DED For Rapid Tooling: From Design To Production Workflow

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Rapid Tooling Evolution and Objectives

Directed Energy Deposition (DED) technology has evolved significantly over the past three decades, transforming from experimental additive manufacturing processes to sophisticated rapid tooling solutions. The journey began in the 1990s with early laser cladding systems that demonstrated the potential for direct metal deposition but lacked precision and material versatility. By the early 2000s, advancements in laser technology, powder delivery systems, and motion control enabled more reliable DED processes, though primarily for repair applications rather than full tool production.

The mid-2000s marked a pivotal shift as DED systems began incorporating multi-axis capabilities and improved process monitoring, allowing for more complex geometries and better quality control. This period saw the first successful implementations of DED for tooling applications, particularly in aerospace and defense sectors where high-value, low-volume tools justified the investment in emerging technology.

From 2010 to 2015, significant improvements in computational modeling and process simulation accelerated DED development, enabling better prediction of material properties and reducing the empirical nature of parameter development. Concurrently, material science advancements expanded the range of compatible alloys, including tool steels, nickel-based superalloys, and tungsten carbide composites essential for industrial tooling applications.

The current generation of DED systems represents a convergence of these technological threads, featuring hybrid manufacturing capabilities that combine additive and subtractive processes in single machines, sophisticated in-situ monitoring, and closed-loop control systems that adjust process parameters in real-time. These developments have positioned DED as a viable solution for rapid tooling production, particularly for large-format tools and those requiring functionally graded materials or complex cooling channels.

Looking forward, the primary objectives for DED rapid tooling technology center on several key areas. First is the enhancement of process reliability and repeatability to ensure consistent mechanical properties across builds. Second is the development of streamlined design-to-production workflows that integrate CAD/CAM systems, process simulation, and machine control. Third is the expansion of material capabilities to include more wear-resistant alloys and multi-material structures.

Additional objectives include reducing the total production time from design to finished tool, minimizing post-processing requirements through near-net-shape capabilities, and developing standardized qualification methodologies that facilitate broader industrial adoption. The ultimate goal is to establish DED as a mainstream rapid tooling solution that offers significant advantages in lead time reduction, design flexibility, and performance optimization compared to conventional tooling production methods.

The mid-2000s marked a pivotal shift as DED systems began incorporating multi-axis capabilities and improved process monitoring, allowing for more complex geometries and better quality control. This period saw the first successful implementations of DED for tooling applications, particularly in aerospace and defense sectors where high-value, low-volume tools justified the investment in emerging technology.

From 2010 to 2015, significant improvements in computational modeling and process simulation accelerated DED development, enabling better prediction of material properties and reducing the empirical nature of parameter development. Concurrently, material science advancements expanded the range of compatible alloys, including tool steels, nickel-based superalloys, and tungsten carbide composites essential for industrial tooling applications.

The current generation of DED systems represents a convergence of these technological threads, featuring hybrid manufacturing capabilities that combine additive and subtractive processes in single machines, sophisticated in-situ monitoring, and closed-loop control systems that adjust process parameters in real-time. These developments have positioned DED as a viable solution for rapid tooling production, particularly for large-format tools and those requiring functionally graded materials or complex cooling channels.

Looking forward, the primary objectives for DED rapid tooling technology center on several key areas. First is the enhancement of process reliability and repeatability to ensure consistent mechanical properties across builds. Second is the development of streamlined design-to-production workflows that integrate CAD/CAM systems, process simulation, and machine control. Third is the expansion of material capabilities to include more wear-resistant alloys and multi-material structures.

Additional objectives include reducing the total production time from design to finished tool, minimizing post-processing requirements through near-net-shape capabilities, and developing standardized qualification methodologies that facilitate broader industrial adoption. The ultimate goal is to establish DED as a mainstream rapid tooling solution that offers significant advantages in lead time reduction, design flexibility, and performance optimization compared to conventional tooling production methods.

Market Analysis for DED Rapid Tooling Solutions

The global market for Directed Energy Deposition (DED) rapid tooling solutions is experiencing significant growth, driven by increasing demand for faster, more cost-effective manufacturing processes across various industries. The market size for additive manufacturing in tooling applications reached approximately $2.3 billion in 2022 and is projected to grow at a compound annual growth rate of 18.5% through 2028, with DED technologies representing a rapidly expanding segment within this space.

