Quality Assurance: Inline Sensors And Real-Time Defect Detection In DED

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Quality Assurance Background and Objectives

Directed Energy Deposition (DED) has emerged as a transformative additive manufacturing technology over the past two decades, enabling the fabrication of complex metal components with unique capabilities for repair, cladding, and full part production. The technology has evolved from early wire-based systems to sophisticated powder-based processes capable of producing near-net-shape components with controlled microstructures. Despite these advancements, quality assurance remains a critical challenge that limits broader industrial adoption.

The primary objective of implementing inline sensors and real-time defect detection in DED processes is to transition from post-process inspection to in-situ monitoring and control. This paradigm shift aims to detect and mitigate defects during fabrication rather than discovering them after completion, which significantly reduces material waste, energy consumption, and production costs. Current post-process inspection methods such as CT scanning and destructive testing are time-consuming, expensive, and often result in part rejection after significant resources have been invested.

Historical approaches to DED quality control have relied heavily on operator expertise and process parameter optimization through trial and error. The industry has gradually moved toward more sophisticated monitoring techniques, beginning with basic thermal imaging in the early 2000s and progressing to multi-sensor fusion approaches in recent years. This evolution reflects the growing recognition that real-time quality assurance is essential for DED technology to achieve its full potential in high-value manufacturing sectors.

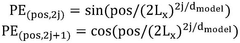

Technical trends indicate a convergence toward integrated sensor systems that combine multiple measurement modalities, including thermal imaging, optical emissions spectroscopy, and acoustic monitoring. These systems aim to provide comprehensive insights into melt pool dynamics, material deposition characteristics, and defect formation mechanisms. The development of machine learning algorithms to interpret complex sensor data represents another significant trend, enabling more accurate defect prediction and process control.

The ultimate technical goal is to establish closed-loop control systems that can automatically adjust process parameters in response to detected anomalies, ensuring consistent part quality regardless of geometric complexity or material challenges. This requires not only advanced sensing capabilities but also robust computational models that can predict defect formation and recommend corrective actions in real-time. Additionally, there is a growing emphasis on developing standardized quality metrics and certification protocols specific to DED processes.

Industry stakeholders, including aerospace, defense, and medical device manufacturers, are increasingly demanding traceable quality assurance documentation for DED-produced components. This has accelerated research into digital twin approaches that maintain comprehensive records of process conditions throughout fabrication, creating a digital pedigree for each manufactured part.

The primary objective of implementing inline sensors and real-time defect detection in DED processes is to transition from post-process inspection to in-situ monitoring and control. This paradigm shift aims to detect and mitigate defects during fabrication rather than discovering them after completion, which significantly reduces material waste, energy consumption, and production costs. Current post-process inspection methods such as CT scanning and destructive testing are time-consuming, expensive, and often result in part rejection after significant resources have been invested.

Historical approaches to DED quality control have relied heavily on operator expertise and process parameter optimization through trial and error. The industry has gradually moved toward more sophisticated monitoring techniques, beginning with basic thermal imaging in the early 2000s and progressing to multi-sensor fusion approaches in recent years. This evolution reflects the growing recognition that real-time quality assurance is essential for DED technology to achieve its full potential in high-value manufacturing sectors.

Technical trends indicate a convergence toward integrated sensor systems that combine multiple measurement modalities, including thermal imaging, optical emissions spectroscopy, and acoustic monitoring. These systems aim to provide comprehensive insights into melt pool dynamics, material deposition characteristics, and defect formation mechanisms. The development of machine learning algorithms to interpret complex sensor data represents another significant trend, enabling more accurate defect prediction and process control.

The ultimate technical goal is to establish closed-loop control systems that can automatically adjust process parameters in response to detected anomalies, ensuring consistent part quality regardless of geometric complexity or material challenges. This requires not only advanced sensing capabilities but also robust computational models that can predict defect formation and recommend corrective actions in real-time. Additionally, there is a growing emphasis on developing standardized quality metrics and certification protocols specific to DED processes.

Industry stakeholders, including aerospace, defense, and medical device manufacturers, are increasingly demanding traceable quality assurance documentation for DED-produced components. This has accelerated research into digital twin approaches that maintain comprehensive records of process conditions throughout fabrication, creating a digital pedigree for each manufactured part.

