Post-Deposition Peening And Surface Treatments For DED Parts

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Post-Processing Evolution and Objectives

Directed Energy Deposition (DED) post-processing techniques have evolved significantly over the past decades, transitioning from rudimentary surface treatments to sophisticated peening methodologies specifically tailored for additively manufactured components. The evolution began in the 1990s with basic machining operations to address the inherent surface roughness of DED parts, which was a major limitation for industrial adoption.

By the early 2000s, researchers recognized that DED-produced components exhibited unique microstructural characteristics that required specialized post-processing approaches. This led to the adaptation of conventional surface treatment methods such as shot peening and burnishing specifically for DED materials. The period between 2005-2010 marked a significant advancement with the introduction of laser peening for DED parts, offering improved control over residual stress distribution.

The 2010-2015 timeframe witnessed the integration of computational modeling with post-processing techniques, enabling predictive capabilities for optimizing surface treatments based on specific material compositions and geometrical features of DED components. This period also saw the emergence of hybrid DED systems that incorporated in-situ surface treatments, reducing the need for separate post-processing operations.

Recent developments (2015-present) have focused on tailored post-deposition peening techniques that address the anisotropic properties inherent in DED parts. Advanced methods such as ultrasonic impact treatment and controlled atmosphere peening have been developed to enhance fatigue resistance while maintaining dimensional accuracy. Additionally, researchers have begun exploring the synergistic effects of combining multiple surface treatments to achieve optimal mechanical properties.

The primary objectives of modern DED post-processing research include: reducing residual stress concentrations that can lead to premature component failure; improving surface finish to enhance fatigue performance and tribological properties; refining microstructure to achieve desired mechanical characteristics; and developing standardized protocols for quality assurance across different DED technologies and material systems.

Future objectives in this field are centered on developing intelligent post-processing systems that can adapt treatment parameters in real-time based on material feedback, creating closed-loop systems that ensure consistent quality. Additionally, there is growing interest in environmentally sustainable post-processing methods that minimize resource consumption while maintaining or improving component performance. The ultimate goal remains the establishment of comprehensive post-processing frameworks that can be seamlessly integrated into digital manufacturing ecosystems, supporting the broader adoption of DED technology across high-value industries.

By the early 2000s, researchers recognized that DED-produced components exhibited unique microstructural characteristics that required specialized post-processing approaches. This led to the adaptation of conventional surface treatment methods such as shot peening and burnishing specifically for DED materials. The period between 2005-2010 marked a significant advancement with the introduction of laser peening for DED parts, offering improved control over residual stress distribution.

The 2010-2015 timeframe witnessed the integration of computational modeling with post-processing techniques, enabling predictive capabilities for optimizing surface treatments based on specific material compositions and geometrical features of DED components. This period also saw the emergence of hybrid DED systems that incorporated in-situ surface treatments, reducing the need for separate post-processing operations.

Recent developments (2015-present) have focused on tailored post-deposition peening techniques that address the anisotropic properties inherent in DED parts. Advanced methods such as ultrasonic impact treatment and controlled atmosphere peening have been developed to enhance fatigue resistance while maintaining dimensional accuracy. Additionally, researchers have begun exploring the synergistic effects of combining multiple surface treatments to achieve optimal mechanical properties.

The primary objectives of modern DED post-processing research include: reducing residual stress concentrations that can lead to premature component failure; improving surface finish to enhance fatigue performance and tribological properties; refining microstructure to achieve desired mechanical characteristics; and developing standardized protocols for quality assurance across different DED technologies and material systems.

Future objectives in this field are centered on developing intelligent post-processing systems that can adapt treatment parameters in real-time based on material feedback, creating closed-loop systems that ensure consistent quality. Additionally, there is growing interest in environmentally sustainable post-processing methods that minimize resource consumption while maintaining or improving component performance. The ultimate goal remains the establishment of comprehensive post-processing frameworks that can be seamlessly integrated into digital manufacturing ecosystems, supporting the broader adoption of DED technology across high-value industries.