Key industries adopting DED rapid tooling include aerospace, automotive, medical devices, and industrial equipment manufacturing. These sectors value DED's ability to produce complex geometries, reduce lead times, and enable on-demand manufacturing of tooling components. The aerospace industry currently represents the largest market share at 32%, followed by automotive at 27%, and medical devices at 18%.

Regional analysis reveals North America leading the market with 38% share, attributed to strong aerospace and defense sectors, followed by Europe at 31% and Asia-Pacific at 24%. The Asia-Pacific region, particularly China and India, demonstrates the highest growth potential due to expanding manufacturing bases and increasing technological adoption.

Customer demand patterns indicate a shift toward hybrid manufacturing solutions that combine DED with traditional machining processes. This trend is particularly evident in the production of large-format tooling where 63% of manufacturers report seeking integrated solutions rather than standalone DED systems.

Market barriers include high initial equipment costs, with industrial-grade DED systems ranging from $250,000 to over $1 million, creating adoption challenges for small and medium enterprises. Additionally, material limitations and certification requirements in regulated industries like aerospace and medical devices present significant market entry barriers.

Competitive analysis reveals three distinct market segments: established industrial equipment manufacturers expanding into DED (35% market share), specialized additive manufacturing companies focusing exclusively on DED solutions (42% market share), and emerging startups developing novel hybrid approaches (23% market share).

Future market projections indicate accelerating adoption rates as system costs decrease and material options expand. The service-based business model for DED tooling is expected to grow at 24% annually, outpacing equipment sales, as manufacturers seek to access the technology without significant capital investment. This shift toward "tooling-as-a-service" represents a transformative trend in the market landscape.

Key industries adopting DED rapid tooling include aerospace, automotive, medical devices, and industrial equipment manufacturing. These sectors value DED's ability to produce complex geometries, reduce lead times, and enable on-demand manufacturing of tooling components. The aerospace industry currently represents the largest market share at 32%, followed by automotive at 27%, and medical devices at 18%.

Regional analysis reveals North America leading the market with 38% share, attributed to strong aerospace and defense sectors, followed by Europe at 31% and Asia-Pacific at 24%. The Asia-Pacific region, particularly China and India, demonstrates the highest growth potential due to expanding manufacturing bases and increasing technological adoption.

Customer demand patterns indicate a shift toward hybrid manufacturing solutions that combine DED with traditional machining processes. This trend is particularly evident in the production of large-format tooling where 63% of manufacturers report seeking integrated solutions rather than standalone DED systems.

Market barriers include high initial equipment costs, with industrial-grade DED systems ranging from $250,000 to over $1 million, creating adoption challenges for small and medium enterprises. Additionally, material limitations and certification requirements in regulated industries like aerospace and medical devices present significant market entry barriers.

Competitive analysis reveals three distinct market segments: established industrial equipment manufacturers expanding into DED (35% market share), specialized additive manufacturing companies focusing exclusively on DED solutions (42% market share), and emerging startups developing novel hybrid approaches (23% market share).

Future market projections indicate accelerating adoption rates as system costs decrease and material options expand. The service-based business model for DED tooling is expected to grow at 24% annually, outpacing equipment sales, as manufacturers seek to access the technology without significant capital investment. This shift toward "tooling-as-a-service" represents a transformative trend in the market landscape.

DED Technology Landscape and Implementation Barriers

The current DED (Directed Energy Deposition) technology landscape is characterized by significant advancements in additive manufacturing capabilities, particularly for rapid tooling applications. DED systems utilize focused thermal energy to fuse materials as they are deposited, enabling the creation of large, complex metal components with relatively high deposition rates compared to other metal additive manufacturing technologies. The market is witnessing a gradual transition from traditional manufacturing methods to hybrid approaches that combine DED with conventional machining.

Despite its promising capabilities, DED technology faces several implementation barriers that hinder widespread industrial adoption. Material limitations represent a primary challenge, as not all metal alloys are compatible with the DED process. The high thermal gradients during deposition can lead to residual stresses, microstructural heterogeneity, and potential cracking in certain materials, particularly those with high thermal conductivity or susceptibility to thermal stress.