Market Demand for Real-Time Defect Detection in Additive Manufacturing

The additive manufacturing (AM) market has witnessed substantial growth in recent years, with the global market value reaching $13.7 billion in 2021 and projected to exceed $50 billion by 2030. Within this expanding landscape, Directed Energy Deposition (DED) technology has emerged as a critical segment, particularly for industries requiring high-precision metal components such as aerospace, automotive, and medical devices.

Real-time defect detection capabilities have become increasingly essential as manufacturers transition from prototyping to production-grade applications. A 2022 industry survey revealed that 78% of manufacturing companies identified quality assurance as their primary concern when adopting AM technologies, with 65% specifically highlighting the need for real-time monitoring solutions.

The economic implications of defect detection are significant. Manufacturing errors in high-value components can result in material waste exceeding $10,000 per build in specialized applications, while downstream failures can incur costs 10-100 times higher. This economic pressure has created a robust demand for inline sensor technologies that can detect defects during the build process rather than through post-production inspection.

Regulatory requirements have further accelerated market demand, particularly in critical industries. The aerospace sector, following FAA and EASA guidelines, requires comprehensive documentation of manufacturing processes, while medical device manufacturers must adhere to FDA regulations demanding thorough quality control measures. These regulatory frameworks have transformed real-time monitoring from a competitive advantage to a compliance necessity.

The defense sector represents another significant market driver, with military contracts increasingly specifying advanced quality assurance protocols for additively manufactured components. The U.S. Department of Defense has allocated substantial funding for research initiatives focused on real-time monitoring technologies for AM processes, including DED.

Industry analysts have noted a shift in customer expectations, with end-users now demanding comprehensive digital thread documentation that includes real-time process data. This trend is particularly pronounced in industries where component traceability is critical, such as nuclear power and aerospace.

The market for inline sensors specifically designed for DED processes is projected to grow at a CAGR of 24% through 2028, outpacing the overall AM market growth. This accelerated demand reflects the industrial recognition that quality assurance represents not merely a technical challenge but a fundamental business requirement for widespread AM adoption in production environments.

Real-time defect detection capabilities have become increasingly essential as manufacturers transition from prototyping to production-grade applications. A 2022 industry survey revealed that 78% of manufacturing companies identified quality assurance as their primary concern when adopting AM technologies, with 65% specifically highlighting the need for real-time monitoring solutions.

The economic implications of defect detection are significant. Manufacturing errors in high-value components can result in material waste exceeding $10,000 per build in specialized applications, while downstream failures can incur costs 10-100 times higher. This economic pressure has created a robust demand for inline sensor technologies that can detect defects during the build process rather than through post-production inspection.

Regulatory requirements have further accelerated market demand, particularly in critical industries. The aerospace sector, following FAA and EASA guidelines, requires comprehensive documentation of manufacturing processes, while medical device manufacturers must adhere to FDA regulations demanding thorough quality control measures. These regulatory frameworks have transformed real-time monitoring from a competitive advantage to a compliance necessity.

The defense sector represents another significant market driver, with military contracts increasingly specifying advanced quality assurance protocols for additively manufactured components. The U.S. Department of Defense has allocated substantial funding for research initiatives focused on real-time monitoring technologies for AM processes, including DED.

Industry analysts have noted a shift in customer expectations, with end-users now demanding comprehensive digital thread documentation that includes real-time process data. This trend is particularly pronounced in industries where component traceability is critical, such as nuclear power and aerospace.

The market for inline sensors specifically designed for DED processes is projected to grow at a CAGR of 24% through 2028, outpacing the overall AM market growth. This accelerated demand reflects the industrial recognition that quality assurance represents not merely a technical challenge but a fundamental business requirement for widespread AM adoption in production environments.

Current Inline Sensor Technologies and Challenges in DED

Directed Energy Deposition (DED) processes have seen significant advancements in inline sensor technologies for quality assurance, yet several challenges remain in achieving comprehensive real-time defect detection. Current sensor technologies deployed in DED systems can be categorized into four main types: thermal monitoring, optical imaging, acoustic emission, and dimensional measurement systems.

Thermal monitoring sensors, including infrared cameras and pyrometers, track temperature distributions across the build area with resolutions reaching 30-50 μm and sampling rates up to 1000 Hz. These systems effectively detect thermal anomalies that often precede defect formation, though they struggle with accurate temperature readings due to varying emissivity of different materials and processing conditions.

