regulatory And Certification Considerations For DED In Aerospace

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Background and Aerospace Applications

Directed Energy Deposition (DED) represents a transformative additive manufacturing technology that has evolved significantly since its inception in the 1990s. Initially developed as a repair technology for high-value components, DED has matured into a sophisticated manufacturing process capable of producing complex aerospace parts with exceptional material properties. The technology operates by creating a melt pool on a substrate using a focused energy source (typically a laser, electron beam, or plasma arc) while simultaneously feeding metal powder or wire into this pool, building parts layer by layer.

In aerospace applications, DED offers unique advantages that traditional manufacturing methods cannot match. The technology enables the production of large structural components with complex geometries, significantly reducing material waste compared to conventional subtractive manufacturing processes. This aspect is particularly valuable for aerospace applications where expensive superalloys and titanium alloys are commonly used, resulting in buy-to-fly ratios as low as 1:1 compared to 10:1 or higher with traditional methods.

The aerospace industry has embraced DED for several critical applications, including the repair and remanufacturing of turbine blades, combustion chambers, and structural components. Companies like GE Aviation and Rolls-Royce have implemented DED processes to extend the service life of high-value engine components, achieving significant cost savings and reducing maintenance downtime. Additionally, DED enables the fabrication of functionally graded materials and multi-material structures, allowing engineers to optimize component performance by varying material composition throughout a single part.

Recent technological advancements have further enhanced DED capabilities for aerospace applications. Hybrid manufacturing systems that combine DED with machining operations in a single setup have emerged, enabling the production of components with tight tolerances and excellent surface finishes. Closed-loop control systems with real-time monitoring capabilities have improved process stability and part quality, addressing key concerns for aerospace certification.

The evolution of DED technology has been marked by significant improvements in deposition rates, material compatibility, and process control. Modern systems can achieve deposition rates exceeding 10 kg/h while maintaining dimensional accuracy within ±0.25 mm. Material options have expanded beyond traditional aerospace alloys to include advanced materials such as titanium aluminides, oxide dispersion strengthened (ODS) alloys, and metal matrix composites, opening new possibilities for next-generation aircraft and spacecraft components.

As the aerospace industry continues its pursuit of lighter, more efficient structures, DED technology is positioned to play an increasingly important role in manufacturing innovation. The ability to produce parts with optimized internal structures, embedded sensors, and tailored material properties aligns perfectly with the industry's goals of improved performance, reduced fuel consumption, and enhanced sustainability.

In aerospace applications, DED offers unique advantages that traditional manufacturing methods cannot match. The technology enables the production of large structural components with complex geometries, significantly reducing material waste compared to conventional subtractive manufacturing processes. This aspect is particularly valuable for aerospace applications where expensive superalloys and titanium alloys are commonly used, resulting in buy-to-fly ratios as low as 1:1 compared to 10:1 or higher with traditional methods.

The aerospace industry has embraced DED for several critical applications, including the repair and remanufacturing of turbine blades, combustion chambers, and structural components. Companies like GE Aviation and Rolls-Royce have implemented DED processes to extend the service life of high-value engine components, achieving significant cost savings and reducing maintenance downtime. Additionally, DED enables the fabrication of functionally graded materials and multi-material structures, allowing engineers to optimize component performance by varying material composition throughout a single part.

Recent technological advancements have further enhanced DED capabilities for aerospace applications. Hybrid manufacturing systems that combine DED with machining operations in a single setup have emerged, enabling the production of components with tight tolerances and excellent surface finishes. Closed-loop control systems with real-time monitoring capabilities have improved process stability and part quality, addressing key concerns for aerospace certification.

The evolution of DED technology has been marked by significant improvements in deposition rates, material compatibility, and process control. Modern systems can achieve deposition rates exceeding 10 kg/h while maintaining dimensional accuracy within ±0.25 mm. Material options have expanded beyond traditional aerospace alloys to include advanced materials such as titanium aluminides, oxide dispersion strengthened (ODS) alloys, and metal matrix composites, opening new possibilities for next-generation aircraft and spacecraft components.

As the aerospace industry continues its pursuit of lighter, more efficient structures, DED technology is positioned to play an increasingly important role in manufacturing innovation. The ability to produce parts with optimized internal structures, embedded sensors, and tailored material properties aligns perfectly with the industry's goals of improved performance, reduced fuel consumption, and enhanced sustainability.

