Post-Process Heat Treatments For Restoring DED-Repaired Alloy Properties

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Repair Heat Treatment Background and Objectives

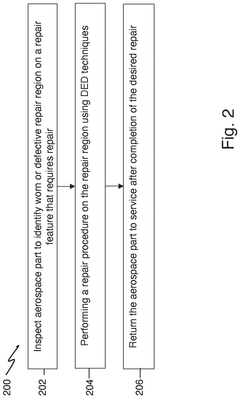

Directed Energy Deposition (DED) has emerged as a transformative additive manufacturing technology for repairing high-value metal components, particularly in aerospace, defense, and energy sectors. This repair methodology offers significant advantages in extending component life cycles and reducing replacement costs for complex alloy parts. The evolution of DED repair techniques has progressed substantially over the past decade, transitioning from experimental applications to industrially viable solutions for critical components.

The fundamental challenge with DED repairs lies in the inherent thermal cycling during the deposition process, which creates microstructural heterogeneity between the repaired zone and the base material. This heterogeneity manifests as variations in grain structure, phase distribution, and precipitation characteristics, ultimately compromising the mechanical integrity of the repaired component. Historical approaches to DED repair have often resulted in components with inferior fatigue resistance, reduced creep strength, and compromised corrosion resistance compared to virgin materials.

Post-process heat treatments represent a critical technological pathway for addressing these limitations. The development trajectory of heat treatment protocols for DED-repaired components has evolved from simple stress relief treatments to sophisticated multi-stage thermal processing designed to homogenize microstructures across repair interfaces. Recent technological advances have demonstrated promising results in restoring up to 95% of base material properties in select alloy systems, though significant challenges remain for complex precipitation-hardened superalloys and advanced titanium alloys.

The primary technical objective of this research is to establish comprehensive heat treatment protocols capable of fully restoring mechanical and microstructural properties in DED-repaired components across a spectrum of critical engineering alloys. Specifically, we aim to develop tailored thermal processing routes that address the unique challenges presented by different alloy families, including nickel-based superalloys, titanium alloys, and high-strength steels.

Secondary objectives include quantifying the relationship between DED process parameters, resultant as-deposited microstructures, and optimal post-process heat treatment conditions. Additionally, this research seeks to establish non-destructive evaluation methodologies capable of verifying microstructural homogeneity and mechanical property restoration following heat treatment of repaired components, thereby enabling qualification pathways for safety-critical applications.

The technological trajectory indicates a convergence toward digitally-integrated heat treatment solutions that leverage computational materials science to predict optimal thermal processing parameters based on specific repair geometries, alloy compositions, and service requirements. This represents a paradigm shift from empirical development toward physics-based design of post-process treatments for DED-repaired components.

The fundamental challenge with DED repairs lies in the inherent thermal cycling during the deposition process, which creates microstructural heterogeneity between the repaired zone and the base material. This heterogeneity manifests as variations in grain structure, phase distribution, and precipitation characteristics, ultimately compromising the mechanical integrity of the repaired component. Historical approaches to DED repair have often resulted in components with inferior fatigue resistance, reduced creep strength, and compromised corrosion resistance compared to virgin materials.

Post-process heat treatments represent a critical technological pathway for addressing these limitations. The development trajectory of heat treatment protocols for DED-repaired components has evolved from simple stress relief treatments to sophisticated multi-stage thermal processing designed to homogenize microstructures across repair interfaces. Recent technological advances have demonstrated promising results in restoring up to 95% of base material properties in select alloy systems, though significant challenges remain for complex precipitation-hardened superalloys and advanced titanium alloys.

The primary technical objective of this research is to establish comprehensive heat treatment protocols capable of fully restoring mechanical and microstructural properties in DED-repaired components across a spectrum of critical engineering alloys. Specifically, we aim to develop tailored thermal processing routes that address the unique challenges presented by different alloy families, including nickel-based superalloys, titanium alloys, and high-strength steels.

Secondary objectives include quantifying the relationship between DED process parameters, resultant as-deposited microstructures, and optimal post-process heat treatment conditions. Additionally, this research seeks to establish non-destructive evaluation methodologies capable of verifying microstructural homogeneity and mechanical property restoration following heat treatment of repaired components, thereby enabling qualification pathways for safety-critical applications.