Optical imaging systems employ high-speed cameras coupled with specialized illumination to capture melt pool dynamics and layer formation. Advanced systems now integrate machine vision algorithms capable of detecting surface irregularities, porosity, and lack-of-fusion defects with detection rates exceeding 90% for defects larger than 100 μm. However, these systems face limitations in penetrating below the surface layer.

Acoustic emission sensors detect ultrasonic waves generated during material deposition, providing insights into internal defect formation. Recent developments have improved signal-to-noise ratios, allowing detection of micro-cracks and voids as small as 50 μm under optimal conditions. The challenge remains in interpreting complex acoustic signatures in real-time manufacturing environments.

Dimensional measurement technologies, including laser profilometry and structured light scanning, offer in-situ geometry verification with accuracies approaching 25 μm. These systems effectively identify geometric deviations but require significant computational resources for real-time processing.

Despite these advances, several technical challenges persist. Integration complexity remains high, with most DED systems requiring multiple sensor types to achieve comprehensive defect detection. This creates significant data fusion challenges, as different sensors operate at varying sampling rates and resolutions.

Processing speed limitations also hinder real-time response capabilities. Current systems typically experience latency of 50-200 milliseconds between defect occurrence and detection, which can be problematic for high-speed DED processes where critical decisions must be made within milliseconds to prevent defect propagation.

Environmental interference presents another significant challenge. Metal vapor, spatter, and thermal radiation inherent to DED processes can obscure sensor readings, reducing detection reliability. Advanced filtering algorithms have improved performance but have not eliminated these issues entirely.

Calibration and standardization remain problematic across different material systems and process parameters. Sensor systems optimized for one material often require extensive recalibration when switching to different alloys or process parameters, limiting manufacturing flexibility.

Thermal monitoring sensors, including infrared cameras and pyrometers, track temperature distributions across the build area with resolutions reaching 30-50 μm and sampling rates up to 1000 Hz. These systems effectively detect thermal anomalies that often precede defect formation, though they struggle with accurate temperature readings due to varying emissivity of different materials and processing conditions.

Optical imaging systems employ high-speed cameras coupled with specialized illumination to capture melt pool dynamics and layer formation. Advanced systems now integrate machine vision algorithms capable of detecting surface irregularities, porosity, and lack-of-fusion defects with detection rates exceeding 90% for defects larger than 100 μm. However, these systems face limitations in penetrating below the surface layer.

Acoustic emission sensors detect ultrasonic waves generated during material deposition, providing insights into internal defect formation. Recent developments have improved signal-to-noise ratios, allowing detection of micro-cracks and voids as small as 50 μm under optimal conditions. The challenge remains in interpreting complex acoustic signatures in real-time manufacturing environments.

Dimensional measurement technologies, including laser profilometry and structured light scanning, offer in-situ geometry verification with accuracies approaching 25 μm. These systems effectively identify geometric deviations but require significant computational resources for real-time processing.

Despite these advances, several technical challenges persist. Integration complexity remains high, with most DED systems requiring multiple sensor types to achieve comprehensive defect detection. This creates significant data fusion challenges, as different sensors operate at varying sampling rates and resolutions.

Processing speed limitations also hinder real-time response capabilities. Current systems typically experience latency of 50-200 milliseconds between defect occurrence and detection, which can be problematic for high-speed DED processes where critical decisions must be made within milliseconds to prevent defect propagation.

Environmental interference presents another significant challenge. Metal vapor, spatter, and thermal radiation inherent to DED processes can obscure sensor readings, reducing detection reliability. Advanced filtering algorithms have improved performance but have not eliminated these issues entirely.

Calibration and standardization remain problematic across different material systems and process parameters. Sensor systems optimized for one material often require extensive recalibration when switching to different alloys or process parameters, limiting manufacturing flexibility.

Existing Inline Sensor Integration Solutions for DED

01 Optical sensing systems for real-time defect detection

Optical sensing technologies utilize light-based methods to detect surface and subsurface defects in real-time during manufacturing processes. These systems employ cameras, lasers, and specialized lighting to capture high-resolution images that are analyzed for anomalies. Advanced image processing algorithms enhance detection capabilities by filtering noise and identifying subtle defects that might be missed by conventional inspection methods. These optical systems can be integrated directly into production lines for continuous monitoring without disrupting manufacturing flow.- Optical sensing systems for defect detection: Optical sensing systems utilize cameras, lasers, and light-based technologies to detect surface defects in real-time during manufacturing processes. These systems can capture high-resolution images of products as they move through production lines, allowing for immediate identification of visual anomalies, scratches, color variations, and dimensional inconsistencies. Advanced image processing algorithms analyze the captured data to distinguish between acceptable variations and actual defects, enabling continuous quality control without interrupting production.