Aerospace Market Demand for DED Manufacturing

The aerospace industry is witnessing a significant shift toward advanced manufacturing technologies, with Directed Energy Deposition (DED) emerging as a critical enabler for next-generation aircraft and spacecraft components. Market analysis indicates that the global aerospace additive manufacturing market, which includes DED technologies, is projected to grow at a compound annual growth rate of 20.3% through 2028, driven primarily by the need for lightweight components and complex geometries that traditional manufacturing cannot efficiently produce.

The demand for DED in aerospace stems from several key industry requirements. First, weight reduction remains paramount in aircraft design, with manufacturers constantly seeking methods to decrease fuel consumption and emissions. DED enables the production of topology-optimized parts with internal lattice structures that maintain structural integrity while significantly reducing weight compared to conventionally manufactured components.

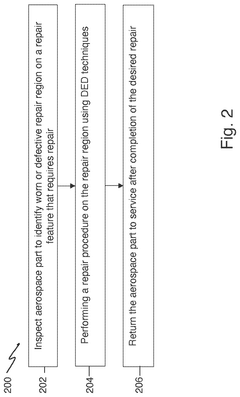

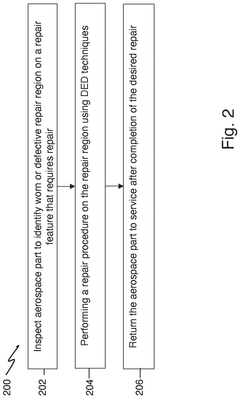

Repair and maintenance represent another substantial market driver. The ability of DED systems to restore damaged high-value components, particularly turbine blades and structural elements, offers aerospace companies potential savings in the billions annually. Rather than replacing entire assemblies, DED allows for targeted material deposition to rebuild worn or damaged areas with minimal waste and downtime.

Supply chain resilience has emerged as a critical concern following recent global disruptions. Major aerospace manufacturers are increasingly investing in DED capabilities to enable on-demand, in-house production of critical components. This shift reduces dependency on complex supply networks and decreases lead times from months to days for certain specialized parts.

The space sector presents particularly promising growth opportunities for DED manufacturing. With launch costs decreasing and satellite constellations expanding, there is heightened demand for custom, lightweight components that can withstand extreme conditions. DED's ability to work with high-performance materials like titanium alloys, Inconel, and specialized aluminum compositions makes it especially valuable for space applications.

Military aerospace applications are driving significant investment in DED technologies, with defense departments worldwide funding research into field-deployable DED systems for battlefield repairs and rapid prototyping. The strategic advantage of being able to produce replacement parts in remote locations represents a paradigm shift in military logistics planning.

Commercial aviation's push toward more fuel-efficient aircraft designs has created demand for complex components with integrated cooling channels and variable material compositions that DED can uniquely deliver. Major manufacturers have reported up to 30% performance improvements in certain engine components manufactured using DED processes compared to traditional methods.

The demand for DED in aerospace stems from several key industry requirements. First, weight reduction remains paramount in aircraft design, with manufacturers constantly seeking methods to decrease fuel consumption and emissions. DED enables the production of topology-optimized parts with internal lattice structures that maintain structural integrity while significantly reducing weight compared to conventionally manufactured components.

Repair and maintenance represent another substantial market driver. The ability of DED systems to restore damaged high-value components, particularly turbine blades and structural elements, offers aerospace companies potential savings in the billions annually. Rather than replacing entire assemblies, DED allows for targeted material deposition to rebuild worn or damaged areas with minimal waste and downtime.

Supply chain resilience has emerged as a critical concern following recent global disruptions. Major aerospace manufacturers are increasingly investing in DED capabilities to enable on-demand, in-house production of critical components. This shift reduces dependency on complex supply networks and decreases lead times from months to days for certain specialized parts.

The space sector presents particularly promising growth opportunities for DED manufacturing. With launch costs decreasing and satellite constellations expanding, there is heightened demand for custom, lightweight components that can withstand extreme conditions. DED's ability to work with high-performance materials like titanium alloys, Inconel, and specialized aluminum compositions makes it especially valuable for space applications.

Military aerospace applications are driving significant investment in DED technologies, with defense departments worldwide funding research into field-deployable DED systems for battlefield repairs and rapid prototyping. The strategic advantage of being able to produce replacement parts in remote locations represents a paradigm shift in military logistics planning.

