Material Feedstock Specification And Quality Control For DED Lines

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Material Feedstock Evolution and Objectives

Directed Energy Deposition (DED) technology has evolved significantly since its inception in the early 1990s, transforming from experimental applications to a commercially viable additive manufacturing process. The evolution of material feedstock for DED has been particularly noteworthy, progressing from basic metal powders to sophisticated alloy compositions tailored for specific industrial applications. Initially limited to a handful of metal alloys, DED material feedstock now encompasses a diverse range of materials including titanium alloys, nickel-based superalloys, stainless steels, and increasingly, composite materials with enhanced properties.

The historical trajectory shows a clear shift from adapting existing powder metallurgy materials to developing specialized powders optimized for the unique thermal and mechanical conditions of the DED process. Early challenges included inconsistent powder flow rates, variable particle morphology, and limited understanding of how powder characteristics influenced final part properties. These challenges drove significant research into powder characterization techniques and the establishment of more rigorous quality control parameters.

Current objectives in DED material feedstock development focus on several key areas. First is the enhancement of powder flowability and consistency, critical factors for achieving uniform deposition and reducing process variability. This includes optimizing particle size distribution, typically within the 45-150 μm range, and developing more spherical particle morphologies through improved atomization techniques. Second is the expansion of the material palette to include high-performance alloys, functionally graded materials, and multi-material systems that can deliver components with location-specific properties.

Another primary objective is the development of comprehensive material specifications that standardize feedstock requirements across the industry. Organizations such as ASTM International and ISO are actively working to establish these standards, which will facilitate broader industrial adoption of DED technology. These specifications aim to address critical parameters including chemical composition, particle size distribution, flowability, moisture content, and oxygen levels.

Quality control objectives have also evolved significantly, moving beyond basic sieve analysis and chemical composition testing to incorporate advanced characterization techniques. These include laser diffraction for particle size analysis, scanning electron microscopy for morphology assessment, and rheological testing for flow behavior prediction. Real-time monitoring systems that can detect feedstock anomalies during the deposition process represent the frontier of quality control development.

The ultimate goal is to establish a robust material feedstock ecosystem that enables repeatable, certifiable DED processes suitable for critical applications in aerospace, medical, and energy sectors. This requires not only technical advancements in material development but also the creation of comprehensive supply chain infrastructure and quality assurance protocols that can deliver consistent, high-quality feedstock materials to end users.

The historical trajectory shows a clear shift from adapting existing powder metallurgy materials to developing specialized powders optimized for the unique thermal and mechanical conditions of the DED process. Early challenges included inconsistent powder flow rates, variable particle morphology, and limited understanding of how powder characteristics influenced final part properties. These challenges drove significant research into powder characterization techniques and the establishment of more rigorous quality control parameters.

Current objectives in DED material feedstock development focus on several key areas. First is the enhancement of powder flowability and consistency, critical factors for achieving uniform deposition and reducing process variability. This includes optimizing particle size distribution, typically within the 45-150 μm range, and developing more spherical particle morphologies through improved atomization techniques. Second is the expansion of the material palette to include high-performance alloys, functionally graded materials, and multi-material systems that can deliver components with location-specific properties.

Another primary objective is the development of comprehensive material specifications that standardize feedstock requirements across the industry. Organizations such as ASTM International and ISO are actively working to establish these standards, which will facilitate broader industrial adoption of DED technology. These specifications aim to address critical parameters including chemical composition, particle size distribution, flowability, moisture content, and oxygen levels.

Quality control objectives have also evolved significantly, moving beyond basic sieve analysis and chemical composition testing to incorporate advanced characterization techniques. These include laser diffraction for particle size analysis, scanning electron microscopy for morphology assessment, and rheological testing for flow behavior prediction. Real-time monitoring systems that can detect feedstock anomalies during the deposition process represent the frontier of quality control development.

The ultimate goal is to establish a robust material feedstock ecosystem that enables repeatable, certifiable DED processes suitable for critical applications in aerospace, medical, and energy sectors. This requires not only technical advancements in material development but also the creation of comprehensive supply chain infrastructure and quality assurance protocols that can deliver consistent, high-quality feedstock materials to end users.

