Interfacial Bond Strength Testing Between Substrate And DED Deposition

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Interfacial Bond Strength Background and Objectives

Directed Energy Deposition (DED) has emerged as a transformative additive manufacturing technology over the past two decades, enabling the fabrication of complex metallic components with enhanced material properties. The interfacial bond strength between the substrate and DED deposition represents a critical parameter that determines the structural integrity and performance reliability of manufactured components. This technical domain has evolved from early experimental approaches in the 1990s to sophisticated multi-physics modeling and advanced characterization techniques in recent years.

The evolution of DED technology has been characterized by significant improvements in process control, material compatibility, and quality assurance methodologies. Initially developed for repair applications in aerospace and defense sectors, DED has expanded into various industries including automotive, medical, and energy production. This expansion has intensified the need for standardized testing protocols to evaluate interfacial bond strength across diverse material combinations and processing conditions.

Current technological trends indicate a shift toward multi-material DED processes, where dissimilar metals are deposited in controlled sequences to achieve gradient properties. This advancement introduces additional complexities in interfacial bonding mechanisms, necessitating more sophisticated testing methodologies that can accurately characterize bond strength across heterogeneous interfaces. The scientific community has responded with innovations in non-destructive evaluation techniques and in-situ monitoring systems.

The primary objective of this technical investigation is to comprehensively assess existing methodologies for testing interfacial bond strength between substrates and DED depositions. This includes evaluating standardized mechanical testing procedures such as tensile, shear, and fatigue testing, as well as emerging techniques like acoustic emission monitoring and digital image correlation. Additionally, we aim to identify correlations between processing parameters, microstructural features, and resultant bond strengths to establish predictive models.

Secondary objectives include mapping the influence of substrate surface preparation techniques on interfacial bond quality, quantifying the effects of thermal cycling during multi-layer deposition on bond integrity, and developing guidelines for optimizing process parameters to enhance interfacial strength. Furthermore, this investigation seeks to establish a framework for real-time quality assurance during DED manufacturing through integration of sensor technologies and machine learning algorithms.

The ultimate goal is to contribute to the development of industry standards for interfacial bond strength testing in DED processes, enabling more reliable qualification of components for critical applications. This standardization would facilitate broader adoption of DED technology across industries and accelerate the certification process for additively manufactured parts in regulated sectors such as aerospace and medical device manufacturing.

The evolution of DED technology has been characterized by significant improvements in process control, material compatibility, and quality assurance methodologies. Initially developed for repair applications in aerospace and defense sectors, DED has expanded into various industries including automotive, medical, and energy production. This expansion has intensified the need for standardized testing protocols to evaluate interfacial bond strength across diverse material combinations and processing conditions.

Current technological trends indicate a shift toward multi-material DED processes, where dissimilar metals are deposited in controlled sequences to achieve gradient properties. This advancement introduces additional complexities in interfacial bonding mechanisms, necessitating more sophisticated testing methodologies that can accurately characterize bond strength across heterogeneous interfaces. The scientific community has responded with innovations in non-destructive evaluation techniques and in-situ monitoring systems.

The primary objective of this technical investigation is to comprehensively assess existing methodologies for testing interfacial bond strength between substrates and DED depositions. This includes evaluating standardized mechanical testing procedures such as tensile, shear, and fatigue testing, as well as emerging techniques like acoustic emission monitoring and digital image correlation. Additionally, we aim to identify correlations between processing parameters, microstructural features, and resultant bond strengths to establish predictive models.

Secondary objectives include mapping the influence of substrate surface preparation techniques on interfacial bond quality, quantifying the effects of thermal cycling during multi-layer deposition on bond integrity, and developing guidelines for optimizing process parameters to enhance interfacial strength. Furthermore, this investigation seeks to establish a framework for real-time quality assurance during DED manufacturing through integration of sensor technologies and machine learning algorithms.

The ultimate goal is to contribute to the development of industry standards for interfacial bond strength testing in DED processes, enabling more reliable qualification of components for critical applications. This standardization would facilitate broader adoption of DED technology across industries and accelerate the certification process for additively manufactured parts in regulated sectors such as aerospace and medical device manufacturing.

