Weldability And Metallurgical Compatibility In Multi-Material DED Repairs

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Repair Technology Background and Objectives

Directed Energy Deposition (DED) has emerged as a transformative additive manufacturing technology with significant applications in repair and remanufacturing of high-value components. The evolution of DED technology can be traced back to the early 1990s, when it was primarily used for cladding and coating applications. Over the past three decades, DED has evolved substantially, incorporating advanced laser systems, precise powder delivery mechanisms, and sophisticated control algorithms that enable the deposition of complex geometries with high precision.

The technological trajectory of DED has been characterized by continuous improvements in deposition accuracy, material compatibility, and process stability. Recent advancements have focused on expanding the range of compatible materials, enhancing deposition rates, and improving the metallurgical properties of the deposited structures. The integration of real-time monitoring systems and closed-loop control mechanisms has further enhanced the reliability and repeatability of DED processes.

Multi-material DED repair represents a frontier in this technological evolution, addressing the growing demand for repairing components with heterogeneous material compositions. This approach is particularly relevant in industries such as aerospace, defense, and energy, where components often feature complex material systems designed to withstand extreme operating conditions.

The primary technical objective of multi-material DED repair is to restore damaged components to their original specifications while maintaining or enhancing their functional properties. This involves addressing several critical challenges, including ensuring weldability between dissimilar materials, managing thermal gradients during deposition, controlling microstructural evolution, and minimizing residual stresses in the repaired regions.

A key goal is to develop robust methodologies for predicting and controlling the metallurgical interactions that occur at the interfaces between different materials during the DED process. This includes understanding phase transformations, diffusion phenomena, and the formation of intermetallic compounds that can significantly impact the mechanical properties and service life of repaired components.

Additionally, the technology aims to establish standardized protocols for qualifying and certifying multi-material DED repairs, ensuring that repaired components meet or exceed the performance requirements of their original specifications. This involves developing comprehensive testing methodologies, non-destructive evaluation techniques, and predictive models that can accurately assess the integrity and durability of multi-material repairs.

The long-term vision for multi-material DED repair technology extends beyond simple restoration to enabling the functional enhancement of components through strategic material selection and deposition strategies, potentially leading to components with superior performance characteristics compared to their original designs.

The technological trajectory of DED has been characterized by continuous improvements in deposition accuracy, material compatibility, and process stability. Recent advancements have focused on expanding the range of compatible materials, enhancing deposition rates, and improving the metallurgical properties of the deposited structures. The integration of real-time monitoring systems and closed-loop control mechanisms has further enhanced the reliability and repeatability of DED processes.

Multi-material DED repair represents a frontier in this technological evolution, addressing the growing demand for repairing components with heterogeneous material compositions. This approach is particularly relevant in industries such as aerospace, defense, and energy, where components often feature complex material systems designed to withstand extreme operating conditions.

The primary technical objective of multi-material DED repair is to restore damaged components to their original specifications while maintaining or enhancing their functional properties. This involves addressing several critical challenges, including ensuring weldability between dissimilar materials, managing thermal gradients during deposition, controlling microstructural evolution, and minimizing residual stresses in the repaired regions.

A key goal is to develop robust methodologies for predicting and controlling the metallurgical interactions that occur at the interfaces between different materials during the DED process. This includes understanding phase transformations, diffusion phenomena, and the formation of intermetallic compounds that can significantly impact the mechanical properties and service life of repaired components.

Additionally, the technology aims to establish standardized protocols for qualifying and certifying multi-material DED repairs, ensuring that repaired components meet or exceed the performance requirements of their original specifications. This involves developing comprehensive testing methodologies, non-destructive evaluation techniques, and predictive models that can accurately assess the integrity and durability of multi-material repairs.

The long-term vision for multi-material DED repair technology extends beyond simple restoration to enabling the functional enhancement of components through strategic material selection and deposition strategies, potentially leading to components with superior performance characteristics compared to their original designs.

Market Analysis for Multi-Material DED Repair Solutions

The global market for Multi-Material Directed Energy Deposition (DED) repair solutions is experiencing significant growth, driven by increasing demands across aerospace, defense, automotive, and heavy machinery sectors. These industries face critical challenges with component repair and maintenance, where traditional repair methods often fall short in addressing complex multi-material structures.