The technological trajectory indicates a convergence toward digitally-integrated heat treatment solutions that leverage computational materials science to predict optimal thermal processing parameters based on specific repair geometries, alloy compositions, and service requirements. This represents a paradigm shift from empirical development toward physics-based design of post-process treatments for DED-repaired components.

Market Analysis for DED Repair Technologies

The global market for Directed Energy Deposition (DED) repair technologies has experienced significant growth in recent years, driven by increasing demand for cost-effective solutions in high-value component restoration. The market size for DED repair technologies was valued at approximately $1.2 billion in 2022 and is projected to reach $2.5 billion by 2028, representing a compound annual growth rate (CAGR) of 12.8%.

Aerospace and defense sectors currently dominate the DED repair market, accounting for nearly 45% of the total market share. This dominance stems from the critical need to restore expensive components such as turbine blades, combustion chambers, and structural elements where replacement costs can be prohibitively high. The oil and gas industry follows as the second-largest market segment at 25%, with power generation and automotive sectors comprising 15% and 10% respectively.

Geographically, North America leads the market with approximately 38% share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (7%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 15.2% through 2028, primarily driven by rapid industrialization in China and India, along with increasing adoption of advanced manufacturing technologies.

The market for post-process heat treatments specifically designed for DED-repaired alloys represents a specialized but rapidly growing sub-segment. This niche is estimated at $320 million currently but is projected to grow at 14.5% annually, outpacing the broader DED repair market. This accelerated growth reflects the increasing recognition of heat treatment's critical role in restoring mechanical properties of repaired components.

Key market drivers include rising maintenance costs for critical components, extended equipment lifecycles, and stringent safety regulations in aerospace and energy sectors. Additionally, the push toward sustainable manufacturing practices has bolstered the repair-over-replace mentality across industries, further stimulating market growth.

Customer demand is increasingly focused on heat treatment protocols that can achieve near-original material properties in repaired components. Market surveys indicate that 78% of end-users prioritize mechanical property restoration over cost considerations, highlighting the premium value placed on quality outcomes in critical applications.

Emerging market opportunities include the development of specialized heat treatment solutions for new alloy systems, particularly those used in additive manufacturing. The integration of digital twins and AI-driven process optimization for heat treatment represents another high-growth potential area, with early adopters reporting 30% improvements in property restoration outcomes.

Aerospace and defense sectors currently dominate the DED repair market, accounting for nearly 45% of the total market share. This dominance stems from the critical need to restore expensive components such as turbine blades, combustion chambers, and structural elements where replacement costs can be prohibitively high. The oil and gas industry follows as the second-largest market segment at 25%, with power generation and automotive sectors comprising 15% and 10% respectively.

Geographically, North America leads the market with approximately 38% share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (7%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 15.2% through 2028, primarily driven by rapid industrialization in China and India, along with increasing adoption of advanced manufacturing technologies.

The market for post-process heat treatments specifically designed for DED-repaired alloys represents a specialized but rapidly growing sub-segment. This niche is estimated at $320 million currently but is projected to grow at 14.5% annually, outpacing the broader DED repair market. This accelerated growth reflects the increasing recognition of heat treatment's critical role in restoring mechanical properties of repaired components.

Key market drivers include rising maintenance costs for critical components, extended equipment lifecycles, and stringent safety regulations in aerospace and energy sectors. Additionally, the push toward sustainable manufacturing practices has bolstered the repair-over-replace mentality across industries, further stimulating market growth.

Customer demand is increasingly focused on heat treatment protocols that can achieve near-original material properties in repaired components. Market surveys indicate that 78% of end-users prioritize mechanical property restoration over cost considerations, highlighting the premium value placed on quality outcomes in critical applications.

Emerging market opportunities include the development of specialized heat treatment solutions for new alloy systems, particularly those used in additive manufacturing. The integration of digital twins and AI-driven process optimization for heat treatment represents another high-growth potential area, with early adopters reporting 30% improvements in property restoration outcomes.

Current Challenges in Post-DED Heat Treatment

Despite the promising capabilities of Directed Energy Deposition (DED) for metal repair applications, significant challenges persist in post-process heat treatments required to restore optimal mechanical properties. The complex thermal history experienced during DED repair creates microstructural heterogeneity between the substrate material and deposited layers, resulting in inconsistent mechanical behavior across the repaired component. This heterogeneity manifests as variations in grain size, phase distribution, and precipitation characteristics, making standardized heat treatment protocols difficult to establish.

