Powder Handling And Flowability Solutions For Wire-Less DED Systems

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Powder Flow Technology Background and Objectives

Powder handling and flowability have been critical aspects of additive manufacturing since its inception in the 1980s. The evolution of Direct Energy Deposition (DED) systems has particularly highlighted the importance of consistent powder flow for achieving dimensional accuracy and material properties in manufactured components. Traditional DED systems relied on wire feedstock, but wire-less systems have emerged as a promising alternative, offering greater material flexibility and reduced waste.

The development of powder flow technology has progressed through several distinct phases. Initially, simple gravity-fed systems dominated the market, but these proved inadequate for precise applications due to inconsistent flow rates and clogging issues. The 1990s saw the introduction of mechanical vibration systems to improve flow consistency, while the early 2000s brought sophisticated pressure-differential systems that significantly enhanced control over powder delivery rates.

Current powder handling technologies for wire-less DED systems face several persistent challenges, including moisture sensitivity, particle agglomeration, and electrostatic charging effects. These issues can lead to flow interruptions, inconsistent material deposition, and ultimately, compromised part quality. The industry has responded with innovations in powder characterization methods, anti-static treatments, and environmental control systems.

The primary technical objective in this field is to develop robust powder handling solutions that ensure consistent flowability across diverse material types and operating conditions. This includes achieving uniform particle distribution, minimizing the effects of environmental factors such as humidity and temperature, and maintaining precise control over flow rates throughout the build process.

Secondary objectives include reducing system complexity and maintenance requirements, minimizing powder waste during handling and transfer operations, and developing intelligent monitoring systems capable of detecting and compensating for flow irregularities in real-time. These advancements would significantly enhance the economic viability and practical implementation of wire-less DED systems across various industrial applications.

Recent research has increasingly focused on the relationship between powder morphology and flow characteristics, with particular emphasis on optimizing particle size distribution and surface properties. Computational fluid dynamics (CFD) modeling has emerged as a valuable tool for predicting powder behavior under different conditions, enabling more informed system design and process parameter selection.

The convergence of advanced sensing technologies, machine learning algorithms, and precision engineering is expected to drive the next generation of powder handling solutions, potentially revolutionizing the capabilities and reliability of wire-less DED systems in high-value manufacturing sectors such as aerospace, medical devices, and energy production.

The development of powder flow technology has progressed through several distinct phases. Initially, simple gravity-fed systems dominated the market, but these proved inadequate for precise applications due to inconsistent flow rates and clogging issues. The 1990s saw the introduction of mechanical vibration systems to improve flow consistency, while the early 2000s brought sophisticated pressure-differential systems that significantly enhanced control over powder delivery rates.

Current powder handling technologies for wire-less DED systems face several persistent challenges, including moisture sensitivity, particle agglomeration, and electrostatic charging effects. These issues can lead to flow interruptions, inconsistent material deposition, and ultimately, compromised part quality. The industry has responded with innovations in powder characterization methods, anti-static treatments, and environmental control systems.

The primary technical objective in this field is to develop robust powder handling solutions that ensure consistent flowability across diverse material types and operating conditions. This includes achieving uniform particle distribution, minimizing the effects of environmental factors such as humidity and temperature, and maintaining precise control over flow rates throughout the build process.

Secondary objectives include reducing system complexity and maintenance requirements, minimizing powder waste during handling and transfer operations, and developing intelligent monitoring systems capable of detecting and compensating for flow irregularities in real-time. These advancements would significantly enhance the economic viability and practical implementation of wire-less DED systems across various industrial applications.

Recent research has increasingly focused on the relationship between powder morphology and flow characteristics, with particular emphasis on optimizing particle size distribution and surface properties. Computational fluid dynamics (CFD) modeling has emerged as a valuable tool for predicting powder behavior under different conditions, enabling more informed system design and process parameter selection.

The convergence of advanced sensing technologies, machine learning algorithms, and precision engineering is expected to drive the next generation of powder handling solutions, potentially revolutionizing the capabilities and reliability of wire-less DED systems in high-value manufacturing sectors such as aerospace, medical devices, and energy production.

