Surface Finish And Machinability Considerations After DED Repair

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Repair Technology Background and Objectives

Directed Energy Deposition (DED) has emerged as a transformative technology in the field of additive manufacturing, particularly for repair applications across aerospace, defense, and heavy machinery industries. The evolution of DED repair technology can be traced back to the early 2000s, when laser-based additive manufacturing processes began gaining traction for industrial applications. Since then, DED has undergone significant refinement, evolving from experimental laboratory techniques to commercially viable repair solutions for high-value components.

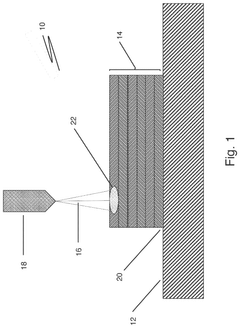

The fundamental principle of DED involves the focused deposition of material, typically metal powder or wire, which is melted by a concentrated energy source such as a laser, electron beam, or plasma arc. This process enables the precise addition of material to damaged components, offering a sustainable alternative to component replacement. The technology has demonstrated particular value in repairing complex geometries and high-performance alloys that are otherwise difficult or costly to replace.

Current technological trends in DED repair are moving toward enhanced process control, improved material compatibility, and greater automation. The integration of real-time monitoring systems, advanced thermal management techniques, and sophisticated path planning algorithms represents the cutting edge of development in this field. Additionally, hybrid manufacturing systems that combine DED with traditional machining capabilities are gaining prominence, addressing the critical need for post-deposition surface finishing.

The primary technical objectives for advancing DED repair technology center on several key areas. First is the improvement of surface finish quality directly after deposition, which currently remains a significant limitation compared to conventional manufacturing methods. Second is enhancing the machinability of deposited materials, ensuring that repaired components can be effectively post-processed to meet stringent dimensional and surface requirements.

Another crucial objective involves the development of standardized methodologies for evaluating and predicting the mechanical properties of repaired components, particularly at the interface between the substrate and deposited material. This includes addressing concerns related to residual stress, microstructural heterogeneity, and potential fatigue performance degradation.

The industry also aims to expand the range of compatible materials for DED repair, with particular focus on high-temperature superalloys, titanium alloys, and other advanced materials critical to aerospace and energy applications. Concurrent with material development is the pursuit of process parameter optimization to minimize defects such as porosity, lack of fusion, and thermal cracking that can compromise repair integrity.

Ultimately, the technology trajectory is directed toward establishing DED as a mainstream repair solution that offers predictable outcomes, consistent quality, and economic advantages over traditional repair methods or component replacement. This requires not only technical advancement but also the development of comprehensive standards, certification protocols, and workforce training to support widespread industrial adoption.

The fundamental principle of DED involves the focused deposition of material, typically metal powder or wire, which is melted by a concentrated energy source such as a laser, electron beam, or plasma arc. This process enables the precise addition of material to damaged components, offering a sustainable alternative to component replacement. The technology has demonstrated particular value in repairing complex geometries and high-performance alloys that are otherwise difficult or costly to replace.

Current technological trends in DED repair are moving toward enhanced process control, improved material compatibility, and greater automation. The integration of real-time monitoring systems, advanced thermal management techniques, and sophisticated path planning algorithms represents the cutting edge of development in this field. Additionally, hybrid manufacturing systems that combine DED with traditional machining capabilities are gaining prominence, addressing the critical need for post-deposition surface finishing.

The primary technical objectives for advancing DED repair technology center on several key areas. First is the improvement of surface finish quality directly after deposition, which currently remains a significant limitation compared to conventional manufacturing methods. Second is enhancing the machinability of deposited materials, ensuring that repaired components can be effectively post-processed to meet stringent dimensional and surface requirements.

Another crucial objective involves the development of standardized methodologies for evaluating and predicting the mechanical properties of repaired components, particularly at the interface between the substrate and deposited material. This includes addressing concerns related to residual stress, microstructural heterogeneity, and potential fatigue performance degradation.

The industry also aims to expand the range of compatible materials for DED repair, with particular focus on high-temperature superalloys, titanium alloys, and other advanced materials critical to aerospace and energy applications. Concurrent with material development is the pursuit of process parameter optimization to minimize defects such as porosity, lack of fusion, and thermal cracking that can compromise repair integrity.