The aerospace industry represents the largest market segment, valued at approximately $1.2 billion in 2022, with projected annual growth of 8.7% through 2028. This sector's demand stems from the need to repair high-value components such as turbine blades, combustion chambers, and structural elements that frequently incorporate dissimilar metal combinations. The ability to restore these components rather than replace them translates to substantial cost savings, with aerospace companies reporting maintenance cost reductions of 30-45% when implementing advanced DED repair technologies.

Defense applications follow closely, with market valuation reaching $950 million in 2022. Military equipment maintenance represents a particularly promising growth area, as defense organizations worldwide seek to extend the service life of critical assets while reducing downtime and replacement costs. The automotive industry, though currently a smaller segment at $650 million, is showing the fastest growth rate at 11.3% annually, particularly in high-performance and electric vehicle segments where multi-material components are increasingly common.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization in China and India, alongside significant aerospace and defense investments.

Customer demand patterns reveal strong interest in turnkey solutions that combine DED hardware, specialized materials, process monitoring systems, and post-processing capabilities. End users increasingly prioritize repair solutions that can address metallurgical compatibility challenges between dissimilar materials while maintaining or enhancing component performance characteristics.

Market analysis indicates that the total addressable market for multi-material DED repair technologies could reach $5.8 billion by 2030, representing a significant opportunity for technology providers who can overcome current metallurgical compatibility challenges. Industry surveys show that 78% of potential customers identify weldability between dissimilar materials as their primary technical concern, followed by microstructural control (65%) and mechanical property consistency (61%).

The aerospace industry represents the largest market segment, valued at approximately $1.2 billion in 2022, with projected annual growth of 8.7% through 2028. This sector's demand stems from the need to repair high-value components such as turbine blades, combustion chambers, and structural elements that frequently incorporate dissimilar metal combinations. The ability to restore these components rather than replace them translates to substantial cost savings, with aerospace companies reporting maintenance cost reductions of 30-45% when implementing advanced DED repair technologies.

Defense applications follow closely, with market valuation reaching $950 million in 2022. Military equipment maintenance represents a particularly promising growth area, as defense organizations worldwide seek to extend the service life of critical assets while reducing downtime and replacement costs. The automotive industry, though currently a smaller segment at $650 million, is showing the fastest growth rate at 11.3% annually, particularly in high-performance and electric vehicle segments where multi-material components are increasingly common.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization in China and India, alongside significant aerospace and defense investments.

Customer demand patterns reveal strong interest in turnkey solutions that combine DED hardware, specialized materials, process monitoring systems, and post-processing capabilities. End users increasingly prioritize repair solutions that can address metallurgical compatibility challenges between dissimilar materials while maintaining or enhancing component performance characteristics.

Market analysis indicates that the total addressable market for multi-material DED repair technologies could reach $5.8 billion by 2030, representing a significant opportunity for technology providers who can overcome current metallurgical compatibility challenges. Industry surveys show that 78% of potential customers identify weldability between dissimilar materials as their primary technical concern, followed by microstructural control (65%) and mechanical property consistency (61%).

Current Weldability Challenges in Multi-Material DED

Multi-material Directed Energy Deposition (DED) repair processes face significant weldability challenges that stem from the inherent metallurgical incompatibilities between dissimilar materials. When attempting to join materials with different chemical compositions, crystal structures, and thermophysical properties, a range of issues emerge that compromise the integrity of the repaired components.

One of the primary challenges is the formation of brittle intermetallic compounds at the interface between dissimilar metals. These compounds, often characterized by high hardness and low ductility, create stress concentration points that can lead to premature failure under service conditions. For example, when repairing titanium alloys with steel-based materials, Ti-Fe intermetallics form readily and significantly reduce mechanical performance.

Thermal expansion coefficient mismatches represent another critical obstacle. During the rapid heating and cooling cycles characteristic of DED processes, materials with different expansion rates generate residual stresses at the interface. These stresses can cause distortion, cracking, or delamination, particularly in applications subjected to thermal cycling during service.

Elemental segregation during solidification presents additional complications. The high cooling rates in DED processes can lead to non-equilibrium microstructures with localized compositional variations. This segregation often results in regions with compromised corrosion resistance or mechanical properties, creating weak points in the repaired structure.

