DED Process Parameter Mapping For Duplex Stainless Steel Repairs

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Background and Repair Objectives

Directed Energy Deposition (DED) technology has evolved significantly over the past three decades, transitioning from experimental applications to a commercially viable additive manufacturing process. Initially developed in the 1990s as a laser cladding technique, DED has expanded to encompass various energy sources including electron beams, plasma arcs, and high-powered lasers. This evolution has been driven by increasing demands for efficient repair solutions in high-value industries such as aerospace, defense, and energy production.

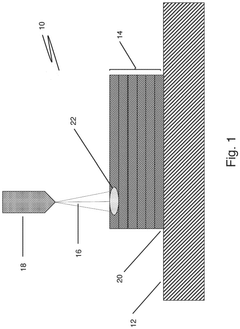

The fundamental principle of DED involves the simultaneous deposition of material (typically metal powder or wire) and focused energy to create a melt pool that solidifies into a dense metallic structure. This layer-by-layer approach allows for precise material addition to existing components, making it particularly suitable for repair applications where traditional manufacturing methods fall short.

Duplex stainless steels (DSS) represent a significant material class in industrial applications due to their exceptional combination of strength and corrosion resistance. These alloys, characterized by their dual-phase microstructure of austenite and ferrite, are extensively used in marine environments, chemical processing equipment, and oil and gas infrastructure. However, the repair of DSS components presents unique challenges due to the necessity of maintaining phase balance and preventing detrimental intermetallic precipitates during thermal processing.

The primary objective of DED parameter mapping for DSS repairs is to establish a comprehensive understanding of the process-structure-property relationships specific to these alloys. This includes identifying optimal combinations of laser power, travel speed, powder feed rate, and thermal management strategies that preserve the critical microstructural features of DSS while ensuring mechanical integrity of the repaired components.

Secondary objectives include developing standardized repair protocols that can be implemented across various industrial sectors, reducing the lead time for component restoration, and minimizing the need for complete replacement of expensive DSS parts. The economic implications are substantial, with potential savings in the range of 40-60% compared to component replacement costs.

From an environmental perspective, successful implementation of DSS repair technologies aligns with sustainable manufacturing principles by extending component lifecycles and reducing material waste. This aspect has gained increasing importance as industries face stricter environmental regulations and corporate sustainability targets.

The technological trajectory suggests that future developments will focus on in-situ monitoring systems, adaptive control algorithms, and hybrid manufacturing approaches that combine DED with conventional machining processes to achieve near-net-shape repairs with minimal post-processing requirements.

The fundamental principle of DED involves the simultaneous deposition of material (typically metal powder or wire) and focused energy to create a melt pool that solidifies into a dense metallic structure. This layer-by-layer approach allows for precise material addition to existing components, making it particularly suitable for repair applications where traditional manufacturing methods fall short.

Duplex stainless steels (DSS) represent a significant material class in industrial applications due to their exceptional combination of strength and corrosion resistance. These alloys, characterized by their dual-phase microstructure of austenite and ferrite, are extensively used in marine environments, chemical processing equipment, and oil and gas infrastructure. However, the repair of DSS components presents unique challenges due to the necessity of maintaining phase balance and preventing detrimental intermetallic precipitates during thermal processing.

The primary objective of DED parameter mapping for DSS repairs is to establish a comprehensive understanding of the process-structure-property relationships specific to these alloys. This includes identifying optimal combinations of laser power, travel speed, powder feed rate, and thermal management strategies that preserve the critical microstructural features of DSS while ensuring mechanical integrity of the repaired components.

Secondary objectives include developing standardized repair protocols that can be implemented across various industrial sectors, reducing the lead time for component restoration, and minimizing the need for complete replacement of expensive DSS parts. The economic implications are substantial, with potential savings in the range of 40-60% compared to component replacement costs.

From an environmental perspective, successful implementation of DSS repair technologies aligns with sustainable manufacturing principles by extending component lifecycles and reducing material waste. This aspect has gained increasing importance as industries face stricter environmental regulations and corporate sustainability targets.

The technological trajectory suggests that future developments will focus on in-situ monitoring systems, adaptive control algorithms, and hybrid manufacturing approaches that combine DED with conventional machining processes to achieve near-net-shape repairs with minimal post-processing requirements.

