DED Design Guidelines To Minimize Distortion During Repair

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Repair Technology Background and Objectives

Directed Energy Deposition (DED) has emerged as a transformative additive manufacturing technology over the past two decades, evolving from experimental applications to a commercially viable repair solution for high-value components. This technology utilizes focused thermal energy to fuse materials as they are deposited, making it particularly suitable for repair operations in aerospace, defense, and heavy machinery industries where component replacement costs are prohibitive.

The evolution of DED technology has been marked by significant improvements in process control, material compatibility, and equipment sophistication. Initially developed as a research concept in the 1990s, DED systems have progressed from rudimentary setups with limited material options to advanced multi-axis systems capable of processing a wide range of metals, including titanium alloys, nickel-based superalloys, and tool steels.

Current technological trends in DED repair focus on enhancing precision, reducing heat input, and minimizing distortion—a critical challenge that directly impacts the dimensional accuracy and mechanical integrity of repaired components. The industry has witnessed a shift toward hybrid manufacturing approaches that combine DED with subtractive processes, allowing for in-situ machining and improved surface finish.

The primary objective of developing DED design guidelines for distortion minimization is to establish standardized protocols that ensure consistent repair quality across various applications. These guidelines aim to address the complex thermomechanical interactions that occur during the deposition process, which can lead to residual stresses and subsequent distortion in the repaired components.

Specifically, the technical goals include: quantifying the relationship between process parameters and resultant distortion; developing predictive models for distortion behavior; establishing material-specific deposition strategies; and creating design rules for support structures and build orientations that minimize distortion effects.

The significance of this research extends beyond immediate repair applications. As industries increasingly adopt circular economy principles, effective repair technologies become essential for extending component lifecycles and reducing material waste. DED repair represents a sustainable alternative to traditional manufacturing approaches, potentially reducing energy consumption by up to 70% compared to new part production.

Furthermore, the development of robust distortion minimization guidelines addresses a critical barrier to wider DED adoption. Current implementation challenges often stem from inconsistent repair quality and dimensional accuracy issues, which limit confidence in the technology's reliability for critical applications. By establishing science-based design guidelines, this research aims to transform DED repair from a specialized niche technology to a mainstream manufacturing solution with predictable outcomes and consistent quality.

The evolution of DED technology has been marked by significant improvements in process control, material compatibility, and equipment sophistication. Initially developed as a research concept in the 1990s, DED systems have progressed from rudimentary setups with limited material options to advanced multi-axis systems capable of processing a wide range of metals, including titanium alloys, nickel-based superalloys, and tool steels.

Current technological trends in DED repair focus on enhancing precision, reducing heat input, and minimizing distortion—a critical challenge that directly impacts the dimensional accuracy and mechanical integrity of repaired components. The industry has witnessed a shift toward hybrid manufacturing approaches that combine DED with subtractive processes, allowing for in-situ machining and improved surface finish.

The primary objective of developing DED design guidelines for distortion minimization is to establish standardized protocols that ensure consistent repair quality across various applications. These guidelines aim to address the complex thermomechanical interactions that occur during the deposition process, which can lead to residual stresses and subsequent distortion in the repaired components.

Specifically, the technical goals include: quantifying the relationship between process parameters and resultant distortion; developing predictive models for distortion behavior; establishing material-specific deposition strategies; and creating design rules for support structures and build orientations that minimize distortion effects.

The significance of this research extends beyond immediate repair applications. As industries increasingly adopt circular economy principles, effective repair technologies become essential for extending component lifecycles and reducing material waste. DED repair represents a sustainable alternative to traditional manufacturing approaches, potentially reducing energy consumption by up to 70% compared to new part production.

Furthermore, the development of robust distortion minimization guidelines addresses a critical barrier to wider DED adoption. Current implementation challenges often stem from inconsistent repair quality and dimensional accuracy issues, which limit confidence in the technology's reliability for critical applications. By establishing science-based design guidelines, this research aims to transform DED repair from a specialized niche technology to a mainstream manufacturing solution with predictable outcomes and consistent quality.

Market Demand Analysis for DED Repair Solutions

The global market for Directed Energy Deposition (DED) repair solutions is experiencing significant growth, driven by increasing demand across aerospace, defense, oil and gas, power generation, and heavy machinery sectors. These industries face critical challenges with high-value component maintenance, where traditional repair methods often prove inadequate or cost-prohibitive. The market value for metal additive manufacturing repair technologies, including DED, reached approximately $950 million in 2022 and is projected to grow at a compound annual growth rate of 14.8% through 2028.