Equipment costs present another significant barrier, with industrial-grade DED systems requiring substantial capital investment, often exceeding $500,000 for comprehensive setups. This financial threshold restricts adoption primarily to large enterprises or specialized service providers, limiting accessibility for small and medium-sized manufacturers interested in rapid tooling applications.

Process control and repeatability challenges persist across the DED landscape. The complex thermal interactions during deposition make it difficult to maintain consistent material properties throughout large builds. Parameters such as laser power, travel speed, powder feed rate, and shielding gas flow must be precisely controlled to ensure dimensional accuracy and mechanical performance, requiring sophisticated monitoring systems and operator expertise.

Surface finish and dimensional accuracy remain inferior to traditional machining processes, necessitating post-processing operations that add time and cost to the production workflow. The typical surface roughness of as-deposited DED parts ranges from 15-40 μm Ra, requiring subsequent machining to achieve tooling-grade surface finishes below 3.2 μm Ra.

Qualification and certification frameworks for DED-produced tooling components are still evolving, creating uncertainty for potential adopters. The lack of standardized testing protocols and design guidelines specific to DED-manufactured tooling impedes confidence in the technology's reliability for critical applications.

Software integration presents additional challenges, as current CAD/CAM systems are not fully optimized for DED process planning. The transition from design to production requires specialized toolpath generation that accounts for material deposition characteristics, thermal management, and build orientation considerations unique to DED technology.

Despite its promising capabilities, DED technology faces several implementation barriers that hinder widespread industrial adoption. Material limitations represent a primary challenge, as not all metal alloys are compatible with the DED process. The high thermal gradients during deposition can lead to residual stresses, microstructural heterogeneity, and potential cracking in certain materials, particularly those with high thermal conductivity or susceptibility to thermal stress.

Equipment costs present another significant barrier, with industrial-grade DED systems requiring substantial capital investment, often exceeding $500,000 for comprehensive setups. This financial threshold restricts adoption primarily to large enterprises or specialized service providers, limiting accessibility for small and medium-sized manufacturers interested in rapid tooling applications.

Process control and repeatability challenges persist across the DED landscape. The complex thermal interactions during deposition make it difficult to maintain consistent material properties throughout large builds. Parameters such as laser power, travel speed, powder feed rate, and shielding gas flow must be precisely controlled to ensure dimensional accuracy and mechanical performance, requiring sophisticated monitoring systems and operator expertise.

Surface finish and dimensional accuracy remain inferior to traditional machining processes, necessitating post-processing operations that add time and cost to the production workflow. The typical surface roughness of as-deposited DED parts ranges from 15-40 μm Ra, requiring subsequent machining to achieve tooling-grade surface finishes below 3.2 μm Ra.

Qualification and certification frameworks for DED-produced tooling components are still evolving, creating uncertainty for potential adopters. The lack of standardized testing protocols and design guidelines specific to DED-manufactured tooling impedes confidence in the technology's reliability for critical applications.

Software integration presents additional challenges, as current CAD/CAM systems are not fully optimized for DED process planning. The transition from design to production requires specialized toolpath generation that accounts for material deposition characteristics, thermal management, and build orientation considerations unique to DED technology.

Current DED Rapid Tooling Workflow Solutions

01 DED process fundamentals for rapid tooling

Directed Energy Deposition (DED) is an additive manufacturing technique that uses focused thermal energy to fuse materials as they are deposited. For rapid tooling applications, DED offers advantages in creating complex geometries directly from digital designs. The process involves a heat source (typically laser or electron beam) that melts metal powder or wire as it is precisely deposited layer by layer, allowing for the direct fabrication of tooling components with reduced lead times compared to conventional manufacturing methods.- DED process fundamentals for rapid tooling: Directed Energy Deposition (DED) is an additive manufacturing technique that uses focused thermal energy to fuse materials as they are deposited. For rapid tooling applications, DED offers advantages in creating complex geometries directly from digital designs. The process involves depositing metal powder or wire that is simultaneously melted by a laser, electron beam, or plasma arc, allowing for the direct fabrication of functional tooling components with reduced lead times compared to conventional manufacturing methods.

- Material considerations for DED rapid tooling: Material selection plays a crucial role in DED rapid tooling applications. Various metal alloys including tool steels, stainless steels, titanium alloys, and nickel-based superalloys can be processed using DED technology. The material properties of the final tooling components are influenced by processing parameters and post-processing treatments. Proper material selection ensures that the produced tools meet the mechanical, thermal, and wear resistance requirements for specific applications, while also considering factors such as material compatibility with the DED process and the intended use of the tooling.

