Standardized Reporting Metrics For DED Build And Repair Quality

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Background and Objectives

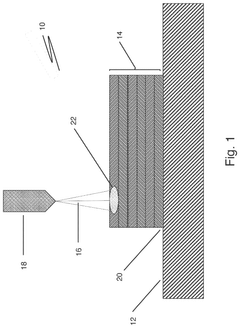

Directed Energy Deposition (DED) represents a transformative additive manufacturing technology that has evolved significantly since its inception in the 1990s. Initially developed for repair applications in aerospace and defense sectors, DED has expanded into a versatile manufacturing process capable of both building new components and repairing existing ones. The technology utilizes focused thermal energy to fuse materials as they are deposited, enabling the creation of complex metal structures with superior mechanical properties.

The evolution of DED technology has been marked by continuous improvements in process control, material compatibility, and system integration. Early systems were limited by inconsistent quality outcomes and restricted material options. However, advancements in laser technology, powder delivery systems, and real-time monitoring capabilities have dramatically enhanced the precision and reliability of DED processes over the past decade.

Despite these advancements, a significant challenge persists in the DED ecosystem: the lack of standardized reporting metrics for build and repair quality. This absence of unified measurement standards has hindered widespread industrial adoption, as manufacturers struggle to consistently evaluate and communicate process outcomes across different platforms and applications. The variability in reporting methodologies makes it difficult to compare results between research institutions, equipment manufacturers, and end-users.

The primary objective of standardizing reporting metrics for DED build and repair quality is to establish a common language for quality assessment that transcends equipment manufacturers and application domains. Such standardization would facilitate meaningful comparisons between different DED systems, enable more effective knowledge transfer across the industry, and accelerate the technology's maturation process.

Additional technical goals include developing comprehensive frameworks for characterizing microstructural properties, dimensional accuracy, surface finish, mechanical performance, and defect identification. These standardized metrics must be applicable across various DED technologies, including laser-based, electron beam, and arc-based systems, while accommodating the diverse range of materials processed through DED, from titanium alloys to high-temperature superalloys.

The establishment of these standards represents a critical step toward enabling DED technology to reach its full potential in advanced manufacturing ecosystems. By creating reliable, reproducible quality assessment methodologies, the industry can build greater confidence in DED processes, facilitate certification pathways for critical applications, and ultimately drive broader adoption across aerospace, medical, energy, and automotive sectors where quality assurance is paramount.

The evolution of DED technology has been marked by continuous improvements in process control, material compatibility, and system integration. Early systems were limited by inconsistent quality outcomes and restricted material options. However, advancements in laser technology, powder delivery systems, and real-time monitoring capabilities have dramatically enhanced the precision and reliability of DED processes over the past decade.

Despite these advancements, a significant challenge persists in the DED ecosystem: the lack of standardized reporting metrics for build and repair quality. This absence of unified measurement standards has hindered widespread industrial adoption, as manufacturers struggle to consistently evaluate and communicate process outcomes across different platforms and applications. The variability in reporting methodologies makes it difficult to compare results between research institutions, equipment manufacturers, and end-users.

The primary objective of standardizing reporting metrics for DED build and repair quality is to establish a common language for quality assessment that transcends equipment manufacturers and application domains. Such standardization would facilitate meaningful comparisons between different DED systems, enable more effective knowledge transfer across the industry, and accelerate the technology's maturation process.

Additional technical goals include developing comprehensive frameworks for characterizing microstructural properties, dimensional accuracy, surface finish, mechanical performance, and defect identification. These standardized metrics must be applicable across various DED technologies, including laser-based, electron beam, and arc-based systems, while accommodating the diverse range of materials processed through DED, from titanium alloys to high-temperature superalloys.

The establishment of these standards represents a critical step toward enabling DED technology to reach its full potential in advanced manufacturing ecosystems. By creating reliable, reproducible quality assessment methodologies, the industry can build greater confidence in DED processes, facilitate certification pathways for critical applications, and ultimately drive broader adoption across aerospace, medical, energy, and automotive sectors where quality assurance is paramount.

