Repair Qualification Protocols For Critical Aerospace Components Using DED

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Repair Technology Background and Objectives

Directed Energy Deposition (DED) has emerged as a transformative additive manufacturing technology in the aerospace industry, particularly for repair applications of critical components. The technology evolved from traditional welding processes in the 1990s, with significant advancements occurring in the past decade as aerospace manufacturers sought more efficient and cost-effective repair solutions. DED utilizes focused thermal energy to fuse materials as they are deposited, allowing for precise material addition to damaged components while maintaining structural integrity.

The aerospace industry faces unique challenges with component repair, including strict regulatory requirements, material compatibility issues, and the high cost of component replacement. Traditional repair methods often involve extensive manual processes, resulting in inconsistent quality and limited repeatability. DED technology addresses these limitations by offering controlled material deposition with minimal heat-affected zones and superior metallurgical bonding.

The primary objective of DED repair qualification protocols is to establish standardized procedures that ensure repaired aerospace components meet or exceed original performance specifications. These protocols aim to validate the mechanical properties, microstructural characteristics, and long-term durability of repaired components under operational conditions. Additionally, they seek to demonstrate compliance with aerospace industry standards such as AS9100 and specific OEM requirements.

Current technological trends in DED repair focus on expanding material compatibility, improving process monitoring capabilities, and enhancing automation to reduce human error. The integration of in-situ monitoring systems allows for real-time quality control, while advanced simulation tools enable predictive modeling of repair outcomes. Machine learning algorithms are increasingly being applied to optimize process parameters based on component geometry and damage characteristics.

The development of qualification protocols represents a critical step in the broader adoption of DED repair technologies across the aerospace sector. These protocols must address the entire repair lifecycle, from damage assessment and repair planning to post-repair inspection and certification. The ultimate goal is to establish DED as a reliable, cost-effective alternative to component replacement, potentially saving the aerospace industry billions in maintenance costs while extending the service life of critical components.

Research indicates that properly qualified DED repairs can restore components to 95-100% of original performance specifications, with significant reductions in repair time and material waste compared to conventional methods. As the technology continues to mature, qualification protocols will play a pivotal role in ensuring safety, reliability, and regulatory compliance.

The aerospace industry faces unique challenges with component repair, including strict regulatory requirements, material compatibility issues, and the high cost of component replacement. Traditional repair methods often involve extensive manual processes, resulting in inconsistent quality and limited repeatability. DED technology addresses these limitations by offering controlled material deposition with minimal heat-affected zones and superior metallurgical bonding.

The primary objective of DED repair qualification protocols is to establish standardized procedures that ensure repaired aerospace components meet or exceed original performance specifications. These protocols aim to validate the mechanical properties, microstructural characteristics, and long-term durability of repaired components under operational conditions. Additionally, they seek to demonstrate compliance with aerospace industry standards such as AS9100 and specific OEM requirements.

Current technological trends in DED repair focus on expanding material compatibility, improving process monitoring capabilities, and enhancing automation to reduce human error. The integration of in-situ monitoring systems allows for real-time quality control, while advanced simulation tools enable predictive modeling of repair outcomes. Machine learning algorithms are increasingly being applied to optimize process parameters based on component geometry and damage characteristics.

The development of qualification protocols represents a critical step in the broader adoption of DED repair technologies across the aerospace sector. These protocols must address the entire repair lifecycle, from damage assessment and repair planning to post-repair inspection and certification. The ultimate goal is to establish DED as a reliable, cost-effective alternative to component replacement, potentially saving the aerospace industry billions in maintenance costs while extending the service life of critical components.

Research indicates that properly qualified DED repairs can restore components to 95-100% of original performance specifications, with significant reductions in repair time and material waste compared to conventional methods. As the technology continues to mature, qualification protocols will play a pivotal role in ensuring safety, reliability, and regulatory compliance.

Aerospace Market Demand for Component Repair Solutions

The aerospace component repair market is experiencing significant growth driven by the increasing age of global aircraft fleets and the economic advantages of repair over replacement. Current market valuations indicate the global aerospace MRO (Maintenance, Repair, and Overhaul) sector exceeds $80 billion annually, with component repair representing approximately 17% of this market. Industry forecasts project a compound annual growth rate of 4.6% through 2028, highlighting substantial demand for advanced repair technologies like Directed Energy Deposition (DED).