- Hybrid manufacturing approaches combining DED with machining: Hybrid manufacturing systems integrate DED technology with conventional machining processes to enhance the capabilities of rapid tooling. These systems allow for alternating between additive and subtractive operations within the same setup, enabling the production of complex tooling with high dimensional accuracy and surface finish. The hybrid approach addresses some limitations of standalone DED processes by incorporating in-process machining to achieve tight tolerances and superior surface quality, particularly important for tooling applications that require precise dimensions and smooth surfaces.

- Process optimization and control strategies for DED tooling: Advanced process control strategies are essential for optimizing DED rapid tooling applications. These include real-time monitoring systems that use sensors to track thermal conditions, melt pool dynamics, and deposition quality. Closed-loop control algorithms adjust process parameters such as laser power, travel speed, and material feed rate to maintain consistent quality throughout the build. Machine learning and artificial intelligence approaches are being implemented to predict and prevent defects, optimize build strategies, and improve the overall reliability and repeatability of DED tooling production.

- Applications and case studies of DED rapid tooling: DED technology has been successfully applied to various rapid tooling applications across industries. These include the production of injection molds with conformal cooling channels, repair and modification of existing tooling, fabrication of large-scale forming dies, and creation of specialized tooling for aerospace and automotive components. Case studies demonstrate significant reductions in lead time and cost compared to conventional tooling methods, while also enabling design improvements such as optimized cooling systems that enhance the performance of the final tooling. The technology is particularly valuable for low-volume production, customized tooling, and repair applications.

02 Material considerations for DED rapid tooling

Material selection plays a crucial role in DED rapid tooling applications. Various metal alloys including tool steels, stainless steels, titanium alloys, and nickel-based superalloys can be processed using DED technology. The material properties such as thermal conductivity, wear resistance, and mechanical strength must be optimized for specific tooling applications. Multi-material deposition capabilities allow for functionally graded tools with tailored properties in different regions, enhancing performance and durability of the manufactured tools.Expand Specific Solutions03 Hybrid manufacturing approaches combining DED with machining

Hybrid manufacturing systems integrate DED technology with conventional machining processes to overcome limitations of standalone additive manufacturing. These systems allow for in-process machining operations between deposition layers or as finishing operations, achieving higher dimensional accuracy and surface quality. The combination enables repair and remanufacturing of existing tools, adding features to pre-existing components, and creating complex internal features that would be difficult to machine conventionally. This approach optimizes the benefits of both additive and subtractive manufacturing techniques.Expand Specific Solutions04 Process control and monitoring systems for DED tooling

Advanced process control and monitoring systems are essential for ensuring quality and repeatability in DED rapid tooling. These systems incorporate real-time sensors to monitor critical parameters such as melt pool temperature, deposition rate, and dimensional accuracy. Machine learning algorithms analyze sensor data to detect anomalies and make process adjustments automatically. Closed-loop control systems maintain consistent build quality by dynamically adjusting laser power, feed rate, and other parameters based on feedback from the monitoring systems, resulting in improved tool quality and reduced defects.Expand Specific Solutions05 Applications and case studies of DED rapid tooling

DED technology has been successfully applied in various rapid tooling applications across industries. Case studies demonstrate its effectiveness in producing injection molds with conformal cooling channels that improve cycle times and part quality. The aerospace industry utilizes DED for creating complex tooling with lightweight structures and integrated functionality. Repair and refurbishment of high-value tooling components extend service life and reduce replacement costs. The automotive sector benefits from rapid prototyping of stamping dies and forming tools with reduced lead times compared to conventional manufacturing methods.Expand Specific Solutions

Leading Manufacturers and Research Institutions in DED

The Direct Energy Deposition (DED) for Rapid Tooling market is currently in a growth phase, with increasing adoption across manufacturing sectors. The global market size is expanding rapidly, driven by demand for faster production cycles and customized tooling solutions. Technologically, the field shows varying maturity levels among key players. Companies like GE Avio and RTX Corp. demonstrate advanced capabilities in aerospace applications, while Stratasys and HP Development lead in commercial implementations. Ford Motor Co. and Boeing are integrating DED into automotive and aerospace production workflows respectively. Academic institutions including South China University of Technology and Huazhong University are advancing fundamental research. The industry is witnessing convergence between traditional manufacturing expertise (DMG MORI) and digital innovation (IBM), creating a competitive landscape where established players and specialized entrants like Divergent Technologies are driving workflow optimization from design to production.