Market Analysis for Duplex Stainless Steel Repair Solutions

The global market for duplex stainless steel repair solutions is experiencing significant growth, driven by the increasing use of these materials in critical infrastructure and industrial applications. The current market size for duplex stainless steel repair technologies is estimated at $2.3 billion, with a projected annual growth rate of 6.8% through 2028. This growth trajectory is primarily fueled by aging infrastructure in developed economies and rapid industrialization in emerging markets.

Oil and gas remains the dominant sector for duplex stainless steel applications, accounting for approximately 38% of the repair solutions market. This is followed by chemical processing (22%), marine applications (17%), power generation (12%), and other industries (11%). The demand for advanced repair technologies like Directed Energy Deposition (DED) is particularly strong in regions with extensive offshore operations, including the North Sea, Gulf of Mexico, and Southeast Asian waters.

Market research indicates that end-users are increasingly prioritizing repair solutions that minimize downtime and extend asset life cycles. A survey of maintenance engineers across industries revealed that 73% consider repair speed and durability as the most critical factors when selecting repair methodologies. This trend strongly favors advanced technologies like DED parameter mapping, which can optimize repair quality while reducing implementation time.

The competitive landscape for duplex stainless steel repair solutions is moderately fragmented, with specialized service providers holding approximately 45% market share, followed by OEM repair services (30%) and in-house maintenance departments (25%). Regional analysis shows North America leading with 34% market share, followed by Europe (28%), Asia-Pacific (26%), and rest of the world (12%).

Customer pain points identified through market research include inconsistent repair quality (cited by 68% of respondents), high costs associated with equipment downtime (62%), and limited availability of specialized repair services in remote locations (57%). These challenges present significant opportunities for technologies that can standardize repair processes through parameter mapping.

Price sensitivity varies significantly by application, with critical safety components showing low price elasticity compared to non-critical applications. The average cost premium that customers are willing to pay for guaranteed high-quality repairs is approximately 35% above standard repair methods, highlighting the value proposition for advanced parameter mapping technologies.

Future market growth is expected to be driven by increasing regulatory requirements for asset integrity, particularly in environmentally sensitive operations. Additionally, the trend toward predictive maintenance and digital twin technologies is creating new opportunities for integrated repair solutions that incorporate parameter mapping data into broader asset management systems.

Oil and gas remains the dominant sector for duplex stainless steel applications, accounting for approximately 38% of the repair solutions market. This is followed by chemical processing (22%), marine applications (17%), power generation (12%), and other industries (11%). The demand for advanced repair technologies like Directed Energy Deposition (DED) is particularly strong in regions with extensive offshore operations, including the North Sea, Gulf of Mexico, and Southeast Asian waters.

Market research indicates that end-users are increasingly prioritizing repair solutions that minimize downtime and extend asset life cycles. A survey of maintenance engineers across industries revealed that 73% consider repair speed and durability as the most critical factors when selecting repair methodologies. This trend strongly favors advanced technologies like DED parameter mapping, which can optimize repair quality while reducing implementation time.

The competitive landscape for duplex stainless steel repair solutions is moderately fragmented, with specialized service providers holding approximately 45% market share, followed by OEM repair services (30%) and in-house maintenance departments (25%). Regional analysis shows North America leading with 34% market share, followed by Europe (28%), Asia-Pacific (26%), and rest of the world (12%).

Customer pain points identified through market research include inconsistent repair quality (cited by 68% of respondents), high costs associated with equipment downtime (62%), and limited availability of specialized repair services in remote locations (57%). These challenges present significant opportunities for technologies that can standardize repair processes through parameter mapping.

Price sensitivity varies significantly by application, with critical safety components showing low price elasticity compared to non-critical applications. The average cost premium that customers are willing to pay for guaranteed high-quality repairs is approximately 35% above standard repair methods, highlighting the value proposition for advanced parameter mapping technologies.

Future market growth is expected to be driven by increasing regulatory requirements for asset integrity, particularly in environmentally sensitive operations. Additionally, the trend toward predictive maintenance and digital twin technologies is creating new opportunities for integrated repair solutions that incorporate parameter mapping data into broader asset management systems.

Current DED Process Challenges for Duplex Stainless Steel

Directed Energy Deposition (DED) processes for duplex stainless steel repairs face several significant challenges that limit their widespread industrial adoption. The complex microstructure of duplex stainless steel, consisting of approximately equal proportions of austenite and ferrite phases, requires precise control of thermal cycles to maintain the desired phase balance. Current DED processes struggle to consistently achieve the optimal 50:50 phase ratio, often resulting in excessive ferrite formation that compromises corrosion resistance and mechanical properties.