Market Analysis for DED Interfacial Bond Testing Solutions

The global market for Directed Energy Deposition (DED) interfacial bond testing solutions is experiencing significant growth, driven by the expanding adoption of additive manufacturing technologies across various industrial sectors. Current market valuations indicate that the DED technology segment within the broader additive manufacturing market is growing at a compound annual rate of approximately 15%, with particular acceleration in aerospace, defense, and medical device manufacturing.

Market demand for reliable bond strength testing solutions stems primarily from industries where component integrity is critical to performance and safety. Aerospace manufacturers represent the largest market segment, accounting for nearly 30% of the total demand, followed by medical device manufacturers at 22% and automotive applications at 18%. This distribution reflects the high-value nature of components produced using DED technology in these sectors.

Regional analysis reveals that North America currently leads the market with the highest concentration of DED technology implementation, particularly in the United States where defense contractors and aerospace manufacturers have made significant investments. Europe follows closely, with Germany, France, and the UK showing strong growth trajectories. The Asia-Pacific region, particularly China and Japan, represents the fastest-growing market segment with increasing industrial adoption of advanced manufacturing technologies.

Customer requirements in this market segment emphasize non-destructive testing capabilities, integration with existing quality control systems, and solutions that can be validated against established industry standards. Survey data from manufacturing engineers indicates that 76% prioritize testing solutions that can be implemented in-line with production processes, rather than requiring separate post-production testing procedures.

Market barriers include the high cost of specialized testing equipment, which typically ranges from $50,000 to $250,000 depending on capabilities and automation levels. Additionally, the lack of universally accepted standards for interfacial bond strength in DED applications creates market fragmentation and slows adoption rates among more conservative industrial sectors.

Emerging opportunities exist in developing portable testing solutions for field applications, particularly for repair and maintenance operations where DED technology is increasingly utilized. The market for such portable systems is projected to grow at twice the rate of laboratory-based systems over the next five years.

Price sensitivity varies significantly by industry segment, with aerospace and medical device manufacturers demonstrating greater willingness to invest in premium testing solutions that offer comprehensive data collection and analysis capabilities, while general industrial applications tend to favor more cost-effective options with focused functionality.

Market demand for reliable bond strength testing solutions stems primarily from industries where component integrity is critical to performance and safety. Aerospace manufacturers represent the largest market segment, accounting for nearly 30% of the total demand, followed by medical device manufacturers at 22% and automotive applications at 18%. This distribution reflects the high-value nature of components produced using DED technology in these sectors.

Regional analysis reveals that North America currently leads the market with the highest concentration of DED technology implementation, particularly in the United States where defense contractors and aerospace manufacturers have made significant investments. Europe follows closely, with Germany, France, and the UK showing strong growth trajectories. The Asia-Pacific region, particularly China and Japan, represents the fastest-growing market segment with increasing industrial adoption of advanced manufacturing technologies.

Customer requirements in this market segment emphasize non-destructive testing capabilities, integration with existing quality control systems, and solutions that can be validated against established industry standards. Survey data from manufacturing engineers indicates that 76% prioritize testing solutions that can be implemented in-line with production processes, rather than requiring separate post-production testing procedures.

Market barriers include the high cost of specialized testing equipment, which typically ranges from $50,000 to $250,000 depending on capabilities and automation levels. Additionally, the lack of universally accepted standards for interfacial bond strength in DED applications creates market fragmentation and slows adoption rates among more conservative industrial sectors.

Emerging opportunities exist in developing portable testing solutions for field applications, particularly for repair and maintenance operations where DED technology is increasingly utilized. The market for such portable systems is projected to grow at twice the rate of laboratory-based systems over the next five years.

Price sensitivity varies significantly by industry segment, with aerospace and medical device manufacturers demonstrating greater willingness to invest in premium testing solutions that offer comprehensive data collection and analysis capabilities, while general industrial applications tend to favor more cost-effective options with focused functionality.

Current Challenges in Substrate-DED Bond Strength Evaluation

Despite significant advancements in Directed Energy Deposition (DED) technology, the evaluation of interfacial bond strength between substrate materials and DED depositions remains one of the most challenging aspects in the field. Current testing methodologies suffer from a lack of standardization, making it difficult to compare results across different research groups and industrial applications. The absence of universally accepted testing protocols creates inconsistencies in reported bond strength values, hindering the broader adoption of DED technology in critical applications.