Aerospace and defense sectors represent the largest market segments, accounting for nearly 40% of the total DED repair market. These industries require solutions for repairing high-value components such as turbine blades, combustion chambers, and structural elements where component replacement costs can exceed hundreds of thousands of dollars per part. The ability to repair rather than replace these components presents potential cost savings of 50-70%.

Industrial surveys indicate that minimizing distortion during DED repair processes ranks among the top three technical requirements from end-users, with 78% of respondents citing it as "critical" or "very important" to their operations. This demand stems from the fact that thermal distortion can render repaired components unusable, resulting in material waste, increased production time, and significant financial losses.

The market shows strong regional variations, with North America leading adoption (38% market share), followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 17.2% annually, driven by rapid industrialization and increasing aerospace manufacturing activities in China and India.

Customer pain points specifically related to distortion in DED repairs include unpredictable dimensional accuracy (cited by 82% of users), post-repair machining requirements (76%), and repair process repeatability issues (71%). These challenges directly impact production efficiency and repair economics, with distortion-related rework adding an estimated 15-25% to total repair costs.

Market research indicates a willingness-to-pay premium of 20-30% for DED systems and design guidelines that can demonstrably reduce distortion by at least 50% compared to current standards. This represents a significant market opportunity for technology providers who can develop and commercialize effective distortion minimization solutions.

The market is further driven by sustainability considerations, as repair-versus-replace approaches can reduce carbon footprint by 60-85% for complex metal components. This aligns with increasingly stringent environmental regulations and corporate sustainability goals across industrial sectors.

Aerospace and defense sectors represent the largest market segments, accounting for nearly 40% of the total DED repair market. These industries require solutions for repairing high-value components such as turbine blades, combustion chambers, and structural elements where component replacement costs can exceed hundreds of thousands of dollars per part. The ability to repair rather than replace these components presents potential cost savings of 50-70%.

Industrial surveys indicate that minimizing distortion during DED repair processes ranks among the top three technical requirements from end-users, with 78% of respondents citing it as "critical" or "very important" to their operations. This demand stems from the fact that thermal distortion can render repaired components unusable, resulting in material waste, increased production time, and significant financial losses.

The market shows strong regional variations, with North America leading adoption (38% market share), followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 17.2% annually, driven by rapid industrialization and increasing aerospace manufacturing activities in China and India.

Customer pain points specifically related to distortion in DED repairs include unpredictable dimensional accuracy (cited by 82% of users), post-repair machining requirements (76%), and repair process repeatability issues (71%). These challenges directly impact production efficiency and repair economics, with distortion-related rework adding an estimated 15-25% to total repair costs.

Market research indicates a willingness-to-pay premium of 20-30% for DED systems and design guidelines that can demonstrably reduce distortion by at least 50% compared to current standards. This represents a significant market opportunity for technology providers who can develop and commercialize effective distortion minimization solutions.

The market is further driven by sustainability considerations, as repair-versus-replace approaches can reduce carbon footprint by 60-85% for complex metal components. This aligns with increasingly stringent environmental regulations and corporate sustainability goals across industrial sectors.

Current Challenges in DED Distortion Control

Despite significant advancements in Directed Energy Deposition (DED) technology, controlling distortion during repair operations remains one of the most challenging aspects of the process. The inherent thermal cycles during DED repair create complex residual stress fields that lead to dimensional inaccuracies and potential structural integrity issues. Current DED processes struggle with the prediction and mitigation of these thermal distortions, particularly when working with high-value components where dimensional precision is critical.