Thermal management represents a critical challenge in DED processing of duplex stainless steels. The rapid heating and cooling cycles inherent to additive manufacturing processes create steep thermal gradients that can lead to undesirable microstructural transformations. The cooling rates typically experienced in DED processes (10³-10⁶ K/s) often exceed the optimal range for duplex stainless steels, resulting in ferrite-dominated structures with reduced toughness and corrosion resistance.

Parameter optimization remains largely empirical, with limited predictive capabilities for duplex stainless steel repairs. The interdependence of process parameters such as laser power, scan speed, powder feed rate, and layer thickness creates a vast parameter space that is difficult to navigate systematically. Current process mapping approaches lack the sophistication to account for the unique metallurgical requirements of duplex stainless steels, particularly in repair scenarios where substrate conditions vary significantly.

Residual stress development presents another substantial challenge. The thermal cycling during DED processing induces significant residual stresses that can lead to distortion, cracking, and premature failure of repaired components. For duplex stainless steel repairs, these stresses are particularly problematic as they can trigger stress-induced phase transformations that further compromise material properties.

Interpass temperature control, critical for maintaining phase balance in multi-layer deposits, remains difficult to implement effectively in current DED systems. Most commercial systems lack the integrated thermal monitoring and feedback control necessary to maintain optimal thermal conditions throughout the build process, resulting in inconsistent microstructures across the deposited material.

Post-processing requirements further complicate the implementation of DED repairs for duplex stainless steels. Current processes often necessitate heat treatment to restore phase balance and relieve residual stresses, adding complexity and cost to repair operations. The development of in-process solutions that minimize or eliminate these post-processing steps represents a significant technological gap in current DED capabilities.

Thermal management represents a critical challenge in DED processing of duplex stainless steels. The rapid heating and cooling cycles inherent to additive manufacturing processes create steep thermal gradients that can lead to undesirable microstructural transformations. The cooling rates typically experienced in DED processes (10³-10⁶ K/s) often exceed the optimal range for duplex stainless steels, resulting in ferrite-dominated structures with reduced toughness and corrosion resistance.

Parameter optimization remains largely empirical, with limited predictive capabilities for duplex stainless steel repairs. The interdependence of process parameters such as laser power, scan speed, powder feed rate, and layer thickness creates a vast parameter space that is difficult to navigate systematically. Current process mapping approaches lack the sophistication to account for the unique metallurgical requirements of duplex stainless steels, particularly in repair scenarios where substrate conditions vary significantly.

Residual stress development presents another substantial challenge. The thermal cycling during DED processing induces significant residual stresses that can lead to distortion, cracking, and premature failure of repaired components. For duplex stainless steel repairs, these stresses are particularly problematic as they can trigger stress-induced phase transformations that further compromise material properties.

Interpass temperature control, critical for maintaining phase balance in multi-layer deposits, remains difficult to implement effectively in current DED systems. Most commercial systems lack the integrated thermal monitoring and feedback control necessary to maintain optimal thermal conditions throughout the build process, resulting in inconsistent microstructures across the deposited material.

Post-processing requirements further complicate the implementation of DED repairs for duplex stainless steels. Current processes often necessitate heat treatment to restore phase balance and relieve residual stresses, adding complexity and cost to repair operations. The development of in-process solutions that minimize or eliminate these post-processing steps represents a significant technological gap in current DED capabilities.

Current Parameter Mapping Methodologies for DED Repairs

01 Process parameter optimization for DED

Directed Energy Deposition (DED) processes require careful optimization of parameters such as laser power, powder feed rate, and scanning speed to achieve desired material properties. Advanced algorithms and computational methods are used to map the relationship between these parameters and the resulting material characteristics. This optimization helps in achieving consistent quality, reducing defects, and enhancing the mechanical properties of the fabricated components.- Process parameter optimization for DED: Directed Energy Deposition (DED) processes require careful optimization of parameters to achieve desired material properties and build quality. This involves mapping relationships between process parameters (laser power, feed rate, scan speed) and resulting material characteristics. Advanced algorithms and machine learning techniques can be used to create parameter maps that guide optimal settings for different materials and geometries, ensuring consistent quality and reducing defects in the final parts.