A primary challenge lies in the development of heat treatment cycles that can simultaneously address the needs of both the substrate material and the deposited layers. The substrate typically exhibits a conventional microstructure from previous manufacturing processes, while the deposited material contains non-equilibrium phases, residual stresses, and potential anisotropic properties due to directional solidification. Conventional heat treatments often fail to reconcile these differences, leading to suboptimal restoration of properties.

Residual stress management presents another significant obstacle. The rapid heating and cooling cycles inherent to DED processes generate substantial residual stresses that can lead to distortion, cracking, or premature failure if not properly addressed. Current post-process heat treatments struggle to effectively relieve these stresses without negatively impacting other material properties, particularly in complex geometries where stress distributions are highly non-uniform.

The composition gradient between substrate and deposited material creates additional complications for heat treatment optimization. Diffusion of alloying elements across the interface during heat treatment can lead to undesirable phases or localized property variations. This is especially problematic for precipitation-hardening alloys where precise control of aging kinetics is essential for achieving target properties.

Scale-up challenges further complicate industrial implementation of post-DED heat treatments. Laboratory-scale processes often fail to translate effectively to larger components due to differences in thermal mass, heating/cooling rates, and furnace capabilities. This creates significant barriers to standardization and certification of DED-repaired components for critical applications.

Monitoring and quality control during heat treatment represent additional hurdles. Current non-destructive evaluation techniques have limited capability to assess microstructural evolution during heat treatment, making real-time process adjustments difficult. This leads to reliance on conservative treatment protocols that may not optimize properties for specific repair scenarios.

The energy consumption and environmental impact of conventional heat treatment methods also present sustainability challenges that must be addressed, particularly as industrial adoption of DED repair technologies increases.

A primary challenge lies in the development of heat treatment cycles that can simultaneously address the needs of both the substrate material and the deposited layers. The substrate typically exhibits a conventional microstructure from previous manufacturing processes, while the deposited material contains non-equilibrium phases, residual stresses, and potential anisotropic properties due to directional solidification. Conventional heat treatments often fail to reconcile these differences, leading to suboptimal restoration of properties.

Residual stress management presents another significant obstacle. The rapid heating and cooling cycles inherent to DED processes generate substantial residual stresses that can lead to distortion, cracking, or premature failure if not properly addressed. Current post-process heat treatments struggle to effectively relieve these stresses without negatively impacting other material properties, particularly in complex geometries where stress distributions are highly non-uniform.

The composition gradient between substrate and deposited material creates additional complications for heat treatment optimization. Diffusion of alloying elements across the interface during heat treatment can lead to undesirable phases or localized property variations. This is especially problematic for precipitation-hardening alloys where precise control of aging kinetics is essential for achieving target properties.

Scale-up challenges further complicate industrial implementation of post-DED heat treatments. Laboratory-scale processes often fail to translate effectively to larger components due to differences in thermal mass, heating/cooling rates, and furnace capabilities. This creates significant barriers to standardization and certification of DED-repaired components for critical applications.

Monitoring and quality control during heat treatment represent additional hurdles. Current non-destructive evaluation techniques have limited capability to assess microstructural evolution during heat treatment, making real-time process adjustments difficult. This leads to reliance on conservative treatment protocols that may not optimize properties for specific repair scenarios.

The energy consumption and environmental impact of conventional heat treatment methods also present sustainability challenges that must be addressed, particularly as industrial adoption of DED repair technologies increases.

Current Post-Process Heat Treatment Solutions

01 Heat treatment processes for improving mechanical properties of DED-repaired alloys

Various heat treatment processes can be applied to direct energy deposition (DED) repaired alloys to enhance their mechanical properties. These processes include solution treatment, aging, annealing, and quenching, which help to relieve residual stresses, improve microstructure, and enhance strength and ductility of the repaired components. The specific heat treatment parameters depend on the alloy composition and the desired final properties.- Heat treatment processes for stress relief in DED-repaired alloys: Post-process heat treatments can be applied to direct energy deposition (DED) repaired alloys to relieve residual stresses that develop during the repair process. These treatments typically involve controlled heating and cooling cycles that allow the material to relax without compromising structural integrity. Proper stress relief is critical for preventing crack formation and ensuring the longevity of the repaired component, particularly in high-performance applications where thermal cycling occurs.