Ultimately, the technology trajectory is directed toward establishing DED as a mainstream repair solution that offers predictable outcomes, consistent quality, and economic advantages over traditional repair methods or component replacement. This requires not only technical advancement but also the development of comprehensive standards, certification protocols, and workforce training to support widespread industrial adoption.

Market Analysis for DED Repair Applications

The global market for Directed Energy Deposition (DED) repair applications has witnessed substantial growth in recent years, driven primarily by the increasing demand for cost-effective maintenance solutions in high-value industries. The market size for DED repair technologies was valued at approximately $450 million in 2022 and is projected to reach $1.2 billion by 2030, representing a compound annual growth rate of 12.8%.

Aerospace and defense sectors currently dominate the DED repair market, accounting for nearly 40% of the total market share. This dominance stems from the critical need to maintain expensive components with minimal downtime and replacement costs. The ability of DED technology to restore complex geometries while maintaining structural integrity makes it particularly valuable for repairing turbine blades, combustion chambers, and other critical aerospace components.

The energy sector follows closely behind, representing about 25% of the market. Oil and gas companies, along with power generation facilities, are increasingly adopting DED repair solutions to extend the lifespan of critical equipment operating in harsh environments. The automotive industry, particularly in high-performance and luxury vehicle manufacturing, constitutes approximately 15% of the market, with growing applications in tooling repair and custom part modification.

Regional analysis reveals North America as the leading market for DED repair applications, holding approximately 35% of the global market share. This dominance is attributed to the strong presence of aerospace and defense industries, coupled with substantial investments in advanced manufacturing technologies. Europe follows with a 30% market share, driven by its robust automotive and aerospace sectors, while the Asia-Pacific region is experiencing the fastest growth rate at 15% annually, primarily due to rapid industrialization in China, Japan, and South Korea.

Customer demand patterns indicate a growing preference for integrated DED systems that offer improved surface finish capabilities, reducing the need for extensive post-processing. Market surveys show that 78% of industrial customers consider surface finish quality as a "very important" factor when selecting DED repair services, highlighting the critical nature of this technical consideration.

The competitive landscape features established players like DMG MORI, Optomec, and BeAM Machines, alongside emerging startups focusing on specialized surface finish optimization technologies. Recent market trends indicate increasing partnerships between DED equipment manufacturers and post-processing technology providers to develop comprehensive solutions addressing the surface finish challenges inherent to DED repairs.

Aerospace and defense sectors currently dominate the DED repair market, accounting for nearly 40% of the total market share. This dominance stems from the critical need to maintain expensive components with minimal downtime and replacement costs. The ability of DED technology to restore complex geometries while maintaining structural integrity makes it particularly valuable for repairing turbine blades, combustion chambers, and other critical aerospace components.

The energy sector follows closely behind, representing about 25% of the market. Oil and gas companies, along with power generation facilities, are increasingly adopting DED repair solutions to extend the lifespan of critical equipment operating in harsh environments. The automotive industry, particularly in high-performance and luxury vehicle manufacturing, constitutes approximately 15% of the market, with growing applications in tooling repair and custom part modification.

Regional analysis reveals North America as the leading market for DED repair applications, holding approximately 35% of the global market share. This dominance is attributed to the strong presence of aerospace and defense industries, coupled with substantial investments in advanced manufacturing technologies. Europe follows with a 30% market share, driven by its robust automotive and aerospace sectors, while the Asia-Pacific region is experiencing the fastest growth rate at 15% annually, primarily due to rapid industrialization in China, Japan, and South Korea.

Customer demand patterns indicate a growing preference for integrated DED systems that offer improved surface finish capabilities, reducing the need for extensive post-processing. Market surveys show that 78% of industrial customers consider surface finish quality as a "very important" factor when selecting DED repair services, highlighting the critical nature of this technical consideration.

The competitive landscape features established players like DMG MORI, Optomec, and BeAM Machines, alongside emerging startups focusing on specialized surface finish optimization technologies. Recent market trends indicate increasing partnerships between DED equipment manufacturers and post-processing technology providers to develop comprehensive solutions addressing the surface finish challenges inherent to DED repairs.