Market Analysis for Wire-Less DED Powder Systems

The global market for Wire-Less Directed Energy Deposition (DED) powder systems is experiencing significant growth, driven by increasing adoption in aerospace, automotive, medical, and energy sectors. Current market valuations indicate that the metal additive manufacturing industry, which encompasses DED technologies, has reached approximately 2.7 billion USD in 2022 and is projected to grow at a compound annual growth rate of 18% through 2028.

Wire-Less DED systems specifically represent a rapidly expanding segment within this market due to their versatility in processing complex geometries and ability to work with a wide range of materials. The powder-based approach offers superior precision and material efficiency compared to wire-fed alternatives, making it particularly attractive for high-value applications requiring tight tolerances and exceptional material properties.

Regional analysis reveals that North America currently holds the largest market share at approximately 40%, followed by Europe at 30% and Asia-Pacific at 25%. The remaining 5% is distributed across other regions. This distribution reflects the concentration of aerospace and defense industries in North America and Europe, which are primary adopters of advanced manufacturing technologies.

Customer segmentation shows that large enterprises account for 65% of the market, while small and medium enterprises represent 35%. This disparity is primarily due to the significant capital investment required for Wire-Less DED systems, which can range from 500,000 to 2 million USD depending on specifications and capabilities.

Key market drivers include increasing demand for lightweight components in transportation sectors, growing need for repair and remanufacturing solutions, and the push for more sustainable manufacturing processes with reduced material waste. The ability of powder-based DED systems to efficiently utilize expensive materials like titanium alloys and superalloys provides compelling economic advantages in industries where material costs represent a significant portion of production expenses.

Market challenges primarily revolve around powder handling and flowability issues, which directly impact process reliability and final part quality. End users consistently report that powder management challenges account for approximately 30% of operational difficulties when using these systems. This represents a critical market need that, if addressed effectively, could significantly accelerate adoption rates.

Emerging market trends include increasing integration with robotic systems for enhanced automation, development of closed-loop monitoring systems for quality assurance, and growing interest in multi-material capabilities. The market is also witnessing a shift toward hybrid manufacturing systems that combine additive and subtractive processes, offering more comprehensive manufacturing solutions.

Wire-Less DED systems specifically represent a rapidly expanding segment within this market due to their versatility in processing complex geometries and ability to work with a wide range of materials. The powder-based approach offers superior precision and material efficiency compared to wire-fed alternatives, making it particularly attractive for high-value applications requiring tight tolerances and exceptional material properties.

Regional analysis reveals that North America currently holds the largest market share at approximately 40%, followed by Europe at 30% and Asia-Pacific at 25%. The remaining 5% is distributed across other regions. This distribution reflects the concentration of aerospace and defense industries in North America and Europe, which are primary adopters of advanced manufacturing technologies.

Customer segmentation shows that large enterprises account for 65% of the market, while small and medium enterprises represent 35%. This disparity is primarily due to the significant capital investment required for Wire-Less DED systems, which can range from 500,000 to 2 million USD depending on specifications and capabilities.

Key market drivers include increasing demand for lightweight components in transportation sectors, growing need for repair and remanufacturing solutions, and the push for more sustainable manufacturing processes with reduced material waste. The ability of powder-based DED systems to efficiently utilize expensive materials like titanium alloys and superalloys provides compelling economic advantages in industries where material costs represent a significant portion of production expenses.

Market challenges primarily revolve around powder handling and flowability issues, which directly impact process reliability and final part quality. End users consistently report that powder management challenges account for approximately 30% of operational difficulties when using these systems. This represents a critical market need that, if addressed effectively, could significantly accelerate adoption rates.

Emerging market trends include increasing integration with robotic systems for enhanced automation, development of closed-loop monitoring systems for quality assurance, and growing interest in multi-material capabilities. The market is also witnessing a shift toward hybrid manufacturing systems that combine additive and subtractive processes, offering more comprehensive manufacturing solutions.

Current Challenges in Powder Flowability for DED

Powder flowability presents significant challenges in Directed Energy Deposition (DED) systems, particularly in wire-less configurations where consistent powder delivery is critical for build quality. The primary challenge stems from the inherent physical properties of metal powders used in DED processes, including particle size distribution, morphology, and surface characteristics. These properties directly influence how powders flow through delivery systems and interact with the melt pool.