Airlines and military operators face mounting pressure to extend component lifecycles while maintaining stringent safety standards. The average commercial aircraft contains over 3 million parts, with critical components such as turbine blades, compressor discs, and structural elements requiring regular inspection and repair. These high-value components often represent significant capital investment, with a single turbine blade potentially costing upwards of $30,000, making repair solutions economically compelling when technically feasible.

The market demand is particularly acute for qualification protocols that can standardize and validate DED repair processes. A recent industry survey revealed that 78% of aerospace maintenance providers identified regulatory approval and qualification as their primary barrier to adopting advanced repair technologies. This represents a critical market gap that effective qualification protocols could address, potentially unlocking billions in maintenance cost savings across the industry.

Regional analysis shows North America currently dominates the aerospace component repair market with 38% share, followed by Europe at 29% and Asia-Pacific at 24%. However, the fastest growth is occurring in emerging markets, particularly in Southeast Asia and the Middle East, where air traffic is expanding rapidly and new maintenance hubs are being established.

Customer segmentation reveals distinct needs across military, commercial, and business aviation sectors. Military operators prioritize rapid repair qualification to maximize fleet readiness, while commercial airlines focus on cost efficiency and minimizing aircraft downtime. Business aviation operators, meanwhile, emphasize quality and longevity of repairs due to their different utilization patterns.

The economic case for qualified DED repair solutions is compelling. Industry data suggests that effective component repair can reduce part replacement costs by 60-80% while decreasing maintenance turnaround times by up to 70% compared to traditional replacement processes. These efficiency gains translate directly to reduced aircraft on-ground time, which costs operators between $10,000-$150,000 per hour depending on aircraft type.

Airlines and military operators face mounting pressure to extend component lifecycles while maintaining stringent safety standards. The average commercial aircraft contains over 3 million parts, with critical components such as turbine blades, compressor discs, and structural elements requiring regular inspection and repair. These high-value components often represent significant capital investment, with a single turbine blade potentially costing upwards of $30,000, making repair solutions economically compelling when technically feasible.

The market demand is particularly acute for qualification protocols that can standardize and validate DED repair processes. A recent industry survey revealed that 78% of aerospace maintenance providers identified regulatory approval and qualification as their primary barrier to adopting advanced repair technologies. This represents a critical market gap that effective qualification protocols could address, potentially unlocking billions in maintenance cost savings across the industry.

Regional analysis shows North America currently dominates the aerospace component repair market with 38% share, followed by Europe at 29% and Asia-Pacific at 24%. However, the fastest growth is occurring in emerging markets, particularly in Southeast Asia and the Middle East, where air traffic is expanding rapidly and new maintenance hubs are being established.

Customer segmentation reveals distinct needs across military, commercial, and business aviation sectors. Military operators prioritize rapid repair qualification to maximize fleet readiness, while commercial airlines focus on cost efficiency and minimizing aircraft downtime. Business aviation operators, meanwhile, emphasize quality and longevity of repairs due to their different utilization patterns.

The economic case for qualified DED repair solutions is compelling. Industry data suggests that effective component repair can reduce part replacement costs by 60-80% while decreasing maintenance turnaround times by up to 70% compared to traditional replacement processes. These efficiency gains translate directly to reduced aircraft on-ground time, which costs operators between $10,000-$150,000 per hour depending on aircraft type.

Current State and Challenges in DED Repair Qualification

Directed Energy Deposition (DED) has emerged as a promising technology for repairing high-value aerospace components, yet the qualification of these repairs remains a significant challenge in the industry. Currently, qualification protocols for DED repairs vary considerably across organizations and regulatory bodies, creating inconsistency in implementation and acceptance. The aerospace industry, bound by stringent safety requirements, faces particular difficulties in establishing standardized approaches to validate DED-repaired components for flight-critical applications.

The existing qualification frameworks typically involve extensive mechanical testing, microstructural analysis, and non-destructive evaluation. However, these protocols were largely developed for conventional manufacturing processes and often fail to address the unique characteristics of additive manufacturing repairs, including material heterogeneity, residual stress distributions, and potential defect formations specific to DED processes.

Regulatory bodies such as the FAA, EASA, and military standards organizations have begun developing guidelines for additive manufacturing in aerospace, but comprehensive standards specifically for repair qualification remain underdeveloped. This regulatory gap creates uncertainty for manufacturers and maintenance organizations seeking to implement DED repair solutions at scale.