Hot cracking susceptibility increases dramatically in multi-material DED repairs. Materials with wide solidification temperature ranges are particularly vulnerable to solidification cracking as tensile stresses develop during the final stages of solidification. This issue is exacerbated when joining materials with significantly different melting points.

The dilution control between the substrate and deposited material presents a technical challenge requiring precise process parameter optimization. Excessive dilution can introduce undesirable elements into the melt pool, altering the intended composition and compromising the repair's performance characteristics.

Microstructural heterogeneity across the repair interface creates property gradients that can lead to premature failure. The transition from substrate to deposited material often exhibits varying grain structures, phases, and hardness profiles that complicate mechanical behavior prediction and quality control.

Oxidation and contamination during the deposition process further complicate multi-material DED repairs. Reactive metals such as titanium and aluminum readily form oxides that can become entrapped in the deposit, creating defects and reducing mechanical properties. This necessitates stringent atmospheric control during processing, adding complexity to repair operations.

One of the primary challenges is the formation of brittle intermetallic compounds at the interface between dissimilar metals. These compounds, often characterized by high hardness and low ductility, create stress concentration points that can lead to premature failure under service conditions. For example, when repairing titanium alloys with steel-based materials, Ti-Fe intermetallics form readily and significantly reduce mechanical performance.

Thermal expansion coefficient mismatches represent another critical obstacle. During the rapid heating and cooling cycles characteristic of DED processes, materials with different expansion rates generate residual stresses at the interface. These stresses can cause distortion, cracking, or delamination, particularly in applications subjected to thermal cycling during service.

Elemental segregation during solidification presents additional complications. The high cooling rates in DED processes can lead to non-equilibrium microstructures with localized compositional variations. This segregation often results in regions with compromised corrosion resistance or mechanical properties, creating weak points in the repaired structure.

Hot cracking susceptibility increases dramatically in multi-material DED repairs. Materials with wide solidification temperature ranges are particularly vulnerable to solidification cracking as tensile stresses develop during the final stages of solidification. This issue is exacerbated when joining materials with significantly different melting points.

The dilution control between the substrate and deposited material presents a technical challenge requiring precise process parameter optimization. Excessive dilution can introduce undesirable elements into the melt pool, altering the intended composition and compromising the repair's performance characteristics.

Microstructural heterogeneity across the repair interface creates property gradients that can lead to premature failure. The transition from substrate to deposited material often exhibits varying grain structures, phases, and hardness profiles that complicate mechanical behavior prediction and quality control.

Oxidation and contamination during the deposition process further complicate multi-material DED repairs. Reactive metals such as titanium and aluminum readily form oxides that can become entrapped in the deposit, creating defects and reducing mechanical properties. This necessitates stringent atmospheric control during processing, adding complexity to repair operations.

Existing Multi-Material Compatibility Solutions

01 Material compatibility in multi-material DED repairs

Material compatibility is crucial in multi-material Directed Energy Deposition repairs to ensure structural integrity. The selection of compatible materials with similar thermal expansion coefficients, melting points, and chemical compositions helps prevent defects such as cracks and delamination at the interface. Advanced computational models can predict material interactions and optimize the repair process, ensuring strong metallurgical bonding between the substrate and deposited materials.- Material compatibility in multi-material DED repairs: Material compatibility is crucial in multi-material Directed Energy Deposition repairs to ensure structural integrity. The selection of compatible materials with similar thermal expansion coefficients, melting points, and chemical compositions helps prevent issues like cracking, delamination, and residual stress. Advanced computational models can predict material interactions and optimize the repair process, ensuring strong metallurgical bonds between the substrate and deposited materials.

- Weldability considerations for DED repair processes: Weldability is a key factor in successful DED repairs, involving the ability of materials to be joined without defects. Factors affecting weldability include material composition, thermal properties, and process parameters. Pre-heating techniques, controlled cooling rates, and proper shielding gas selection can improve weldability of difficult-to-weld materials. Advanced monitoring systems help maintain optimal welding conditions throughout the deposition process, reducing the risk of defects such as porosity, hot cracking, and incomplete fusion.

- Process parameter optimization for metallurgical compatibility: Optimizing process parameters is essential for achieving metallurgical compatibility in multi-material DED repairs. Parameters such as laser power, travel speed, powder feed rate, and layer thickness significantly impact the microstructure and properties of the deposited material. Real-time monitoring and adaptive control systems can adjust parameters during deposition to maintain consistent quality. Proper parameter selection helps minimize dilution between dissimilar materials and controls the heat-affected zone, resulting in superior mechanical properties and repair durability.