Commercial aviation's push toward more fuel-efficient aircraft designs has created demand for complex components with integrated cooling channels and variable material compositions that DED can uniquely deliver. Major manufacturers have reported up to 30% performance improvements in certain engine components manufactured using DED processes compared to traditional methods.

Current State and Technical Challenges of DED in Aerospace

Directed Energy Deposition (DED) in aerospace applications currently exists in a transitional state between research laboratories and industrial implementation. The technology has demonstrated significant potential for manufacturing and repairing complex aerospace components, particularly for high-value materials such as titanium alloys, nickel-based superalloys, and other specialty metals used in critical aerospace applications. Several tier-one aerospace manufacturers have begun integrating DED processes into their production workflows, primarily for repair operations and limited production of non-critical components.

Despite promising advancements, DED faces substantial technical challenges that impede its widespread adoption in aerospace manufacturing. Material consistency remains a primary concern, as the layer-by-layer deposition process can introduce microstructural variations that affect mechanical properties. Current DED processes struggle to maintain uniform material characteristics throughout complex geometries, resulting in anisotropic behavior that complicates structural analysis and certification.

Process stability and repeatability present another significant hurdle. Environmental factors such as ambient temperature, humidity, and oxygen levels can substantially influence deposition quality. The aerospace industry's stringent quality requirements necessitate process stability levels that current DED systems have difficulty consistently achieving. This variability directly impacts the certification pathway for DED-manufactured components.

Surface finish and dimensional accuracy limitations also restrict DED applications in aerospace. Most DED processes produce components requiring substantial post-processing to meet aerospace tolerances, adding cost and complexity to the manufacturing workflow. The typical surface roughness of as-deposited DED parts (Ra 15-25μm) falls short of aerospace requirements (often Ra <1.6μm), necessitating additional machining operations that can introduce new stress concentrations and potential failure points.

Monitoring and quality control systems for DED remain underdeveloped compared to conventional manufacturing methods. Real-time process monitoring technologies capable of detecting defects during deposition exist but lack the sensitivity and reliability required for aerospace certification. Non-destructive testing (NDT) methods for DED components are still evolving, with challenges in detecting subsurface defects and characterizing material properties throughout complex geometries.

Geographically, DED technology development shows concentration in North America, Western Europe, and increasingly in East Asia. Research institutions and aerospace manufacturers in these regions have established collaborative networks to address technical challenges, though significant disparities exist in regulatory approaches and certification pathways across different jurisdictions, creating additional complexity for global implementation.

Despite promising advancements, DED faces substantial technical challenges that impede its widespread adoption in aerospace manufacturing. Material consistency remains a primary concern, as the layer-by-layer deposition process can introduce microstructural variations that affect mechanical properties. Current DED processes struggle to maintain uniform material characteristics throughout complex geometries, resulting in anisotropic behavior that complicates structural analysis and certification.

Process stability and repeatability present another significant hurdle. Environmental factors such as ambient temperature, humidity, and oxygen levels can substantially influence deposition quality. The aerospace industry's stringent quality requirements necessitate process stability levels that current DED systems have difficulty consistently achieving. This variability directly impacts the certification pathway for DED-manufactured components.

Surface finish and dimensional accuracy limitations also restrict DED applications in aerospace. Most DED processes produce components requiring substantial post-processing to meet aerospace tolerances, adding cost and complexity to the manufacturing workflow. The typical surface roughness of as-deposited DED parts (Ra 15-25μm) falls short of aerospace requirements (often Ra <1.6μm), necessitating additional machining operations that can introduce new stress concentrations and potential failure points.

Monitoring and quality control systems for DED remain underdeveloped compared to conventional manufacturing methods. Real-time process monitoring technologies capable of detecting defects during deposition exist but lack the sensitivity and reliability required for aerospace certification. Non-destructive testing (NDT) methods for DED components are still evolving, with challenges in detecting subsurface defects and characterizing material properties throughout complex geometries.

Geographically, DED technology development shows concentration in North America, Western Europe, and increasingly in East Asia. Research institutions and aerospace manufacturers in these regions have established collaborative networks to address technical challenges, though significant disparities exist in regulatory approaches and certification pathways across different jurisdictions, creating additional complexity for global implementation.