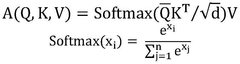

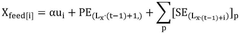

- Machine learning and AI-based defect detection: Artificial intelligence and machine learning algorithms enhance real-time defect detection by analyzing complex patterns in sensor data. These systems can be trained to recognize various defect types and adapt to new defect patterns over time, improving detection accuracy and reducing false positives. Deep learning models process multiple data streams simultaneously from inline sensors, enabling the system to detect subtle defects that might be missed by conventional methods. The AI-based systems can also predict potential defects before they occur by identifying patterns in production parameters.

- Integrated multi-sensor detection systems: Integrated systems combine multiple sensor types (ultrasonic, infrared, electromagnetic, and optical) to provide comprehensive defect detection capabilities. By fusing data from various sensors, these systems can detect both surface and internal defects in materials during production. The multi-sensor approach compensates for the limitations of individual sensor technologies, offering more reliable detection across different material types and production environments. Real-time data integration allows for immediate cross-validation of potential defects identified by different sensors.

- Inline process control and feedback systems: These systems not only detect defects but also automatically adjust production parameters in real-time to prevent further defects. When sensors identify a developing quality issue, the feedback mechanism can immediately modify machine settings, material flow, or processing conditions. This closed-loop approach minimizes waste by correcting problems before they result in defective products. The systems also collect and analyze defect data over time to identify patterns and optimize production processes for long-term quality improvement.

- Miniaturized and embedded sensor networks: Advanced manufacturing incorporates miniaturized sensors embedded directly within production equipment or integrated into the production line at critical points. These compact sensor networks can monitor multiple quality parameters simultaneously without disrupting the production flow. Wireless connectivity enables real-time data transmission to central monitoring systems, allowing for immediate defect detection and process adjustment. The distributed nature of these sensor networks provides comprehensive coverage of the entire production process, ensuring no potential defect zones are overlooked.

02 Machine learning and AI-based defect recognition algorithms

Artificial intelligence and machine learning algorithms significantly enhance real-time defect detection capabilities by learning from historical data to identify patterns and anomalies. These systems can automatically classify defects, predict potential failures, and continuously improve detection accuracy through self-learning mechanisms. Deep learning neural networks analyze complex visual data to detect subtle defects that traditional rule-based systems might miss. The AI-powered systems can adapt to new product variations and manufacturing conditions with minimal reconfiguration.Expand Specific Solutions03 Integrated sensor networks for comprehensive defect monitoring

Integrated sensor networks combine multiple sensor types (ultrasonic, infrared, electromagnetic, etc.) to provide comprehensive defect detection across various materials and manufacturing processes. These networks synchronize data from different sensors to create a complete picture of product quality, enabling detection of both surface and internal defects simultaneously. The distributed nature of these networks allows for monitoring at multiple critical points in the production line, with centralized data processing for coordinated analysis and response. Real-time data fusion techniques combine inputs from various sensors to improve detection reliability.Expand Specific Solutions04 Inline quality control systems with automated feedback loops

Automated inline quality control systems not only detect defects but also provide immediate feedback to production equipment to correct issues in real-time. These systems integrate defect detection with process control mechanisms to automatically adjust manufacturing parameters when defects are identified, minimizing waste and downtime. Statistical process control methods are employed to distinguish between random variations and systematic defects, triggering appropriate responses. The feedback loops enable self-correcting production systems that maintain quality standards with minimal human intervention.Expand Specific Solutions05 Miniaturized and embedded sensor technologies

Miniaturized sensor technologies can be embedded directly within production equipment or even within the products themselves to monitor quality throughout the manufacturing process and product lifecycle. These compact sensors utilize microelectromechanical systems (MEMS) technology to achieve high sensitivity in small form factors. Wireless connectivity enables these sensors to transmit data continuously without physical connections that might interfere with production. Energy-efficient designs allow for extended operation with minimal power requirements, making them suitable for continuous monitoring applications.Expand Specific Solutions