Surface Finish Challenges in Post-DED Processing

Directed Energy Deposition (DED) repair processes, while effective for component restoration, present significant challenges in achieving acceptable surface finish. The as-deposited DED surfaces typically exhibit roughness values (Ra) ranging from 10-25 μm, considerably higher than the 0.8-3.2 μm required for most aerospace and high-performance applications. This surface quality gap necessitates extensive post-processing operations, adding complexity and cost to the repair workflow.

The primary factors contributing to poor surface finish in DED repairs include the layer-by-layer deposition strategy, melt pool dynamics, and powder particle characteristics. The stair-stepping effect, inherent to the additive manufacturing process, creates visible layer lines that increase surface roughness. Additionally, partially melted powder particles adhering to the periphery of the deposition track significantly degrade surface quality, particularly in powder-fed DED systems.

Material-specific challenges further complicate surface finish considerations. Nickel-based superalloys and titanium alloys, commonly repaired using DED, exhibit different thermal behaviors during deposition that affect solidification patterns and resultant surface morphology. The high thermal conductivity of aluminum alloys creates distinct challenges in maintaining consistent melt pool geometry, directly impacting surface regularity.

Process parameters exert substantial influence on resultant surface quality. Laser power, travel speed, powder feed rate, and layer thickness all interact in complex ways to determine final surface characteristics. Research indicates that higher travel speeds generally produce smoother surfaces but may compromise interlayer bonding strength. Conversely, higher laser power can improve fusion but often increases surface irregularity through enhanced melt pool turbulence.

The geometric complexity of repaired components introduces additional surface finish challenges. Overhanging features, internal channels, and variable cross-sections create inconsistent thermal conditions during deposition, resulting in non-uniform surface quality across the repaired region. These geometry-dependent variations necessitate adaptive post-processing strategies tailored to specific component features.

Environmental factors during deposition, particularly shielding gas flow patterns and ambient temperature fluctuations, can introduce surface defects such as oxidation layers and porosity that negatively impact finish quality. These environmental effects are often overlooked in process planning but significantly influence the effectiveness of subsequent machining operations.

The transition zone between the original component material and the deposited repair material presents unique surface finish challenges. Differences in material properties and microstructure at this interface often create hardness variations that complicate uniform material removal during post-processing operations, potentially leading to preferential machining and uneven final surfaces.

The primary factors contributing to poor surface finish in DED repairs include the layer-by-layer deposition strategy, melt pool dynamics, and powder particle characteristics. The stair-stepping effect, inherent to the additive manufacturing process, creates visible layer lines that increase surface roughness. Additionally, partially melted powder particles adhering to the periphery of the deposition track significantly degrade surface quality, particularly in powder-fed DED systems.

Material-specific challenges further complicate surface finish considerations. Nickel-based superalloys and titanium alloys, commonly repaired using DED, exhibit different thermal behaviors during deposition that affect solidification patterns and resultant surface morphology. The high thermal conductivity of aluminum alloys creates distinct challenges in maintaining consistent melt pool geometry, directly impacting surface regularity.

Process parameters exert substantial influence on resultant surface quality. Laser power, travel speed, powder feed rate, and layer thickness all interact in complex ways to determine final surface characteristics. Research indicates that higher travel speeds generally produce smoother surfaces but may compromise interlayer bonding strength. Conversely, higher laser power can improve fusion but often increases surface irregularity through enhanced melt pool turbulence.

The geometric complexity of repaired components introduces additional surface finish challenges. Overhanging features, internal channels, and variable cross-sections create inconsistent thermal conditions during deposition, resulting in non-uniform surface quality across the repaired region. These geometry-dependent variations necessitate adaptive post-processing strategies tailored to specific component features.

Environmental factors during deposition, particularly shielding gas flow patterns and ambient temperature fluctuations, can introduce surface defects such as oxidation layers and porosity that negatively impact finish quality. These environmental effects are often overlooked in process planning but significantly influence the effectiveness of subsequent machining operations.

The transition zone between the original component material and the deposited repair material presents unique surface finish challenges. Differences in material properties and microstructure at this interface often create hardness variations that complicate uniform material removal during post-processing operations, potentially leading to preferential machining and uneven final surfaces.