Market Analysis for DED Material Feedstock

The global market for Directed Energy Deposition (DED) material feedstock is experiencing robust growth, driven by increasing adoption of additive manufacturing technologies across various industrial sectors. Current market valuations indicate that the DED material feedstock market reached approximately 320 million USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 14.8% through 2028. This growth trajectory is significantly outpacing traditional manufacturing material markets, which typically grow at 3-5% annually.

The aerospace and defense sectors currently represent the largest market share for DED material feedstock, accounting for roughly 38% of total consumption. These industries prioritize high-performance alloys such as titanium, nickel-based superalloys, and specialized steel compositions that can withstand extreme operating conditions. The medical and dental sectors follow with approximately 21% market share, where there is particular demand for biocompatible materials including titanium alloys and cobalt-chrome compositions.

Regional analysis reveals that North America dominates the market with approximately 42% share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is demonstrating the fastest growth rate at nearly 18% annually, primarily driven by rapid industrialization in China and significant government investments in advanced manufacturing technologies across South Korea, Japan, and Singapore.

Material-wise, metal powders constitute about 85% of the DED feedstock market, with wire feedstock making up the remaining 15%. However, wire-based DED systems are gaining traction due to their higher deposition rates and material efficiency, suggesting a potential shift in this ratio over the coming years. Among metal powders, titanium alloys command the highest market value due to their extensive use in aerospace applications and high material cost.

Key market drivers include the growing demand for component repair and remanufacturing, particularly in aerospace and heavy machinery sectors, where DED technologies offer significant cost advantages over traditional replacement approaches. Additionally, the push toward sustainable manufacturing practices is bolstering market growth, as DED processes typically generate less material waste compared to conventional subtractive manufacturing methods.

Market challenges primarily revolve around material quality consistency and certification requirements, particularly for critical applications in aerospace and medical industries. The high cost of specialized metal powders also remains a barrier to wider adoption, with premium titanium and nickel-based superalloy powders commanding prices between 200-500 USD per kilogram depending on particle specifications and quality requirements.

The aerospace and defense sectors currently represent the largest market share for DED material feedstock, accounting for roughly 38% of total consumption. These industries prioritize high-performance alloys such as titanium, nickel-based superalloys, and specialized steel compositions that can withstand extreme operating conditions. The medical and dental sectors follow with approximately 21% market share, where there is particular demand for biocompatible materials including titanium alloys and cobalt-chrome compositions.

Regional analysis reveals that North America dominates the market with approximately 42% share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is demonstrating the fastest growth rate at nearly 18% annually, primarily driven by rapid industrialization in China and significant government investments in advanced manufacturing technologies across South Korea, Japan, and Singapore.

Material-wise, metal powders constitute about 85% of the DED feedstock market, with wire feedstock making up the remaining 15%. However, wire-based DED systems are gaining traction due to their higher deposition rates and material efficiency, suggesting a potential shift in this ratio over the coming years. Among metal powders, titanium alloys command the highest market value due to their extensive use in aerospace applications and high material cost.

Key market drivers include the growing demand for component repair and remanufacturing, particularly in aerospace and heavy machinery sectors, where DED technologies offer significant cost advantages over traditional replacement approaches. Additionally, the push toward sustainable manufacturing practices is bolstering market growth, as DED processes typically generate less material waste compared to conventional subtractive manufacturing methods.

Market challenges primarily revolve around material quality consistency and certification requirements, particularly for critical applications in aerospace and medical industries. The high cost of specialized metal powders also remains a barrier to wider adoption, with premium titanium and nickel-based superalloy powders commanding prices between 200-500 USD per kilogram depending on particle specifications and quality requirements.

Current Challenges in DED Material Quality Control

Despite significant advancements in Directed Energy Deposition (DED) technologies, material feedstock quality control remains one of the most challenging aspects of the process. The inconsistency in powder or wire feedstock properties directly impacts the final part quality, creating substantial barriers to widespread industrial adoption of DED manufacturing lines.