Norsk Titanium AS

Technical Solution: Norsk Titanium has developed a specialized Rapid Plasma Deposition (RPD) technology, a variant of DED specifically optimized for rapid tooling applications. Their proprietary process utilizes a plasma arc to melt titanium wire feedstock in an inert gas environment, enabling deposition rates up to 10kg/hour while maintaining precise dimensional control. The company's end-to-end workflow begins with their MERKE IV machine platform, which incorporates advanced path planning algorithms that optimize deposition strategies based on part geometry and thermal considerations. Their system features multi-axis deposition capabilities with real-time monitoring through thermal imaging and machine learning algorithms that predict and compensate for distortion. Norsk's approach includes a digital twin concept where each physical tool has a corresponding virtual model that tracks the entire manufacturing history and material properties. Their process is particularly notable for producing near-net-shape components with mechanical properties exceeding cast titanium, achieving 99.5% density without secondary consolidation processes.

Strengths: Extremely high deposition rates compared to powder-based systems; superior material properties particularly for titanium components; reduced material waste compared to traditional manufacturing. Weaknesses: Currently limited primarily to titanium alloys; higher energy consumption than some competing technologies; requires specialized facilities due to plasma arc requirements.

HP Development Co. LP

Technical Solution: HP has pioneered an innovative approach to DED for rapid tooling through their Metal Jet technology, which they've adapted specifically for tooling applications. Their workflow begins with HP's proprietary design software that incorporates topology optimization and generative design algorithms to create lightweight yet structurally sound tool designs. The system utilizes a multi-jet fusion process that deposits binding agents onto metal powder beds, followed by sintering to create fully dense metal parts. HP's solution includes automated powder handling systems and integrated quality control measures using machine vision and AI-based defect detection. Their process enables the production of complex internal cooling channels and conformal cooling designs that significantly improve tool performance and longevity. HP has also developed specialized post-processing techniques including surface finishing and heat treatment protocols specifically optimized for tooling applications, ensuring dimensional stability and surface quality suitable for immediate production use.

Strengths: High precision and surface quality suitable for direct tooling applications; ability to create complex internal features like conformal cooling channels; scalable production capacity for various tool sizes. Weaknesses: Limited to specific metal alloys compared to other DED technologies; higher material costs; requires significant post-processing for certain applications.

Critical Patents and Innovations in DED Technology

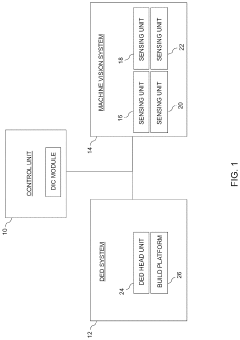

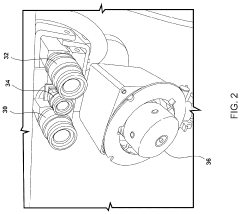

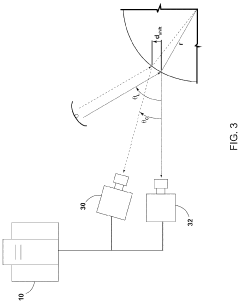

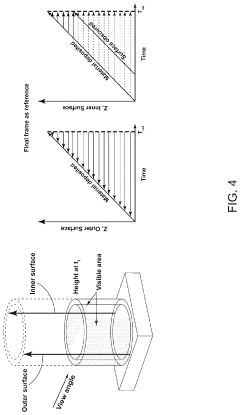

In-situ digital image correlation and thermal monitoring in directed energy deposition

PatentActiveUS11890808B2

Innovation

- A method and system for digital image correlation and thermal monitoring using global off-axis 3D mapping with natural surface roughness, infrared thermography, and a machine vision system comprising stereo imaging cameras and an infrared camera, allowing for strain and temperature data acquisition without a speckle pattern and enabling synthetic reference frames for inner surface features.