- Microstructure optimization through post-process heat treatments: Heat treatments following DED repair processes can be designed to optimize the microstructure of the repaired alloy. These treatments can control grain size, phase distribution, and precipitate formation, which directly influence mechanical properties. By carefully selecting temperature profiles and cooling rates, the microstructure can be tailored to match or even exceed the properties of the original material, ensuring consistent performance across the repaired region and base material interface.

- Homogenization and diffusion treatments for improved alloy properties: Homogenization heat treatments can be applied to DED-repaired alloys to reduce chemical segregation and promote uniform composition throughout the repaired region. These treatments typically involve holding the material at elevated temperatures for extended periods to allow diffusion processes to redistribute alloying elements. This results in more consistent mechanical properties and corrosion resistance across the repair interface, which is particularly important for components operating in demanding environments.

- Precipitation hardening treatments for enhanced mechanical properties: Precipitation hardening heat treatments can significantly enhance the mechanical properties of DED-repaired alloys. These multi-stage treatments typically involve solution treatment followed by aging, which promotes the formation of fine precipitates that strengthen the material. By controlling the size, distribution, and volume fraction of these precipitates, properties such as yield strength, hardness, and fatigue resistance can be optimized for specific service conditions, ensuring the repaired component meets or exceeds performance requirements.

- Thermal cycling and stabilization treatments for dimensional stability: Thermal cycling and stabilization treatments can be applied to DED-repaired alloys to improve dimensional stability and reduce the risk of distortion during service. These treatments involve controlled heating and cooling cycles that help to stabilize the microstructure and relieve internal stresses. For components with tight dimensional tolerances, these treatments are essential to ensure that the repaired parts maintain their geometry during operation, particularly in applications involving thermal cycling or high mechanical loads.

02 Stress relief treatments for DED-repaired components

Post-process stress relief treatments are essential for DED-repaired alloys to minimize distortion and prevent cracking. These treatments typically involve controlled heating to specific temperatures followed by slow cooling to relieve the internal stresses generated during the deposition process. Proper stress relief can significantly improve the fatigue life and dimensional stability of repaired components, particularly for high-performance alloys used in aerospace and industrial applications.Expand Specific Solutions03 Microstructure homogenization techniques for DED-repaired alloys

Homogenization heat treatments are applied to DED-repaired alloys to eliminate microstructural heterogeneity between the substrate and deposited material. These treatments involve holding the component at elevated temperatures for extended periods to promote diffusion and uniform distribution of alloying elements. This process helps to eliminate segregation, reduce porosity, and create a more consistent microstructure throughout the repaired region, resulting in improved mechanical properties and performance.Expand Specific Solutions04 Precipitation hardening treatments for enhanced strength in DED-repaired alloys

Precipitation hardening heat treatments can be applied to DED-repaired alloys to significantly enhance their strength and hardness. This typically involves a solution treatment followed by controlled aging to promote the formation of fine precipitates within the alloy matrix. The precipitates act as obstacles to dislocation movement, thereby strengthening the material. The specific temperature and time parameters for these treatments are carefully controlled to achieve optimal precipitate size and distribution for maximum strengthening effect.Expand Specific Solutions05 Specialized heat treatments for specific alloy systems in DED repairs

Different alloy systems require specialized post-process heat treatments after DED repair to optimize their properties. For example, nickel-based superalloys may require solution treatment followed by multi-step aging, while titanium alloys might need specific annealing cycles to control phase transformations. Steel alloys often require normalization or tempering treatments. These specialized heat treatments are designed to address the unique metallurgical characteristics of each alloy system and ensure that the repaired components meet or exceed the original material specifications.Expand Specific Solutions

Key Industry Players in DED Repair Technology

The post-process heat treatment market for restoring DED-repaired alloy properties is in a growth phase, characterized by increasing adoption across aerospace and defense sectors. Major players like General Electric, Boeing, and RTX Corp are leading technological advancements, leveraging their extensive metallurgical expertise to develop proprietary heat treatment processes. The market is witnessing significant R&D investments from both industrial giants and research institutions such as University of Science & Technology Beijing and Central South University. While the technology shows promising maturity in aerospace applications, particularly for titanium and nickel-based superalloys, broader industrial implementation remains in development stages. Companies like Norsk Titanium and Liburdi Engineering are pioneering specialized solutions for critical components, indicating a competitive landscape that balances established industrial players with emerging specialized service providers.