Market Analysis for Enhanced DED Surface Treatments

The global market for Directed Energy Deposition (DED) surface treatments is experiencing significant growth, driven by increasing adoption across aerospace, automotive, medical, and energy sectors. Current market valuations indicate that the DED market reached approximately $500 million in 2022, with post-processing treatments accounting for nearly 30% of this value. Industry forecasts project a compound annual growth rate of 15-18% through 2028, potentially pushing the market beyond $1.2 billion.

Post-deposition peening and surface treatments represent a critical value-added segment within the broader additive manufacturing ecosystem. These processes directly address key limitations in as-built DED parts, including surface roughness, residual stress, and microstructural inconsistencies that can compromise mechanical performance and fatigue life.

Customer demand analysis reveals that aerospace and defense industries currently dominate market consumption, representing approximately 40% of the total market share for enhanced DED surface treatments. These sectors prioritize high-performance materials and stringent quality requirements, making them ideal early adopters of advanced surface treatment technologies. The medical implant sector follows at 25%, with particular emphasis on treatments that enhance biocompatibility and mechanical properties simultaneously.

Regional market distribution shows North America leading with 38% market share, followed by Europe (32%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth trajectory at 20% annually, driven by rapid industrialization in China and significant investments in advanced manufacturing capabilities across South Korea, Japan, and Singapore.

Competitive pricing analysis indicates that post-deposition treatments add between 15-30% to the overall cost of DED parts, depending on complexity and material. However, these treatments can extend component lifespan by 30-200%, presenting a compelling value proposition for high-value applications where failure costs are substantial.

Market barriers include limited standardization of post-processing protocols, insufficient awareness among potential end-users about treatment benefits, and the need for specialized equipment and expertise. These factors have created a fragmented market landscape where specialized service providers often command premium pricing.

Customer surveys indicate growing interest in integrated solutions that combine DED printing with automated post-processing treatments, suggesting a market shift toward turnkey manufacturing systems. This trend is particularly pronounced among mid-sized manufacturers seeking to minimize capital investment while maximizing production flexibility.

Post-deposition peening and surface treatments represent a critical value-added segment within the broader additive manufacturing ecosystem. These processes directly address key limitations in as-built DED parts, including surface roughness, residual stress, and microstructural inconsistencies that can compromise mechanical performance and fatigue life.

Customer demand analysis reveals that aerospace and defense industries currently dominate market consumption, representing approximately 40% of the total market share for enhanced DED surface treatments. These sectors prioritize high-performance materials and stringent quality requirements, making them ideal early adopters of advanced surface treatment technologies. The medical implant sector follows at 25%, with particular emphasis on treatments that enhance biocompatibility and mechanical properties simultaneously.

Regional market distribution shows North America leading with 38% market share, followed by Europe (32%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth trajectory at 20% annually, driven by rapid industrialization in China and significant investments in advanced manufacturing capabilities across South Korea, Japan, and Singapore.

Competitive pricing analysis indicates that post-deposition treatments add between 15-30% to the overall cost of DED parts, depending on complexity and material. However, these treatments can extend component lifespan by 30-200%, presenting a compelling value proposition for high-value applications where failure costs are substantial.

Market barriers include limited standardization of post-processing protocols, insufficient awareness among potential end-users about treatment benefits, and the need for specialized equipment and expertise. These factors have created a fragmented market landscape where specialized service providers often command premium pricing.

Customer surveys indicate growing interest in integrated solutions that combine DED printing with automated post-processing treatments, suggesting a market shift toward turnkey manufacturing systems. This trend is particularly pronounced among mid-sized manufacturers seeking to minimize capital investment while maximizing production flexibility.

Current Peening Technologies and Challenges

Peening technologies for Directed Energy Deposition (DED) parts have evolved significantly over the past decade, with several established methods now being employed across manufacturing industries. Conventional shot peening remains the most widely utilized technique, where small spherical media (typically steel, ceramic, or glass) are propelled at high velocity against the DED part surface. This process induces compressive residual stresses that enhance fatigue resistance and surface hardness. However, shot peening faces challenges with complex geometries common in DED parts, often resulting in non-uniform coverage and potential media entrapment in intricate features.