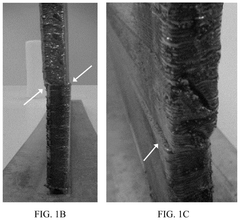

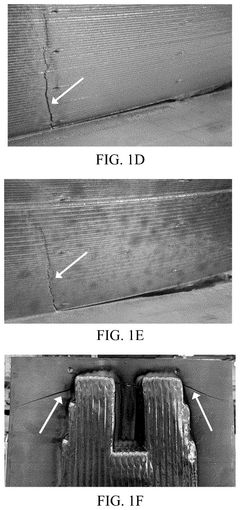

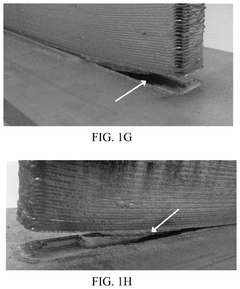

The non-uniform heating and cooling cycles characteristic of DED processes create steep thermal gradients that induce localized expansion and contraction. This thermal cycling results in plastic deformation and residual stresses that manifest as warping, bending, or twisting of the component. For repair applications, these challenges are compounded by the existing stress state of the component and the interface between the original material and the deposited material.

Material-specific challenges further complicate distortion control. Different materials exhibit varying thermal expansion coefficients, yield strengths, and phase transformation behaviors, all of which influence the magnitude and pattern of distortion. High-performance alloys commonly used in aerospace and energy sectors, such as nickel-based superalloys and titanium alloys, are particularly susceptible to distortion due to their thermal properties and microstructural sensitivity.

Geometry-dependent factors also present significant challenges. Complex geometries with thin walls, sharp corners, or varying cross-sections experience non-uniform stress distributions that are difficult to predict and control. The build strategy, including deposition path planning and layer sequencing, significantly impacts distortion patterns but lacks standardized optimization approaches for repair scenarios.

Current simulation tools for predicting DED-induced distortion have limitations in accuracy and computational efficiency. While finite element analysis (FEA) models can provide insights into distortion patterns, they often require simplifications that reduce their predictive capability for complex repair scenarios. Real-time monitoring and control systems that could potentially adjust process parameters to minimize distortion are still in early development stages and lack robust implementation in industrial settings.

Post-processing techniques to correct distortion, such as heat treatment or mechanical straightening, add time and cost to the repair process and may not be suitable for all materials or geometries. Additionally, these corrective measures can introduce additional residual stresses or microstructural changes that affect the mechanical properties of the repaired component.

The lack of standardized design guidelines specifically tailored for distortion control in DED repair operations represents a significant gap in current practice. While general principles exist for additive manufacturing processes, the unique challenges associated with repair scenarios—including substrate condition, interface properties, and pre-existing stress states—require specialized approaches that are not yet well-established in industry standards or best practices.

The non-uniform heating and cooling cycles characteristic of DED processes create steep thermal gradients that induce localized expansion and contraction. This thermal cycling results in plastic deformation and residual stresses that manifest as warping, bending, or twisting of the component. For repair applications, these challenges are compounded by the existing stress state of the component and the interface between the original material and the deposited material.

Material-specific challenges further complicate distortion control. Different materials exhibit varying thermal expansion coefficients, yield strengths, and phase transformation behaviors, all of which influence the magnitude and pattern of distortion. High-performance alloys commonly used in aerospace and energy sectors, such as nickel-based superalloys and titanium alloys, are particularly susceptible to distortion due to their thermal properties and microstructural sensitivity.

Geometry-dependent factors also present significant challenges. Complex geometries with thin walls, sharp corners, or varying cross-sections experience non-uniform stress distributions that are difficult to predict and control. The build strategy, including deposition path planning and layer sequencing, significantly impacts distortion patterns but lacks standardized optimization approaches for repair scenarios.

Current simulation tools for predicting DED-induced distortion have limitations in accuracy and computational efficiency. While finite element analysis (FEA) models can provide insights into distortion patterns, they often require simplifications that reduce their predictive capability for complex repair scenarios. Real-time monitoring and control systems that could potentially adjust process parameters to minimize distortion are still in early development stages and lack robust implementation in industrial settings.

Post-processing techniques to correct distortion, such as heat treatment or mechanical straightening, add time and cost to the repair process and may not be suitable for all materials or geometries. Additionally, these corrective measures can introduce additional residual stresses or microstructural changes that affect the mechanical properties of the repaired component.

The lack of standardized design guidelines specifically tailored for distortion control in DED repair operations represents a significant gap in current practice. While general principles exist for additive manufacturing processes, the unique challenges associated with repair scenarios—including substrate condition, interface properties, and pre-existing stress states—require specialized approaches that are not yet well-established in industry standards or best practices.