Market Analysis for DED Build and Repair Applications

The Directed Energy Deposition (DED) build and repair market has experienced significant growth in recent years, driven by increasing adoption across aerospace, defense, oil and gas, and heavy machinery sectors. Current market valuations place the global DED technology market at approximately 1.2 billion USD in 2023, with projections indicating a compound annual growth rate of 14.8% through 2030, potentially reaching 3.5 billion USD.

The aerospace and defense sectors currently dominate DED applications, accounting for roughly 45% of the total market share. These industries particularly value DED for component repair and restoration of high-value parts, where standardized quality metrics are becoming increasingly critical for certification and compliance requirements. The oil and gas sector follows at 20% market share, with heavy machinery and automotive applications comprising another 25%.

Regional analysis reveals North America leading the market with approximately 38% share, followed by Europe (30%) and Asia-Pacific (25%). The remaining 7% is distributed across other regions. This distribution correlates strongly with the concentration of aerospace, defense, and advanced manufacturing hubs in these regions, as well as with investment in additive manufacturing research and development.

Customer demand analysis indicates a clear shift toward service-based business models, where DED repair services are offered as part of maintenance contracts rather than equipment sales alone. This trend is particularly evident in the aerospace maintenance, repair, and overhaul (MRO) segment, where standardized quality metrics directly impact service provider selection and pricing models.

Market barriers include the high initial investment costs for DED equipment, which typically range from 500,000 to 2 million USD depending on system capabilities. Additionally, the lack of universally accepted quality standards and reporting metrics represents a significant market constraint, creating uncertainty for potential adopters and limiting wider implementation.

Growth opportunities exist in emerging applications such as rapid prototyping and hybrid manufacturing, where DED is combined with traditional machining processes. The medical implant sector also shows promising growth potential, with an expected market entry acceleration once standardized quality metrics are established and regulatory approval pathways become more defined.

Customer surveys indicate that 78% of current and potential DED technology users consider standardized quality metrics as "very important" or "critical" to their adoption decisions, highlighting the market demand for the development of unified reporting standards for build and repair quality.

The aerospace and defense sectors currently dominate DED applications, accounting for roughly 45% of the total market share. These industries particularly value DED for component repair and restoration of high-value parts, where standardized quality metrics are becoming increasingly critical for certification and compliance requirements. The oil and gas sector follows at 20% market share, with heavy machinery and automotive applications comprising another 25%.

Regional analysis reveals North America leading the market with approximately 38% share, followed by Europe (30%) and Asia-Pacific (25%). The remaining 7% is distributed across other regions. This distribution correlates strongly with the concentration of aerospace, defense, and advanced manufacturing hubs in these regions, as well as with investment in additive manufacturing research and development.

Customer demand analysis indicates a clear shift toward service-based business models, where DED repair services are offered as part of maintenance contracts rather than equipment sales alone. This trend is particularly evident in the aerospace maintenance, repair, and overhaul (MRO) segment, where standardized quality metrics directly impact service provider selection and pricing models.

Market barriers include the high initial investment costs for DED equipment, which typically range from 500,000 to 2 million USD depending on system capabilities. Additionally, the lack of universally accepted quality standards and reporting metrics represents a significant market constraint, creating uncertainty for potential adopters and limiting wider implementation.

Growth opportunities exist in emerging applications such as rapid prototyping and hybrid manufacturing, where DED is combined with traditional machining processes. The medical implant sector also shows promising growth potential, with an expected market entry acceleration once standardized quality metrics are established and regulatory approval pathways become more defined.

Customer surveys indicate that 78% of current and potential DED technology users consider standardized quality metrics as "very important" or "critical" to their adoption decisions, highlighting the market demand for the development of unified reporting standards for build and repair quality.