Technical challenges in qualification include the accurate prediction of mechanical properties in repaired regions, particularly at the interface between the substrate and deposited material. The heat-affected zone created during the DED process can exhibit complex microstructural changes that are difficult to characterize using conventional testing methods. Additionally, the anisotropic nature of properties in additively manufactured materials complicates the establishment of reliable acceptance criteria.

Process parameter variability presents another significant hurdle. The relationship between process parameters, resulting microstructure, and mechanical performance is highly complex in DED systems. This complexity is magnified when dealing with repairs, where substrate conditions may vary considerably between components. Current qualification approaches struggle to account for this variability in a systematic manner.

Data availability represents a critical limitation, as the aerospace industry's conservative approach to new technologies has resulted in limited publicly available performance data for DED-repaired components in service conditions. This shortage of long-term performance data creates barriers to widespread adoption and regulatory approval.

Geographically, qualification capabilities are concentrated in advanced manufacturing hubs in North America, Western Europe, and parts of Asia, creating disparities in global implementation potential. Organizations without access to sophisticated testing infrastructure face significant barriers to entry in developing qualified DED repair processes.

The existing qualification frameworks typically involve extensive mechanical testing, microstructural analysis, and non-destructive evaluation. However, these protocols were largely developed for conventional manufacturing processes and often fail to address the unique characteristics of additive manufacturing repairs, including material heterogeneity, residual stress distributions, and potential defect formations specific to DED processes.

Regulatory bodies such as the FAA, EASA, and military standards organizations have begun developing guidelines for additive manufacturing in aerospace, but comprehensive standards specifically for repair qualification remain underdeveloped. This regulatory gap creates uncertainty for manufacturers and maintenance organizations seeking to implement DED repair solutions at scale.

Technical challenges in qualification include the accurate prediction of mechanical properties in repaired regions, particularly at the interface between the substrate and deposited material. The heat-affected zone created during the DED process can exhibit complex microstructural changes that are difficult to characterize using conventional testing methods. Additionally, the anisotropic nature of properties in additively manufactured materials complicates the establishment of reliable acceptance criteria.

Process parameter variability presents another significant hurdle. The relationship between process parameters, resulting microstructure, and mechanical performance is highly complex in DED systems. This complexity is magnified when dealing with repairs, where substrate conditions may vary considerably between components. Current qualification approaches struggle to account for this variability in a systematic manner.

Data availability represents a critical limitation, as the aerospace industry's conservative approach to new technologies has resulted in limited publicly available performance data for DED-repaired components in service conditions. This shortage of long-term performance data creates barriers to widespread adoption and regulatory approval.

Geographically, qualification capabilities are concentrated in advanced manufacturing hubs in North America, Western Europe, and parts of Asia, creating disparities in global implementation potential. Organizations without access to sophisticated testing infrastructure face significant barriers to entry in developing qualified DED repair processes.

Current DED Repair Qualification Protocols

01 Quality control and testing protocols for DED repairs

Directed Energy Deposition repair processes require rigorous quality control and testing protocols to ensure the integrity of repaired components. These protocols include non-destructive testing methods, microstructural analysis, and mechanical property verification to validate the repair quality. The qualification process involves standardized testing procedures to assess the bond strength between the deposited material and substrate, as well as the overall structural integrity of the repaired component.- Quality control and testing protocols for DED repairs: Directed Energy Deposition repair processes require rigorous quality control and testing protocols to ensure the repaired components meet industry standards. These protocols include non-destructive testing methods, microstructural analysis, and mechanical property verification. The qualification process typically involves testing the repaired area for defects, evaluating the bond strength between the deposited material and substrate, and confirming that the repaired component maintains its original performance characteristics.

- Material certification and parameter optimization for DED repairs: The qualification of materials used in Directed Energy Deposition repair processes involves certification of feedstock materials and optimization of process parameters. This includes characterizing powder properties, validating chemical composition, and establishing optimal deposition parameters such as laser power, feed rate, and travel speed. The protocols ensure that the repair material is compatible with the substrate and that the deposition process creates a metallurgical bond with minimal defects, resulting in repairs with consistent quality and performance.