Current Distortion Minimization Techniques

01 Thermal management techniques for DED distortion control

Various thermal management approaches can be implemented to control distortion in Directed Energy Deposition processes. These include preheating the substrate, controlled cooling rates, and thermal monitoring systems that adjust energy input in real-time. By managing the thermal gradients and cooling rates during deposition, residual stresses that lead to distortion can be significantly reduced, resulting in more dimensionally accurate parts.- Distortion prediction and compensation in DED processes: Various methods and systems have been developed to predict and compensate for distortion in Directed Energy Deposition processes. These include computational models that simulate thermal behavior, stress development, and resulting deformations during the build process. By accurately predicting distortion patterns, manufacturers can implement pre-emptive adjustments to the build parameters or part geometry to counteract expected distortions, resulting in more dimensionally accurate final components.

- Thermal management techniques to reduce DED distortion: Thermal management is critical in controlling distortion during Directed Energy Deposition. Techniques include controlled preheating of substrates, active cooling systems, optimized heat input parameters, and strategic deposition patterns that distribute thermal energy more evenly. By managing the thermal gradients and cooling rates during the build process, residual stresses can be minimized, which directly reduces warping and distortion in the final parts.

- Process parameter optimization for distortion control: Optimizing process parameters plays a crucial role in minimizing distortion in DED processes. Parameters such as laser power, travel speed, powder feed rate, layer thickness, and deposition path strategies significantly impact thermal gradients and resulting distortion. Advanced algorithms and machine learning approaches have been developed to identify optimal parameter combinations for specific geometries and materials, enabling manufacturers to achieve parts with minimal distortion without extensive trial and error.

- Post-processing methods to correct DED distortion: Various post-processing techniques have been developed to address distortion in DED-manufactured parts. These include heat treatment protocols specifically designed to relieve residual stresses, machining operations to restore dimensional accuracy, and hot isostatic pressing to eliminate internal defects that contribute to distortion. Some approaches involve hybrid manufacturing systems that integrate additive and subtractive processes, allowing for in-situ correction of distortion during the build process.

- Material selection and modification for distortion reduction: The choice and modification of materials can significantly impact distortion in DED processes. Research has focused on developing alloy compositions with reduced thermal expansion coefficients, improved thermal conductivity, or modified phase transformation behaviors that generate less residual stress during processing. Additionally, the use of composite materials, functionally graded materials, or reinforced metal matrices can help distribute thermal stresses more evenly, resulting in reduced overall distortion in the final components.

02 Predictive modeling and simulation for distortion prevention

Advanced computational models and simulation techniques can predict and mitigate distortion in DED processes. These models account for thermal behavior, material properties, and process parameters to forecast potential distortion patterns. By simulating the deposition process before actual manufacturing, parameters can be optimized to minimize distortion, and compensatory strategies can be developed to counteract predicted deformations.Expand Specific Solutions03 Path planning and deposition strategies to minimize distortion

Strategic path planning and deposition sequences can significantly reduce distortion in DED processes. Techniques such as island scanning, alternating deposition directions, and optimized toolpath generation help distribute thermal stresses more evenly throughout the part. By carefully controlling the order and pattern of material deposition, thermal gradients can be managed more effectively, resulting in reduced warping and distortion.Expand Specific Solutions04 In-process monitoring and adaptive control systems

Real-time monitoring and adaptive control systems can detect and correct distortion during the DED process. These systems utilize sensors to measure thermal distributions, dimensional changes, and other process variables, allowing for immediate adjustments to process parameters. By implementing closed-loop control mechanisms, deviations from desired geometries can be detected early and corrected through automated parameter adjustments, significantly reducing overall distortion.Expand Specific Solutions05 Post-processing techniques for distortion correction

Various post-processing methods can be employed to correct distortion in DED-manufactured parts. These include heat treatment protocols, mechanical stress relief, and hybrid manufacturing approaches that combine additive and subtractive processes. By applying controlled thermal or mechanical treatments after deposition, residual stresses can be relieved and dimensional accuracy can be restored to parts that experienced distortion during the DED process.Expand Specific Solutions

Key Industry Players in DED Technology

The Directed Energy Deposition (DED) design guidelines for minimizing distortion during repair are evolving in a rapidly maturing market, with key players demonstrating varying levels of technological advancement. RTX Corp. and GE Avio lead the aerospace sector implementation, while Norsk Titanium has pioneered specialized titanium deposition techniques. Academic institutions like Nanjing University of Aeronautics & Astronautics and Chongqing University contribute significant research advancements. The market is transitioning from early adoption to mainstream implementation, with estimated growth reaching $1.5 billion by 2025. Companies like LPKF Laser & Electronics and Michelin Recherche et Technique are developing cross-industry applications, indicating the technology's expanding versatility beyond aerospace into automotive and industrial repair sectors.