- Microstructure control and post-processing treatments: Controlling the microstructure of multi-material DED repairs is critical for achieving desired mechanical properties. Techniques such as controlled cooling rates, substrate preheating, and in-situ heat treatment can influence grain structure and phase formation. Post-processing treatments including heat treatment, hot isostatic pressing, and surface finishing can further enhance metallurgical properties, reduce residual stresses, and improve fatigue resistance. These treatments help homogenize the microstructure across the repair interface and optimize the performance of the repaired component.

- Advanced monitoring and quality control systems: Advanced monitoring and quality control systems are essential for ensuring consistent metallurgical quality in multi-material DED repairs. In-situ monitoring techniques including thermal imaging, spectroscopy, and high-speed cameras can detect defects during deposition. Machine learning algorithms can analyze sensor data to predict and prevent metallurgical issues. Non-destructive testing methods such as ultrasonic testing, X-ray computed tomography, and eddy current inspection help verify the integrity of completed repairs, ensuring they meet required specifications for structural applications.

02 Weldability assessment for DED repair processes

Weldability assessment is essential for successful DED repairs, involving evaluation of material properties before, during, and after deposition. This includes analyzing the heat-affected zone, potential for crack formation, and residual stress development. Advanced testing methods such as hot cracking susceptibility tests and dilution control techniques help optimize process parameters to achieve sound metallurgical bonds. Proper weldability assessment ensures the repaired components maintain their mechanical properties and service life.Expand Specific Solutions03 Process parameter optimization for metallurgical compatibility

Optimizing process parameters is critical for achieving metallurgical compatibility in multi-material DED repairs. Parameters such as laser power, scanning speed, powder feed rate, and layer thickness significantly affect the microstructure and properties of the deposited material. Real-time monitoring systems can adjust these parameters during deposition to control dilution, cooling rates, and thermal gradients. This optimization ensures proper fusion between dissimilar materials while minimizing defects and achieving desired mechanical properties.Expand Specific Solutions04 Microstructure control and post-processing treatments

Controlling the microstructure during DED repairs and applying appropriate post-processing treatments are essential for ensuring metallurgical compatibility. Techniques such as controlled cooling, in-situ heat treatment, and strategic deposition patterns can manipulate grain structure and phase formation. Post-processing treatments including heat treatment, hot isostatic pressing, and surface finishing can further enhance the metallurgical properties, reduce residual stresses, and improve the overall quality of the repaired components.Expand Specific Solutions05 Innovative alloy design for improved DED repair compatibility

Innovative alloy design approaches are being developed specifically for multi-material DED repairs to address compatibility challenges. These include functionally graded materials that create a gradual transition between dissimilar metals, reducing stress concentrations and improving bonding. Custom-designed intermediate layers can serve as metallurgical bridges between incompatible materials. Additionally, novel powder blends with tailored compositions can minimize cracking susceptibility and enhance the overall repair quality by promoting favorable microstructural development.Expand Specific Solutions

Leading Companies and Research Institutions in DED Repair

The multi-material Directed Energy Deposition (DED) repair market is currently in its growth phase, characterized by increasing adoption across aerospace, defense, and heavy manufacturing sectors. The global market for this technology is estimated at approximately $2-3 billion, with projected annual growth of 15-20%. Technologically, the field shows varying maturity levels, with companies like RTX Corp. and Mitsubishi Heavy Industries leading advanced applications in aerospace components, while academic institutions such as Huazhong University and Tuskegee University focus on fundamental metallurgical compatibility research. EWI and General Electric are developing standardized processes for industrial implementation, while specialized materials companies including Kobe Steel and Daido Steel are advancing compatible alloy formulations. The competitive landscape features aerospace giants leveraging proprietary technologies alongside emerging specialized repair service providers.