- Standardization and certification frameworks for DED repair processes: Standardization and certification frameworks provide guidelines for qualifying Directed Energy Deposition repair processes across different industries. These frameworks establish minimum requirements for equipment calibration, operator training, process documentation, and repair validation. They also define acceptance criteria for repaired components and specify the necessary documentation for regulatory compliance. By following these standardized protocols, organizations can ensure consistency in repair quality and gain approval from certification bodies for critical applications.

- In-situ monitoring and process control for DED repair qualification: In-situ monitoring systems play a crucial role in qualifying Directed Energy Deposition repairs by providing real-time data on process stability and quality. These systems use sensors to monitor parameters such as melt pool temperature, dimensions, and cooling rates during the deposition process. The collected data is analyzed to detect anomalies and ensure the repair meets predefined quality metrics. Advanced process control algorithms can automatically adjust deposition parameters based on this feedback, improving repair consistency and reducing the need for post-process inspection.

- Application-specific qualification protocols for critical components: Different industries have developed specialized qualification protocols for Directed Energy Deposition repairs of critical components. These protocols address the unique requirements of aerospace, power generation, oil and gas, and defense applications. They include specific testing regimes, performance criteria, and service life predictions based on the operating conditions of the repaired components. The qualification process may involve simulated service testing, accelerated aging, and fatigue testing to validate the long-term performance of the repairs under actual operating conditions.

02 Material qualification for DED repair applications

Material qualification is a critical aspect of DED repair protocols, involving the selection and validation of appropriate feedstock materials compatible with both the substrate and the intended application. The qualification process includes characterization of powder or wire feedstock properties, evaluation of material deposition behavior, and assessment of the resulting microstructure and mechanical properties. Protocols specify requirements for material composition, particle size distribution, flowability, and other parameters essential for successful DED repairs.Expand Specific Solutions03 Process parameter optimization and validation

Qualification protocols for DED repairs include systematic approaches to optimize and validate process parameters. This involves establishing parameter windows for laser power, travel speed, powder feed rate, and other variables that ensure consistent deposition quality. The protocols define methodologies for parameter development, including design of experiments approaches, and specify acceptance criteria for validating parameter sets. Qualification procedures also address the verification of process repeatability and reproducibility across different equipment and operators.Expand Specific Solutions04 Certification standards and regulatory compliance

DED repair qualification protocols are developed in accordance with industry certification standards and regulatory requirements, particularly for critical applications in aerospace, defense, and energy sectors. These protocols establish documentation requirements, traceability procedures, and certification pathways for DED-repaired components. The qualification framework includes risk assessment methodologies, failure mode analysis, and compliance verification with relevant industry standards to ensure that repaired components meet or exceed original equipment specifications.Expand Specific Solutions05 In-process monitoring and adaptive control systems

Advanced qualification protocols for DED repairs incorporate in-process monitoring and adaptive control systems to ensure consistent quality. These systems utilize sensors to monitor melt pool characteristics, thermal profiles, and deposition geometry in real-time. The qualification procedures define methodologies for sensor calibration, data acquisition, and analysis to detect and correct process anomalies during deposition. Implementation of closed-loop control systems enables automatic adjustment of process parameters to maintain quality throughout the repair process.Expand Specific Solutions

Key Industry Players in Aerospace DED Repair

The aerospace component repair sector using Directed Energy Deposition (DED) technology is currently in a growth phase, with the market expected to expand significantly as the technology matures. The global market for aerospace additive manufacturing, including DED repair protocols, is projected to reach several billion dollars by 2025. Leading aerospace manufacturers like RTX Corp., Lockheed Martin, Boeing, and Rolls-Royce are investing heavily in DED technology for critical component repair, with varying levels of technological maturity. Research institutions such as Jiangsu University and Nanjing University of Aeronautics & Astronautics are collaborating with industry players to advance the technology. While DED repair protocols have demonstrated success in laboratory settings, full-scale industrial implementation remains in development, with companies like Safran and Airbus working to establish standardized qualification procedures for critical aerospace applications.

RTX Corp.