Cohesion between powder particles frequently leads to agglomeration and bridging within feeding mechanisms, causing irregular flow rates and potential blockages. This issue is exacerbated when working with fine powders (typically <45μm) which demonstrate increased inter-particle forces due to their high surface area-to-volume ratio. Environmental factors further complicate powder handling, as moisture absorption can significantly alter flowability characteristics, particularly with reactive materials like titanium and aluminum alloys.

The geometry of powder delivery nozzles presents another critical challenge. Current designs struggle to maintain uniform powder distribution patterns, especially when processing complex geometries or during directional changes in multi-axis systems. Inconsistent powder distribution results in localized variations in material deposition, creating potential defects and compromising mechanical properties of the final components.

Powder recycling and cross-contamination issues also present significant operational challenges. Unlike wire-based systems, powder-based DED processes typically experience material waste rates of 40-60%. The recycling of unused powder introduces potential degradation concerns, including oxidation and moisture absorption, which progressively alter flowability characteristics across multiple build cycles.

Electrostatic charging during powder transport represents another substantial challenge, particularly in low humidity environments. The accumulation of static charge causes powder particles to adhere to delivery system components, resulting in inconsistent flow rates and potential system blockages. Current grounding and ionization solutions provide only partial mitigation of these effects.

Real-time monitoring and control of powder flow parameters remains underdeveloped in commercial systems. Unlike wire-based processes where material feed rates can be precisely controlled, powder-based systems lack robust feedback mechanisms to detect and compensate for flow irregularities during operation. This limitation restricts the ability to implement closed-loop control strategies that could otherwise enhance process stability and repeatability.

The combination of these challenges creates significant barriers to the widespread industrial adoption of wire-less DED technologies, particularly for applications requiring high precision and repeatability. Addressing these powder flowability issues represents a critical path toward expanding the practical applications of powder-based DED systems across various manufacturing sectors.

Cohesion between powder particles frequently leads to agglomeration and bridging within feeding mechanisms, causing irregular flow rates and potential blockages. This issue is exacerbated when working with fine powders (typically <45μm) which demonstrate increased inter-particle forces due to their high surface area-to-volume ratio. Environmental factors further complicate powder handling, as moisture absorption can significantly alter flowability characteristics, particularly with reactive materials like titanium and aluminum alloys.

The geometry of powder delivery nozzles presents another critical challenge. Current designs struggle to maintain uniform powder distribution patterns, especially when processing complex geometries or during directional changes in multi-axis systems. Inconsistent powder distribution results in localized variations in material deposition, creating potential defects and compromising mechanical properties of the final components.

Powder recycling and cross-contamination issues also present significant operational challenges. Unlike wire-based systems, powder-based DED processes typically experience material waste rates of 40-60%. The recycling of unused powder introduces potential degradation concerns, including oxidation and moisture absorption, which progressively alter flowability characteristics across multiple build cycles.

Electrostatic charging during powder transport represents another substantial challenge, particularly in low humidity environments. The accumulation of static charge causes powder particles to adhere to delivery system components, resulting in inconsistent flow rates and potential system blockages. Current grounding and ionization solutions provide only partial mitigation of these effects.

Real-time monitoring and control of powder flow parameters remains underdeveloped in commercial systems. Unlike wire-based processes where material feed rates can be precisely controlled, powder-based systems lack robust feedback mechanisms to detect and compensate for flow irregularities during operation. This limitation restricts the ability to implement closed-loop control strategies that could otherwise enhance process stability and repeatability.

The combination of these challenges creates significant barriers to the widespread industrial adoption of wire-less DED technologies, particularly for applications requiring high precision and repeatability. Addressing these powder flowability issues represents a critical path toward expanding the practical applications of powder-based DED systems across various manufacturing sectors.

Current Powder Flow Control Solutions

01 Additives and modifiers for improving powder flowability

Various additives and modifiers can be incorporated into powder formulations to enhance their flowability characteristics. These include flow agents, lubricants, and surface modifiers that reduce inter-particle friction and cohesion. By coating particle surfaces or filling void spaces between particles, these additives minimize agglomeration and promote consistent flow behavior, which is crucial for industrial processing operations.- Additives for improving powder flowability: Various additives can be incorporated into powder formulations to enhance flowability. These include flow agents, lubricants, and anti-caking agents that reduce inter-particle friction and cohesion. By coating particle surfaces, these additives minimize attractive forces between particles, preventing agglomeration and improving flow characteristics. Common additives include silica, talc, and stearates that create physical separation between powder particles, allowing them to flow more freely during processing and handling.

