickness, which directly influence the thermal history, melt pool dynamics, and resulting microstructure at the interface. Advanced monitoring systems and closed-loop control strategies are implemented to maintain consistent deposition conditions. Computational modeling and machine learning approaches are also utilized to predict and optimize interface properties based on process parameters, material combinations, and component geometry.Expand Specific Solutions05 Multi-material and functionally graded interfaces in DED repairs

Multi-material and functionally graded interfaces represent advanced approaches in DED repair technology. These techniques involve the strategic deposition of different materials or gradually changing material compositions across the interface to mitigate issues related to thermal expansion mismatch, residual stress, and mechanical property discontinuities. By creating compositional gradients between the substrate and repair material, these methods enhance interface strength, improve crack resistance, and enable the repair of complex components with specialized functional requirements or those subjected to severe operating conditions.Expand Specific Solutions

Leading Companies in DED Repair Technology

The DED (Directed Energy Deposition) for composite-to-metal repair interfaces market is currently in a growth phase, with increasing adoption across aerospace, defense, and industrial sectors. The global market size for this technology is estimated to reach $1.2 billion by 2025, driven by demand for cost-effective repair solutions. Leading players include RTX Corp. and GE Avio, who have developed advanced DED systems for critical aerospace components, while Norsk Titanium and FormAlloy Technologies are pioneering specialized applications for composite-metal interfaces. Research institutions like Huazhong University of Science & Technology and Tsinghua University are addressing key technical challenges including thermal management, material compatibility, and process control. The technology is approaching maturity for certain applications, though challenges in standardization and qualification for safety-critical components remain significant barriers to widespread implementation.

Norsk Titanium AS

Technical Solution: Norsk Titanium has pioneered Rapid Plasma Deposition (RPD) technology, a specialized form of DED optimized for titanium-composite interfaces. Their process utilizes a plasma arc to deposit titanium in a controlled atmosphere, creating strong metallurgical bonds with specially prepared composite surfaces. The company has developed a proprietary surface preparation technique that enhances adhesion between titanium deposits and carbon fiber composites by creating microscopic anchoring features without damaging the composite's structural integrity. Their multi-layer approach includes an intermediate functionally graded material (FGM) zone that transitions from metal-dominant to composite-compatible chemistry, effectively distributing thermal and mechanical stresses. Norsk's system incorporates closed-loop control algorithms that adjust deposition parameters in real-time based on thermal feedback, preventing composite degradation while ensuring optimal metal consolidation.

Strengths: Specialized expertise in titanium deposition with exceptional material efficiency and reduced thermal impact on composites. Weaknesses: Limited material versatility beyond titanium alloys; technology requires significant capital investment and specialized training for implementation.

GE Avio Srl

Technical Solution: GE Avio has developed a specialized DED process for repairing composite-to-metal interfaces in aircraft engine components. Their technology employs a laser-based DED system with adaptive power modulation specifically calibrated for the thermal sensitivity of composite materials. The process incorporates a proprietary interlayer technology that creates a graduated transition between dissimilar materials, addressing the critical challenge of coefficient of thermal expansion mismatches. GE Avio's solution includes pre-treatment of composite surfaces using plasma activation to enhance chemical bonding with the deposited metal. Their system utilizes multi-material feedstock delivery that can dynamically adjust composition during deposition, creating functionally graded interfaces that distribute mechanical stresses. The company has demonstrated successful repairs on fan blade components where carbon fiber composites interface with titanium alloys, achieving restoration of original mechanical properties while maintaining aerodynamic profiles.

Strengths: Highly specialized for aerospace engine applications with proven results in high-performance environments; excellent thermal management during deposition process. Weaknesses: Highly specialized equipment requirements limit widespread adoption; process requires extensive material-specific parameter development.

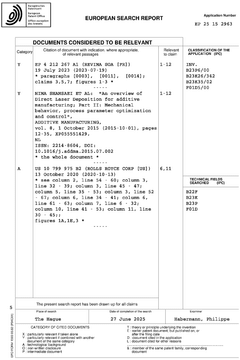

Key Patents in Composite-Metal Interface Repair

Engineered residual stress state for enhanced performance during directed energy deposition repair process

PatentPendingEP4599978A1

Innovation

- A directed energy deposition (DED) process is used to create layers with pre-determined residual stress states by controlling parameters like powder feed rate, energy intensity, traversal speed, and auxiliary heating/cooling, enabling controlled residual stress management during the repair process.