Leading Companies and Research Institutions in DED Quality Assurance

Quality Assurance in Directed Energy Deposition (DED) is evolving rapidly, with inline sensors and real-time defect detection representing a critical technological frontier. The market is in its growth phase, with an estimated value exceeding $500 million and projected annual growth of 15-20%. Leading players include established industrial giants like Siemens Energy, Honeywell International, and 3M Innovative Properties, who are developing proprietary sensing technologies. Academic institutions such as Huazhong University of Science & Technology and Wuhan University of Technology are advancing fundamental research, while specialized companies like Luna Innovations and Ler Technologies are creating novel optical sensing solutions. The technology is approaching commercial maturity, with early adopters in aerospace (Boeing) and automotive sectors demonstrating successful implementations.

Luna Innovations, Inc.

Technical Solution: Luna Innovations has created "ODiSI-DED," a specialized quality assurance system for DED processes based on their proprietary distributed fiber optic sensing technology. Their solution employs high-density fiber optic sensors embedded within or adjacent to the build platform to provide unprecedented spatial resolution of temperature distributions during the deposition process. The system can detect thermal anomalies with temperature resolution as fine as 0.1°C and spatial resolution of 0.65mm[4]. Luna's approach includes real-time strain monitoring capabilities that can detect residual stress development during material deposition and cooling, a critical factor in predicting part deformation and potential crack formation. Their technology incorporates specialized algorithms that correlate thermal patterns with known defect signatures, enabling proactive process adjustments. The system features a modular design that can be adapted to various DED equipment configurations, including both powder and wire-fed systems. Luna has also developed specialized sensor protection mechanisms that allow their fiber optic sensors to withstand the harsh conditions present in metal DED environments.

Strengths: Luna's fiber optic sensing technology provides unmatched spatial resolution and temperature sensitivity compared to conventional thermal imaging approaches. Their system can detect subtle thermal anomalies that other technologies might miss. Weaknesses: The fiber optic sensors require careful installation and integration with the DED equipment, potentially increasing setup complexity. The system is also more focused on thermal monitoring than other process variables, potentially requiring complementary technologies for comprehensive monitoring.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered a comprehensive quality assurance platform for DED processes called "Forge Monitor" that incorporates distributed fiber optic sensors and spectroscopic analysis tools. Their system monitors not only the melt pool but also the surrounding thermal affected zone to predict and detect defects before they form. The technology employs hyperspectral imaging to analyze the plasma plume during deposition, providing insights into material composition variations and potential contamination issues. Honeywell's solution features edge computing capabilities that process sensor data locally to enable microsecond response times for process adjustments[2]. The system includes specialized algorithms that can distinguish between normal process variations and actual defects, significantly reducing false positives. Additionally, Honeywell has integrated their QA system with their broader Industrial IoT platform, allowing for comprehensive data analytics and process optimization across multiple machines and facilities.

Strengths: Honeywell's solution offers exceptional sensitivity to subtle defect indicators and provides comprehensive data integration with existing manufacturing systems. Their industrial automation expertise enables seamless integration with various DED equipment. Weaknesses: The system requires significant calibration for new materials and process parameters, creating a steeper implementation curve. The advanced sensors also demand regular maintenance and recalibration to maintain optimal performance.

Critical Technologies for Real-Time Defect Detection in DED

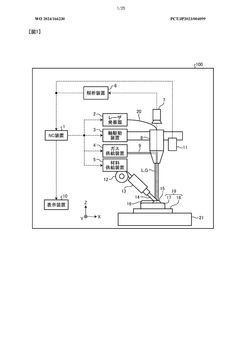

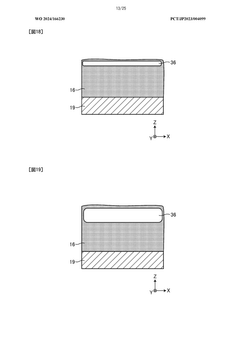

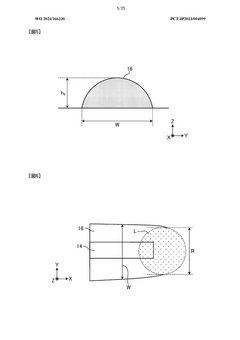

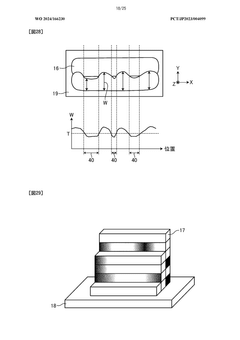

Defect estimation device, numerical control device, additive manufacturing device, and defect estimation method

PatentWO2024166230A1

Innovation

- A defect estimation device that identifies internal defects by detecting phenomena like unmelted material collisions, rubbing, and bead gaps during the additive manufacturing process, allowing for real-time estimation without additional measurement steps.