Directed energy deposition to facilitate high speed applications

PatentActiveUS10669653B2

Innovation

- The method involves impulsively heating a portion of a fluid to create a lower density region within a higher density region, synchronized with detonating a reactant in a pulsed propulsion unit, using techniques like laser filamentation or electrical discharges to form a low-density tube through which objects can travel with reduced drag and acoustic signature.

Material Compatibility and Performance Considerations

Material compatibility represents a critical factor in the successful implementation of Directed Energy Deposition (DED) for rapid tooling applications. The selection of appropriate materials significantly impacts the performance, durability, and functionality of the produced tools. When considering DED processes, material compatibility must be evaluated across multiple dimensions including the substrate material, feedstock powder or wire, and the intended application environment.

Primary considerations for material selection include thermal properties, as DED involves localized melting and rapid solidification. Materials with high thermal conductivity can help manage heat distribution, reducing residual stresses and preventing distortion in the final tool. Conversely, materials with significant thermal expansion coefficients may present challenges during processing, potentially leading to cracking or delamination between layers.

Mechanical performance requirements further constrain material selection. Tools produced via DED must withstand specific operational conditions, including cyclic loading, wear resistance, and in some cases, elevated temperatures. The microstructural characteristics resulting from the DED process—such as grain size, orientation, and phase distribution—directly influence these mechanical properties. For instance, tools intended for injection molding applications require materials with excellent wear resistance and thermal fatigue properties.

Chemical compatibility between the substrate and deposited material demands careful consideration. Metallurgical bonding at the interface is essential for structural integrity, necessitating compatible chemical compositions. In cases where dissimilar materials are used, intermediate layers or functionally graded materials may be required to mitigate issues related to coefficient of thermal expansion mismatches or the formation of brittle intermetallic compounds.

Post-processing treatments significantly impact material performance in DED-produced tools. Heat treatments can relieve residual stresses, homogenize microstructures, and enhance mechanical properties. Surface finishing operations may be necessary to achieve required dimensional tolerances and surface quality, particularly for tooling applications where surface finish directly affects part quality.

Environmental factors during service life must also be evaluated when selecting materials. Corrosion resistance, oxidation behavior at elevated temperatures, and chemical compatibility with processed materials (such as polymer melts in injection molding tools) all influence long-term performance. The ability to maintain dimensional stability and mechanical properties throughout the tool's service life directly impacts production efficiency and part quality.

Cost considerations ultimately balance technical requirements with economic feasibility. While high-performance superalloys or specialized metal matrix composites may offer superior properties, their cost may be prohibitive for certain applications. Material selection therefore represents an optimization process balancing performance requirements, processing constraints, and economic considerations within the specific context of the intended tooling application.

Primary considerations for material selection include thermal properties, as DED involves localized melting and rapid solidification. Materials with high thermal conductivity can help manage heat distribution, reducing residual stresses and preventing distortion in the final tool. Conversely, materials with significant thermal expansion coefficients may present challenges during processing, potentially leading to cracking or delamination between layers.

Mechanical performance requirements further constrain material selection. Tools produced via DED must withstand specific operational conditions, including cyclic loading, wear resistance, and in some cases, elevated temperatures. The microstructural characteristics resulting from the DED process—such as grain size, orientation, and phase distribution—directly influence these mechanical properties. For instance, tools intended for injection molding applications require materials with excellent wear resistance and thermal fatigue properties.

Chemical compatibility between the substrate and deposited material demands careful consideration. Metallurgical bonding at the interface is essential for structural integrity, necessitating compatible chemical compositions. In cases where dissimilar materials are used, intermediate layers or functionally graded materials may be required to mitigate issues related to coefficient of thermal expansion mismatches or the formation of brittle intermetallic compounds.

Post-processing treatments significantly impact material performance in DED-produced tools. Heat treatments can relieve residual stresses, homogenize microstructures, and enhance mechanical properties. Surface finishing operations may be necessary to achieve required dimensional tolerances and surface quality, particularly for tooling applications where surface finish directly affects part quality.

Environmental factors during service life must also be evaluated when selecting materials. Corrosion resistance, oxidation behavior at elevated temperatures, and chemical compatibility with processed materials (such as polymer melts in injection molding tools) all influence long-term performance. The ability to maintain dimensional stability and mechanical properties throughout the tool's service life directly impacts production efficiency and part quality.