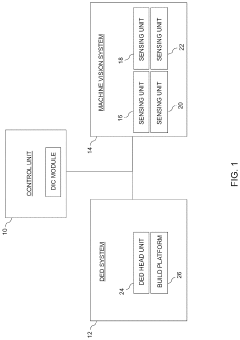

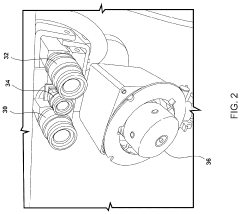

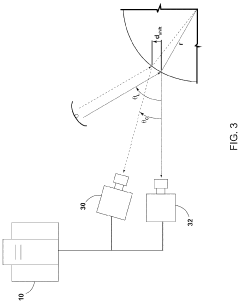

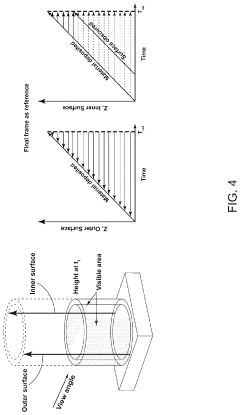

In-situ digital image correlation and thermal monitoring in directed energy deposition

PatentActiveUS11890808B2

Innovation

- A method and system for digital image correlation and thermal monitoring using global off-axis 3D mapping with natural surface roughness, infrared thermography, and a machine vision system comprising stereo imaging cameras and an infrared camera, allowing for strain and temperature data acquisition without a speckle pattern and enabling synthetic reference frames for inner surface features.

Material Compatibility and Characterization Methods

Material compatibility represents a critical challenge in the implementation of Directed Energy Deposition (DED) for composite-to-metal repair interfaces. The fundamental differences in physical and chemical properties between metallic substrates and composite materials create significant hurdles for achieving robust bonding. These disparities include thermal expansion coefficients, melting points, and chemical reactivity, which can lead to residual stresses, delamination, and premature failure at the interface region.

Characterization methods play a pivotal role in understanding and optimizing these complex interfaces. Non-destructive evaluation techniques such as ultrasonic testing, X-ray computed tomography, and infrared thermography enable the assessment of bond integrity without compromising the repaired structure. These methods can detect subsurface defects, voids, and delaminations that may not be visible through surface inspection alone.

Microstructural analysis through scanning electron microscopy (SEM) and transmission electron microscopy (TEM) provides detailed insights into the interfacial zone morphology, revealing critical information about diffusion layers, intermetallic compounds, and potential reaction products. Energy-dispersive X-ray spectroscopy (EDS) and electron backscatter diffraction (EBSD) complement these techniques by mapping elemental distribution and crystallographic orientation across the interface.

Mechanical property evaluation through micro-hardness testing, nanoindentation, and interfacial shear strength measurements helps quantify the performance of the repaired region. These tests are essential for validating the effectiveness of DED repairs and ensuring they meet or exceed the original material specifications. Pull-off adhesion testing and lap shear testing provide practical measures of bond strength under different loading conditions.

Advanced characterization approaches such as in-situ monitoring during the DED process offer real-time feedback on thermal gradients, cooling rates, and solidification behavior. This information is invaluable for process optimization and quality control. Digital image correlation (DIC) techniques can track strain development during mechanical testing, highlighting potential failure initiation sites at the interface.

Accelerated aging tests and environmental exposure studies help predict the long-term durability of composite-to-metal interfaces in service conditions. These tests simulate harsh environments including temperature cycling, humidity exposure, and corrosive media to evaluate interface degradation mechanisms over time. The data collected from these characterization methods forms the foundation for developing improved DED parameters and interface design strategies.

Standardization of characterization protocols remains an ongoing challenge in this field, as the diversity of material combinations and repair scenarios necessitates tailored approaches. Efforts to establish industry-wide testing standards will be crucial for widespread adoption of DED repair technologies for composite-to-metal interfaces.

Characterization methods play a pivotal role in understanding and optimizing these complex interfaces. Non-destructive evaluation techniques such as ultrasonic testing, X-ray computed tomography, and infrared thermography enable the assessment of bond integrity without compromising the repaired structure. These methods can detect subsurface defects, voids, and delaminations that may not be visible through surface inspection alone.

Microstructural analysis through scanning electron microscopy (SEM) and transmission electron microscopy (TEM) provides detailed insights into the interfacial zone morphology, revealing critical information about diffusion layers, intermetallic compounds, and potential reaction products. Energy-dispersive X-ray spectroscopy (EDS) and electron backscatter diffraction (EBSD) complement these techniques by mapping elemental distribution and crystallographic orientation across the interface.