- Real-time monitoring and control systems: Real-time monitoring systems are essential for DED processes to track parameter variations during fabrication. These systems collect data from sensors that measure thermal conditions, melt pool characteristics, and deposition rates. The collected data is mapped against process parameters to enable closed-loop control systems that can make automatic adjustments during the build process, maintaining optimal conditions and ensuring consistent part quality even when environmental or material conditions change.

- Digital twin and simulation frameworks: Digital twin technology creates virtual representations of DED processes to predict outcomes before physical fabrication. These simulation frameworks map process parameters to expected results through physics-based models and empirical data. By simulating various parameter combinations, manufacturers can identify optimal processing windows without extensive physical testing, reducing development time and material waste while improving first-time-right manufacturing capabilities.

- Material-specific parameter mapping: Different materials require specific parameter sets for successful DED processing. Material-specific parameter mapping involves creating databases that correlate material properties with optimal process parameters. These maps consider factors such as thermal conductivity, melting point, and powder characteristics to establish processing windows for various alloys and composites. This approach enables rapid process development when working with new or custom materials and facilitates parameter transfer between different DED systems.

- Data analytics and machine learning for parameter prediction: Advanced data analytics and machine learning techniques are increasingly used to process large datasets from DED operations. These methods identify patterns and correlations between process parameters and build outcomes that might not be apparent through traditional analysis. By training models on historical process data, AI systems can predict optimal parameter settings for new geometries or materials, continuously improving as more data becomes available and reducing the need for extensive experimental parameter development.

02 Real-time monitoring and control systems

Real-time monitoring systems are implemented in DED processes to track critical parameters during fabrication. These systems use sensors and imaging technologies to collect data on melt pool characteristics, thermal gradients, and deposition rates. The collected data is mapped to process parameters, enabling closed-loop control systems that can make adjustments during the build process to maintain quality and consistency.Expand Specific Solutions03 Machine learning approaches for parameter mapping

Machine learning algorithms are increasingly used to develop sophisticated parameter mapping models for DED processes. These approaches analyze large datasets of process parameters and corresponding outcomes to identify patterns and correlations that might not be apparent through traditional analysis. Neural networks and other AI techniques help predict optimal parameter combinations for specific material properties and geometrical features, reducing the need for extensive experimental trials.Expand Specific Solutions04 Multi-parameter correlation and visualization techniques

Advanced visualization and correlation techniques are employed to understand the complex relationships between multiple DED process parameters. These techniques create multi-dimensional parameter maps that illustrate how combinations of variables affect build quality. Interactive visualization tools allow engineers to explore parameter spaces efficiently, identifying optimal processing windows and understanding the sensitivity of outcomes to parameter variations.Expand Specific Solutions05 Material-specific parameter mapping strategies

Different materials require specific parameter mapping strategies in DED processes due to their unique thermal, physical, and chemical properties. Research focuses on developing material-specific parameter maps that account for these differences, enabling the successful processing of challenging materials like superalloys, refractory metals, and composites. These specialized mapping approaches consider factors such as thermal conductivity, melting point, and oxidation behavior to optimize the deposition process for each material system.Expand Specific Solutions

Leading Companies in DED Repair Technology

The DED (Directed Energy Deposition) process parameter mapping for duplex stainless steel repairs is in an emerging growth phase, with the global market for metal additive manufacturing expected to reach $10-15 billion by 2030. The technology is advancing from experimental to commercial application, with varying maturity levels across key players. Companies like NIPPON STEEL, Outokumpu Stainless, and Alleima Tube demonstrate advanced capabilities in stainless steel production, while research institutions such as Central South University and South China University of Technology are driving innovation. Military and aerospace entities including RTX Corp. and Norsk Titanium are accelerating adoption for critical repair applications, creating a competitive landscape where material expertise and process control differentiate market leaders.

Sandvik Intellectual Property AB

Technical Solution: Sandvik has developed an advanced DED (Directed Energy Deposition) process parameter mapping system specifically for duplex stainless steel repairs. Their approach utilizes a comprehensive matrix of process variables including laser power (ranging from 400-2000W), powder feed rate (2-15 g/min), and scanning speed (5-30 mm/s) to optimize microstructural balance between austenite and ferrite phases. The company employs in-situ monitoring with thermal imaging cameras that capture real-time temperature gradients during deposition, allowing for closed-loop control of the process parameters. Their proprietary algorithm adjusts nitrogen content in the shielding gas (between 2-10%) based on thermal history to maintain the critical phase balance required for duplex stainless steels. Post-processing heat treatment protocols have been standardized at 1050-1150°C with controlled cooling rates to ensure optimal corrosion resistance while maintaining mechanical properties.