- Particle size and shape optimization: The size and shape of powder particles significantly impact flowability. Spherical particles typically flow better than irregular shapes due to reduced mechanical interlocking and contact area between particles. Controlling particle size distribution is also crucial, as uniform particles tend to flow more consistently. Processing techniques such as milling, granulation, and spheronization can be employed to modify particle morphology and improve flow characteristics, resulting in more efficient powder handling during manufacturing processes.

- Measurement and testing methods for powder flowability: Various analytical techniques and instruments are used to measure and characterize powder flowability. These include angle of repose measurements, shear cell testing, flow function determination, and avalanche analyzers. These methods provide quantitative data on flow properties such as cohesion, internal friction, and wall friction. Advanced testing equipment can simulate process conditions to predict how powders will behave during handling, storage, and processing, allowing for optimization of formulations and handling procedures.

- Environmental control for powder handling: Environmental factors significantly impact powder flowability. Controlling humidity, temperature, and electrostatic charge is essential for maintaining consistent flow properties. Humidity control systems prevent moisture absorption that can cause caking and agglomeration. Temperature regulation prevents thermal gradients that can affect flow behavior. Anti-static measures reduce particle adhesion caused by electrostatic forces. Implementing controlled environments for powder handling operations ensures reliable processing and consistent product quality.

- Equipment design for improved powder flow: Specialized equipment designs can significantly enhance powder flow during handling and processing. Features such as optimized hopper angles, vibration assistance, and air-assisted flow systems help overcome flow problems. Surface treatments and coatings on equipment surfaces reduce friction and prevent powder adhesion. Innovative discharge aids, such as mechanical agitators and pulsed gas systems, can break bridging and rat-holing in storage containers. These engineering solutions ensure consistent powder discharge and transfer throughout manufacturing processes.

02 Particle size and shape optimization techniques

The physical characteristics of powder particles significantly impact flowability. Controlling particle size distribution, shape uniformity, and surface roughness can enhance flow properties. Techniques such as milling, granulation, and spheronization are employed to achieve optimal particle morphology. Particles with more spherical shapes and narrower size distributions typically demonstrate superior flow behavior compared to irregular or widely distributed particle populations.Expand Specific Solutions03 Measurement and characterization methods for powder flowability

Accurate assessment of powder flow properties is essential for process design and quality control. Various analytical techniques and instruments are used to measure flowability parameters such as angle of repose, compressibility index, and shear strength. Advanced methods include powder rheometers, flow function testers, and dynamic flow analyzers that provide comprehensive characterization of powder behavior under different conditions and stress states.Expand Specific Solutions04 Environmental control strategies for powder handling

Environmental factors significantly influence powder flowability. Controlling humidity, temperature, electrostatic charge, and atmospheric conditions can prevent flow problems. Specialized equipment and facilities designed with controlled environments help maintain consistent powder properties during processing and storage. Techniques such as humidity regulation, temperature control, and ionization systems are employed to mitigate environmental effects on powder flow behavior.Expand Specific Solutions05 Equipment design for improved powder handling

Specialized equipment designs can overcome flowability challenges in industrial powder processing. Features such as optimized hopper geometries, vibration assistance, and fluidization systems facilitate reliable powder discharge and transport. Advanced conveying systems, feeders with adaptive control mechanisms, and innovative silo designs minimize flow problems like ratholing, bridging, and segregation, ensuring consistent powder handling across manufacturing operations.Expand Specific Solutions

Leading Manufacturers in DED Powder Systems

The Powder Handling and Flowability Solutions for Wire-Less DED Systems market is currently in an early growth phase, characterized by increasing adoption across additive manufacturing sectors. The global market size is estimated to reach $1.2-1.5 billion by 2027, driven by demand for more efficient metal powder delivery systems. Technologically, the field remains in development with varying maturity levels across solutions. Leading players like FormAlloy Technologies and 3D Systems are advancing commercial applications, while research institutions including Massachusetts Institute of Technology and Nanjing Tech University focus on fundamental innovations. Companies such as Relativity Space and Group14 Technologies are developing specialized powder handling solutions for specific industrial applications, while established manufacturers like General Electric and Lam Research are integrating these technologies into broader manufacturing systems.