Current Challenges in DED Quality Assessment

Despite significant advancements in Directed Energy Deposition (DED) technology, the field continues to face substantial challenges in quality assessment and standardization. The absence of universally accepted reporting metrics creates inconsistencies across research publications, industrial applications, and regulatory frameworks. This fragmentation hinders meaningful comparison of results between different DED systems and methodologies, ultimately slowing industry-wide progress.

One primary challenge is the multidimensional nature of DED quality parameters. Unlike conventional manufacturing processes, DED quality encompasses geometric accuracy, material properties, microstructural characteristics, and surface finish—all of which interact in complex ways. Current assessment approaches often prioritize certain aspects while neglecting others, resulting in incomplete quality evaluations that fail to capture the holistic performance of DED components.

Real-time monitoring capabilities present another significant hurdle. While in-process monitoring tools exist, they generate vast amounts of heterogeneous data that lack standardized interpretation frameworks. The correlation between in-process signals and final part quality remains poorly defined, making it difficult to establish predictive quality metrics that could enable adaptive control systems and reduce post-production inspection requirements.

The diversity of DED technologies further complicates standardization efforts. Laser-based, electron beam, and arc-based DED systems each exhibit unique process characteristics and quality concerns. Current assessment methodologies rarely account for these technological variations, leading to metrics that may be relevant for one DED variant but inappropriate for others.

Material-specific considerations add another layer of complexity. Different materials respond uniquely to DED processing conditions, yet current quality metrics seldom incorporate material-specific benchmarks. This is particularly problematic for repair applications, where the interface between deposited material and substrate requires specialized quality assessment approaches that are currently underdeveloped.

Regulatory uncertainty compounds these technical challenges. Without standardized reporting metrics, certification bodies struggle to establish clear guidelines for DED-manufactured components, especially in safety-critical industries like aerospace and medical devices. This regulatory ambiguity creates market hesitation and limits broader industrial adoption of DED technologies.

Cross-disciplinary integration represents a final significant challenge. Quality assessment in DED requires expertise spanning materials science, process engineering, metrology, and data analytics. However, current approaches often remain siloed within individual disciplines, lacking the integrated perspective necessary for comprehensive quality evaluation frameworks.

One primary challenge is the multidimensional nature of DED quality parameters. Unlike conventional manufacturing processes, DED quality encompasses geometric accuracy, material properties, microstructural characteristics, and surface finish—all of which interact in complex ways. Current assessment approaches often prioritize certain aspects while neglecting others, resulting in incomplete quality evaluations that fail to capture the holistic performance of DED components.

Real-time monitoring capabilities present another significant hurdle. While in-process monitoring tools exist, they generate vast amounts of heterogeneous data that lack standardized interpretation frameworks. The correlation between in-process signals and final part quality remains poorly defined, making it difficult to establish predictive quality metrics that could enable adaptive control systems and reduce post-production inspection requirements.

The diversity of DED technologies further complicates standardization efforts. Laser-based, electron beam, and arc-based DED systems each exhibit unique process characteristics and quality concerns. Current assessment methodologies rarely account for these technological variations, leading to metrics that may be relevant for one DED variant but inappropriate for others.

Material-specific considerations add another layer of complexity. Different materials respond uniquely to DED processing conditions, yet current quality metrics seldom incorporate material-specific benchmarks. This is particularly problematic for repair applications, where the interface between deposited material and substrate requires specialized quality assessment approaches that are currently underdeveloped.

Regulatory uncertainty compounds these technical challenges. Without standardized reporting metrics, certification bodies struggle to establish clear guidelines for DED-manufactured components, especially in safety-critical industries like aerospace and medical devices. This regulatory ambiguity creates market hesitation and limits broader industrial adoption of DED technologies.

Cross-disciplinary integration represents a final significant challenge. Quality assessment in DED requires expertise spanning materials science, process engineering, metrology, and data analytics. However, current approaches often remain siloed within individual disciplines, lacking the integrated perspective necessary for comprehensive quality evaluation frameworks.