Strengths: Proprietary algorithms for real-time parameter adjustment provide exceptional phase balance control. Their extensive materials database allows for tailored solutions across various duplex grades. Weaknesses: System requires significant initial calibration for each specific component geometry, and the high-precision equipment demands substantial capital investment compared to conventional repair methods.

Outokumpu Stainless AB

Technical Solution: Outokumpu has pioneered a DED parameter mapping technology specifically designed for repairing duplex stainless steel components used in harsh environments. Their system employs a dual-laser approach with variable power distribution (400-1800W) that creates controlled thermal gradients to achieve optimal ferrite-austenite ratios (typically targeting 45-55% ferrite). The company's process incorporates real-time spectroscopic analysis of the melt pool to monitor elemental composition, particularly nitrogen and chromium levels which are critical for maintaining corrosion resistance. Their parameter mapping includes a proprietary "cooling rate control" technology that modulates laser power during cool-down to prevent detrimental intermetallic phase formation. The process parameters are mapped across a 3D space considering material thickness, geometry complexity, and service environment of the component, with specialized settings for components exposed to chloride-containing environments where pitting resistance is paramount.

Strengths: Exceptional control over microstructural development with proven success in maintaining PREN (Pitting Resistance Equivalent Number) values comparable to base material. Their parameter maps include specific adjustments for various duplex grades (2205, 2507, etc.). Weaknesses: Process requires specialized powder compositions with tight particle size distribution, increasing material costs, and the technology has shown limitations when repairing components with complex geometries requiring multi-directional builds.

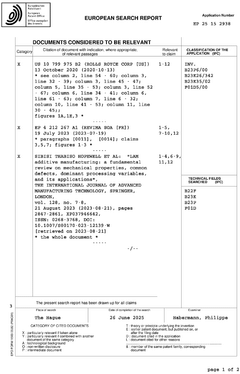

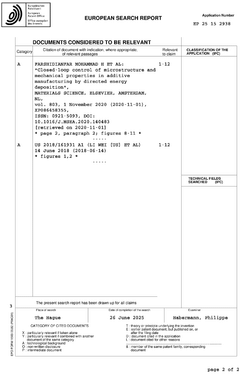

Critical Process Parameters and Metallurgical Considerations

Engineered microstructure for enhanced performance during directed energy deposition repair process

PatentPendingEP4599977A1

Innovation

- A directed energy deposition (DED) process is used to create layers with controlled microstructures by adjusting parameters like powder feed rate, energy intensity, traversal rate, and auxiliary heating/cooling to form repair layers with predetermined properties, enabling repair of components that were previously unrepairable.

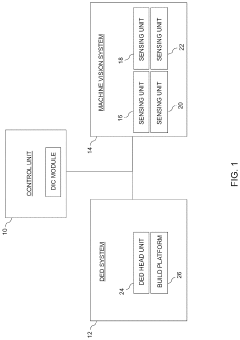

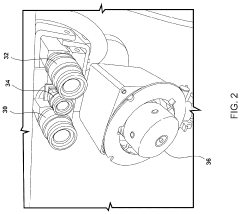

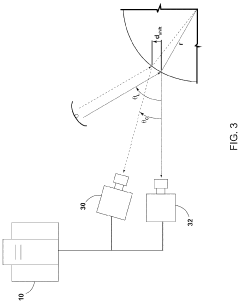

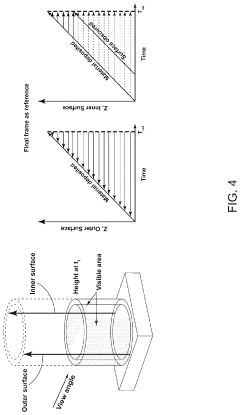

In-situ digital image correlation and thermal monitoring in directed energy deposition

PatentActiveUS11890808B2

Innovation

- A method and system for digital image correlation and thermal monitoring using global off-axis 3D mapping with natural surface roughness, infrared thermography, and a machine vision system comprising stereo imaging cameras and an infrared camera, allowing for strain and temperature data acquisition without a speckle pattern and enabling synthetic reference frames for inner surface features.