A fundamental challenge lies in the complex nature of the substrate-deposition interface itself. This region exhibits unique microstructural characteristics that differ significantly from both the substrate and the bulk deposition. The heat-affected zone (HAZ) created during the deposition process introduces metallurgical changes that are difficult to isolate and evaluate independently. Conventional mechanical testing methods often fail to specifically target this interfacial region, instead measuring a combination of properties from the substrate, interface, and deposition.

Sample preparation presents another significant hurdle. The creation of test specimens that accurately represent real-world conditions while maintaining the integrity of the interface requires sophisticated preparation techniques. Current methods often introduce artifacts or damage to the interface during specimen preparation, potentially skewing test results and leading to erroneous conclusions about bond strength.

The multi-parameter nature of the DED process further complicates bond strength evaluation. Process variables such as laser power, scan speed, powder feed rate, and substrate preheating all influence the resulting interfacial bond characteristics. This creates a vast parameter space that is difficult to fully characterize with existing testing approaches. Researchers struggle to establish clear correlations between process parameters and resulting bond strengths due to these complex interdependencies.

Environmental factors during testing also present challenges. Temperature variations, oxidation effects, and residual stress states can significantly impact measured bond strengths. Current testing methodologies often fail to account for these environmental influences, leading to poor reproducibility of results across different testing conditions and facilities.

Non-destructive evaluation (NDE) techniques for bond strength assessment remain limited in their capabilities. While methods such as ultrasonic testing and acoustic emission can provide some insights into interface quality, they typically lack the resolution and specificity needed to quantitatively measure bond strength. This forces researchers to rely heavily on destructive testing methods, which are inherently limited in their ability to support in-process quality control and real-time monitoring applications.

A fundamental challenge lies in the complex nature of the substrate-deposition interface itself. This region exhibits unique microstructural characteristics that differ significantly from both the substrate and the bulk deposition. The heat-affected zone (HAZ) created during the deposition process introduces metallurgical changes that are difficult to isolate and evaluate independently. Conventional mechanical testing methods often fail to specifically target this interfacial region, instead measuring a combination of properties from the substrate, interface, and deposition.

Sample preparation presents another significant hurdle. The creation of test specimens that accurately represent real-world conditions while maintaining the integrity of the interface requires sophisticated preparation techniques. Current methods often introduce artifacts or damage to the interface during specimen preparation, potentially skewing test results and leading to erroneous conclusions about bond strength.

The multi-parameter nature of the DED process further complicates bond strength evaluation. Process variables such as laser power, scan speed, powder feed rate, and substrate preheating all influence the resulting interfacial bond characteristics. This creates a vast parameter space that is difficult to fully characterize with existing testing approaches. Researchers struggle to establish clear correlations between process parameters and resulting bond strengths due to these complex interdependencies.

Environmental factors during testing also present challenges. Temperature variations, oxidation effects, and residual stress states can significantly impact measured bond strengths. Current testing methodologies often fail to account for these environmental influences, leading to poor reproducibility of results across different testing conditions and facilities.

Non-destructive evaluation (NDE) techniques for bond strength assessment remain limited in their capabilities. While methods such as ultrasonic testing and acoustic emission can provide some insights into interface quality, they typically lack the resolution and specificity needed to quantitatively measure bond strength. This forces researchers to rely heavily on destructive testing methods, which are inherently limited in their ability to support in-process quality control and real-time monitoring applications.

Established Testing Methodologies for DED-Substrate Interfaces

01 Mechanical Testing Methods for Interfacial Bond Strength

Various mechanical testing methods are employed to evaluate the interfacial bond strength between different materials. These methods include pull-off tests, shear tests, and tensile tests that apply controlled forces to measure the strength of bonds at interfaces. The testing equipment typically includes load cells, displacement sensors, and specialized fixtures designed to isolate and measure the interfacial bond properties accurately.- Mechanical Testing Methods for Interfacial Bond Strength: Various mechanical testing methods are employed to evaluate the interfacial bond strength between different materials. These methods include pull-off tests, shear tests, and tensile tests that apply controlled forces to measure the strength at which bonded interfaces fail. The testing apparatus typically includes fixtures to hold the test specimens and mechanisms to apply force in a specific direction until bond failure occurs. These methods provide quantitative data on bond strength that can be used for quality control and material development.