Powder-based DED systems face particular challenges with flowability variations, which can cause irregular material deposition rates and lead to porosity or inclusion defects. Current powder characterization methods often fail to adequately predict how materials will behave during the actual deposition process, creating a disconnect between quality control metrics and real-world performance.

Particle size distribution represents another critical challenge, as even minor deviations can significantly alter melt pool dynamics and solidification behavior. The industry lacks standardized specifications for optimal particle size distributions across different DED processes and parameter sets, forcing manufacturers to develop proprietary solutions through costly trial-and-error approaches.

Chemical composition control presents additional complications, particularly for reactive materials like titanium alloys and aluminum. Oxygen and nitrogen contamination during powder handling and storage can dramatically alter material properties, yet real-time monitoring systems for detecting these changes remain inadequate. The sensitivity of these materials demands more sophisticated storage, handling, and quality verification protocols than are currently standardized.

Moisture content in feedstock materials constitutes a persistent problem that can lead to hydrogen embrittlement and porosity in final parts. Current drying and storage solutions provide inconsistent results, and moisture detection methods lack the precision needed for high-performance applications in aerospace and medical industries.

For wire-based DED systems, dimensional consistency and surface condition of the feedstock wire significantly impact process stability. Variations in wire diameter as small as 0.02mm can cause substantial changes in deposition characteristics, yet current quality control standards permit wider tolerances than the process actually requires for optimal performance.

Cross-contamination between different material batches represents another significant challenge, particularly in multi-material DED systems. The industry lacks effective cleaning protocols and contamination detection methods that can be integrated into production environments without causing excessive downtime or cost increases.

The absence of in-line quality monitoring systems for feedstock materials forces manufacturers to rely on batch testing, which cannot detect real-time changes in material properties during the deposition process. This gap between quality verification and actual production creates significant risks for critical applications where material integrity is paramount.

Powder-based DED systems face particular challenges with flowability variations, which can cause irregular material deposition rates and lead to porosity or inclusion defects. Current powder characterization methods often fail to adequately predict how materials will behave during the actual deposition process, creating a disconnect between quality control metrics and real-world performance.

Particle size distribution represents another critical challenge, as even minor deviations can significantly alter melt pool dynamics and solidification behavior. The industry lacks standardized specifications for optimal particle size distributions across different DED processes and parameter sets, forcing manufacturers to develop proprietary solutions through costly trial-and-error approaches.

Chemical composition control presents additional complications, particularly for reactive materials like titanium alloys and aluminum. Oxygen and nitrogen contamination during powder handling and storage can dramatically alter material properties, yet real-time monitoring systems for detecting these changes remain inadequate. The sensitivity of these materials demands more sophisticated storage, handling, and quality verification protocols than are currently standardized.

Moisture content in feedstock materials constitutes a persistent problem that can lead to hydrogen embrittlement and porosity in final parts. Current drying and storage solutions provide inconsistent results, and moisture detection methods lack the precision needed for high-performance applications in aerospace and medical industries.

For wire-based DED systems, dimensional consistency and surface condition of the feedstock wire significantly impact process stability. Variations in wire diameter as small as 0.02mm can cause substantial changes in deposition characteristics, yet current quality control standards permit wider tolerances than the process actually requires for optimal performance.

Cross-contamination between different material batches represents another significant challenge, particularly in multi-material DED systems. The industry lacks effective cleaning protocols and contamination detection methods that can be integrated into production environments without causing excessive downtime or cost increases.

The absence of in-line quality monitoring systems for feedstock materials forces manufacturers to rely on batch testing, which cannot detect real-time changes in material properties during the deposition process. This gap between quality verification and actual production creates significant risks for critical applications where material integrity is paramount.

Existing Quality Control Methods for DED Feedstock

01 Analytical methods for feedstock quality assessment

Various analytical techniques are employed to assess the quality of material feedstocks. These methods include spectroscopic analysis, chromatography, and other testing procedures that can identify impurities, measure composition, and verify conformity to specifications. Advanced sensors and detection systems enable real-time monitoring of feedstock properties, allowing for immediate quality control decisions during manufacturing processes.- Analytical methods for feedstock quality control: Various analytical techniques are employed to assess and control the quality of material feedstocks. These methods include spectroscopic analysis, chromatography, and sensor-based monitoring systems that can detect impurities, measure composition, and verify conformity to specifications. Real-time monitoring capabilities allow for immediate adjustments to processing parameters, ensuring consistent quality throughout production cycles.