Existing DED Quality Reporting Frameworks

01 Quality metrics for network performance monitoring

Standardized reporting metrics are used to evaluate and monitor network performance quality. These metrics include parameters such as latency, packet loss, throughput, and jitter. By establishing standardized measurements, network operators can consistently assess service quality, identify issues, and implement improvements. These metrics enable objective comparison across different network environments and help maintain service level agreements.- Quality metrics for network performance monitoring: Standardized reporting metrics for network performance quality involve systems that collect, analyze, and report on network performance indicators. These systems monitor various aspects of network quality including latency, packet loss, throughput, and availability. The metrics are standardized to ensure consistent measurement across different network environments, enabling better comparison and benchmarking. These reporting frameworks help identify performance issues, optimize network resources, and ensure service level agreements are met.

- Data quality assessment frameworks: Standardized frameworks for assessing and reporting data quality metrics help organizations evaluate the reliability and integrity of their data assets. These frameworks include metrics for data accuracy, completeness, consistency, timeliness, and validity. By implementing standardized reporting metrics for data quality, organizations can identify data issues, track improvements over time, and make more informed decisions based on high-quality data. These frameworks often include automated tools for continuous monitoring and reporting of data quality metrics.

- Quality metrics for business performance reporting: Standardized reporting metrics for business performance quality provide consistent methods for measuring and reporting on key performance indicators across an organization. These metrics cover financial performance, operational efficiency, customer satisfaction, and other business outcomes. By standardizing these reporting metrics, organizations can better compare performance across different business units, track progress toward strategic goals, and identify areas for improvement. These frameworks often include dashboards and visualization tools to make the metrics more accessible to stakeholders.

- Quality metrics for healthcare reporting: Standardized reporting metrics for healthcare quality involve systems for measuring and reporting on various aspects of healthcare delivery and outcomes. These metrics cover patient safety, clinical effectiveness, patient experience, and operational efficiency. By implementing standardized reporting metrics, healthcare organizations can benchmark their performance against industry standards, identify areas for improvement, and demonstrate compliance with regulatory requirements. These reporting frameworks help drive quality improvement initiatives and support value-based care models.

- Automated quality metric collection and analysis systems: Advanced systems for automated collection, analysis, and reporting of quality metrics leverage technologies such as artificial intelligence and machine learning to process large volumes of data and generate meaningful insights. These systems can automatically identify patterns, anomalies, and trends in quality metrics, enabling proactive quality management. By automating the collection and analysis of standardized reporting metrics, organizations can reduce manual effort, increase the frequency of reporting, and improve the accuracy and consistency of quality measurements across different domains.

02 Data quality assessment frameworks

Frameworks for assessing and reporting data quality use standardized metrics to evaluate accuracy, completeness, consistency, and timeliness of data. These frameworks establish objective criteria for measuring data quality across systems and organizations. By implementing standardized reporting metrics, organizations can identify data quality issues, track improvements over time, and ensure data meets required quality standards for decision-making processes.Expand Specific Solutions03 Quality metrics for business performance evaluation

Standardized reporting metrics are implemented to evaluate business performance quality across various dimensions. These metrics include financial indicators, operational efficiency measures, customer satisfaction scores, and compliance metrics. By standardizing these measurements, organizations can benchmark performance, identify areas for improvement, and make data-driven decisions. These metrics provide a consistent framework for evaluating business quality and driving continuous improvement.Expand Specific Solutions04 Automated quality metric collection and reporting systems

Systems for automating the collection, analysis, and reporting of quality metrics utilize standardized approaches to ensure consistency and reliability. These systems incorporate data collection mechanisms, processing algorithms, and reporting interfaces to streamline quality assessment processes. By automating quality metric reporting, organizations can reduce manual effort, minimize human error, and generate timely insights. These systems often include dashboards and visualization tools to present quality metrics in an accessible format.Expand Specific Solutions05 Quality metrics standardization for regulatory compliance