Technical Solution: RTX Corp. (formerly Raytheon Technologies) has developed comprehensive repair qualification protocols for aerospace components using Directed Energy Deposition (DED). Their approach integrates real-time monitoring systems with advanced material characterization techniques to ensure precise control over the repair process. RTX's protocol includes multi-stage validation procedures: initial material compatibility assessment, process parameter optimization, non-destructive testing, and performance validation through simulated service conditions. Their system employs adaptive control algorithms that adjust deposition parameters based on real-time feedback from thermal imaging and laser profilometry, ensuring consistent material properties throughout the repaired component. RTX has successfully implemented this technology for high-value components in jet engines, particularly for turbine blade repair, where their protocol has demonstrated the ability to restore components to original specifications with verification through fatigue testing and microstructural analysis.

Strengths: Superior integration with existing aerospace certification frameworks; comprehensive digital twin approach for validation; extensive experience with high-temperature superalloys used in critical components. Weaknesses: Higher implementation costs compared to conventional repair methods; requires specialized training for technicians; limited application for certain complex geometries.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has pioneered an advanced qualification protocol for DED repairs specifically tailored for critical aerospace components in defense applications. Their system employs a multi-layered verification approach combining in-situ monitoring with post-process validation. The protocol features proprietary algorithms that analyze real-time data from thermal sensors, melt pool monitoring, and layer-by-layer inspection to ensure adherence to strict aerospace standards. Lockheed's methodology includes comprehensive material traceability from powder characterization through final component testing, with particular emphasis on fatigue performance and microstructural integrity. Their qualification process incorporates accelerated aging tests that simulate extreme operational conditions, including thermal cycling and mechanical loading representative of actual flight conditions. Lockheed has successfully implemented this protocol for F-35 components, demonstrating significant cost savings while maintaining or exceeding original part specifications through their rigorous testing regime.

Strengths: Exceptional integration with military certification requirements; advanced predictive modeling capabilities for performance validation; proven implementation on flight-critical components. Weaknesses: Protocol optimization primarily focused on defense applications; higher initial qualification costs; requires specialized equipment not widely available in commercial repair facilities.

Critical Technical Standards and Certification Requirements

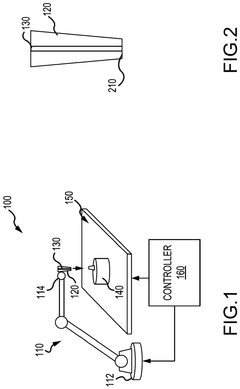

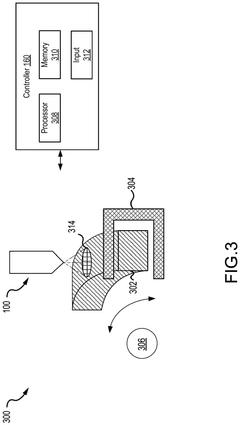

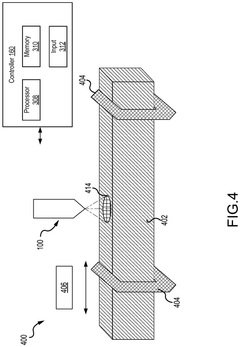

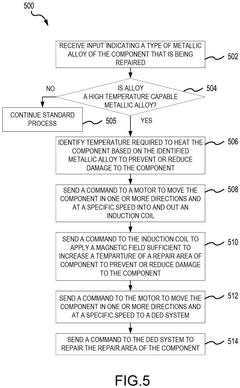

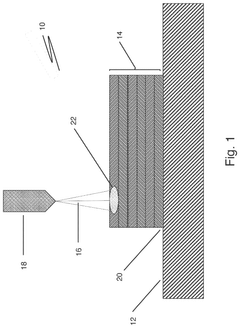

Induction heating of a component during direct energy deposition repair

PatentPendingEP4494785A1

Innovation

- A method and system that utilize induction heating to control the temperature of aerospace components during DED repair, where a magnetic field is applied via an induction coil to preheat the component to a desired temperature before repair, thereby reducing the risk of cracking.

Engineered microstructure for enhanced performance during directed energy deposition repair process

PatentPendingUS20250242410A1

Innovation

- A directed energy deposition (DED) process is used to control the microstructure of each repair layer by adjusting parameters like powder feed rate, energy intensity, traversal rate, and auxiliary heating/cooling, ensuring each layer has a pre-determined microstructure to meet specific structural and functional needs.