- Non-Destructive Testing Techniques for Bond Strength Evaluation: Non-destructive testing techniques allow for the evaluation of interfacial bond strength without damaging the specimen. These methods include ultrasonic testing, acoustic emission analysis, and thermal imaging that can detect defects or weaknesses in bonded interfaces. By analyzing wave propagation, sound emissions, or thermal patterns, these techniques can identify areas of poor adhesion or potential failure points. Non-destructive methods are particularly valuable for testing critical components where preservation of the specimen is necessary.

- Specialized Equipment for Bond Strength Measurement: Specialized equipment has been developed specifically for measuring interfacial bond strength in various applications. These include automated bond testers, micro-indentation devices, and custom fixtures designed for specific material combinations or geometries. The equipment often incorporates precision load cells, displacement sensors, and computerized data acquisition systems to ensure accurate and repeatable measurements. Advanced systems may also include environmental chambers to test bond strength under different temperature and humidity conditions.

- Material-Specific Bond Strength Testing Protocols: Different materials and applications require specific testing protocols to accurately assess interfacial bond strength. These protocols define specimen preparation, testing parameters, and data analysis methods tailored to particular material combinations such as metal-ceramic interfaces, polymer-substrate bonds, or composite material layers. The protocols often specify surface preparation techniques, curing conditions, and aging procedures to simulate real-world conditions. Standardized testing methods ensure consistency and comparability of results across different laboratories and research institutions.

- Data Analysis and Interpretation for Bond Strength Testing: Advanced data analysis methods are essential for interpreting bond strength test results and extracting meaningful information. These methods include statistical analysis techniques, failure mode classification, and correlation with microstructural features. Computer modeling and simulation may be used to predict bond behavior under various conditions. The analysis often involves identifying the type of failure (adhesive, cohesive, or mixed) and relating test results to actual performance in service conditions. This information helps in optimizing bonding processes and improving material compatibility.

02 Non-Destructive Testing Techniques for Bond Strength Evaluation

Non-destructive testing techniques provide ways to evaluate interfacial bond strength without damaging the specimen. These methods include ultrasonic testing, acoustic emission analysis, and thermal imaging that can detect defects, delamination, or weak bonding at interfaces. These techniques are particularly valuable for in-situ monitoring of bond integrity in composite materials, coatings, and adhesive joints.Expand Specific Solutions03 Specialized Equipment for Bond Strength Measurement

Specialized equipment has been developed specifically for measuring interfacial bond strength in various applications. These include automated bond testers, micro-indentation devices, and scratch testers that can provide quantitative measurements of adhesion strength. The equipment often incorporates precision control systems, data acquisition capabilities, and analysis software to ensure accurate and reproducible results.Expand Specific Solutions04 Sample Preparation Methods for Bond Strength Testing

Proper sample preparation is crucial for accurate bond strength testing. Techniques include surface cleaning and treatment, controlled application of adhesives or coatings, and specimen conditioning to ensure representative testing conditions. Standardized sample geometries and preparation protocols have been developed to enable consistent and comparable measurements across different testing laboratories.Expand Specific Solutions05 Data Analysis and Interpretation for Bond Strength Tests

Advanced data analysis methods are essential for interpreting bond strength test results. These include statistical analysis techniques, failure mode classification, and correlation of test data with material properties. Computational models and simulation tools can also be used to predict interfacial behavior and validate experimental results, providing deeper insights into the mechanisms of interfacial bonding and failure.Expand Specific Solutions

Leading Organizations in DED Bond Strength Testing Research

The interfacial bond strength testing between substrate and DED deposition market is in an early growth phase, characterized by increasing research activity and emerging commercial applications. The market size is expanding as additive manufacturing adoption grows across aerospace, automotive, and industrial sectors. From a technical maturity perspective, the landscape shows varying degrees of advancement. Research institutions like Jiangsu University, Tsinghua University, and MIT are establishing fundamental testing methodologies, while companies including Boeing, Applied Materials, and Bruker Nano are developing specialized equipment and standardized testing protocols. The competitive environment features collaboration between academic institutions and industry leaders, with aerospace companies and materials testing specialists driving innovation in this critical quality assurance domain.

The Boeing Co.