Standardized reporting metrics are developed to meet regulatory requirements across various industries. These metrics ensure that quality assessments comply with industry standards and government regulations. By implementing standardized quality metrics, organizations can demonstrate compliance, facilitate audits, and maintain necessary certifications. These standardized approaches help organizations navigate complex regulatory environments while maintaining consistent quality reporting practices.Expand Specific Solutions

Leading Organizations in DED Technology Development

The Directed Energy Deposition (DED) build and repair quality standardization landscape is currently in an early growth phase, with the market expected to expand significantly as additive manufacturing technologies mature. The global market size for DED technologies is gaining momentum, driven by aerospace, defense, and automotive applications. From a technical maturity perspective, the field shows varying levels of development across key players. RTX Corp. and NASA lead with advanced research initiatives, while companies like BeAM SAS and Southwest Research Institute focus on specialized DED applications. Academic institutions including Zhejiang University and Nanyang Technological University contribute fundamental research. Industrial players such as Ford Motor Co. and BMW are exploring DED for repair applications, while specialized firms like Etegent Technologies develop quality control systems. The industry is moving toward establishing common metrics but lacks universal standards.

RTX Corp.

Technical Solution: RTX Corporation (formerly Raytheon Technologies) has developed comprehensive standardized reporting metrics for DED (Directed Energy Deposition) build and repair quality through its Pratt & Whitney and Collins Aerospace divisions. Their approach integrates real-time monitoring systems that capture over 20 critical parameters during the DED process, including laser power, material feed rate, thermal gradients, and melt pool characteristics. RTX's framework incorporates machine learning algorithms to analyze this data stream and establish correlations between process parameters and final part quality. Their standardized reporting system features a five-tier quality classification system that evaluates microstructural integrity, mechanical properties, and dimensional accuracy against predetermined benchmarks. The company has implemented this system across multiple manufacturing facilities, enabling consistent quality assessment and process optimization across different equipment configurations and material systems.

Strengths: Comprehensive integration with aerospace quality management systems; extensive validation through aerospace component manufacturing; robust traceability from raw material to finished part. Weaknesses: System complexity requires significant computational resources; primarily optimized for aerospace applications rather than broader industrial use cases.

National Aeronautics & Space Administration

Technical Solution: NASA has developed a sophisticated standardized reporting framework for DED processes as part of its advanced manufacturing initiatives for space applications. Their system, designated AMSQR (Additive Manufacturing Standardized Quality Reporting), incorporates multi-scale characterization techniques ranging from macro-level dimensional verification to nano-scale microstructural analysis. NASA's approach emphasizes traceability throughout the entire manufacturing process, with standardized documentation of feedstock material properties, process parameters, and post-processing treatments. Their reporting metrics include quantitative assessments of microstructural homogeneity using electron backscatter diffraction (EBSD), porosity distribution mapping with resolutions down to 5 microns, and mechanical property verification through standardized test coupons built concurrently with production parts. The AMSQR system has been implemented across multiple NASA centers and contractor facilities, ensuring consistent quality assessment for critical space hardware. The framework includes specialized metrics for evaluating repair quality, with particular emphasis on fatigue performance and fracture resistance at the interface between substrate and deposited material.

Strengths: Exceptional rigor suitable for mission-critical applications; comprehensive traceability from raw material to finished component; extensive validation across multiple material systems and equipment configurations. Weaknesses: Implementation requires significant resources and specialized equipment; reporting complexity exceeds requirements for many commercial applications; lengthy qualification process for new materials or process variations.

Critical Metrics for DED Build and Repair Evaluation

Engineered microstructure for enhanced performance during directed energy deposition repair process

PatentPendingUS20250242410A1

Innovation

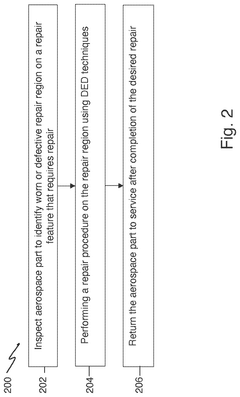

- A directed energy deposition (DED) process is used to control the microstructure of each repair layer by adjusting parameters like powder feed rate, energy intensity, traversal rate, and auxiliary heating/cooling, ensuring each layer has a pre-determined microstructure to meet specific structural and functional needs.