Current DED Certification Frameworks for Aerospace Components

01 DED process fundamentals and equipment

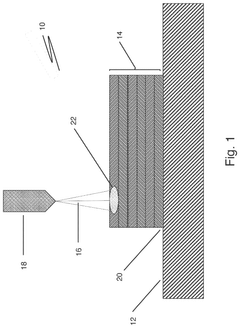

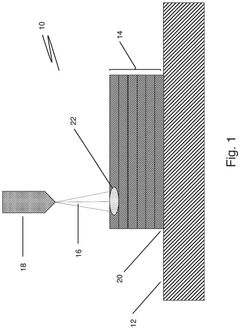

Directed Energy Deposition (DED) is an additive manufacturing process that uses focused thermal energy to fuse materials as they are deposited. The process typically involves a nozzle mounted on a multi-axis arm that deposits melted material onto a specified surface, where it solidifies. The energy source can be a laser, electron beam, or plasma arc. DED systems often include powder or wire feedstock delivery systems, motion control mechanisms, and process monitoring equipment to ensure precise deposition.- DED process optimization and control: Directed Energy Deposition (DED) processes can be optimized through various control mechanisms to improve build quality and efficiency. This includes real-time monitoring systems, feedback control loops, and parameter optimization for different materials. Advanced control strategies help maintain consistent deposition rates, minimize defects, and ensure dimensional accuracy of the printed parts. Process optimization also involves adjusting laser power, feed rate, and other parameters based on material properties and desired part characteristics.

- Multi-material DED applications: Multi-material Directed Energy Deposition enables the fabrication of components with varying material compositions and functionally graded properties. This approach allows for the strategic placement of different materials within a single component to optimize mechanical properties, thermal performance, or wear resistance. The technology enables the creation of composite structures, bimetallic components, and parts with tailored material transitions that would be difficult or impossible to produce using conventional manufacturing methods.

- DED equipment and system design: Innovations in DED equipment design focus on improving deposition precision, system reliability, and manufacturing flexibility. Advanced DED systems incorporate specialized nozzle designs, multi-axis motion platforms, and integrated cooling systems. Some systems feature hybrid manufacturing capabilities that combine additive and subtractive processes in a single machine. Equipment developments also include portable DED systems for in-situ repair applications and specialized setups for large-scale component manufacturing.

- Post-processing techniques for DED parts: Post-processing methods are essential for enhancing the properties and surface quality of DED-manufactured components. These techniques include heat treatment to relieve residual stresses, hot isostatic pressing to reduce porosity, and various surface finishing operations. Post-processing can significantly improve mechanical properties, dimensional accuracy, and surface roughness of DED parts. Advanced post-processing approaches may also involve controlled cooling strategies and specialized treatments to achieve desired microstructures.

- Material development for DED applications: Development of specialized materials for DED processes focuses on improving processability, mechanical properties, and microstructural characteristics of deposited parts. Research includes the formulation of custom alloys with enhanced weldability, reduced cracking susceptibility, and improved high-temperature performance. Material innovations also address challenges related to thermal cycling during deposition, such as controlling grain structure and minimizing segregation. Advanced powder and wire feedstock materials are designed specifically to optimize deposition efficiency and part quality.

02 Material innovations for DED applications

Various materials are being developed and optimized specifically for DED processes, including metal alloys, composites, and functionally graded materials. These materials are engineered to have specific properties such as improved flowability, reduced oxidation during processing, enhanced layer adhesion, and better mechanical properties in the final parts. Material innovations also focus on expanding the range of compatible feedstocks for DED systems, enabling the production of components with novel properties and performance characteristics.Expand Specific Solutions03 Process control and monitoring systems

Advanced control and monitoring systems are essential for DED processes to ensure consistent quality and dimensional accuracy. These systems incorporate real-time feedback mechanisms using sensors that monitor parameters such as melt pool temperature, deposition rate, and layer geometry. Machine learning algorithms and computer vision systems are increasingly being integrated to detect and correct process anomalies during fabrication. Closed-loop control systems adjust process parameters automatically to maintain optimal deposition conditions throughout the build.Expand Specific Solutions04 Multi-material and hybrid manufacturing approaches

DED technology enables the fabrication of components with multiple materials or functionally graded properties. Hybrid manufacturing approaches combine DED with conventional manufacturing methods such as machining or forming to leverage the advantages of both additive and subtractive processes. These hybrid systems can produce near-net-shape parts with complex geometries and then finish critical surfaces to tight tolerances. Multi-material deposition allows for the creation of components with location-specific properties, such as wear resistance in certain areas or heat resistance in others.Expand Specific Solutions05 Repair and remanufacturing applications