Mechanical property evaluation through micro-hardness testing, nanoindentation, and interfacial shear strength measurements helps quantify the performance of the repaired region. These tests are essential for validating the effectiveness of DED repairs and ensuring they meet or exceed the original material specifications. Pull-off adhesion testing and lap shear testing provide practical measures of bond strength under different loading conditions.

Advanced characterization approaches such as in-situ monitoring during the DED process offer real-time feedback on thermal gradients, cooling rates, and solidification behavior. This information is invaluable for process optimization and quality control. Digital image correlation (DIC) techniques can track strain development during mechanical testing, highlighting potential failure initiation sites at the interface.

Accelerated aging tests and environmental exposure studies help predict the long-term durability of composite-to-metal interfaces in service conditions. These tests simulate harsh environments including temperature cycling, humidity exposure, and corrosive media to evaluate interface degradation mechanisms over time. The data collected from these characterization methods forms the foundation for developing improved DED parameters and interface design strategies.

Standardization of characterization protocols remains an ongoing challenge in this field, as the diversity of material combinations and repair scenarios necessitates tailored approaches. Efforts to establish industry-wide testing standards will be crucial for widespread adoption of DED repair technologies for composite-to-metal interfaces.

Quality Assurance and Certification Standards

Quality assurance and certification standards for DED composite-to-metal repair interfaces represent a critical framework that ensures the reliability, safety, and performance of these complex repair solutions. Currently, the aerospace and defense industries lead in establishing rigorous protocols, with standards such as AMS7003 for metal additive manufacturing and various ASTM specifications providing partial guidance.

The certification landscape for DED composite-to-metal interfaces remains fragmented, with no unified standard specifically addressing the unique challenges of these hybrid repairs. This gap necessitates the development of comprehensive standards that account for the distinct material properties, thermal behaviors, and mechanical responses at these critical junctions.

Non-destructive testing (NDT) methodologies form the cornerstone of quality assurance for these interfaces. Advanced techniques including computed tomography (CT), ultrasonic testing, and thermography have demonstrated effectiveness in detecting subsurface defects, delamination, and porosity at the composite-metal boundary. However, standardization of these inspection protocols requires further refinement to ensure consistent interpretation across the industry.

Process monitoring during DED application has emerged as an essential quality control measure. Real-time monitoring systems that track thermal profiles, deposition rates, and material flow characteristics provide valuable data for validating repair integrity. The integration of machine learning algorithms with these monitoring systems shows promise for predictive quality assurance, though standardized implementation remains in development.

Material qualification standards present particular challenges for composite-to-metal interfaces. Current frameworks typically address either composite or metallic materials separately, failing to account for the complex interactions at the interface. Industry leaders are working toward developing hybrid material qualification protocols that consider the unique thermomechanical behaviors at these junctions.

Certification bodies including FAA, EASA, and military standards organizations are actively working to establish performance-based certification approaches rather than prescriptive methodologies. This shift acknowledges the rapid evolution of DED technologies and allows for innovation while maintaining safety standards. The development of digital certification frameworks that incorporate material data, process parameters, and performance metrics represents the next frontier in quality assurance for these complex repair interfaces.

The certification landscape for DED composite-to-metal interfaces remains fragmented, with no unified standard specifically addressing the unique challenges of these hybrid repairs. This gap necessitates the development of comprehensive standards that account for the distinct material properties, thermal behaviors, and mechanical responses at these critical junctions.

Non-destructive testing (NDT) methodologies form the cornerstone of quality assurance for these interfaces. Advanced techniques including computed tomography (CT), ultrasonic testing, and thermography have demonstrated effectiveness in detecting subsurface defects, delamination, and porosity at the composite-metal boundary. However, standardization of these inspection protocols requires further refinement to ensure consistent interpretation across the industry.

Process monitoring during DED application has emerged as an essential quality control measure. Real-time monitoring systems that track thermal profiles, deposition rates, and material flow characteristics provide valuable data for validating repair integrity. The integration of machine learning algorithms with these monitoring systems shows promise for predictive quality assurance, though standardized implementation remains in development.

Material qualification standards present particular challenges for composite-to-metal interfaces. Current frameworks typically address either composite or metallic materials separately, failing to account for the complex interactions at the interface. Industry leaders are working toward developing hybrid material qualification protocols that consider the unique thermomechanical behaviors at these junctions.

Certification bodies including FAA, EASA, and military standards organizations are actively working to establish performance-based certification approaches rather than prescriptive methodologies. This shift acknowledges the rapid evolution of DED technologies and allows for innovation while maintaining safety standards. The development of digital certification frameworks that incorporate material data, process parameters, and performance metrics represents the next frontier in quality assurance for these complex repair interfaces.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!