Material Compatibility and Microstructural Analysis

Material compatibility represents a critical consideration in Directed Energy Deposition (DED) repair processes for aerospace components. The interaction between the substrate material and the deposited material significantly influences the structural integrity and performance of the repaired component. Current research indicates that nickel-based superalloys, titanium alloys, and high-strength steels demonstrate favorable compatibility characteristics when repaired using DED technology. These materials exhibit good fusion properties and minimal thermal distortion during the deposition process, making them suitable candidates for aerospace repair applications.

Microstructural analysis reveals that the heat-affected zone (HAZ) between the substrate and deposited material often presents unique challenges. Studies have documented the formation of distinct microstructural regions, including the fusion zone, partially melted zone, and heat-affected zone. Each region exhibits different grain structures, precipitate distributions, and mechanical properties. Advanced characterization techniques such as Electron Backscatter Diffraction (EBSD) and Transmission Electron Microscopy (TEM) have enabled researchers to identify specific microstructural features that influence repair quality.

The cooling rates during DED processing significantly impact the resultant microstructure. Rapid solidification typically leads to finer grain structures with enhanced mechanical properties, while slower cooling promotes larger grain formation. Process parameters such as laser power, scan speed, and powder feed rate must be carefully optimized to achieve desired microstructural characteristics. Research indicates that controlled preheating of the substrate can reduce thermal gradients and minimize residual stress accumulation, thereby improving microstructural homogeneity across the repair interface.

Post-deposition heat treatments have emerged as effective methods for microstructural refinement and property enhancement. Solution treatment followed by aging processes can promote precipitate formation and distribution, leading to improved mechanical performance. Studies have shown that properly designed heat treatment protocols can reduce anisotropy in mechanical properties and enhance the overall durability of repaired components.

Residual stress distribution represents another critical aspect of material compatibility. The thermal cycling inherent to DED processes generates complex stress patterns that can affect fatigue performance and dimensional stability. Advanced modeling techniques coupled with experimental validation have enabled researchers to predict and mitigate adverse residual stress effects. Strategies such as controlled deposition paths, interlayer cooling, and post-process stress relief treatments have demonstrated effectiveness in managing residual stress profiles.

Recent advancements in in-situ monitoring technologies have facilitated real-time assessment of material compatibility and microstructural evolution during DED repairs. These systems utilize thermal imaging, optical emissions spectroscopy, and acoustic monitoring to detect anomalies in the deposition process that might compromise material integrity. Such capabilities represent a significant step toward establishing robust qualification protocols for aerospace component repairs.

Microstructural analysis reveals that the heat-affected zone (HAZ) between the substrate and deposited material often presents unique challenges. Studies have documented the formation of distinct microstructural regions, including the fusion zone, partially melted zone, and heat-affected zone. Each region exhibits different grain structures, precipitate distributions, and mechanical properties. Advanced characterization techniques such as Electron Backscatter Diffraction (EBSD) and Transmission Electron Microscopy (TEM) have enabled researchers to identify specific microstructural features that influence repair quality.

The cooling rates during DED processing significantly impact the resultant microstructure. Rapid solidification typically leads to finer grain structures with enhanced mechanical properties, while slower cooling promotes larger grain formation. Process parameters such as laser power, scan speed, and powder feed rate must be carefully optimized to achieve desired microstructural characteristics. Research indicates that controlled preheating of the substrate can reduce thermal gradients and minimize residual stress accumulation, thereby improving microstructural homogeneity across the repair interface.

Post-deposition heat treatments have emerged as effective methods for microstructural refinement and property enhancement. Solution treatment followed by aging processes can promote precipitate formation and distribution, leading to improved mechanical performance. Studies have shown that properly designed heat treatment protocols can reduce anisotropy in mechanical properties and enhance the overall durability of repaired components.

Residual stress distribution represents another critical aspect of material compatibility. The thermal cycling inherent to DED processes generates complex stress patterns that can affect fatigue performance and dimensional stability. Advanced modeling techniques coupled with experimental validation have enabled researchers to predict and mitigate adverse residual stress effects. Strategies such as controlled deposition paths, interlayer cooling, and post-process stress relief treatments have demonstrated effectiveness in managing residual stress profiles.

Recent advancements in in-situ monitoring technologies have facilitated real-time assessment of material compatibility and microstructural evolution during DED repairs. These systems utilize thermal imaging, optical emissions spectroscopy, and acoustic monitoring to detect anomalies in the deposition process that might compromise material integrity. Such capabilities represent a significant step toward establishing robust qualification protocols for aerospace component repairs.