DED technology is particularly valuable for repair and remanufacturing of high-value components. The process can be used to restore damaged or worn parts by selectively depositing material onto specific areas. This approach is especially beneficial for expensive components in industries such as aerospace, defense, and heavy machinery. The repair process typically involves surface preparation, controlled deposition of compatible materials, and post-processing treatments to ensure the repaired area has properties matching or exceeding the original component.Expand Specific Solutions

Key Industry Players in Aerospace DED Manufacturing

The Directed Energy Deposition (DED) market in aerospace is currently in an early growth phase, characterized by increasing adoption but still evolving regulatory frameworks. The global market size is projected to expand significantly as aerospace manufacturers seek more efficient additive manufacturing solutions. Technologically, DED is advancing rapidly with companies at different maturity levels. Industry leaders like RTX Corp. and Thales SA have established robust certification pathways, while specialized firms such as Divergent Technologies and Norsk Titanium are driving innovation in process optimization. Academic institutions including Northwestern Polytechnical University and University of Florida are contributing fundamental research. The regulatory landscape remains complex, with aerospace giants like Israel Aerospace Industries and Northrop Grumman Systems working closely with authorities to develop standardized certification protocols for flight-critical DED components.

RTX Corp.

Technical Solution: RTX Corp. (formerly Raytheon Technologies) has developed a comprehensive approach to regulatory compliance for Directed Energy Deposition (DED) in aerospace applications. Their technology solution integrates material qualification protocols with process monitoring systems to ensure consistent part quality. RTX has implemented a digital thread approach that documents the entire manufacturing process from powder characterization to final part inspection, creating a complete audit trail for certification authorities. Their system includes real-time monitoring with multiple sensors that track melt pool characteristics, thermal gradients, and build environment parameters to detect anomalies during fabrication. This data is integrated into a qualification framework aligned with FAA AC 21-26A and EASA AMC 20-42 guidelines for additive manufacturing certification. RTX has also established material allowables databases specifically for DED-produced aerospace components, focusing on titanium alloys and nickel-based superalloys commonly used in engine components.

Strengths: Comprehensive digital thread approach provides complete traceability required by aerospace regulators; established relationships with certification authorities facilitate approval processes; extensive materials testing database supports certification efforts. Weaknesses: System complexity increases implementation costs; certification approach is heavily tailored to US/EU regulatory frameworks which may require adaptation for other markets.

Norsk Titanium AS

Technical Solution: Norsk Titanium has pioneered the Rapid Plasma Deposition (RPD) technology, a specialized form of DED optimized for aerospace titanium components. Their certification approach centers on their proprietary RPD process, which has received FAA approval for structural titanium components on commercial aircraft. Norsk's technology solution includes a standardized parameter set that has been extensively validated through mechanical testing and microstructural analysis. Their certification strategy involves a building block approach, starting with material property equivalence testing, then moving to element and subcomponent testing, and finally full-scale component validation. The company has developed a Statistical Process Control (SPC) system that monitors over 600 parameters during the build process to ensure part quality and consistency. Norsk has worked closely with Boeing to achieve the first FAA approval for additively manufactured structural titanium components for the 787 Dreamliner, establishing a certification precedent for DED technology in primary aircraft structures.

Strengths: First-mover advantage with established FAA certification precedents; specialized expertise in titanium DED for structural components; proven implementation on commercial aircraft programs. Weaknesses: Technology solution is highly specialized for titanium components, limiting application range; heavy dependence on proprietary process parameters creates vendor lock-in for aerospace customers.

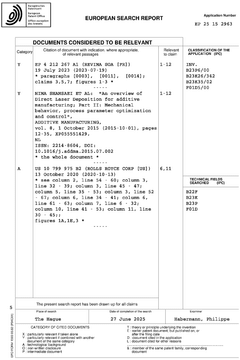

Critical Patents and Technical Standards for Aerospace DED

Engineered microstructure for enhanced performance during directed energy deposition repair process

PatentPendingUS20250242410A1

Innovation

- A directed energy deposition (DED) process is used to control the microstructure of each repair layer by adjusting parameters like powder feed rate, energy intensity, traversal rate, and auxiliary heating/cooling, ensuring each layer has a pre-determined microstructure to meet specific structural and functional needs.