- Standardization of feedstock specifications: Establishing standardized specifications for raw materials is crucial for maintaining product quality. This involves defining acceptable ranges for physical properties, chemical composition, and purity levels. Standardization processes include developing reference materials, validation protocols, and certification procedures to ensure that feedstock materials meet predetermined quality criteria before entering production processes.

- Advanced monitoring systems for process control: Automated monitoring systems are implemented to continuously track feedstock quality throughout the manufacturing process. These systems utilize sensors, machine learning algorithms, and data analytics to detect deviations from specifications in real-time. Integration with production equipment allows for automated adjustments to processing parameters, reducing waste and ensuring consistent product quality.

- Biological feedstock quality management: Specialized methods for controlling the quality of biological feedstocks, such as cell cultures, microorganisms, and biomass materials. These approaches include sterility testing, genetic verification, viability assessment, and contamination control protocols. Maintaining the integrity and consistency of biological materials requires specific storage conditions, handling procedures, and preservation techniques to ensure their efficacy in downstream applications.

- Recycled material quality assurance: Methods for ensuring the quality and consistency of recycled or reclaimed materials used as feedstock. These techniques include sorting, purification, characterization, and blending strategies to achieve desired specifications. Quality control measures address challenges such as contamination, degradation, and variability in recycled materials to enable their effective use in manufacturing processes while maintaining end-product performance.

02 Automated quality control systems for material processing

Automated systems are implemented to monitor and control the quality of material feedstocks throughout the production process. These systems utilize computer-controlled equipment, sensors, and data analysis to detect deviations from specifications in real-time. By automating quality control procedures, manufacturers can achieve consistent product quality, reduce waste, and optimize production efficiency while maintaining compliance with industry standards.Expand Specific Solutions03 Standardization of feedstock specifications for manufacturing

Establishing standardized specifications for material feedstocks ensures consistency in manufacturing processes. These specifications define acceptable ranges for physical properties, chemical composition, and performance characteristics. Standardization facilitates quality control by providing clear benchmarks against which incoming materials can be evaluated, enabling manufacturers to maintain product quality while optimizing production processes and reducing variability in finished products.Expand Specific Solutions04 Feedstock purification and treatment processes

Various purification and treatment processes are employed to enhance the quality of raw materials before they enter production. These processes include filtration, chemical treatments, thermal processing, and other methods designed to remove impurities and contaminants. By improving feedstock quality through purification, manufacturers can ensure better performance of finished products, reduce defects, and extend product lifespan while meeting stringent quality standards.Expand Specific Solutions05 Advanced monitoring technologies for feedstock quality

Innovative technologies are being developed to monitor feedstock quality with greater precision and efficiency. These include machine learning algorithms for predictive quality assessment, IoT-enabled sensors for continuous monitoring, and digital twin technologies that simulate material behavior. By implementing these advanced monitoring systems, manufacturers can detect quality issues earlier, optimize material usage, and ensure consistent product quality across production batches.Expand Specific Solutions

Leading Suppliers and Manufacturers in DED Materials

The material feedstock specification and quality control for Directed Energy Deposition (DED) lines market is currently in a growth phase, with increasing adoption across aerospace and defense sectors. The market is expanding as manufacturers seek more efficient additive manufacturing solutions, estimated to reach significant scale within the next five years. Technologically, the field shows varying maturity levels among key players. Industry leaders like RTX Corp., Boeing, and JFE Steel have established advanced quality control protocols, while specialized firms such as Norsk Titanium and BeAM SAS are driving innovation in feedstock specification technologies. Research institutions including Nanyang Technological University and Chinese Academy of Sciences are contributing fundamental research, creating a competitive landscape balanced between established industrial giants and emerging specialized providers.