Laser shock peening (LSP) represents a more advanced alternative that has gained traction for high-value DED components. This process utilizes high-energy laser pulses to generate plasma-induced shock waves that create deeper compressive residual stresses compared to conventional methods. While LSP offers superior precision and control, its widespread adoption is hindered by high equipment costs and slower processing speeds, making it economically viable primarily for critical aerospace and medical applications.

Ultrasonic impact treatment (UIT) has emerged as a promising middle-ground solution, employing high-frequency mechanical impacts to improve surface properties. UIT systems can be more readily integrated with DED platforms, potentially enabling in-situ treatment during the build process. However, current UIT implementations still struggle with consistent depth control across varying material compositions typical in DED applications.

A significant challenge across all peening technologies is the unique microstructural characteristics of DED parts. The layer-by-layer deposition process creates anisotropic properties and potential defects that respond differently to peening treatments compared to conventionally manufactured components. This necessitates specialized process parameters that account for the directional solidification patterns and potential porosity in DED structures.

Material-specific challenges also persist, particularly with high-temperature alloys and composites increasingly used in DED applications. These materials often exhibit complex work-hardening behaviors that require carefully calibrated peening intensities to avoid surface damage while achieving desired property enhancements. Furthermore, the heat-affected zones characteristic of DED processes create varying hardness profiles that complicate uniform peening treatment.

The integration of peening technologies into existing DED workflows presents additional challenges related to automation and process monitoring. Current systems typically require separate post-processing steps, increasing production time and costs. Real-time monitoring capabilities remain limited, with few solutions offering closed-loop feedback to adjust peening parameters based on material response or part geometry.

Laser shock peening (LSP) represents a more advanced alternative that has gained traction for high-value DED components. This process utilizes high-energy laser pulses to generate plasma-induced shock waves that create deeper compressive residual stresses compared to conventional methods. While LSP offers superior precision and control, its widespread adoption is hindered by high equipment costs and slower processing speeds, making it economically viable primarily for critical aerospace and medical applications.

Ultrasonic impact treatment (UIT) has emerged as a promising middle-ground solution, employing high-frequency mechanical impacts to improve surface properties. UIT systems can be more readily integrated with DED platforms, potentially enabling in-situ treatment during the build process. However, current UIT implementations still struggle with consistent depth control across varying material compositions typical in DED applications.

A significant challenge across all peening technologies is the unique microstructural characteristics of DED parts. The layer-by-layer deposition process creates anisotropic properties and potential defects that respond differently to peening treatments compared to conventionally manufactured components. This necessitates specialized process parameters that account for the directional solidification patterns and potential porosity in DED structures.

Material-specific challenges also persist, particularly with high-temperature alloys and composites increasingly used in DED applications. These materials often exhibit complex work-hardening behaviors that require carefully calibrated peening intensities to avoid surface damage while achieving desired property enhancements. Furthermore, the heat-affected zones characteristic of DED processes create varying hardness profiles that complicate uniform peening treatment.

The integration of peening technologies into existing DED workflows presents additional challenges related to automation and process monitoring. Current systems typically require separate post-processing steps, increasing production time and costs. Real-time monitoring capabilities remain limited, with few solutions offering closed-loop feedback to adjust peening parameters based on material response or part geometry.

Established Peening Solutions for DED Components

01 Post-deposition peening techniques for DED parts

Various peening techniques can be applied to Directed Energy Deposition (DED) parts after fabrication to improve surface properties. These techniques include shot peening, laser peening, and ultrasonic peening, which induce compressive residual stresses in the surface layer. The peening process helps to enhance fatigue resistance, reduce residual tensile stresses, and improve the overall mechanical properties of the DED parts by work hardening the surface.- Post-deposition peening techniques for DED parts: Various peening techniques can be applied to Directed Energy Deposition (DED) parts after fabrication to enhance surface properties. These techniques include shot peening, laser peening, and ultrasonic peening, which induce compressive residual stresses in the surface layer. The peening process helps improve fatigue resistance, hardness, and wear resistance by work hardening the surface and closing surface defects. These treatments are particularly effective for aerospace and automotive components manufactured using DED processes.