Engineered residual stress state for enhanced performance during directed energy deposition repair process

PatentPendingEP4599978A1

Innovation

- A directed energy deposition (DED) process is used to create layers with pre-determined residual stress states by controlling parameters like powder feed rate, energy intensity, traversal speed, and auxiliary heating/cooling, enabling controlled residual stress management during the repair process.

Regulatory Compliance Strategies for DED Aerospace Parts

Implementing effective regulatory compliance strategies for Directed Energy Deposition (DED) aerospace components requires a systematic approach that addresses the unique challenges of this additive manufacturing technology. Organizations must first establish comprehensive documentation systems that track material provenance, process parameters, and quality control measures throughout the production lifecycle. This documentation forms the foundation for demonstrating compliance with aerospace standards such as AS9100, ASTM F3413, and relevant FAA or EASA requirements.

Risk assessment frameworks specifically tailored to DED processes should be developed to identify potential failure modes and their impacts on part performance. These assessments must consider the unique metallurgical characteristics of DED-produced parts, including potential anisotropy, residual stresses, and microstructural variations that may affect mechanical properties. Implementing process monitoring systems that capture real-time data on laser power, material feed rates, and thermal conditions provides critical evidence for certification bodies.

Material qualification protocols represent another essential compliance strategy. Organizations should establish rigorous testing regimes that validate both feedstock materials and finished components against aerospace requirements. This includes mechanical property testing, microstructural analysis, and non-destructive evaluation techniques optimized for the unique characteristics of DED-manufactured parts. Developing material-specific databases that correlate process parameters with resulting properties enables more predictable outcomes and supports certification efforts.

Engagement with regulatory bodies early in the development process significantly streamlines certification pathways. This collaborative approach allows manufacturers to address potential compliance issues before they become barriers to implementation. Establishing qualification equivalency methods that demonstrate how DED processes meet or exceed traditional manufacturing requirements provides a framework for regulatory acceptance without requiring extensive modifications to existing standards.

Training and personnel certification programs focused specifically on DED technology ensure that operators understand the critical parameters affecting part quality and regulatory compliance. These programs should cover not only technical operation but also documentation requirements, quality control procedures, and regulatory awareness. Creating a culture of compliance through regular audits and continuous improvement initiatives maintains ongoing adherence to standards.

Finally, developing industry partnerships and participating in standards development organizations positions companies to influence emerging regulatory frameworks for DED technology. By contributing to the evolution of standards like those being developed by ASTM Committee F42 on Additive Manufacturing Technologies, organizations can help shape requirements that appropriately address the unique characteristics of DED processes while ensuring safety and reliability in aerospace applications.

Risk assessment frameworks specifically tailored to DED processes should be developed to identify potential failure modes and their impacts on part performance. These assessments must consider the unique metallurgical characteristics of DED-produced parts, including potential anisotropy, residual stresses, and microstructural variations that may affect mechanical properties. Implementing process monitoring systems that capture real-time data on laser power, material feed rates, and thermal conditions provides critical evidence for certification bodies.

Material qualification protocols represent another essential compliance strategy. Organizations should establish rigorous testing regimes that validate both feedstock materials and finished components against aerospace requirements. This includes mechanical property testing, microstructural analysis, and non-destructive evaluation techniques optimized for the unique characteristics of DED-manufactured parts. Developing material-specific databases that correlate process parameters with resulting properties enables more predictable outcomes and supports certification efforts.

Engagement with regulatory bodies early in the development process significantly streamlines certification pathways. This collaborative approach allows manufacturers to address potential compliance issues before they become barriers to implementation. Establishing qualification equivalency methods that demonstrate how DED processes meet or exceed traditional manufacturing requirements provides a framework for regulatory acceptance without requiring extensive modifications to existing standards.

Training and personnel certification programs focused specifically on DED technology ensure that operators understand the critical parameters affecting part quality and regulatory compliance. These programs should cover not only technical operation but also documentation requirements, quality control procedures, and regulatory awareness. Creating a culture of compliance through regular audits and continuous improvement initiatives maintains ongoing adherence to standards.