Direct energy deposition (DED) process neural network online monitoring system and method based on time sequence data set

PatentPendingCN119442861A

Innovation

- 采用基于时间序列数据集的直接能量沉积DED过程神经网络在线监控系统,该系统包括获取时间序列数据、预测温度趋势、确定缺陷预测结果并优化工艺参数。

Standards and Certification Requirements for DED Quality Systems

The implementation of quality assurance systems in Directed Energy Deposition (DED) processes requires adherence to established standards and certification frameworks. Currently, several international organizations have developed standards specifically addressing additive manufacturing quality requirements, including ISO/ASTM 52901:2017 for general principles and requirements, and ISO/ASTM 52904:2019 for process qualification. These standards provide foundational guidelines for quality management systems in DED operations, though many are still evolving as the technology matures.

For inline sensors and real-time defect detection systems in DED, manufacturers must comply with IEC 61508 for functional safety of electronic systems and ISO 13849 for safety-related parts of control systems. These standards ensure that sensor implementations maintain operational integrity and reliability during critical manufacturing processes. Additionally, the ASME V&V 10 standard provides verification and validation protocols for computational modeling of manufacturing systems, which is essential for the algorithms supporting real-time defect detection.

Certification requirements for DED quality systems typically involve third-party assessment against industry-specific standards. Organizations such as TÜV, UL, and DNV GL offer certification programs that validate the performance and reliability of quality monitoring systems. For aerospace applications, the AS9100 quality management system incorporates specific requirements for additive manufacturing processes, including those utilizing inline monitoring technologies.

Regulatory bodies in different regions have established varying requirements for DED quality systems. In the European Union, the Machinery Directive 2006/42/EC and the Electromagnetic Compatibility Directive 2014/30/EU apply to sensor systems integrated into manufacturing equipment. In the United States, NIST has published guidelines for qualification and certification of additive manufacturing processes, which include recommendations for implementing real-time monitoring systems.

Emerging standards specifically addressing inline monitoring in additive manufacturing include the draft ISO/ASTM 52909, which focuses on calibration and validation of monitoring systems. The America Makes & ANSI Additive Manufacturing Standardization Collaborative (AMSC) has also identified standardization gaps in real-time monitoring and quality assurance systems, indicating areas where future standards development is needed.

Companies implementing DED quality systems must also consider data security standards such as IEC 62443 for industrial automation and control systems, particularly as real-time monitoring systems increasingly integrate with networked manufacturing environments and cloud-based analytics platforms. This ensures that quality data remains protected while enabling the advanced analytics necessary for effective defect detection.

For inline sensors and real-time defect detection systems in DED, manufacturers must comply with IEC 61508 for functional safety of electronic systems and ISO 13849 for safety-related parts of control systems. These standards ensure that sensor implementations maintain operational integrity and reliability during critical manufacturing processes. Additionally, the ASME V&V 10 standard provides verification and validation protocols for computational modeling of manufacturing systems, which is essential for the algorithms supporting real-time defect detection.

Certification requirements for DED quality systems typically involve third-party assessment against industry-specific standards. Organizations such as TÜV, UL, and DNV GL offer certification programs that validate the performance and reliability of quality monitoring systems. For aerospace applications, the AS9100 quality management system incorporates specific requirements for additive manufacturing processes, including those utilizing inline monitoring technologies.

Regulatory bodies in different regions have established varying requirements for DED quality systems. In the European Union, the Machinery Directive 2006/42/EC and the Electromagnetic Compatibility Directive 2014/30/EU apply to sensor systems integrated into manufacturing equipment. In the United States, NIST has published guidelines for qualification and certification of additive manufacturing processes, which include recommendations for implementing real-time monitoring systems.