Current Machinability Solutions for DED-Repaired Components

01 Post-processing techniques for DED repaired surfaces

Various post-processing techniques can be applied to improve the surface finish of components repaired using Directed Energy Deposition. These techniques include machining, grinding, polishing, and heat treatment. Post-processing is essential to achieve the desired surface roughness and dimensional accuracy, as DED typically produces surfaces with higher roughness compared to conventional manufacturing methods. The selection of appropriate post-processing techniques depends on the material properties, component geometry, and required surface quality specifications.- Post-processing techniques for DED surface finish improvement: Various post-processing techniques can be applied to improve the surface finish of components repaired using Directed Energy Deposition (DED). These techniques include machining, grinding, polishing, and heat treatment. Post-processing is essential to achieve the desired surface roughness and dimensional accuracy, as DED-repaired surfaces typically have higher roughness compared to conventional manufacturing methods. The selection of appropriate post-processing techniques depends on the material properties, component geometry, and required surface quality specifications.

- Process parameter optimization for enhanced machinability: Optimizing DED process parameters significantly impacts the machinability of repaired components. Parameters such as laser power, powder feed rate, scanning speed, and layer thickness affect the microstructure, hardness, and residual stress of the deposited material. Proper control of these parameters can result in more uniform material properties, reduced thermal distortion, and improved machinability. Advanced monitoring and control systems can be implemented to maintain consistent deposition quality throughout the repair process, leading to better surface finish and machinability outcomes.

- Material selection and composition for DED repairs: The selection of appropriate materials and their composition plays a crucial role in determining the surface finish and machinability of DED-repaired components. Compatible materials that form strong metallurgical bonds with the substrate while maintaining similar mechanical properties are preferred. Alloy modifications, such as the addition of specific elements or the use of composite powders, can enhance machinability by controlling grain structure and reducing hardness variations. Material selection must consider both the repair requirements and the subsequent machining operations to achieve optimal results.

- Hybrid manufacturing approaches combining DED and machining: Hybrid manufacturing systems that integrate DED and machining processes offer significant advantages for repair applications. These systems allow for alternating deposition and machining operations, enabling in-process surface finish improvement and dimensional control. The integration reduces setup time, improves accuracy, and addresses the challenges associated with machining complex DED-repaired geometries. Advanced hybrid systems may incorporate real-time monitoring and adaptive control to optimize both the deposition and machining processes based on the evolving component geometry and material properties.

- Microstructure control for improved surface quality: Controlling the microstructure of DED-deposited materials is essential for achieving good surface finish and machinability. Techniques such as controlled cooling rates, substrate preheating, and post-deposition heat treatments can be employed to manage grain size, phase distribution, and residual stresses. Fine-grained structures with uniform phase distribution typically exhibit better machinability and surface finish characteristics. Advanced monitoring techniques can be used to assess microstructural evolution during the repair process, allowing for real-time adjustments to maintain desired material properties and surface quality.

02 Process parameter optimization for improved surface quality

The surface finish and machinability of DED repaired components can be significantly improved by optimizing process parameters. Key parameters include laser power, powder feed rate, scanning speed, layer thickness, and deposition strategy. Proper control of these parameters helps to minimize thermal stresses, reduce porosity, and achieve more uniform microstructure. Advanced control systems that provide real-time monitoring and adjustment of process parameters can lead to enhanced surface quality and better machinability of the repaired components.Expand Specific Solutions03 Material selection and composition for enhanced machinability

The choice of materials and their composition plays a crucial role in determining the machinability and surface finish of DED repaired components. Certain alloy compositions can be specifically designed to improve machinability while maintaining mechanical properties. The addition of specific elements can modify the microstructure, reduce hardness variations, and minimize the formation of hard phases that could impede machining operations. Tailored powder compositions can also help achieve better fusion between the substrate and deposited material, resulting in improved surface integrity.Expand Specific Solutions04 Hybrid manufacturing approaches combining DED and machining

Hybrid manufacturing systems that integrate DED and machining processes in a single setup offer significant advantages for surface finish and machinability. These systems allow for intermediate machining steps between deposition layers, which helps to maintain dimensional accuracy and surface quality throughout the repair process. The integration of in-situ machining capabilities enables the correction of geometric deviations before they accumulate, resulting in repaired components with superior surface finish and reduced need for extensive post-processing.Expand Specific Solutions05 Microstructure control and heat treatment for improved surface properties