Norsk Titanium AS

Technical Solution: Norsk Titanium has developed the proprietary Rapid Plasma Deposition™ (RPD™) technology, a specialized form of DED specifically optimized for titanium components. Their material feedstock specification system includes precise control of titanium wire properties including chemical composition, diameter consistency, and surface contamination levels. The company implements a comprehensive quality management system that incorporates real-time monitoring of process parameters such as plasma temperature, deposition rate, and environmental conditions. Their approach includes automated inspection systems that verify material properties throughout the manufacturing process, with particular emphasis on maintaining aerospace-grade quality standards. Norsk has established a closed-loop feedback system that continuously adjusts process parameters based on material performance data, ensuring consistent mechanical properties across production runs[1].

Strengths: Specialized expertise in titanium processing; established aerospace qualification standards; proprietary technology optimized for specific high-value applications. Weaknesses: Limited material versatility compared to powder-based systems; higher initial investment costs; technology primarily optimized for titanium rather than a broad range of materials.

Stratasys, Inc.

Technical Solution: Stratasys has developed specialized material feedstock specification protocols for their DED systems as part of their expanding metal additive manufacturing portfolio. Their approach focuses on polymer-metal composite materials and pure metal feedstocks with precisely controlled properties. Stratasys implements a comprehensive quality control system that begins with raw material certification and continues through processing with in-situ monitoring technologies. Their feedstock specification system includes detailed requirements for chemical composition, particle size distribution for powders, and dimensional consistency for wire feedstocks. The company has developed proprietary software algorithms that correlate material properties with process parameters to ensure consistent part quality. Stratasys's quality control framework incorporates machine learning techniques to identify patterns in process data that might indicate potential quality issues before they manifest in completed parts. Their systems include automated documentation of material batch information, process parameters, and quality metrics to ensure complete traceability throughout the manufacturing process[4].

Strengths: Strong integration with existing additive manufacturing ecosystems; user-friendly interfaces; extensive material development expertise. Weaknesses: Relatively newer entrant to metal DED compared to specialized competitors; systems may require adaptation for certain industrial applications; ongoing development of material portfolio.

Critical Patents in DED Material Specification

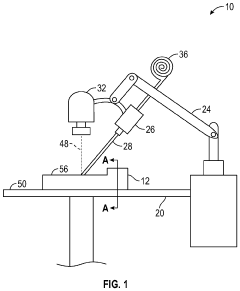

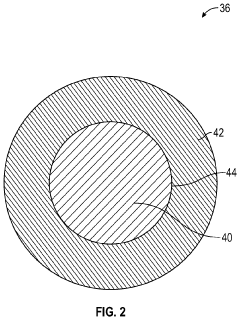

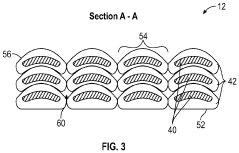

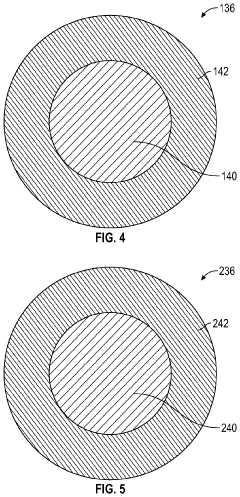

Clad wire feedstock for directed energy deposition additive manufacturing

PatentPendingUS20230415267A1

Innovation

- A coaxial clad wire feedstock is introduced, comprising a core material surrounded by one or more clad metal layers, allowing for the creation of articles with unique properties by maintaining the clad metal layer's integrity during the deposition process, using materials with different melt temperatures or surface tensions.