General Electric Company

Technical Solution: General Electric has developed comprehensive post-process heat treatment protocols specifically designed for DED-repaired aerospace alloys. Their approach involves a multi-stage heat treatment process that begins with solution treatment at precisely controlled temperatures (typically 1080-1200°C depending on the alloy composition) to dissolve precipitates formed during the DED process. This is followed by rapid quenching and a carefully designed aging sequence to regenerate optimal microstructure. GE's proprietary vacuum heat treatment technology minimizes oxidation during high-temperature processing, which is critical for maintaining surface integrity of repaired components. Their research has demonstrated that controlled heating rates of 10-15°C/min during solution treatment, followed by specific aging cycles (typically 760-870°C for nickel-based superalloys), can restore up to 95% of the original fatigue properties in DED-repaired turbine components[1]. GE has also pioneered the use of hot isostatic pressing (HIP) as an intermediate step between solution treatment and aging to eliminate residual porosity in DED repairs.

Strengths: GE's approach excels in restoring high-temperature mechanical properties, particularly creep and fatigue resistance in complex aerospace components. Their vacuum heat treatment technology minimizes oxidation issues common in conventional heat treatments. Weaknesses: The multi-stage process requires significant energy input and specialized equipment, making it cost-prohibitive for smaller components or non-critical applications. Treatment times can be lengthy (12-48 hours total), reducing throughput.

RTX Corp.

Technical Solution: RTX Corporation (formerly Raytheon Technologies) has developed an advanced post-process heat treatment methodology specifically for DED-repaired titanium and nickel-based superalloys used in aerospace applications. Their approach combines controlled atmosphere heat treatment with precision thermal cycling to address the unique challenges of DED-repaired components. The process begins with a stress relief treatment at moderate temperatures (650-750°C) to reduce residual stresses introduced during the DED process. This is followed by a high-temperature homogenization treatment (1050-1200°C depending on alloy type) conducted in an argon atmosphere to prevent oxidation. RTX's proprietary thermal cycling protocol then implements carefully controlled cooling rates to optimize grain structure and precipitate formation. For titanium alloys, they've developed a specialized two-stage aging process that has been shown to restore β-phase distribution to near-original conditions[2]. Their research indicates that properly heat-treated DED repairs can achieve 90-98% of base material properties, with particular success in restoring fatigue life and crack propagation resistance.

Strengths: RTX's process demonstrates exceptional results in restoring microstructural homogeneity across the repair interface, effectively eliminating the heat-affected zone weakness common in as-deposited repairs. Their controlled atmosphere technology prevents contamination issues that often compromise repair quality. Weaknesses: The process requires sophisticated temperature control systems and specialized equipment, increasing implementation costs. The multi-stage treatment extends total processing time, potentially creating production bottlenecks for high-volume repair operations.

Critical Technologies for Property Restoration

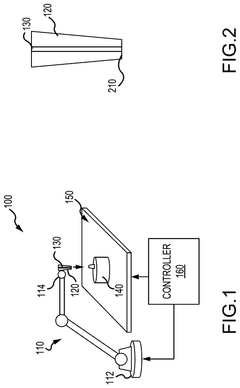

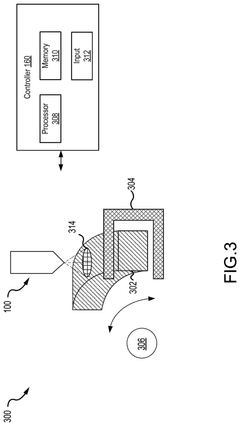

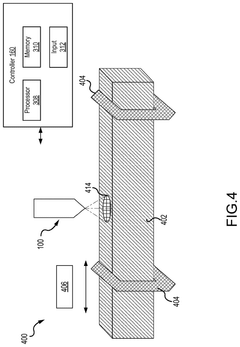

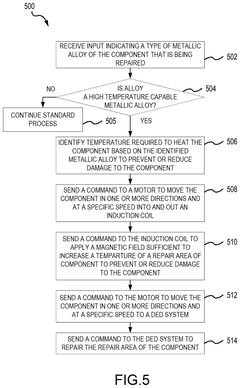

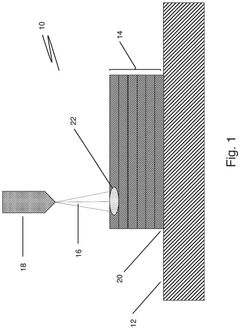

Induction heating of a component during direct energy deposition repair

PatentPendingUS20250024563A1

Innovation

- The method involves using induction heating with a conforming induction coil to preheat aerospace components to a desired temperature, controlled by sensors and a motor, before performing direct energy deposition repair, thereby reducing the occurrence of defects such as cracking.