Finally, developing industry partnerships and participating in standards development organizations positions companies to influence emerging regulatory frameworks for DED technology. By contributing to the evolution of standards like those being developed by ASTM Committee F42 on Additive Manufacturing Technologies, organizations can help shape requirements that appropriately address the unique characteristics of DED processes while ensuring safety and reliability in aerospace applications.

Material Qualification Processes for Aerospace DED Applications

Material qualification for Directed Energy Deposition (DED) in aerospace applications follows a rigorous, multi-stage process designed to ensure the safety, reliability, and performance of additively manufactured components. The qualification framework typically begins with material characterization, where the chemical composition, microstructure, and physical properties of the feedstock materials are thoroughly analyzed and documented. This initial assessment establishes baseline properties that will serve as reference points throughout the qualification process.

Following characterization, process parameter development becomes critical. Engineers must identify optimal deposition parameters including laser power, travel speed, powder feed rate, and layer thickness that consistently produce parts meeting aerospace specifications. This phase often involves extensive design of experiments (DOE) to map the process window and understand the relationship between parameters and resultant material properties.

Statistical process control methodologies are then implemented to ensure repeatability and reproducibility across multiple builds and machines. This involves manufacturing numerous test specimens under identical conditions and subjecting them to comprehensive mechanical testing regimes including tensile, fatigue, creep, and fracture toughness evaluations. The data collected must demonstrate statistical consistency within predetermined acceptance criteria.

Non-destructive evaluation (NDE) qualification represents another crucial element in the aerospace DED material qualification process. Techniques such as ultrasonic testing, X-ray computed tomography, and eddy current inspection must be validated specifically for DED-produced components, as traditional NDE methods may require modification to account for the unique microstructural features of additively manufactured parts.

Environmental testing further extends the qualification process, with specimens subjected to the extreme conditions encountered during aerospace operations. This includes high-temperature oxidation resistance, cryogenic performance, and resistance to various corrosive environments. Additionally, specimens undergo accelerated aging tests to predict long-term material behavior and potential degradation mechanisms.

The final stage involves building and testing representative components or subscale demonstrators that incorporate the geometric complexities and loading conditions of actual aerospace parts. These demonstrators validate not only the material properties but also the design methodologies and structural performance predictions. Throughout this qualification process, comprehensive documentation is maintained, creating a traceable record that regulatory authorities can review during certification proceedings.

Industry standards organizations including ASTM International, SAE, and the America Makes & ANSI Additive Manufacturing Standardization Collaborative have developed specialized frameworks for aerospace material qualification, providing structured approaches that manufacturers can follow to achieve regulatory acceptance of DED-produced components.

Following characterization, process parameter development becomes critical. Engineers must identify optimal deposition parameters including laser power, travel speed, powder feed rate, and layer thickness that consistently produce parts meeting aerospace specifications. This phase often involves extensive design of experiments (DOE) to map the process window and understand the relationship between parameters and resultant material properties.

Statistical process control methodologies are then implemented to ensure repeatability and reproducibility across multiple builds and machines. This involves manufacturing numerous test specimens under identical conditions and subjecting them to comprehensive mechanical testing regimes including tensile, fatigue, creep, and fracture toughness evaluations. The data collected must demonstrate statistical consistency within predetermined acceptance criteria.

Non-destructive evaluation (NDE) qualification represents another crucial element in the aerospace DED material qualification process. Techniques such as ultrasonic testing, X-ray computed tomography, and eddy current inspection must be validated specifically for DED-produced components, as traditional NDE methods may require modification to account for the unique microstructural features of additively manufactured parts.

Environmental testing further extends the qualification process, with specimens subjected to the extreme conditions encountered during aerospace operations. This includes high-temperature oxidation resistance, cryogenic performance, and resistance to various corrosive environments. Additionally, specimens undergo accelerated aging tests to predict long-term material behavior and potential degradation mechanisms.

The final stage involves building and testing representative components or subscale demonstrators that incorporate the geometric complexities and loading conditions of actual aerospace parts. These demonstrators validate not only the material properties but also the design methodologies and structural performance predictions. Throughout this qualification process, comprehensive documentation is maintained, creating a traceable record that regulatory authorities can review during certification proceedings.

Industry standards organizations including ASTM International, SAE, and the America Makes & ANSI Additive Manufacturing Standardization Collaborative have developed specialized frameworks for aerospace material qualification, providing structured approaches that manufacturers can follow to achieve regulatory acceptance of DED-produced components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!