General Electric Company

Technical Solution: General Electric has developed advanced multi-material Directed Energy Deposition (DED) repair solutions focusing on high-temperature superalloys for aerospace applications. Their approach utilizes controlled heat input strategies and specialized powder feedstock compositions to address dissimilar metal joining challenges. GE's technology employs pre-weld heat treatments and carefully designed transition layers between dissimilar materials to minimize residual stress and prevent formation of brittle intermetallic compounds. Their process incorporates real-time monitoring systems that adjust laser power and deposition parameters based on thermal feedback, ensuring optimal metallurgical bonding while preventing excessive dilution between repair and substrate materials. GE has particularly focused on nickel-based superalloy repairs for turbine components, developing proprietary powder blends with modified compositions that improve weldability while maintaining high-temperature mechanical properties. Their approach includes post-deposition heat treatments specifically designed to homogenize the microstructure across the repair interface.

Strengths: Superior control of heat-affected zone properties through advanced thermal management; extensive experience with aerospace-grade superalloys; comprehensive material compatibility database. Weaknesses: Solutions primarily optimized for their own product ecosystem; relatively high implementation costs; requires specialized equipment and expertise.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed comprehensive multi-material DED repair technologies focusing on challenging material combinations including dissimilar metal joints and high-strength alloys. Their approach employs a systematic material compatibility assessment framework that evaluates thermal properties, phase transformation behaviors, and potential intermetallic formation to determine optimal processing parameters. Kobe Steel's technology utilizes controlled dilution techniques where deposition parameters are precisely managed to create optimal mixing between substrate and repair materials while preventing excessive dilution that could compromise mechanical properties. Their process incorporates specialized interlayer materials designed to serve as metallurgical bridges between dissimilar metals, with compositions carefully selected to be compatible with both base materials. Kobe Steel has developed advanced thermal management strategies including localized pre-heating and controlled cooling paths to minimize residual stress development across the repair interface. Their approach includes comprehensive post-repair heat treatment protocols tailored to specific material combinations, designed to homogenize microstructures and relieve residual stresses while maintaining critical mechanical properties.

Strengths: Extensive metallurgical expertise across diverse material systems; strong focus on practical industrial applications; solutions developed with manufacturability and cost-effectiveness in mind. Weaknesses: Less public documentation of aerospace applications compared to competitors; solutions may require adaptation for highest-performance applications.

Key Metallurgical Interface Innovations

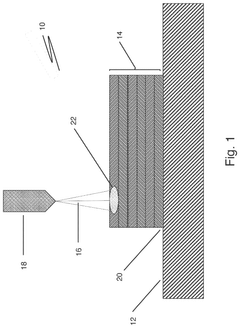

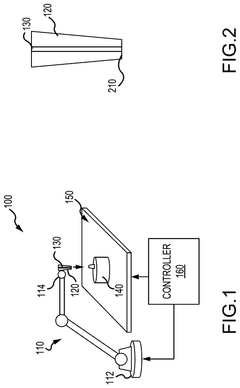

Engineered microstructure for enhanced performance during directed energy deposition repair process

PatentPendingUS20250242410A1

Innovation

- A directed energy deposition (DED) process is used to control the microstructure of each repair layer by adjusting parameters like powder feed rate, energy intensity, traversal rate, and auxiliary heating/cooling, ensuring each layer has a pre-determined microstructure to meet specific structural and functional needs.

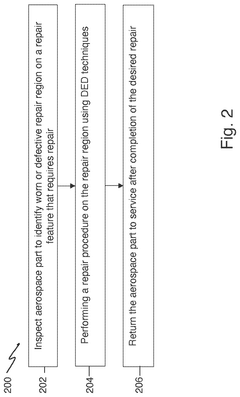

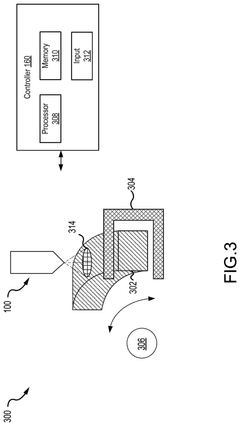

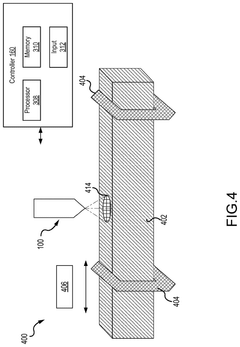

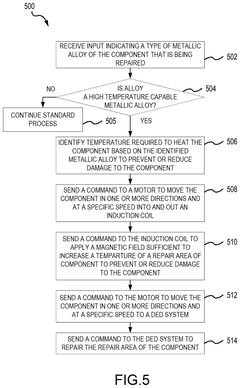

Induction heating of a component during direct energy deposition repair

PatentPendingUS20250024563A1

Innovation

- The method involves using induction heating with a conforming induction coil to preheat aerospace components to a desired temperature, controlled by sensors and a motor, before performing direct energy deposition repair, thereby reducing the occurrence of defects such as cracking.