Norsk Titanium AS

Technical Solution: Norsk Titanium has pioneered Rapid Plasma Deposition™ (RPD™) technology, a specialized form of DED optimized for titanium components with minimal distortion during manufacturing and repair. Their distortion minimization approach centers on precise thermal management through their patented plasma arc control system that maintains consistent energy input. The company has developed specific design guidelines for repair applications that include substrate fixturing techniques using adaptive clamping systems that adjust pressure based on thermal expansion during deposition. Their process incorporates interlayer cooling periods calculated based on thermal modeling of specific geometries, allowing for controlled heat dissipation. Norsk's guidelines specify optimal build orientations and support structures based on extensive empirical testing across various titanium alloy grades. Their approach includes proprietary algorithms for toolpath generation that account for anticipated shrinkage and distortion, with compensation factors built into the deposition strategy. The company reports achieving dimensional accuracy within ±0.5mm for repaired components up to 2 meters in length.

Strengths: Exceptional expertise with titanium alloys makes them industry leaders for aerospace-grade titanium component repair with minimal distortion. Their proprietary plasma technology offers superior control over energy input compared to many other DED methods. Weaknesses: Their solutions are highly specialized for titanium alloys, with limited applicability to other material systems. The technology requires significant capital investment and specialized training.

GE Avio Srl

Technical Solution: GE Avio has developed specialized DED design guidelines focused on aero-engine component repair with minimal distortion. Their approach integrates computational fluid dynamics with thermal-mechanical modeling to predict and mitigate distortion during the repair process. The company employs a proprietary "sectional repair" methodology where complex geometries are divided into smaller regions with optimized deposition sequences to balance thermal stresses. Their guidelines specify material-specific parameters including laser power modulation patterns that vary throughout the build based on geometry and thermal history. GE Avio's process incorporates intermittent cooling cycles with compressed air jets strategically positioned to target high-temperature zones. For critical aerospace components, they've developed a hybrid approach combining DED with subsequent precision machining, with allowances for distortion built into the initial deposition strategy. Their repair guidelines include detailed specifications for substrate preparation, including stress-relief heat treatments prior to deposition and surface activation procedures to ensure optimal metallurgical bonding while minimizing thermal impact. Implementation of these guidelines has reportedly reduced repair-related distortion by approximately 40-50% compared to conventional methods.

Strengths: Deep expertise in aerospace component repair with proven results on complex, high-value parts. Their integrated computational modeling approach enables accurate prediction and compensation for distortion. Weaknesses: Solutions are highly specialized for aerospace applications and may not translate well to other industries. The combined process approach requires multiple specialized manufacturing systems, increasing overall complexity and cost.

Critical Patents in DED Distortion Control

Distortion mitigation in directed energy deposition

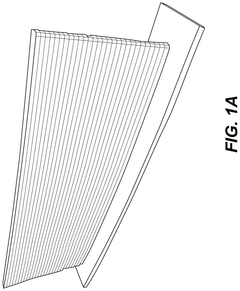

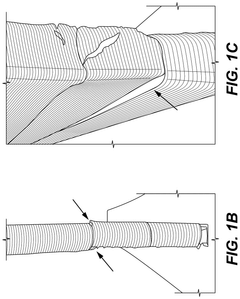

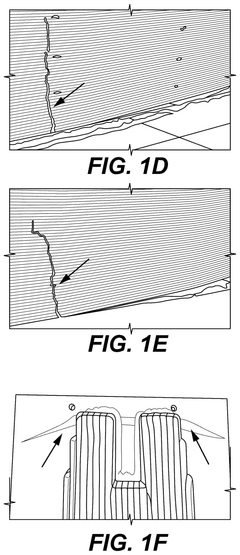

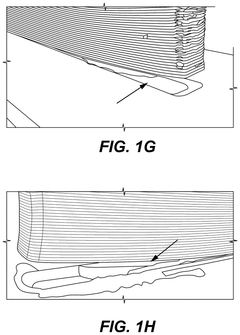

PatentPendingUS20250187075A1

Innovation

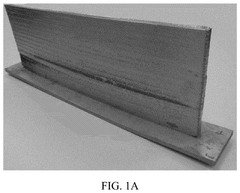

- The use of a pre-bent substrate with a curved clamping mold and pre-heating techniques to minimize residual stress and distortion during DED manufacturing. This involves thermally pre-bending the substrate to induce residual stresses, securing it to a jig with a curved clamping mold, and pre-heating the substrate to uniform temperature before deposition.