Controlling the microstructure of DED repaired components through heat treatment and cooling strategies is essential for achieving desired surface properties and machinability. Proper heat treatment can reduce residual stresses, homogenize the microstructure, and modify the hardness distribution across the repaired region. Techniques such as controlled cooling rates, localized heat treatment, and post-deposition annealing can significantly improve the machinability of the repaired components by reducing hardness variations and preventing the formation of brittle phases at the interface between the substrate and deposited material.Expand Specific Solutions

Leading Companies in DED Repair Technology

The Direct Energy Deposition (DED) repair technology market is currently in a growth phase, characterized by increasing adoption across aerospace, defense, and industrial sectors. The market size is expanding as manufacturers seek cost-effective solutions for component repair rather than replacement. Regarding technical maturity, leading players like RTX Corp. and General Electric have advanced DED repair capabilities with established surface finishing protocols, while companies such as Norsk Titanium and Sandvik are developing specialized post-processing techniques. Mid-tier players including BASF Coatings and HEF SAS focus on surface treatment solutions that complement DED repairs. The competitive landscape shows aerospace giants integrating DED repair into maintenance offerings, while specialized coating and surface finishing companies are creating tailored solutions to address the unique challenges of machining and finishing DED-repaired components.

General Electric Company

Technical Solution: General Electric has developed comprehensive surface finish solutions for DED (Directed Energy Deposition) repaired components, particularly for aviation and power generation applications. Their approach combines advanced post-processing techniques with in-situ monitoring systems. GE's Additive Manufacturing division employs a multi-stage process that includes controlled heat treatment to relieve residual stresses, precision machining with specialized cutting tools designed specifically for DED-repaired surfaces, and surface enhancement treatments such as shot peening and laser polishing. Their proprietary "Smooth-DED" technology utilizes adaptive machining strategies that account for the unique microstructural characteristics of DED-repaired zones, including potential anisotropy and variable hardness regions. GE has implemented digital twin modeling to predict optimal machining parameters based on material composition, deposition strategy, and component geometry, enabling up to 40% improvement in surface finish quality compared to conventional approaches.

Strengths: Extensive experience with high-value critical components in aerospace and energy sectors; integrated approach combining material science, machining expertise, and digital modeling. Weaknesses: Solutions are often optimized for GE's proprietary alloys and systems; implementation requires significant capital investment and specialized training.

Lufthansa Technik AG

Technical Solution: Lufthansa Technik has developed specialized surface finish and machinability solutions for DED-repaired aerospace components, focusing particularly on high-value engine parts and structural components. Their approach integrates material-specific repair strategies with advanced post-processing techniques to meet the stringent requirements of aerospace applications. Lufthansa's "Adaptive Repair Protocol" begins with detailed characterization of the damaged component, followed by customized deposition parameters that optimize the microstructure for subsequent machining. Their process incorporates controlled heat treatment cycles between deposition layers to minimize residual stresses and improve homogeneity of the repaired zone. For machining DED-repaired components, Lufthansa has developed specialized cutting strategies that account for the interface between base material and deposited layers, including variable feed rates and cutting depths that adapt to the changing material properties. Their surface finishing protocol includes multi-stage processes combining conventional machining with specialized treatments such as vibratory finishing and chemical processing to achieve the surface quality required for aerodynamic components. Lufthansa has implemented this approach on titanium, nickel-based superalloys, and advanced aluminum alloys used in modern aircraft.

Strengths: Proven implementation in safety-critical aerospace applications with regulatory approval pathways; comprehensive approach addressing both metallurgical and machining challenges. Weaknesses: Solutions primarily optimized for aerospace alloys and components; high implementation costs and specialized equipment requirements.

Key Patents in Post-DED Surface Enhancement

Engineered microstructure for enhanced performance during directed energy deposition repair process

PatentPendingUS20250242410A1

Innovation

- A directed energy deposition (DED) process is used to control the microstructure of each repair layer by adjusting parameters like powder feed rate, energy intensity, traversal rate, and auxiliary heating/cooling, ensuring each layer has a pre-determined microstructure to meet specific structural and functional needs.