FormAlloy Technologies, Inc.

Technical Solution: FormAlloy has developed advanced powder handling systems specifically designed for wire-less Directed Energy Deposition (DED) applications. Their proprietary powder delivery technology incorporates precision flow control mechanisms that maintain consistent powder feed rates regardless of build orientation or geometry complexity. The system utilizes a combination of electromagnetic vibration patterns and controlled gas pressure differentials to achieve uniform powder distribution. FormAlloy's solution includes real-time monitoring of powder flow characteristics through integrated sensors that detect flow irregularities and automatically adjust delivery parameters. Their powder handling system features a closed-loop feedback mechanism that continuously optimizes powder flow based on deposition conditions, ensuring consistent material properties throughout the build process. Additionally, FormAlloy has implemented anti-clogging mechanisms that prevent powder agglomeration in high humidity environments, addressing one of the key challenges in powder-based DED systems.

Strengths: Specialized expertise in DED powder delivery systems with proven implementation in industrial applications. Their closed-loop feedback system provides superior consistency in material deposition. Weaknesses: Their solutions may require significant customization for integration with third-party DED systems, potentially increasing implementation costs and complexity.

HP Development Co. LP

Technical Solution: HP has developed sophisticated powder handling solutions for wire-less DED systems that leverage their extensive experience in powder-based printing technologies. Their approach focuses on precise powder rheology control through environmental management and mechanical conditioning. HP's powder handling system incorporates advanced powder storage containers with integrated desiccant systems that maintain optimal moisture levels below 0.05% by weight, preventing agglomeration issues that impact flowability. The system utilizes precision vibratory feeders with variable frequency and amplitude control that can be dynamically adjusted based on powder characteristics and environmental conditions. HP's solution features electrostatic charge management through corona discharge neutralization, addressing a key factor affecting powder flow consistency in DED applications. Their powder delivery system incorporates laminar gas flow technology that creates a stable powder stream with minimal turbulence, ensuring consistent powder distribution at the deposition point. Additionally, HP has implemented comprehensive powder characterization capabilities within their system, continuously monitoring key flowability parameters such as angle of repose, bulk density, and cohesion index to optimize delivery parameters in real-time during the build process.

Strengths: Extensive expertise in powder handling from their traditional printing business with excellent powder characterization capabilities. Their systems offer superior environmental control for maintaining optimal powder conditions. Weaknesses: Their DED-specific experience may be more limited compared to companies focused exclusively on metal additive manufacturing.

Key Innovations in Powder Delivery Mechanisms

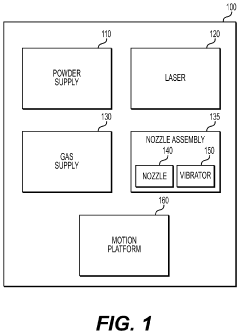

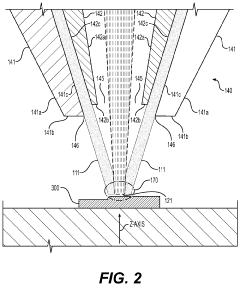

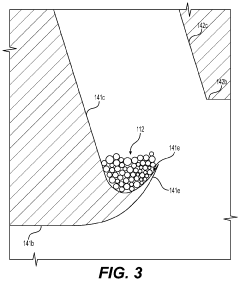

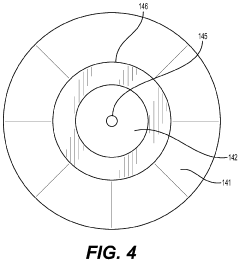

Directed energy deposition nozzle assembly with nozzle and vibrator that vibrates nozzle, and directed energy deposition apparatus having such nozzle assembly

PatentPendingUS20230090734A1

Innovation

- A nozzle assembly with a vibrator that applies a controlled vibration to the nozzle, using a ring-shaped silicone body and an electric motor to move a weight perpendicular to the nozzle's axis, which dislodges and prevents powder adhesion, reducing agglomeration and non-uniformity, and is configured with an annular orifice surrounding the energy beam opening to facilitate efficient powder and gas stream delivery.