Distortion mitigation in directed energy deposition

PatentPendingUS20250065404A1

Innovation

- The use of a mount system and pin support system that pre-bends and pre-heats the substrate, combined with controlled heat transfer and an inert atmosphere, to minimize residual stress and distortion during DED manufacturing.

Material Selection Considerations for DED Repairs

Material selection is a critical factor in the success of Directed Energy Deposition (DED) repair processes, directly influencing the likelihood and severity of distortion. When selecting materials for DED repairs, engineers must consider the thermal properties of both the substrate and the deposited material to minimize thermal gradients that lead to distortion.

Coefficient of thermal expansion (CTE) compatibility between the substrate and repair material is paramount. Materials with significantly different CTEs will expand and contract at different rates during heating and cooling cycles, generating internal stresses that manifest as distortion. For optimal results, the repair material should have a CTE within 10% of the substrate material's value.

Thermal conductivity also plays a crucial role in distortion control. Materials with higher thermal conductivity distribute heat more evenly, reducing localized thermal gradients. When repairing components made of low thermal conductivity materials such as titanium alloys or certain stainless steels, pre-heating strategies become essential to compensate for poor heat distribution.

The yield strength and elastic modulus of the selected materials influence their resistance to plastic deformation under thermal stress. Higher yield strength materials generally exhibit less distortion during DED processes, but may require more precise process control to avoid cracking. Engineers must balance these mechanical properties against the specific repair requirements.

Phase transformation characteristics of the selected materials must be thoroughly evaluated. Materials that undergo significant volume changes during phase transformations (such as martensitic transformations in certain steels) can introduce additional distortion mechanisms. In such cases, post-process heat treatments may be necessary to stabilize the microstructure and relieve residual stresses.

For multi-material repairs, the formation of intermetallic compounds at the interface between dissimilar materials can significantly affect distortion behavior. These compounds often have mechanical properties that differ from either parent material, creating stress concentrations that can amplify distortion. Careful selection of compatible material combinations or the use of functionally graded materials can mitigate these effects.

Powder characteristics for DED repairs, including particle size distribution, morphology, and flowability, influence material deposition behavior and consequently affect distortion. Spherical particles with narrow size distributions typically provide more consistent deposition and reduced porosity, which helps minimize distortion by ensuring uniform material properties throughout the repair.

Coefficient of thermal expansion (CTE) compatibility between the substrate and repair material is paramount. Materials with significantly different CTEs will expand and contract at different rates during heating and cooling cycles, generating internal stresses that manifest as distortion. For optimal results, the repair material should have a CTE within 10% of the substrate material's value.

Thermal conductivity also plays a crucial role in distortion control. Materials with higher thermal conductivity distribute heat more evenly, reducing localized thermal gradients. When repairing components made of low thermal conductivity materials such as titanium alloys or certain stainless steels, pre-heating strategies become essential to compensate for poor heat distribution.

The yield strength and elastic modulus of the selected materials influence their resistance to plastic deformation under thermal stress. Higher yield strength materials generally exhibit less distortion during DED processes, but may require more precise process control to avoid cracking. Engineers must balance these mechanical properties against the specific repair requirements.

Phase transformation characteristics of the selected materials must be thoroughly evaluated. Materials that undergo significant volume changes during phase transformations (such as martensitic transformations in certain steels) can introduce additional distortion mechanisms. In such cases, post-process heat treatments may be necessary to stabilize the microstructure and relieve residual stresses.

For multi-material repairs, the formation of intermetallic compounds at the interface between dissimilar materials can significantly affect distortion behavior. These compounds often have mechanical properties that differ from either parent material, creating stress concentrations that can amplify distortion. Careful selection of compatible material combinations or the use of functionally graded materials can mitigate these effects.