Material Selection Strategies for Optimal DED Repair

Material selection is a critical factor in determining the success of Directed Energy Deposition (DED) repair processes, particularly when dealing with multi-material components. The strategic approach to material selection must consider both the base material properties and the intended repair material characteristics to ensure optimal metallurgical compatibility and weldability.

When selecting materials for DED repairs, engineers must first conduct a comprehensive analysis of the base material's chemical composition, microstructure, and mechanical properties. This baseline assessment provides crucial information about potential challenges in the repair process, such as susceptibility to cracking, formation of brittle intermetallic compounds, or thermal distortion during processing.

For multi-material DED repairs, the selection strategy often involves identifying intermediate or transitional materials that can bridge the gap between dissimilar base materials. These transitional materials create a gradient of properties that minimizes stress concentrations and improves overall metallurgical compatibility. For example, when repairing interfaces between steel and titanium components, a strategic layering of materials with incrementally changing compositions can prevent the formation of brittle intermetallic phases.

Thermal properties must be carefully considered in the material selection process. Materials with similar thermal expansion coefficients reduce residual stress buildup during the heating and cooling cycles inherent to DED processes. Additionally, materials with good thermal conductivity can help dissipate heat more effectively, reducing the risk of thermal damage to the surrounding base material.

Pre-alloyed powders versus elemental powder blends represent another strategic consideration in material selection. Pre-alloyed powders offer consistency in composition but limit flexibility, while elemental powder blends allow for customized compositions tailored to specific repair requirements. The choice between these options depends on the complexity of the repair and the specific metallurgical challenges presented.

Advanced computational tools, including thermodynamic modeling and phase diagram calculations, have become essential in modern material selection strategies for DED repairs. These tools enable prediction of phase formations, solidification behaviors, and potential compatibility issues before physical implementation, significantly reducing trial-and-error approaches and accelerating the development of effective repair solutions.

The material selection strategy must also account for post-processing requirements. Materials that respond well to heat treatment or surface finishing processes may be preferred, as these subsequent operations can further enhance the mechanical properties and performance of the repaired component.

When selecting materials for DED repairs, engineers must first conduct a comprehensive analysis of the base material's chemical composition, microstructure, and mechanical properties. This baseline assessment provides crucial information about potential challenges in the repair process, such as susceptibility to cracking, formation of brittle intermetallic compounds, or thermal distortion during processing.

For multi-material DED repairs, the selection strategy often involves identifying intermediate or transitional materials that can bridge the gap between dissimilar base materials. These transitional materials create a gradient of properties that minimizes stress concentrations and improves overall metallurgical compatibility. For example, when repairing interfaces between steel and titanium components, a strategic layering of materials with incrementally changing compositions can prevent the formation of brittle intermetallic phases.

Thermal properties must be carefully considered in the material selection process. Materials with similar thermal expansion coefficients reduce residual stress buildup during the heating and cooling cycles inherent to DED processes. Additionally, materials with good thermal conductivity can help dissipate heat more effectively, reducing the risk of thermal damage to the surrounding base material.

Pre-alloyed powders versus elemental powder blends represent another strategic consideration in material selection. Pre-alloyed powders offer consistency in composition but limit flexibility, while elemental powder blends allow for customized compositions tailored to specific repair requirements. The choice between these options depends on the complexity of the repair and the specific metallurgical challenges presented.

Advanced computational tools, including thermodynamic modeling and phase diagram calculations, have become essential in modern material selection strategies for DED repairs. These tools enable prediction of phase formations, solidification behaviors, and potential compatibility issues before physical implementation, significantly reducing trial-and-error approaches and accelerating the development of effective repair solutions.

The material selection strategy must also account for post-processing requirements. Materials that respond well to heat treatment or surface finishing processes may be preferred, as these subsequent operations can further enhance the mechanical properties and performance of the repaired component.