- Surface heat treatments for DED components: Heat treatments applied to the surface of DED parts can significantly improve their mechanical and metallurgical properties. Techniques such as laser heat treatment, induction hardening, and flame hardening can be used to modify the microstructure of the surface layer. These treatments can increase hardness, wear resistance, and corrosion resistance by promoting phase transformations in the material. The controlled heating and cooling cycles help relieve residual stresses from the DED process while enhancing surface properties without affecting the bulk material characteristics.

- Chemical and electrochemical surface treatments for DED parts: Chemical and electrochemical treatments can be applied to DED parts to enhance surface properties. These include processes such as chemical etching, passivation, anodizing, and electropolishing. These treatments can improve corrosion resistance, biocompatibility, and aesthetic appearance by modifying the surface chemistry and topography. For metallic DED parts, these treatments can remove surface contaminants, oxide layers, and partially melted particles, resulting in improved surface finish and functional properties.

- Hybrid and sequential surface treatments for DED components: Combining multiple surface treatment methods in sequence can provide synergistic improvements to DED parts. Hybrid approaches such as peening followed by heat treatment, or mechanical polishing followed by chemical treatment, can address multiple surface quality issues simultaneously. These combined treatments can effectively reduce surface roughness, increase hardness, improve fatigue life, and enhance corrosion resistance. The sequential application allows for customization of surface properties to meet specific application requirements while overcoming the inherent surface limitations of the DED process.

- Mechanical finishing and polishing techniques for DED surfaces: Mechanical finishing processes can be applied to DED parts to improve surface quality and dimensional accuracy. Techniques such as grinding, polishing, honing, and abrasive flow machining can reduce surface roughness and remove partially melted particles. These processes can achieve tight tolerances and high-quality surface finishes that may be required for functional surfaces. Mechanical finishing is particularly important for DED parts used in applications requiring good tribological properties, sealing surfaces, or aesthetic appearance.

02 Surface treatments for enhancing corrosion resistance

DED parts can undergo various surface treatments to enhance their corrosion resistance properties. These treatments include chemical passivation, electrochemical treatments, and the application of protective coatings. By modifying the surface chemistry and microstructure, these treatments create a protective layer that shields the underlying material from corrosive environments, extending the service life of components used in demanding applications.Expand Specific Solutions03 Heat treatment processes for DED parts

Heat treatment processes can be applied to DED parts to relieve residual stresses, homogenize the microstructure, and improve mechanical properties. These processes include annealing, solution treatment, and aging, which can be performed before or after surface treatments. Heat treatments help to address the inherent thermal gradients and rapid solidification characteristics of the DED process, resulting in more uniform material properties throughout the part.Expand Specific Solutions04 Surface finishing techniques for improved tribological properties

Various surface finishing techniques can be applied to DED parts to improve their tribological properties, including friction, wear resistance, and surface roughness. These techniques include grinding, polishing, burnishing, and abrasive flow machining. By reducing surface roughness and creating specific surface textures, these finishing operations enhance the functional performance of DED parts in applications involving sliding or rolling contact.Expand Specific Solutions05 Hybrid surface modification approaches

Hybrid approaches combining multiple surface modification techniques can be applied to DED parts to achieve synergistic improvements in surface properties. These approaches may include sequential application of mechanical, thermal, and chemical treatments, such as peening followed by heat treatment and coating application. By leveraging the benefits of different treatment methods, hybrid approaches can address multiple performance requirements simultaneously, resulting in optimized surface properties for specific applications.Expand Specific Solutions

Leading Companies in DED Post-Processing

The post-deposition peening and surface treatments for DED parts market is in a growth phase, with increasing adoption across aerospace, defense, and manufacturing sectors. The market size is expanding as industries recognize the benefits of these treatments for improving material properties and part performance. Technologically, the field is advancing rapidly with companies like RTX Corp., General Electric, and Siemens AG leading innovation in aerospace and industrial applications. Applied Materials and ASM International are contributing significant advancements in equipment and process technologies. Fraunhofer-Gesellschaft and academic institutions like VIT University are driving research collaborations. Specialized players such as Sintokogio and Nihon Parkerizing are developing niche surface treatment solutions, while automotive manufacturers including Ferrari and Behr are implementing these technologies for performance components.