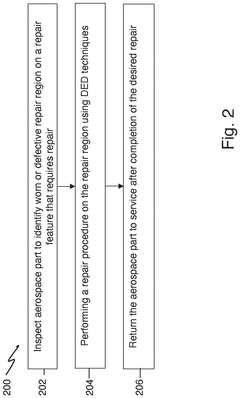

Material Characterization and Quality Assurance Methods

Material characterization for Directed Energy Deposition (DED) repaired duplex stainless steel components requires comprehensive testing protocols to ensure structural integrity and performance. Microstructural analysis using optical microscopy, Scanning Electron Microscopy (SEM), and Electron Backscatter Diffraction (EBSD) provides critical insights into phase balance between ferrite and austenite, which significantly impacts mechanical properties and corrosion resistance. The optimal phase ratio typically ranges between 40-60% ferrite, with deviations potentially compromising material performance.

X-ray diffraction (XRD) techniques enable quantitative phase analysis and residual stress measurements, essential for understanding repair quality. Energy Dispersive X-ray Spectroscopy (EDS) mapping helps identify elemental segregation at interfaces between the substrate and deposited material, a common concern in DED repairs of duplex stainless steels.

Mechanical property verification through hardness mapping, tensile testing, and impact testing ensures repaired sections meet or exceed base material specifications. Particular attention must be paid to the heat-affected zone (HAZ), where thermal cycling can lead to embrittlement or strength reduction. Micro-hardness profiles across repair interfaces provide valuable data on potential property gradients.

Corrosion resistance testing, including ASTM G48 pitting tests and electrochemical potentiodynamic polarization tests, is crucial for duplex stainless steel repairs, as improper processing parameters can compromise the material's inherent corrosion resistance. Intergranular corrosion testing helps identify sensitization issues that may arise from improper cooling rates during the DED process.

Non-destructive evaluation (NDE) methods such as ultrasonic testing, radiographic testing, and dye penetrant inspection are essential for detecting volumetric defects like porosity, lack of fusion, or cracking. Advanced techniques including phased array ultrasonic testing (PAUT) and time-of-flight diffraction (TOFD) offer enhanced detection capabilities for complex geometries typical in repair scenarios.

In-process monitoring systems incorporating thermal imaging cameras, pyrometers, and high-speed cameras enable real-time quality control by tracking melt pool dynamics and thermal history. These systems can be integrated with machine learning algorithms to predict defect formation and adjust process parameters dynamically, significantly improving repair consistency and reliability.

Statistical process control methodologies should be implemented to establish correlations between process parameters, material characteristics, and final component performance. This data-driven approach facilitates the development of robust quality assurance protocols specific to duplex stainless steel DED repairs, ensuring consistent mechanical properties and corrosion resistance across multiple repair operations.

X-ray diffraction (XRD) techniques enable quantitative phase analysis and residual stress measurements, essential for understanding repair quality. Energy Dispersive X-ray Spectroscopy (EDS) mapping helps identify elemental segregation at interfaces between the substrate and deposited material, a common concern in DED repairs of duplex stainless steels.

Mechanical property verification through hardness mapping, tensile testing, and impact testing ensures repaired sections meet or exceed base material specifications. Particular attention must be paid to the heat-affected zone (HAZ), where thermal cycling can lead to embrittlement or strength reduction. Micro-hardness profiles across repair interfaces provide valuable data on potential property gradients.

Corrosion resistance testing, including ASTM G48 pitting tests and electrochemical potentiodynamic polarization tests, is crucial for duplex stainless steel repairs, as improper processing parameters can compromise the material's inherent corrosion resistance. Intergranular corrosion testing helps identify sensitization issues that may arise from improper cooling rates during the DED process.

Non-destructive evaluation (NDE) methods such as ultrasonic testing, radiographic testing, and dye penetrant inspection are essential for detecting volumetric defects like porosity, lack of fusion, or cracking. Advanced techniques including phased array ultrasonic testing (PAUT) and time-of-flight diffraction (TOFD) offer enhanced detection capabilities for complex geometries typical in repair scenarios.

In-process monitoring systems incorporating thermal imaging cameras, pyrometers, and high-speed cameras enable real-time quality control by tracking melt pool dynamics and thermal history. These systems can be integrated with machine learning algorithms to predict defect formation and adjust process parameters dynamically, significantly improving repair consistency and reliability.