Powder characteristics for DED repairs, including particle size distribution, morphology, and flowability, influence material deposition behavior and consequently affect distortion. Spherical particles with narrow size distributions typically provide more consistent deposition and reduced porosity, which helps minimize distortion by ensuring uniform material properties throughout the repair.

Quality Assurance Standards for DED Repair Processes

Quality assurance standards for Directed Energy Deposition (DED) repair processes must be rigorously established to minimize distortion and ensure consistent, high-quality outcomes. These standards should encompass comprehensive inspection protocols that begin with pre-repair material characterization and extend through in-process monitoring to post-repair validation.

Material certification represents the foundation of quality assurance, requiring thorough documentation of feedstock properties including chemical composition, particle size distribution, and flowability for powder-based DED. Standards must specify acceptable ranges for these parameters and mandate regular sampling and testing procedures to verify consistency between batches.

Process parameter validation constitutes another critical element, with standards defining acceptable ranges for laser power, travel speed, powder feed rate, and layer thickness. These parameters should be calibrated against material-specific requirements and documented in standardized process maps that operators can reference to minimize distortion risks.

In-process monitoring technologies form an essential component of modern DED quality assurance frameworks. Standards should mandate the implementation of real-time monitoring systems capable of detecting thermal anomalies, melt pool variations, and dimensional deviations. These systems must include defined threshold values that trigger automatic process adjustments or alerts when parameters drift outside acceptable ranges.

Post-process inspection requirements must be clearly defined, including non-destructive testing protocols for detecting internal defects, surface metrology standards for dimensional accuracy, and mechanical testing procedures to verify material properties. Standards should specify acceptance criteria for porosity levels, crack presence, hardness values, and distortion tolerances based on application requirements.

Documentation and traceability standards ensure that all quality-related data is systematically recorded and preserved. This includes maintaining digital records of process parameters, monitoring data, inspection results, and any corrective actions taken during repair operations. Standards should mandate the implementation of part-specific digital passports that follow components throughout their lifecycle.

Operator qualification standards represent a frequently overlooked but crucial aspect of quality assurance. Standards must define the required training, certification, and periodic requalification processes for personnel involved in DED repair operations. This includes demonstrating proficiency in parameter selection, distortion mitigation techniques, and quality inspection procedures.

Continuous improvement mechanisms should be embedded within the standards framework, requiring regular review of repair outcomes, statistical analysis of defect patterns, and systematic updating of process parameters based on empirical evidence. This feedback loop ensures that quality standards evolve alongside technological advancements in DED repair methodologies.

Material certification represents the foundation of quality assurance, requiring thorough documentation of feedstock properties including chemical composition, particle size distribution, and flowability for powder-based DED. Standards must specify acceptable ranges for these parameters and mandate regular sampling and testing procedures to verify consistency between batches.

Process parameter validation constitutes another critical element, with standards defining acceptable ranges for laser power, travel speed, powder feed rate, and layer thickness. These parameters should be calibrated against material-specific requirements and documented in standardized process maps that operators can reference to minimize distortion risks.

In-process monitoring technologies form an essential component of modern DED quality assurance frameworks. Standards should mandate the implementation of real-time monitoring systems capable of detecting thermal anomalies, melt pool variations, and dimensional deviations. These systems must include defined threshold values that trigger automatic process adjustments or alerts when parameters drift outside acceptable ranges.

Post-process inspection requirements must be clearly defined, including non-destructive testing protocols for detecting internal defects, surface metrology standards for dimensional accuracy, and mechanical testing procedures to verify material properties. Standards should specify acceptance criteria for porosity levels, crack presence, hardness values, and distortion tolerances based on application requirements.

Documentation and traceability standards ensure that all quality-related data is systematically recorded and preserved. This includes maintaining digital records of process parameters, monitoring data, inspection results, and any corrective actions taken during repair operations. Standards should mandate the implementation of part-specific digital passports that follow components throughout their lifecycle.

Operator qualification standards represent a frequently overlooked but crucial aspect of quality assurance. Standards must define the required training, certification, and periodic requalification processes for personnel involved in DED repair operations. This includes demonstrating proficiency in parameter selection, distortion mitigation techniques, and quality inspection procedures.

Continuous improvement mechanisms should be embedded within the standards framework, requiring regular review of repair outcomes, statistical analysis of defect patterns, and systematic updating of process parameters based on empirical evidence. This feedback loop ensures that quality standards evolve alongside technological advancements in DED repair methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!