Emerging standards specifically addressing inline monitoring in additive manufacturing include the draft ISO/ASTM 52909, which focuses on calibration and validation of monitoring systems. The America Makes & ANSI Additive Manufacturing Standardization Collaborative (AMSC) has also identified standardization gaps in real-time monitoring and quality assurance systems, indicating areas where future standards development is needed.

Companies implementing DED quality systems must also consider data security standards such as IEC 62443 for industrial automation and control systems, particularly as real-time monitoring systems increasingly integrate with networked manufacturing environments and cloud-based analytics platforms. This ensures that quality data remains protected while enabling the advanced analytics necessary for effective defect detection.

Economic Impact and ROI Analysis of Inline Quality Assurance

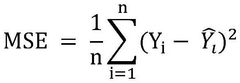

The implementation of inline sensors and real-time defect detection systems in Directed Energy Deposition (DED) processes represents a significant economic opportunity for manufacturing organizations. Initial investment costs for comprehensive inline quality assurance systems typically range from $50,000 to $250,000, depending on the complexity of sensors, integration requirements, and analytical capabilities. While this capital expenditure may appear substantial, the return on investment typically materializes within 12-24 months of implementation.

Cost-benefit analyses across multiple manufacturing sectors indicate that inline quality assurance systems reduce scrap rates by 30-45% on average. For high-value materials commonly used in DED processes, such as titanium alloys and superalloys, this reduction translates to direct material savings of $75,000-$200,000 annually for medium-scale operations. Additionally, the elimination of post-process inspection steps can reduce labor costs by 15-25%, representing further operational savings of $40,000-$90,000 per year.

The economic impact extends beyond direct cost savings. Real-time defect detection significantly reduces time-to-market by minimizing rework cycles and accelerating validation processes. Companies implementing these systems report 20-35% reductions in overall production cycle times, enabling more responsive fulfillment of customer orders and creating competitive advantages in time-sensitive markets. This acceleration of production capabilities can increase annual revenue potential by 10-15% through enhanced capacity utilization.

Quality improvements resulting from inline monitoring systems also generate substantial downstream economic benefits. Warranty claim reductions of 25-40% have been documented across aerospace and medical device manufacturers utilizing advanced DED processes with real-time quality assurance. For complex components with critical applications, the avoidance of field failures can prevent catastrophic costs that might otherwise reach millions of dollars per incident.

From a strategic investment perspective, the total cost of ownership analysis reveals that inline quality assurance systems typically deliver an internal rate of return between 35-60%. Sensitivity analyses indicate that even in conservative scenarios with minimal defect reduction (15-20%), the economic justification remains robust. Furthermore, as these systems accumulate process data over time, the predictive capabilities enhance, creating additional value through preventive maintenance optimization and process refinement that can yield incremental annual savings of 5-8%.

Cost-benefit analyses across multiple manufacturing sectors indicate that inline quality assurance systems reduce scrap rates by 30-45% on average. For high-value materials commonly used in DED processes, such as titanium alloys and superalloys, this reduction translates to direct material savings of $75,000-$200,000 annually for medium-scale operations. Additionally, the elimination of post-process inspection steps can reduce labor costs by 15-25%, representing further operational savings of $40,000-$90,000 per year.

The economic impact extends beyond direct cost savings. Real-time defect detection significantly reduces time-to-market by minimizing rework cycles and accelerating validation processes. Companies implementing these systems report 20-35% reductions in overall production cycle times, enabling more responsive fulfillment of customer orders and creating competitive advantages in time-sensitive markets. This acceleration of production capabilities can increase annual revenue potential by 10-15% through enhanced capacity utilization.

Quality improvements resulting from inline monitoring systems also generate substantial downstream economic benefits. Warranty claim reductions of 25-40% have been documented across aerospace and medical device manufacturers utilizing advanced DED processes with real-time quality assurance. For complex components with critical applications, the avoidance of field failures can prevent catastrophic costs that might otherwise reach millions of dollars per incident.

From a strategic investment perspective, the total cost of ownership analysis reveals that inline quality assurance systems typically deliver an internal rate of return between 35-60%. Sensitivity analyses indicate that even in conservative scenarios with minimal defect reduction (15-20%), the economic justification remains robust. Furthermore, as these systems accumulate process data over time, the predictive capabilities enhance, creating additional value through preventive maintenance optimization and process refinement that can yield incremental annual savings of 5-8%.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!