Quality Assurance Methods for Multi-Material DED Joints

Quality assurance in multi-material Directed Energy Deposition (DED) joints represents a critical challenge due to the complex metallurgical interactions between dissimilar materials. Conventional quality control methods often prove inadequate when applied to these heterogeneous structures, necessitating specialized approaches tailored to the unique characteristics of multi-material interfaces.

Non-destructive testing (NDT) techniques have been adapted specifically for multi-material DED joints, with ultrasonic testing showing particular promise for detecting subsurface defects at material interfaces. Advanced ultrasonic phased array technology enables precise identification of lack-of-fusion defects and intermetallic compound formations that are common in dissimilar metal joints. X-ray computed tomography (CT) provides complementary capabilities, offering three-dimensional visualization of internal structures with resolution down to the micron scale.

In-situ monitoring systems represent a significant advancement in quality assurance for multi-material DED processes. These systems incorporate thermal imaging cameras, high-speed photography, and spectroscopic analysis to detect anomalies during deposition in real-time. Machine learning algorithms have been integrated with these monitoring systems to identify patterns indicative of potential defects before they become critical failures, enabling adaptive control of process parameters.

Mechanical testing protocols for multi-material joints have evolved beyond traditional approaches. Specialized micro-hardness mapping across interface regions provides valuable insights into local property variations and potential weak points. Novel tensile and fatigue testing methodologies have been developed to accurately characterize the unique behavior of these heterogeneous structures under various loading conditions.

Microstructural characterization techniques form another essential component of quality assurance frameworks. Electron backscatter diffraction (EBSD) analysis enables detailed crystallographic mapping across material interfaces, while energy-dispersive X-ray spectroscopy (EDS) provides elemental distribution information critical for identifying diffusion zones and intermetallic phases. These techniques help establish correlations between processing parameters and resultant microstructures.

Standardization efforts for multi-material DED quality assurance remain in nascent stages. Several industry consortia and research institutions are working to establish unified testing protocols and acceptance criteria specifically for multi-material repairs. These emerging standards incorporate metallurgical compatibility considerations that were previously overlooked in single-material quality assurance frameworks.

Digital twin approaches are gaining traction as comprehensive quality assurance tools, integrating process modeling with real-time monitoring data to predict joint performance and identify potential failure modes before they occur in service. These computational frameworks account for the complex thermomechanical history experienced during multi-material DED repairs and their impact on final component integrity.

Non-destructive testing (NDT) techniques have been adapted specifically for multi-material DED joints, with ultrasonic testing showing particular promise for detecting subsurface defects at material interfaces. Advanced ultrasonic phased array technology enables precise identification of lack-of-fusion defects and intermetallic compound formations that are common in dissimilar metal joints. X-ray computed tomography (CT) provides complementary capabilities, offering three-dimensional visualization of internal structures with resolution down to the micron scale.

In-situ monitoring systems represent a significant advancement in quality assurance for multi-material DED processes. These systems incorporate thermal imaging cameras, high-speed photography, and spectroscopic analysis to detect anomalies during deposition in real-time. Machine learning algorithms have been integrated with these monitoring systems to identify patterns indicative of potential defects before they become critical failures, enabling adaptive control of process parameters.

Mechanical testing protocols for multi-material joints have evolved beyond traditional approaches. Specialized micro-hardness mapping across interface regions provides valuable insights into local property variations and potential weak points. Novel tensile and fatigue testing methodologies have been developed to accurately characterize the unique behavior of these heterogeneous structures under various loading conditions.

Microstructural characterization techniques form another essential component of quality assurance frameworks. Electron backscatter diffraction (EBSD) analysis enables detailed crystallographic mapping across material interfaces, while energy-dispersive X-ray spectroscopy (EDS) provides elemental distribution information critical for identifying diffusion zones and intermetallic phases. These techniques help establish correlations between processing parameters and resultant microstructures.

Standardization efforts for multi-material DED quality assurance remain in nascent stages. Several industry consortia and research institutions are working to establish unified testing protocols and acceptance criteria specifically for multi-material repairs. These emerging standards incorporate metallurgical compatibility considerations that were previously overlooked in single-material quality assurance frameworks.

Digital twin approaches are gaining traction as comprehensive quality assurance tools, integrating process modeling with real-time monitoring data to predict joint performance and identify potential failure modes before they occur in service. These computational frameworks account for the complex thermomechanical history experienced during multi-material DED repairs and their impact on final component integrity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!