Engineered residual stress state for enhanced performance during directed energy deposition repair process

PatentPendingEP4599978A1

Innovation

- A directed energy deposition (DED) process is used to create layers with pre-determined residual stress states by controlling parameters like powder feed rate, energy intensity, traversal speed, and auxiliary heating/cooling, enabling controlled residual stress management during the repair process.

International Standards and Certification Requirements

The landscape of international standards for Directed Energy Deposition (DED) build and repair quality is rapidly evolving as the technology gains wider industrial adoption. Currently, several key organizations are leading standardization efforts, including ISO/ASTM, AWS, ASME, and SAE International. These bodies have developed preliminary frameworks that address various aspects of DED processes, though comprehensive standards specifically for quality metrics remain under development.

ISO/ASTM 52900 provides fundamental terminology for additive manufacturing processes, including DED, while ISO/ASTM 52901 covers requirements for purchased parts. More specifically, ASTM F3187 establishes standard practices for directed energy deposition of metals, providing a foundation for quality assessment methodologies. The AWS D20.0 committee has been working on standards for metal additive manufacturing, with sections increasingly addressing DED processes.

Certification requirements for DED processes typically involve multiple layers of compliance. Material certification is paramount, requiring documentation of powder or wire feedstock properties according to standards like ASTM F3303. Process qualification demands demonstration of consistent build parameters and environmental controls, while operator certification ensures proper training and competency in DED equipment operation and post-processing techniques.

Quality assurance certification for DED builds generally follows frameworks established in ISO 9001, with additional requirements specific to additive manufacturing. For aerospace applications, AS9100 certification incorporates DED-specific controls, while medical device applications must adhere to ISO 13485 requirements. These certifications mandate rigorous documentation of process parameters, material traceability, and quality control procedures.

Regional variations in standards and certification requirements present challenges for global DED implementation. European standards through CEN/TC 438 sometimes differ from ASTM approaches, while countries like Japan (through JISC) and China (through SAC) are developing nation-specific standards that may introduce additional compliance requirements for international operations.

Emerging certification pathways are being developed specifically for repair applications using DED technology. These include specialized requirements for surface preparation, interface characterization, and post-repair validation testing. Organizations like America Makes and the National Center for Defense Manufacturing and Machining are collaborating with standards bodies to establish repair-specific protocols that address the unique challenges of restoration versus new builds.

ISO/ASTM 52900 provides fundamental terminology for additive manufacturing processes, including DED, while ISO/ASTM 52901 covers requirements for purchased parts. More specifically, ASTM F3187 establishes standard practices for directed energy deposition of metals, providing a foundation for quality assessment methodologies. The AWS D20.0 committee has been working on standards for metal additive manufacturing, with sections increasingly addressing DED processes.

Certification requirements for DED processes typically involve multiple layers of compliance. Material certification is paramount, requiring documentation of powder or wire feedstock properties according to standards like ASTM F3303. Process qualification demands demonstration of consistent build parameters and environmental controls, while operator certification ensures proper training and competency in DED equipment operation and post-processing techniques.

Quality assurance certification for DED builds generally follows frameworks established in ISO 9001, with additional requirements specific to additive manufacturing. For aerospace applications, AS9100 certification incorporates DED-specific controls, while medical device applications must adhere to ISO 13485 requirements. These certifications mandate rigorous documentation of process parameters, material traceability, and quality control procedures.

Regional variations in standards and certification requirements present challenges for global DED implementation. European standards through CEN/TC 438 sometimes differ from ASTM approaches, while countries like Japan (through JISC) and China (through SAC) are developing nation-specific standards that may introduce additional compliance requirements for international operations.