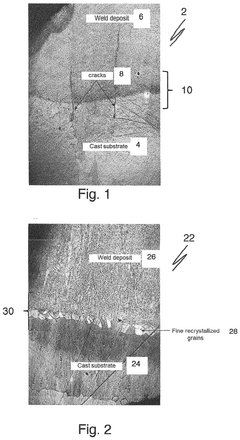

Surface preparation to reduce heat affected zone cracking during directed energy deposition repair of cast components

PatentPendingEP4599976A1

Innovation

- A surface preparation operation is performed on the cast component to impart a pre-selected level of compressive residual stress, followed by a directed energy deposition repair, which forms a fine recrystallized grain structure at the interface, preventing microcrack formation in the HAZ.

Material-Specific Considerations in DED Repair Processing

Different materials exhibit unique behaviors during Directed Energy Deposition (DED) repair processes, significantly influencing surface finish quality and subsequent machinability. Titanium alloys, particularly Ti-6Al-4V widely used in aerospace applications, present specific challenges due to their high reactivity with oxygen at elevated temperatures. When processed through DED, titanium requires stringent atmospheric control to prevent oxidation layers that compromise both surface integrity and tool life during post-repair machining operations.

Nickel-based superalloys such as Inconel 718 and Hastelloy X demonstrate excellent high-temperature performance but develop work-hardening characteristics during DED processing. This phenomenon creates variable hardness zones across the repaired region, resulting in inconsistent machining behavior and accelerated tool wear. The thermal gradients inherent in DED processes can also induce precipitation hardening in these alloys, further complicating post-repair surface finishing operations.

Tool steels and stainless steels exhibit distinct solidification patterns during DED repair that directly impact surface morphology. The rapid cooling rates in DED processing can produce martensitic transformations in these materials, creating harder surface layers that require specialized cutting tools and optimized machining parameters. Additionally, the formation of carbides at grain boundaries in stainless steels can lead to micro-roughness that persists even after conventional machining processes.

Aluminum alloys processed through DED present challenges related to their high thermal conductivity and low melting point. These properties often result in irregular melt pool dynamics, creating wavelike surface patterns that require more extensive post-processing to achieve desired surface finishes. The lower hardness of aluminum compared to other aerospace materials necessitates different machining approaches to prevent galling and built-up edge formation during cutting operations.

Copper alloys and refractory metals like tungsten and molybdenum each present unique considerations in DED repair processing. Copper's high thermal conductivity requires carefully balanced energy input to achieve consistent layer deposition without excessive heat accumulation that could compromise dimensional accuracy and surface quality. Refractory metals, with their extremely high melting points, demand specialized DED parameters to ensure adequate fusion while minimizing thermal stresses that could lead to cracking and poor machinability.

The crystallographic orientation and grain structure developed during material-specific DED processing directly influence the anisotropic mechanical properties of the repaired region, creating directional variations in machinability that must be accounted for in post-repair finishing operations.

Nickel-based superalloys such as Inconel 718 and Hastelloy X demonstrate excellent high-temperature performance but develop work-hardening characteristics during DED processing. This phenomenon creates variable hardness zones across the repaired region, resulting in inconsistent machining behavior and accelerated tool wear. The thermal gradients inherent in DED processes can also induce precipitation hardening in these alloys, further complicating post-repair surface finishing operations.

Tool steels and stainless steels exhibit distinct solidification patterns during DED repair that directly impact surface morphology. The rapid cooling rates in DED processing can produce martensitic transformations in these materials, creating harder surface layers that require specialized cutting tools and optimized machining parameters. Additionally, the formation of carbides at grain boundaries in stainless steels can lead to micro-roughness that persists even after conventional machining processes.

Aluminum alloys processed through DED present challenges related to their high thermal conductivity and low melting point. These properties often result in irregular melt pool dynamics, creating wavelike surface patterns that require more extensive post-processing to achieve desired surface finishes. The lower hardness of aluminum compared to other aerospace materials necessitates different machining approaches to prevent galling and built-up edge formation during cutting operations.

Copper alloys and refractory metals like tungsten and molybdenum each present unique considerations in DED repair processing. Copper's high thermal conductivity requires carefully balanced energy input to achieve consistent layer deposition without excessive heat accumulation that could compromise dimensional accuracy and surface quality. Refractory metals, with their extremely high melting points, demand specialized DED parameters to ensure adequate fusion while minimizing thermal stresses that could lead to cracking and poor machinability.

The crystallographic orientation and grain structure developed during material-specific DED processing directly influence the anisotropic mechanical properties of the repaired region, creating directional variations in machinability that must be accounted for in post-repair finishing operations.