Risk Assessment and Quality Assurance Frameworks

Risk assessment in DED (Directed Energy Deposition) repair qualification protocols for aerospace components requires a comprehensive framework that addresses both process-specific and application-specific risks. The aerospace industry's stringent safety requirements necessitate multi-layered quality assurance systems that can effectively evaluate the integrity of repaired components throughout their lifecycle.

Current risk assessment methodologies for DED repairs typically incorporate Failure Mode and Effects Analysis (FMEA), which identifies potential failure modes in the repair process and their consequences. These assessments must account for the unique challenges of DED technology, including thermal management, material compatibility, and microstructural integrity. Statistical Process Control (SPC) techniques are increasingly being integrated to monitor key process parameters in real-time, enabling early detection of deviations that could compromise component quality.

Quality assurance frameworks for DED repairs in aerospace applications generally follow a hierarchical structure. At the foundation level, material qualification ensures that feedstock materials meet composition and morphology requirements. The process qualification level validates that the DED equipment and parameters consistently produce acceptable results under controlled conditions. Finally, part qualification confirms that the specific repair meets all performance requirements for the intended application.

Non-destructive testing (NDT) protocols form a critical component of these frameworks, with techniques such as ultrasonic testing, X-ray computed tomography, and eddy current inspection being adapted specifically for DED-repaired components. These techniques must be calibrated to detect common DED-specific defects, including lack of fusion, porosity, and residual stress concentrations.

Digital twin technology is emerging as a valuable tool in risk assessment frameworks, allowing for virtual simulation of repair processes and subsequent component performance. This approach enables predictive quality assurance by identifying potential issues before they manifest in physical components. Machine learning algorithms are increasingly being employed to analyze the vast amounts of data generated during DED processes, identifying subtle patterns that may indicate quality concerns.

Regulatory compliance represents another crucial dimension of quality assurance frameworks. Organizations such as the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established certification requirements for repaired aerospace components. These frameworks must align with standards such as AS9100 for aerospace quality management systems and specific additive manufacturing standards like ASTM F3055 and AMS7003.

The implementation of closed-loop feedback systems in DED equipment has significantly enhanced quality assurance capabilities by enabling real-time adjustments to process parameters based on sensor data. This adaptive approach helps maintain consistent quality despite variations in environmental conditions or material properties, reducing the risk of defects in critical aerospace components.

Current risk assessment methodologies for DED repairs typically incorporate Failure Mode and Effects Analysis (FMEA), which identifies potential failure modes in the repair process and their consequences. These assessments must account for the unique challenges of DED technology, including thermal management, material compatibility, and microstructural integrity. Statistical Process Control (SPC) techniques are increasingly being integrated to monitor key process parameters in real-time, enabling early detection of deviations that could compromise component quality.

Quality assurance frameworks for DED repairs in aerospace applications generally follow a hierarchical structure. At the foundation level, material qualification ensures that feedstock materials meet composition and morphology requirements. The process qualification level validates that the DED equipment and parameters consistently produce acceptable results under controlled conditions. Finally, part qualification confirms that the specific repair meets all performance requirements for the intended application.

Non-destructive testing (NDT) protocols form a critical component of these frameworks, with techniques such as ultrasonic testing, X-ray computed tomography, and eddy current inspection being adapted specifically for DED-repaired components. These techniques must be calibrated to detect common DED-specific defects, including lack of fusion, porosity, and residual stress concentrations.

Digital twin technology is emerging as a valuable tool in risk assessment frameworks, allowing for virtual simulation of repair processes and subsequent component performance. This approach enables predictive quality assurance by identifying potential issues before they manifest in physical components. Machine learning algorithms are increasingly being employed to analyze the vast amounts of data generated during DED processes, identifying subtle patterns that may indicate quality concerns.

Regulatory compliance represents another crucial dimension of quality assurance frameworks. Organizations such as the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established certification requirements for repaired aerospace components. These frameworks must align with standards such as AS9100 for aerospace quality management systems and specific additive manufacturing standards like ASTM F3055 and AMS7003.

The implementation of closed-loop feedback systems in DED equipment has significantly enhanced quality assurance capabilities by enabling real-time adjustments to process parameters based on sensor data. This adaptive approach helps maintain consistent quality despite variations in environmental conditions or material properties, reducing the risk of defects in critical aerospace components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!