Statistical process control methodologies should be implemented to establish correlations between process parameters, material characteristics, and final component performance. This data-driven approach facilitates the development of robust quality assurance protocols specific to duplex stainless steel DED repairs, ensuring consistent mechanical properties and corrosion resistance across multiple repair operations.

Environmental and Economic Impact Assessment

The implementation of DED (Directed Energy Deposition) processes for duplex stainless steel repairs presents significant environmental and economic implications that warrant careful assessment. From an environmental perspective, DED technology offers substantial advantages over traditional manufacturing methods by reducing material waste. The precise nature of the additive manufacturing process allows for material deposition only where needed, resulting in up to 90% less material waste compared to conventional subtractive manufacturing techniques used in repair operations.

Energy consumption represents another critical environmental factor. While DED processes require considerable energy input during operation, particularly for laser or electron beam power sources, the overall lifecycle energy consumption is often lower than traditional repair methods that involve multiple manufacturing steps. When specifically applied to duplex stainless steel repairs, the energy efficiency becomes more pronounced due to the reduced need for post-processing treatments that would otherwise be necessary with conventional welding techniques.

Carbon footprint reduction constitutes a measurable environmental benefit of DED repairs. By extending the service life of duplex stainless steel components rather than replacing them entirely, significant reductions in carbon emissions associated with new material production can be achieved. Studies indicate that component repair via DED can reduce CO2 emissions by 60-70% compared to manufacturing new replacement parts.

From an economic standpoint, the implementation of parameter-mapped DED processes for duplex stainless steel repairs delivers compelling cost advantages. Initial investment in DED equipment remains substantial, with industrial systems ranging from $500,000 to over $1.5 million. However, the return on investment becomes favorable when considering the high value of repaired components, particularly in industries such as oil and gas, marine, and chemical processing where duplex stainless steel components are prevalent.

Operational cost analysis reveals that DED repairs typically represent 30-50% of the cost of component replacement, with the precise parameter mapping for duplex stainless steel further enhancing this economic advantage by minimizing repair failures and rework. The technology enables just-in-time repair capabilities, significantly reducing inventory costs and downtime associated with waiting for replacement parts.

Long-term economic benefits extend beyond direct repair costs. The ability to restore components to original specifications through optimized parameter mapping increases asset longevity, improves maintenance planning, and reduces unplanned downtime. For industries utilizing duplex stainless steel components in corrosive environments, these economic benefits compound over time, with some operations reporting overall maintenance cost reductions of 25-40% following DED implementation.

Energy consumption represents another critical environmental factor. While DED processes require considerable energy input during operation, particularly for laser or electron beam power sources, the overall lifecycle energy consumption is often lower than traditional repair methods that involve multiple manufacturing steps. When specifically applied to duplex stainless steel repairs, the energy efficiency becomes more pronounced due to the reduced need for post-processing treatments that would otherwise be necessary with conventional welding techniques.

Carbon footprint reduction constitutes a measurable environmental benefit of DED repairs. By extending the service life of duplex stainless steel components rather than replacing them entirely, significant reductions in carbon emissions associated with new material production can be achieved. Studies indicate that component repair via DED can reduce CO2 emissions by 60-70% compared to manufacturing new replacement parts.

From an economic standpoint, the implementation of parameter-mapped DED processes for duplex stainless steel repairs delivers compelling cost advantages. Initial investment in DED equipment remains substantial, with industrial systems ranging from $500,000 to over $1.5 million. However, the return on investment becomes favorable when considering the high value of repaired components, particularly in industries such as oil and gas, marine, and chemical processing where duplex stainless steel components are prevalent.

Operational cost analysis reveals that DED repairs typically represent 30-50% of the cost of component replacement, with the precise parameter mapping for duplex stainless steel further enhancing this economic advantage by minimizing repair failures and rework. The technology enables just-in-time repair capabilities, significantly reducing inventory costs and downtime associated with waiting for replacement parts.

Long-term economic benefits extend beyond direct repair costs. The ability to restore components to original specifications through optimized parameter mapping increases asset longevity, improves maintenance planning, and reduces unplanned downtime. For industries utilizing duplex stainless steel components in corrosive environments, these economic benefits compound over time, with some operations reporting overall maintenance cost reductions of 25-40% following DED implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!