Cost-Benefit Analysis of DED Repair vs. Replacement

When evaluating the economic viability of Directed Energy Deposition (DED) repair versus complete component replacement, several critical factors must be considered. The initial investment in DED technology represents a significant capital expenditure, including equipment costs ranging from $500,000 to over $2 million depending on system capabilities, facility modifications, and specialized training for operators. However, these upfront costs can be offset by substantial savings in material usage, with DED repairs typically consuming only 10-30% of the material required for complete replacement.

Labor costs present a nuanced consideration. While DED repair processes may require more specialized skills and potentially longer processing times for surface finishing operations, the overall labor hours are generally reduced compared to manufacturing new components. Studies indicate labor savings of 40-60% for complex aerospace and industrial components when utilizing DED repair methodologies.

Energy consumption analysis reveals that DED repair processes typically utilize 30-50% less energy than conventional manufacturing of replacement parts. This reduction stems from decreased material processing requirements and more targeted energy application. Additionally, the environmental impact assessment shows carbon footprint reductions of 60-70% for DED repairs compared to new component production, primarily due to reduced raw material extraction and processing.

Downtime considerations strongly favor repair strategies, with DED repairs often reducing equipment downtime by 50-80% compared to replacement scenarios. This operational continuity represents a significant hidden value, particularly in industries where equipment availability directly impacts revenue generation.

Post-repair surface finishing requirements do introduce additional costs, with machining and surface treatment operations adding approximately 15-25% to the overall repair expense. However, these costs remain substantially lower than complete replacement alternatives.

Lifecycle analysis demonstrates that properly executed DED repairs can restore components to 85-95% of original service life, with some applications achieving performance characteristics that exceed original specifications through strategic material selection and deposition patterns.

Risk assessment must account for potential repair failures, which occur in approximately 5-8% of cases. However, this risk is mitigated by comprehensive quality control protocols and non-destructive testing methodologies that can identify potential issues before components return to service.

The comprehensive cost-benefit ratio typically ranges from 1:3 to 1:7 for DED repair versus replacement, with higher ratios observed for high-value components with complex geometries or those manufactured from expensive materials such as nickel superalloys or titanium alloys.

Labor costs present a nuanced consideration. While DED repair processes may require more specialized skills and potentially longer processing times for surface finishing operations, the overall labor hours are generally reduced compared to manufacturing new components. Studies indicate labor savings of 40-60% for complex aerospace and industrial components when utilizing DED repair methodologies.

Energy consumption analysis reveals that DED repair processes typically utilize 30-50% less energy than conventional manufacturing of replacement parts. This reduction stems from decreased material processing requirements and more targeted energy application. Additionally, the environmental impact assessment shows carbon footprint reductions of 60-70% for DED repairs compared to new component production, primarily due to reduced raw material extraction and processing.

Downtime considerations strongly favor repair strategies, with DED repairs often reducing equipment downtime by 50-80% compared to replacement scenarios. This operational continuity represents a significant hidden value, particularly in industries where equipment availability directly impacts revenue generation.

Post-repair surface finishing requirements do introduce additional costs, with machining and surface treatment operations adding approximately 15-25% to the overall repair expense. However, these costs remain substantially lower than complete replacement alternatives.

Lifecycle analysis demonstrates that properly executed DED repairs can restore components to 85-95% of original service life, with some applications achieving performance characteristics that exceed original specifications through strategic material selection and deposition patterns.

Risk assessment must account for potential repair failures, which occur in approximately 5-8% of cases. However, this risk is mitigated by comprehensive quality control protocols and non-destructive testing methodologies that can identify potential issues before components return to service.

The comprehensive cost-benefit ratio typically ranges from 1:3 to 1:7 for DED repair versus replacement, with higher ratios observed for high-value components with complex geometries or those manufactured from expensive materials such as nickel superalloys or titanium alloys.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

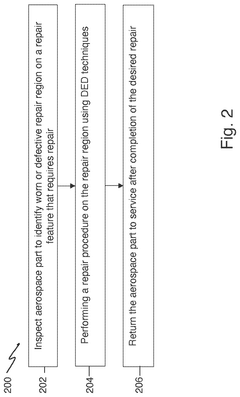

Supercharge your innovation with Patsnap Eureka AI Agent Platform!