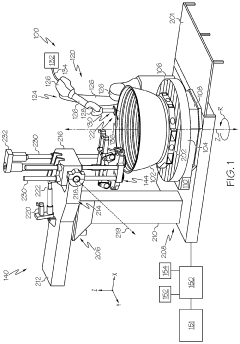

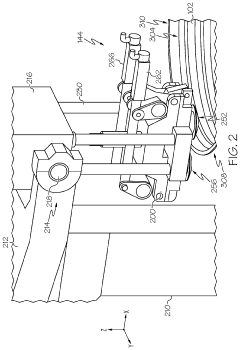

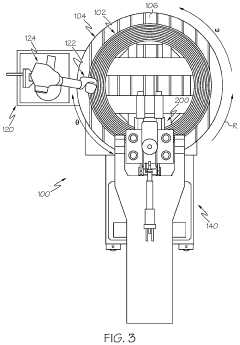

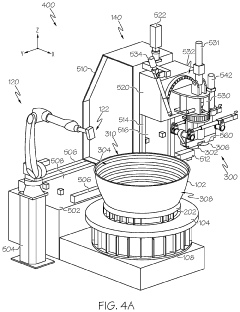

Additive manufacturing systems and methods for compression of material during material deposition

PatentPendingUS20240009740A1

Innovation

- A DED system that integrates a rotary build table and a compression rig allowing simultaneous deposition and compression phases, with a controller managing the application of compressive loads during material deposition to maintain constant temperature and improve microstructure homogeneity.

Standardization and Certification Requirements

Standardization and certification frameworks play a crucial role in ensuring the reliability and consistency of material feedstock for Directed Energy Deposition (DED) processes. Currently, the DED additive manufacturing sector faces significant challenges due to the lack of comprehensive international standards specifically tailored to powder and wire feedstock materials. This standardization gap creates barriers to widespread industrial adoption and complicates quality assurance processes.

The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have begun addressing these challenges through committees focused on additive manufacturing standards. ASTM F42 and ISO/TC 261 are developing guidelines that cover material specifications, process parameters, and quality control methodologies specific to DED technologies. These emerging standards aim to establish minimum requirements for chemical composition, particle size distribution, flowability, and morphology for powder feedstock, as well as dimensional tolerance and surface quality for wire materials.

Material certification pathways for DED processes must address the unique challenges of this technology, including the potential for material property variations due to the layer-by-layer deposition process. Certification requirements typically include extensive material testing, process validation, and documentation of material traceability from raw material sourcing through final part production. For critical applications in aerospace, medical, and defense sectors, additional certification requirements may include lot-specific testing and enhanced traceability protocols.

Industry-specific certification frameworks present another layer of complexity. For instance, aerospace applications must adhere to standards such as AS9100 and specific OEM requirements, while medical applications must comply with FDA regulations and ISO 13485. These sector-specific requirements often necessitate additional testing and validation beyond general additive manufacturing standards, creating a multi-tiered certification landscape that material suppliers must navigate.

The development of in-process monitoring and quality control systems is increasingly becoming integrated into standardization frameworks. Real-time monitoring capabilities that can detect feedstock irregularities during the DED process are being incorporated into emerging standards, enabling closed-loop quality control systems that can adjust process parameters based on material behavior during deposition.

Looking forward, the harmonization of global standards represents a critical path for DED material certification. Efforts to align ASTM, ISO, and regional standards bodies are underway, with the goal of creating a unified global framework that reduces redundancy in testing and certification while maintaining rigorous quality requirements. This harmonization will be essential for enabling cross-border material supply chains and facilitating broader industrial adoption of DED technologies.

The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have begun addressing these challenges through committees focused on additive manufacturing standards. ASTM F42 and ISO/TC 261 are developing guidelines that cover material specifications, process parameters, and quality control methodologies specific to DED technologies. These emerging standards aim to establish minimum requirements for chemical composition, particle size distribution, flowability, and morphology for powder feedstock, as well as dimensional tolerance and surface quality for wire materials.

Material certification pathways for DED processes must address the unique challenges of this technology, including the potential for material property variations due to the layer-by-layer deposition process. Certification requirements typically include extensive material testing, process validation, and documentation of material traceability from raw material sourcing through final part production. For critical applications in aerospace, medical, and defense sectors, additional certification requirements may include lot-specific testing and enhanced traceability protocols.

Industry-specific certification frameworks present another layer of complexity. For instance, aerospace applications must adhere to standards such as AS9100 and specific OEM requirements, while medical applications must comply with FDA regulations and ISO 13485. These sector-specific requirements often necessitate additional testing and validation beyond general additive manufacturing standards, creating a multi-tiered certification landscape that material suppliers must navigate.