Material Compatibility and Powder Characterization

In the context of Wire-Less Directed Energy Deposition (DED) systems, material compatibility and powder characterization represent critical factors determining process efficiency and final part quality. The absence of wire feedstock places greater demands on powder properties, as the powder must flow consistently through delivery systems while maintaining optimal interaction with energy sources. Metal powders used in Wire-Less DED systems typically range from 45-150 μm in particle size, with spherical morphology being preferred for superior flowability characteristics.

Powder flowability is primarily influenced by particle size distribution, shape, surface roughness, and moisture content. Spherical particles with narrow size distribution demonstrate superior flow behavior compared to irregular shapes. Quantitative assessment methods including Hall flowmeter testing, angle of repose measurements, and shear cell analysis provide essential metrics for characterizing powder flow properties. Recent advancements in dynamic powder testing equipment allow for real-time monitoring of flow behavior under various environmental conditions, critical for maintaining process stability.

Material compatibility considerations extend beyond mere flowability to encompass thermal properties, oxidation resistance, and laser absorption characteristics. Reflective materials like aluminum and copper present particular challenges in Wire-Less DED systems due to poor laser energy absorption, often requiring specialized laser wavelengths or surface treatments. Refractory metals demand higher energy inputs and controlled atmospheric conditions to prevent oxidation during processing.

Powder recycling represents another significant consideration, as unused powder in Wire-Less DED systems may undergo physical and chemical changes affecting subsequent processing. Characterization techniques including scanning electron microscopy (SEM), X-ray diffraction (XRD), and laser diffraction particle size analysis help monitor powder degradation through multiple reuse cycles. Establishing standardized protocols for powder characterization becomes essential for quality control and process repeatability.

Environmental factors including humidity, temperature, and oxygen content significantly impact powder behavior during handling and processing. Moisture absorption can lead to agglomeration and inconsistent flow, while oxygen exposure may result in surface oxidation affecting material properties. Advanced powder handling systems incorporating inert gas environments, moisture control, and electrostatic discharge mitigation help maintain powder integrity throughout the manufacturing process.

The development of tailored powder formulations specifically designed for Wire-Less DED applications represents an emerging trend, with manufacturers introducing composite powders and surface-modified variants to enhance flowability while maintaining desired mechanical properties in final components.

Powder flowability is primarily influenced by particle size distribution, shape, surface roughness, and moisture content. Spherical particles with narrow size distribution demonstrate superior flow behavior compared to irregular shapes. Quantitative assessment methods including Hall flowmeter testing, angle of repose measurements, and shear cell analysis provide essential metrics for characterizing powder flow properties. Recent advancements in dynamic powder testing equipment allow for real-time monitoring of flow behavior under various environmental conditions, critical for maintaining process stability.

Material compatibility considerations extend beyond mere flowability to encompass thermal properties, oxidation resistance, and laser absorption characteristics. Reflective materials like aluminum and copper present particular challenges in Wire-Less DED systems due to poor laser energy absorption, often requiring specialized laser wavelengths or surface treatments. Refractory metals demand higher energy inputs and controlled atmospheric conditions to prevent oxidation during processing.

Powder recycling represents another significant consideration, as unused powder in Wire-Less DED systems may undergo physical and chemical changes affecting subsequent processing. Characterization techniques including scanning electron microscopy (SEM), X-ray diffraction (XRD), and laser diffraction particle size analysis help monitor powder degradation through multiple reuse cycles. Establishing standardized protocols for powder characterization becomes essential for quality control and process repeatability.

Environmental factors including humidity, temperature, and oxygen content significantly impact powder behavior during handling and processing. Moisture absorption can lead to agglomeration and inconsistent flow, while oxygen exposure may result in surface oxidation affecting material properties. Advanced powder handling systems incorporating inert gas environments, moisture control, and electrostatic discharge mitigation help maintain powder integrity throughout the manufacturing process.