Technical Solution: Boeing has developed a comprehensive interfacial bond strength testing methodology specifically for DED (Directed Energy Deposition) applications in aerospace components. Their approach combines traditional mechanical testing with advanced non-destructive evaluation techniques. Boeing's system utilizes customized tensile and shear testing fixtures designed to isolate the substrate-deposition interface, complemented by acoustic emission monitoring during testing to detect micro-failures before complete separation. They've implemented a standardized testing protocol that includes pre-test thermal cycling to simulate service conditions and correlates mechanical test results with microstructural analysis. Boeing has also pioneered the use of digital image correlation during mechanical testing to map strain distribution across the interface region, providing insights into failure initiation mechanisms[1]. Their methodology has been validated across multiple titanium and nickel-based superalloy systems commonly used in aerospace applications.

Strengths: Comprehensive testing methodology validated on aerospace-grade materials with excellent correlation between test results and in-service performance. Integration of multiple testing modalities provides robust characterization. Weaknesses: Testing protocols are highly specialized for aerospace materials and may require significant adaptation for other industries. The complex testing setup requires specialized equipment and expertise.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed a comprehensive interfacial bond strength testing methodology for DED applications in semiconductor and advanced manufacturing industries. Their approach integrates automated mechanical testing with in-line process monitoring to provide real-time quality control for DED processes. Applied Materials' system employs specialized fixtures for tensile, shear, and fatigue testing that are designed to isolate the substrate-deposition interface while minimizing sample preparation requirements. A key innovation in their methodology is the implementation of high-throughput testing capabilities that enable statistical analysis of bond strength variability across large production volumes[4]. Their testing protocol incorporates environmental conditioning that simulates actual service conditions, including thermal cycling and humidity exposure. Applied Materials has also developed proprietary algorithms that correlate interfacial bond strength with process parameters, enabling closed-loop process control for optimizing DED deposition quality. Their system includes automated defect classification based on fracture surface analysis, providing insights into failure mechanisms and guiding process improvements.

Strengths: Highly automated and production-oriented approach enables high-throughput testing suitable for industrial applications. Integrated process monitoring and control capabilities provide immediate feedback for process optimization. Weaknesses: System is optimized for semiconductor and electronics applications and may require adaptation for other industries. Significant capital investment required for full implementation of the automated testing infrastructure.

Critical Patents and Literature on Interfacial Bond Strength

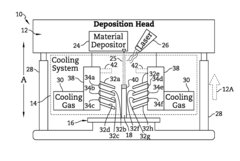

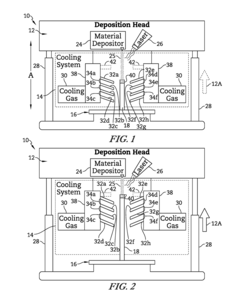

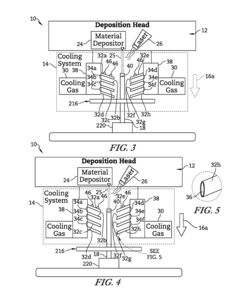

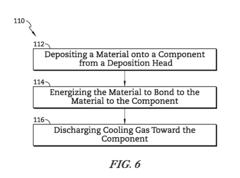

Directed energy deposition with cooling mechanism

PatentActiveUS9988718B2

Innovation

- A material deposition system comprising a platform, a deposition head with a material depositor and an energy source, and a cooling mechanism with conductive bristles that direct a cooling medium to maintain a controlled temperature profile, ensuring consistent cooling and bonding of materials during the deposition process.

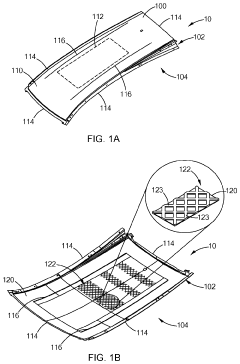

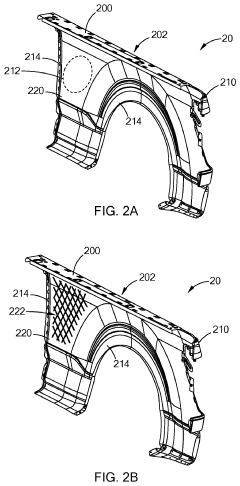

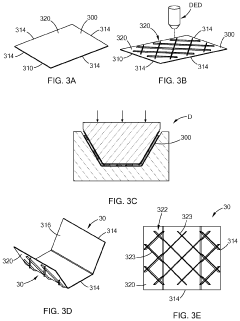

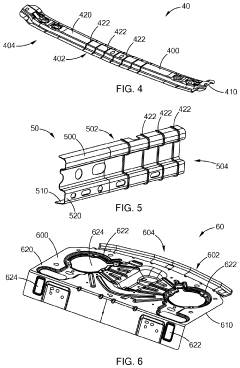

Directed energy deposition (DED) reinforcements on body structures and visible sheet metal surfaces

PatentInactiveUS20220371091A1

Innovation

- The use of additively manufactured reinforcements, deposited via directed energy deposition, metallurgically bonded to sheet metal components, either before or after shaping, to provide enhanced structural support and inhibit deformation.