The development of in-process monitoring and quality control systems is increasingly becoming integrated into standardization frameworks. Real-time monitoring capabilities that can detect feedstock irregularities during the DED process are being incorporated into emerging standards, enabling closed-loop quality control systems that can adjust process parameters based on material behavior during deposition.

Looking forward, the harmonization of global standards represents a critical path for DED material certification. Efforts to align ASTM, ISO, and regional standards bodies are underway, with the goal of creating a unified global framework that reduces redundancy in testing and certification while maintaining rigorous quality requirements. This harmonization will be essential for enabling cross-border material supply chains and facilitating broader industrial adoption of DED technologies.

Environmental Impact of DED Material Production

The production of materials for Directed Energy Deposition (DED) processes carries significant environmental implications that warrant careful consideration. Metal powder production, the primary feedstock for DED systems, involves energy-intensive processes including atomization, which requires substantial electricity consumption and generates considerable carbon emissions. The environmental footprint extends beyond energy usage to include resource extraction impacts, with mining operations for raw materials causing habitat disruption, soil erosion, and potential water contamination. These environmental costs vary significantly depending on the specific metal being processed, with rare earth elements and specialized alloys typically presenting greater ecological challenges.

Water usage represents another critical environmental factor in DED material production. The atomization process and subsequent powder processing steps require substantial quantities of water for cooling and cleaning operations. In regions facing water scarcity, this consumption pattern raises sustainability concerns that must be addressed through recycling systems and process optimization.

Waste generation throughout the DED material supply chain presents additional environmental challenges. Metal powder production creates fine particulate matter that, if improperly managed, can contribute to air pollution and respiratory health risks. Furthermore, the production process generates industrial waste streams containing potentially hazardous materials that require specialized disposal protocols to prevent environmental contamination.

Recent industry developments have focused on implementing more sustainable practices in DED material production. Closed-loop recycling systems for process water, energy recovery technologies, and improved filtration systems represent promising advances. Additionally, powder manufacturers are increasingly adopting renewable energy sources to power production facilities, significantly reducing the carbon footprint associated with DED feedstock materials.

The environmental impact assessment of DED materials must also consider transportation factors. The global supply chain for specialized metal powders often involves long-distance shipping, contributing to the overall carbon footprint. Localized production facilities and strategic supply chain optimization can substantially reduce these transportation-related environmental impacts.

Quality control measures in DED material production, while primarily focused on ensuring consistent performance characteristics, also serve environmental purposes by minimizing waste through reduced rejection rates. Precise specification adherence means fewer failed builds and less material wastage, creating an important intersection between quality control protocols and environmental sustainability goals in advanced manufacturing contexts.

Water usage represents another critical environmental factor in DED material production. The atomization process and subsequent powder processing steps require substantial quantities of water for cooling and cleaning operations. In regions facing water scarcity, this consumption pattern raises sustainability concerns that must be addressed through recycling systems and process optimization.

Waste generation throughout the DED material supply chain presents additional environmental challenges. Metal powder production creates fine particulate matter that, if improperly managed, can contribute to air pollution and respiratory health risks. Furthermore, the production process generates industrial waste streams containing potentially hazardous materials that require specialized disposal protocols to prevent environmental contamination.

Recent industry developments have focused on implementing more sustainable practices in DED material production. Closed-loop recycling systems for process water, energy recovery technologies, and improved filtration systems represent promising advances. Additionally, powder manufacturers are increasingly adopting renewable energy sources to power production facilities, significantly reducing the carbon footprint associated with DED feedstock materials.

The environmental impact assessment of DED materials must also consider transportation factors. The global supply chain for specialized metal powders often involves long-distance shipping, contributing to the overall carbon footprint. Localized production facilities and strategic supply chain optimization can substantially reduce these transportation-related environmental impacts.

Quality control measures in DED material production, while primarily focused on ensuring consistent performance characteristics, also serve environmental purposes by minimizing waste through reduced rejection rates. Precise specification adherence means fewer failed builds and less material wastage, creating an important intersection between quality control protocols and environmental sustainability goals in advanced manufacturing contexts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!