The development of tailored powder formulations specifically designed for Wire-Less DED applications represents an emerging trend, with manufacturers introducing composite powders and surface-modified variants to enhance flowability while maintaining desired mechanical properties in final components.

Process Monitoring and Quality Control Systems

Process monitoring and quality control systems are critical components in wireless Directed Energy Deposition (DED) systems, particularly when addressing powder handling and flowability challenges. These systems employ sophisticated sensor networks that continuously track powder flow rates, particle distribution, and deposition patterns in real-time. Advanced optical monitoring technologies, including high-speed cameras and laser profiling systems, capture visual data of the powder stream behavior and melt pool dynamics, enabling immediate detection of flow irregularities or clogging issues that could compromise build quality.

Thermal monitoring systems utilizing infrared cameras and pyrometers measure temperature gradients across the powder delivery path and deposition zone, providing crucial data on thermal conditions that affect powder flowability. These measurements help maintain optimal viscosity and prevent sintering or agglomeration of particles before reaching the melt pool. Integration of these thermal sensors with machine learning algorithms enables predictive maintenance by identifying patterns that precede flow disruptions.

Acoustic emission sensors detect ultrasonic signatures generated during powder flow, offering another dimension of process monitoring. Variations in acoustic patterns can indicate changes in powder rheology, moisture content, or the presence of foreign particles that might affect flowability. This non-contact monitoring approach provides valuable data without interfering with the powder stream dynamics.

In-situ chemical composition analysis using spectroscopic techniques ensures powder material consistency throughout the build process. Laser-induced breakdown spectroscopy (LIBS) or X-ray fluorescence systems can detect contamination or oxidation issues that might alter powder surface properties and consequently affect flowability characteristics. These systems are particularly valuable when processing reactive materials or when environmental conditions might introduce moisture or contaminants.

Closed-loop control systems represent the culmination of these monitoring technologies, creating intelligent powder delivery systems that automatically adjust process parameters based on real-time feedback. When sensors detect deviations in powder flow behavior, the system can modify gas flow rates, vibration frequency, or powder feed rates to maintain optimal flowability. Machine learning algorithms continuously refine these control responses by analyzing historical process data and outcomes.

Data fusion techniques combine inputs from multiple sensor types to create comprehensive process signatures that characterize normal and abnormal powder flow conditions. These signatures enable more robust anomaly detection than single-sensor approaches and provide operators with intuitive visualizations of complex process dynamics. The implementation of digital twin technology further enhances quality control by comparing real-time process data against validated simulation models.

Thermal monitoring systems utilizing infrared cameras and pyrometers measure temperature gradients across the powder delivery path and deposition zone, providing crucial data on thermal conditions that affect powder flowability. These measurements help maintain optimal viscosity and prevent sintering or agglomeration of particles before reaching the melt pool. Integration of these thermal sensors with machine learning algorithms enables predictive maintenance by identifying patterns that precede flow disruptions.

Acoustic emission sensors detect ultrasonic signatures generated during powder flow, offering another dimension of process monitoring. Variations in acoustic patterns can indicate changes in powder rheology, moisture content, or the presence of foreign particles that might affect flowability. This non-contact monitoring approach provides valuable data without interfering with the powder stream dynamics.

In-situ chemical composition analysis using spectroscopic techniques ensures powder material consistency throughout the build process. Laser-induced breakdown spectroscopy (LIBS) or X-ray fluorescence systems can detect contamination or oxidation issues that might alter powder surface properties and consequently affect flowability characteristics. These systems are particularly valuable when processing reactive materials or when environmental conditions might introduce moisture or contaminants.

Closed-loop control systems represent the culmination of these monitoring technologies, creating intelligent powder delivery systems that automatically adjust process parameters based on real-time feedback. When sensors detect deviations in powder flow behavior, the system can modify gas flow rates, vibration frequency, or powder feed rates to maintain optimal flowability. Machine learning algorithms continuously refine these control responses by analyzing historical process data and outcomes.

Data fusion techniques combine inputs from multiple sensor types to create comprehensive process signatures that characterize normal and abnormal powder flow conditions. These signatures enable more robust anomaly detection than single-sensor approaches and provide operators with intuitive visualizations of complex process dynamics. The implementation of digital twin technology further enhances quality control by comparing real-time process data against validated simulation models.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!