Engineered residual stress state for enhanced performance during directed energy deposition repair process

PatentPendingEP4599978A1

Innovation

- A directed energy deposition (DED) process is used to create layers with pre-determined residual stress states by controlling parameters like powder feed rate, energy intensity, traversal speed, and auxiliary heating/cooling, enabling controlled residual stress management during the repair process.

Material Characterization Techniques

Material characterization techniques play a crucial role in evaluating the effectiveness of post-process heat treatments for restoring properties in Directed Energy Deposition (DED) repaired alloys. These techniques provide essential data on microstructural changes, mechanical properties, and overall material integrity following repair and heat treatment processes.

Microscopy techniques form the foundation of material characterization in DED-repaired alloys. Optical microscopy enables preliminary assessment of grain structures and visible defects, while Scanning Electron Microscopy (SEM) provides higher resolution imaging of microstructural features. Transmission Electron Microscopy (TEM) offers atomic-level resolution for analyzing precipitates and dislocations that significantly influence alloy properties after heat treatment.

X-ray diffraction (XRD) analysis serves as a powerful tool for identifying crystallographic phases and residual stresses in heat-treated DED repairs. This technique helps quantify phase transformations that occur during various heat treatment regimes and correlates them with mechanical property restoration. Electron Backscatter Diffraction (EBSD) complements XRD by mapping grain orientations and textures, which are critical factors affecting mechanical anisotropy in repaired components.

Mechanical property assessment techniques include hardness testing (micro, macro, and nanoindentation), tensile testing, and fatigue testing. These methods provide quantitative data on the effectiveness of heat treatments in restoring strength, ductility, and fatigue resistance to pre-repair levels. Creep testing is particularly important for high-temperature applications where DED-repaired components must maintain dimensional stability under sustained loading.

Non-destructive evaluation (NDE) techniques such as ultrasonic testing, eddy current inspection, and X-ray computed tomography enable volumetric assessment of heat-treated repairs without damaging components. These methods are invaluable for detecting subsurface defects or discontinuities that might compromise the integrity of repaired structures.

Advanced characterization methods including Atom Probe Tomography (APT) and Synchrotron X-ray techniques provide unprecedented insights into atomic-level distributions and nanoscale features that conventional techniques cannot resolve. These sophisticated approaches help researchers understand fundamental mechanisms of property restoration during post-process heat treatments.

Thermal analysis techniques such as Differential Scanning Calorimetry (DSC) and Thermomechanical Analysis (TMA) enable researchers to study phase transformation temperatures and dimensional changes during heat treatment cycles, facilitating the optimization of heat treatment parameters for specific alloy systems and repair geometries.

Microscopy techniques form the foundation of material characterization in DED-repaired alloys. Optical microscopy enables preliminary assessment of grain structures and visible defects, while Scanning Electron Microscopy (SEM) provides higher resolution imaging of microstructural features. Transmission Electron Microscopy (TEM) offers atomic-level resolution for analyzing precipitates and dislocations that significantly influence alloy properties after heat treatment.

X-ray diffraction (XRD) analysis serves as a powerful tool for identifying crystallographic phases and residual stresses in heat-treated DED repairs. This technique helps quantify phase transformations that occur during various heat treatment regimes and correlates them with mechanical property restoration. Electron Backscatter Diffraction (EBSD) complements XRD by mapping grain orientations and textures, which are critical factors affecting mechanical anisotropy in repaired components.

Mechanical property assessment techniques include hardness testing (micro, macro, and nanoindentation), tensile testing, and fatigue testing. These methods provide quantitative data on the effectiveness of heat treatments in restoring strength, ductility, and fatigue resistance to pre-repair levels. Creep testing is particularly important for high-temperature applications where DED-repaired components must maintain dimensional stability under sustained loading.

Non-destructive evaluation (NDE) techniques such as ultrasonic testing, eddy current inspection, and X-ray computed tomography enable volumetric assessment of heat-treated repairs without damaging components. These methods are invaluable for detecting subsurface defects or discontinuities that might compromise the integrity of repaired structures.