Emerging certification pathways are being developed specifically for repair applications using DED technology. These include specialized requirements for surface preparation, interface characterization, and post-repair validation testing. Organizations like America Makes and the National Center for Defense Manufacturing and Machining are collaborating with standards bodies to establish repair-specific protocols that address the unique challenges of restoration versus new builds.

Economic Impact of Standardized DED Quality Metrics

The standardization of quality metrics for Directed Energy Deposition (DED) processes represents a significant economic opportunity across multiple industrial sectors. Implementation of unified reporting standards for DED build and repair quality would generate substantial cost savings through reduced material waste, decreased inspection redundancy, and minimized rework requirements. Industry analyses suggest that standardized quality metrics could reduce production costs by 15-22% in aerospace applications and 10-18% in medical device manufacturing.

From a supply chain perspective, standardized DED quality metrics would facilitate more efficient vendor qualification processes, reducing supplier onboarding time by an estimated 30-45%. This streamlining effect extends to procurement activities, where standardized quality reporting enables more accurate comparison of supplier capabilities and performance, potentially reducing procurement costs by 8-12% according to recent industry surveys.

The insurance and liability landscape would also experience significant economic benefits. Currently, the absence of standardized quality metrics creates uncertainty in risk assessment for DED-manufactured components, resulting in premium increases of 25-40% compared to traditionally manufactured parts. Implementation of standardized reporting would provide insurers with reliable data for risk quantification, potentially reducing premiums by 15-30% and expanding coverage availability for DED applications.

From a market development perspective, standardized quality metrics would accelerate technology adoption by reducing barriers to entry. Market analysis indicates that standardization could expand the addressable market for DED technologies by 30-45% within five years of implementation, primarily by enabling smaller manufacturers to adopt these advanced manufacturing processes with greater confidence and reduced implementation costs.

The economic impact extends to regulatory compliance costs as well. Current estimates suggest that manufacturers spend 12-18% of their operational budgets on compliance activities related to non-standardized quality verification. A unified reporting framework could reduce these costs by 40-60% while simultaneously improving compliance outcomes and reducing approval timelines for new applications.

Long-term economic benefits include enhanced product lifecycle management, with standardized quality metrics enabling more accurate prediction of component performance and maintenance requirements. This predictability translates to lifecycle cost reductions of 10-25% for critical components in aerospace, defense, and energy sectors, where unexpected failures carry significant economic consequences.

From a supply chain perspective, standardized DED quality metrics would facilitate more efficient vendor qualification processes, reducing supplier onboarding time by an estimated 30-45%. This streamlining effect extends to procurement activities, where standardized quality reporting enables more accurate comparison of supplier capabilities and performance, potentially reducing procurement costs by 8-12% according to recent industry surveys.

The insurance and liability landscape would also experience significant economic benefits. Currently, the absence of standardized quality metrics creates uncertainty in risk assessment for DED-manufactured components, resulting in premium increases of 25-40% compared to traditionally manufactured parts. Implementation of standardized reporting would provide insurers with reliable data for risk quantification, potentially reducing premiums by 15-30% and expanding coverage availability for DED applications.

From a market development perspective, standardized quality metrics would accelerate technology adoption by reducing barriers to entry. Market analysis indicates that standardization could expand the addressable market for DED technologies by 30-45% within five years of implementation, primarily by enabling smaller manufacturers to adopt these advanced manufacturing processes with greater confidence and reduced implementation costs.

The economic impact extends to regulatory compliance costs as well. Current estimates suggest that manufacturers spend 12-18% of their operational budgets on compliance activities related to non-standardized quality verification. A unified reporting framework could reduce these costs by 40-60% while simultaneously improving compliance outcomes and reducing approval timelines for new applications.

Long-term economic benefits include enhanced product lifecycle management, with standardized quality metrics enabling more accurate prediction of component performance and maintenance requirements. This predictability translates to lifecycle cost reductions of 10-25% for critical components in aerospace, defense, and energy sectors, where unexpected failures carry significant economic consequences.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!