Standards and Certification Requirements for DED Bond Testing

The standardization landscape for Directed Energy Deposition (DED) bond strength testing remains fragmented, with several organizations working to establish comprehensive frameworks. ASTM International has developed standards such as ASTM F3122 for mechanical testing of metal additive manufactured materials, which includes some provisions applicable to DED bond interfaces. Similarly, ISO/ASTM 52901 addresses requirements for purchased AM parts, including bond integrity specifications.

The American Welding Society (AWS) has contributed significantly through standards like AWS D20.1, which outlines examination methods for metal additive manufactured components. These standards incorporate testing methodologies such as tensile testing, shear testing, and bend testing that can be adapted for DED bond evaluation. However, they often lack specificity for the unique challenges presented by substrate-deposition interfaces.

National standards bodies have also developed region-specific requirements. The National Institute of Standards and Technology (NIST) in the United States has published measurement science guidelines for metal-based additive manufacturing that include bond strength considerations. In Europe, the European Committee for Standardization (CEN) has established technical specifications through documents like CEN/TS 17296, which addresses industrial additive manufacturing qualification.

Certification requirements typically mandate a combination of destructive and non-destructive testing methods. Tensile testing according to ASTM E8/E8M remains the most widely accepted destructive test for bond strength qualification. For critical applications, additional requirements often include fatigue testing (ASTM E466), fracture toughness assessment (ASTM E1820), and microstructural analysis of the interface region.

Non-destructive evaluation requirements typically include ultrasonic testing per ASTM E2580, which has been adapted specifically for additive manufacturing. X-ray computed tomography following ASTM E1570 guidelines is increasingly mandated for high-value components to detect interfacial defects before deployment.

Industry-specific certification frameworks impose additional requirements. Aerospace applications follow guidelines established in SAE AMS7003 for process control and AMS7013 for material property verification. Medical device manufacturers must adhere to FDA guidance documents that incorporate bond integrity testing as part of the validation process.

The certification landscape is evolving rapidly, with organizations like America Makes and the Additive Manufacturing Consortium working to develop standardized test methods specifically designed for DED interfaces. These emerging standards aim to address the unique challenges of evaluating bond strength in components with complex geometries and material gradients characteristic of DED processes.

The American Welding Society (AWS) has contributed significantly through standards like AWS D20.1, which outlines examination methods for metal additive manufactured components. These standards incorporate testing methodologies such as tensile testing, shear testing, and bend testing that can be adapted for DED bond evaluation. However, they often lack specificity for the unique challenges presented by substrate-deposition interfaces.

National standards bodies have also developed region-specific requirements. The National Institute of Standards and Technology (NIST) in the United States has published measurement science guidelines for metal-based additive manufacturing that include bond strength considerations. In Europe, the European Committee for Standardization (CEN) has established technical specifications through documents like CEN/TS 17296, which addresses industrial additive manufacturing qualification.

Certification requirements typically mandate a combination of destructive and non-destructive testing methods. Tensile testing according to ASTM E8/E8M remains the most widely accepted destructive test for bond strength qualification. For critical applications, additional requirements often include fatigue testing (ASTM E466), fracture toughness assessment (ASTM E1820), and microstructural analysis of the interface region.

Non-destructive evaluation requirements typically include ultrasonic testing per ASTM E2580, which has been adapted specifically for additive manufacturing. X-ray computed tomography following ASTM E1570 guidelines is increasingly mandated for high-value components to detect interfacial defects before deployment.

Industry-specific certification frameworks impose additional requirements. Aerospace applications follow guidelines established in SAE AMS7003 for process control and AMS7013 for material property verification. Medical device manufacturers must adhere to FDA guidance documents that incorporate bond integrity testing as part of the validation process.