Advanced characterization methods including Atom Probe Tomography (APT) and Synchrotron X-ray techniques provide unprecedented insights into atomic-level distributions and nanoscale features that conventional techniques cannot resolve. These sophisticated approaches help researchers understand fundamental mechanisms of property restoration during post-process heat treatments.

Thermal analysis techniques such as Differential Scanning Calorimetry (DSC) and Thermomechanical Analysis (TMA) enable researchers to study phase transformation temperatures and dimensional changes during heat treatment cycles, facilitating the optimization of heat treatment parameters for specific alloy systems and repair geometries.

Sustainability Aspects of DED Repair Processes

The sustainability of Directed Energy Deposition (DED) repair processes represents a critical dimension in evaluating their overall viability for industrial applications. When considering post-process heat treatments for restoring DED-repaired alloy properties, environmental impact assessment becomes increasingly important in today's eco-conscious manufacturing landscape.

DED repair processes offer significant sustainability advantages compared to traditional component replacement strategies. By extending component life through repair rather than replacement, these processes substantially reduce raw material consumption and associated mining impacts. Studies indicate that DED repairs can achieve material savings of 60-85% compared to manufacturing new components, depending on the extent of damage and repair complexity.

Energy consumption analysis reveals that while DED processes themselves require considerable energy input, the lifecycle energy footprint remains favorable when compared to complete component remanufacturing. Post-process heat treatments add to this energy requirement, but optimization strategies such as batch processing and recovery systems can mitigate these impacts. Recent advancements in induction and laser-based heat treatment technologies have demonstrated energy efficiency improvements of 15-30% over conventional furnace methods.

Waste reduction represents another sustainability benefit of DED repair with appropriate heat treatments. The additive nature of the process minimizes material waste compared to subtractive manufacturing methods. Additionally, proper heat treatment protocols can reduce the likelihood of repair failure, preventing further waste generation through repeated repair attempts or premature component disposal.

Carbon footprint calculations for DED repair processes including post-process heat treatments typically show 40-70% lower emissions compared to new component manufacturing. This advantage becomes particularly significant for high-value aerospace and energy sector components where material extraction and processing account for substantial environmental impacts.

Circular economy principles are well-aligned with DED repair methodologies. The process enables multiple repair cycles throughout a component's extended lifespan, creating closed-loop material utilization patterns. Heat treatments that restore original material properties without degradation are essential to maintaining this circularity across multiple repair cycles.

Regulatory compliance and industry standards increasingly incorporate sustainability metrics into manufacturing process evaluation. Organizations implementing DED repair processes with optimized heat treatments can achieve favorable sustainability certifications, potentially creating market advantages and meeting evolving customer expectations for environmentally responsible manufacturing practices.

DED repair processes offer significant sustainability advantages compared to traditional component replacement strategies. By extending component life through repair rather than replacement, these processes substantially reduce raw material consumption and associated mining impacts. Studies indicate that DED repairs can achieve material savings of 60-85% compared to manufacturing new components, depending on the extent of damage and repair complexity.

Energy consumption analysis reveals that while DED processes themselves require considerable energy input, the lifecycle energy footprint remains favorable when compared to complete component remanufacturing. Post-process heat treatments add to this energy requirement, but optimization strategies such as batch processing and recovery systems can mitigate these impacts. Recent advancements in induction and laser-based heat treatment technologies have demonstrated energy efficiency improvements of 15-30% over conventional furnace methods.

Waste reduction represents another sustainability benefit of DED repair with appropriate heat treatments. The additive nature of the process minimizes material waste compared to subtractive manufacturing methods. Additionally, proper heat treatment protocols can reduce the likelihood of repair failure, preventing further waste generation through repeated repair attempts or premature component disposal.

Carbon footprint calculations for DED repair processes including post-process heat treatments typically show 40-70% lower emissions compared to new component manufacturing. This advantage becomes particularly significant for high-value aerospace and energy sector components where material extraction and processing account for substantial environmental impacts.

Circular economy principles are well-aligned with DED repair methodologies. The process enables multiple repair cycles throughout a component's extended lifespan, creating closed-loop material utilization patterns. Heat treatments that restore original material properties without degradation are essential to maintaining this circularity across multiple repair cycles.

Regulatory compliance and industry standards increasingly incorporate sustainability metrics into manufacturing process evaluation. Organizations implementing DED repair processes with optimized heat treatments can achieve favorable sustainability certifications, potentially creating market advantages and meeting evolving customer expectations for environmentally responsible manufacturing practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!