Cost considerations ultimately balance technical requirements with economic feasibility. While high-performance superalloys or specialized metal matrix composites may offer superior properties, their cost may be prohibitive for certain applications. Material selection therefore represents an optimization process balancing performance requirements, processing constraints, and economic considerations within the specific context of the intended tooling application.

Cost-Benefit Analysis of DED vs Traditional Tooling Methods

When comparing Directed Energy Deposition (DED) with traditional tooling methods, a comprehensive cost-benefit analysis reveals significant economic advantages for manufacturers. Initial investment in DED technology typically ranges from $500,000 to $2 million, depending on system capabilities and specifications. While this represents a substantial upfront cost compared to some conventional tooling methods, the return on investment timeline is considerably shorter due to operational efficiencies.

Material costs for DED processes average 15-30% higher than traditional methods on a per-unit basis. However, this premium is offset by the dramatic reduction in material waste—DED achieves material utilization rates of 90-98% compared to 20-40% for conventional subtractive manufacturing processes. This efficiency translates to significant cost savings for high-value materials such as titanium alloys, Inconel, and specialized steels commonly used in tooling applications.

Labor costs demonstrate another compelling advantage for DED technology. Traditional tooling methods often require multiple specialized operators across different manufacturing stages, whereas DED systems can be managed by fewer technicians with appropriate training. Studies indicate labor cost reductions of 30-50% for complex tooling projects when utilizing DED workflows.

Time-to-market considerations heavily favor DED technology. Traditional tooling development cycles typically range from 8-16 weeks, while DED-based rapid tooling can deliver functional tools in 1-3 weeks. This acceleration creates substantial indirect economic benefits through faster product launches and more responsive manufacturing capabilities.

Maintenance economics also favor DED systems in the long term. While annual maintenance costs for DED equipment (approximately 8-12% of initial investment) may exceed some traditional equipment, the versatility of DED systems allows for broader utilization across multiple projects, effectively distributing these costs across more revenue-generating activities.

Energy consumption analysis reveals that DED processes consume 20-40% more energy per operating hour than conventional machining. However, the significantly reduced production time often results in lower total energy consumption per finished tool. Additionally, the localized nature of material deposition minimizes the need for extensive heat treatment, further reducing overall energy requirements.

When factoring all direct and indirect costs over a five-year operational period, DED technology demonstrates a 15-25% lower total cost of ownership compared to traditional tooling methods for manufacturers producing medium to high complexity tooling components, particularly when production flexibility and rapid iteration capabilities are valued.

Material costs for DED processes average 15-30% higher than traditional methods on a per-unit basis. However, this premium is offset by the dramatic reduction in material waste—DED achieves material utilization rates of 90-98% compared to 20-40% for conventional subtractive manufacturing processes. This efficiency translates to significant cost savings for high-value materials such as titanium alloys, Inconel, and specialized steels commonly used in tooling applications.

Labor costs demonstrate another compelling advantage for DED technology. Traditional tooling methods often require multiple specialized operators across different manufacturing stages, whereas DED systems can be managed by fewer technicians with appropriate training. Studies indicate labor cost reductions of 30-50% for complex tooling projects when utilizing DED workflows.

Time-to-market considerations heavily favor DED technology. Traditional tooling development cycles typically range from 8-16 weeks, while DED-based rapid tooling can deliver functional tools in 1-3 weeks. This acceleration creates substantial indirect economic benefits through faster product launches and more responsive manufacturing capabilities.

Maintenance economics also favor DED systems in the long term. While annual maintenance costs for DED equipment (approximately 8-12% of initial investment) may exceed some traditional equipment, the versatility of DED systems allows for broader utilization across multiple projects, effectively distributing these costs across more revenue-generating activities.

Energy consumption analysis reveals that DED processes consume 20-40% more energy per operating hour than conventional machining. However, the significantly reduced production time often results in lower total energy consumption per finished tool. Additionally, the localized nature of material deposition minimizes the need for extensive heat treatment, further reducing overall energy requirements.

When factoring all direct and indirect costs over a five-year operational period, DED technology demonstrates a 15-25% lower total cost of ownership compared to traditional tooling methods for manufacturers producing medium to high complexity tooling components, particularly when production flexibility and rapid iteration capabilities are valued.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!