The certification landscape is evolving rapidly, with organizations like America Makes and the Additive Manufacturing Consortium working to develop standardized test methods specifically designed for DED interfaces. These emerging standards aim to address the unique challenges of evaluating bond strength in components with complex geometries and material gradients characteristic of DED processes.

Material Compatibility Factors Affecting Interfacial Bond Quality

The compatibility between substrate and deposited material is a critical factor determining the quality of interfacial bonding in Directed Energy Deposition (DED) processes. Material composition similarity plays a fundamental role, with closer atomic structures and chemical compositions generally yielding stronger metallurgical bonds. When substrate and deposition materials have similar crystal structures and lattice parameters, the atomic arrangement at the interface can achieve greater coherence, minimizing strain and promoting stronger bonding.

Thermal expansion coefficient matching represents another crucial compatibility factor. Significant differences in thermal expansion behavior between substrate and deposited material can generate substantial residual stresses during cooling cycles, potentially leading to delamination, cracking, or premature bond failure. These thermal mismatches create shear stresses at the interface that directly compromise bond integrity, particularly in applications involving thermal cycling.

Chemical affinity between materials significantly influences interfacial reactions. Materials with higher chemical reactivity toward each other tend to form stronger metallurgical bonds through the development of intermediate phases or solid solutions at the interface. However, excessive reactivity can lead to the formation of brittle intermetallic compounds that may compromise mechanical properties. The formation of these compounds depends on processing parameters, particularly temperature and cooling rates during deposition.

Elemental diffusion characteristics across the interface region determine bond development mechanisms. Materials with compatible diffusion coefficients facilitate controlled interdiffusion, creating a gradual transition zone rather than an abrupt interface. This transition zone, often characterized by concentration gradients of alloying elements, can enhance mechanical interlocking and metallurgical bonding. The width and composition of this diffusion zone significantly impact bond strength and durability.

Surface energy compatibility between materials affects wetting behavior during the molten phase of deposition. Better wetting promotes intimate contact between the deposited material and substrate, reducing the likelihood of void formation and enhancing bond quality. Surface roughness of the substrate further influences mechanical interlocking mechanisms, with optimized roughness profiles providing additional anchoring points for the deposited material without introducing stress concentrations.

Oxidation behavior compatibility must also be considered, as differential oxidation rates can lead to oxide layer formation that impedes direct metal-to-metal bonding. Materials with similar oxidation resistance characteristics typically demonstrate more predictable interfacial behavior, particularly in high-temperature applications or when processing occurs in non-inert environments.

Thermal expansion coefficient matching represents another crucial compatibility factor. Significant differences in thermal expansion behavior between substrate and deposited material can generate substantial residual stresses during cooling cycles, potentially leading to delamination, cracking, or premature bond failure. These thermal mismatches create shear stresses at the interface that directly compromise bond integrity, particularly in applications involving thermal cycling.

Chemical affinity between materials significantly influences interfacial reactions. Materials with higher chemical reactivity toward each other tend to form stronger metallurgical bonds through the development of intermediate phases or solid solutions at the interface. However, excessive reactivity can lead to the formation of brittle intermetallic compounds that may compromise mechanical properties. The formation of these compounds depends on processing parameters, particularly temperature and cooling rates during deposition.

Elemental diffusion characteristics across the interface region determine bond development mechanisms. Materials with compatible diffusion coefficients facilitate controlled interdiffusion, creating a gradual transition zone rather than an abrupt interface. This transition zone, often characterized by concentration gradients of alloying elements, can enhance mechanical interlocking and metallurgical bonding. The width and composition of this diffusion zone significantly impact bond strength and durability.

Surface energy compatibility between materials affects wetting behavior during the molten phase of deposition. Better wetting promotes intimate contact between the deposited material and substrate, reducing the likelihood of void formation and enhancing bond quality. Surface roughness of the substrate further influences mechanical interlocking mechanisms, with optimized roughness profiles providing additional anchoring points for the deposited material without introducing stress concentrations.

Oxidation behavior compatibility must also be considered, as differential oxidation rates can lead to oxide layer formation that impedes direct metal-to-metal bonding. Materials with similar oxidation resistance characteristics typically demonstrate more predictable interfacial behavior, particularly in high-temperature applications or when processing occurs in non-inert environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!