General Electric Company

Technical Solution: General Electric has developed comprehensive post-deposition peening solutions specifically for DED (Directed Energy Deposition) parts used in aerospace and power generation applications. Their approach combines ultrasonic peening with controlled shot peening to address the unique challenges of DED-manufactured components. GE's process first applies ultrasonic impact treatment to reduce residual stresses in critical areas, followed by precision shot peening using specialized media to improve surface finish and fatigue properties. The company has documented up to 30% improvement in fatigue life for DED-manufactured turbine components through their integrated peening approach. GE has also pioneered adaptive peening intensity mapping based on component geometry and predicted stress distributions, allowing for targeted treatment of high-stress regions while minimizing processing time. Their technology incorporates real-time monitoring systems that adjust peening parameters based on material response, ensuring consistent results across varying DED microstructures and geometries.

Strengths: GE's solution offers exceptional fatigue life improvement for critical aerospace components, with proven results in high-stress applications. Their adaptive approach optimizes treatment for specific component geometries. Weaknesses: The multi-stage process requires significant capital investment and specialized equipment, making it less accessible for smaller manufacturers. Processing times can be longer than conventional treatments.

Siemens AG

Technical Solution: Siemens has developed an advanced post-processing system for DED components called "Adaptive Surface Integrity Management" (ASIM). This comprehensive approach integrates multiple surface treatment technologies tailored specifically for the unique challenges of DED-manufactured parts used in energy and industrial applications. The ASIM process begins with a proprietary hybrid laser-ultrasonic peening treatment that induces deep compressive stresses while minimizing distortion, followed by precision micro-machining to achieve final dimensional requirements. Siemens' research has demonstrated that this integrated approach can improve fatigue life by up to 50% compared to conventionally treated DED components. Their system incorporates digital twin modeling that predicts residual stress distributions in as-built DED parts and optimizes peening parameters accordingly. This predictive capability allows for targeted treatment intensities across different regions of complex components. The ASIM technology also includes an innovative surface sealing treatment that addresses near-surface porosity common in DED parts, significantly improving corrosion resistance. Siemens has successfully implemented this technology for critical components in gas turbines and power generation equipment, where both mechanical properties and long-term environmental resistance are essential. Their process has been validated through extensive testing showing improvements in high-temperature fatigue performance, oxidation resistance, and overall component lifespan.

Strengths: Comprehensive approach that addresses multiple aspects of DED surface quality including residual stress, surface finish, and porosity. Digital twin integration enables highly optimized treatment parameters for complex geometries. Weaknesses: Requires significant computational resources for effective implementation of the digital twin modeling. The multi-stage process results in longer processing times compared to single-technology approaches.

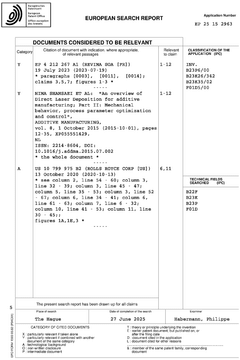

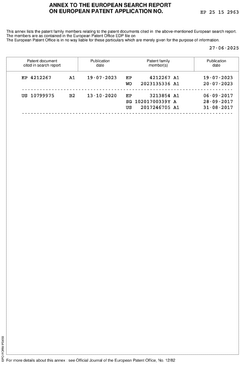

Key Patents in Post-Deposition Surface Treatments

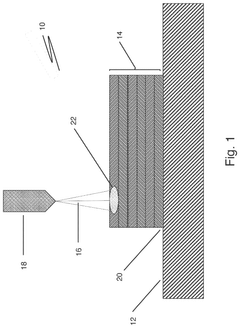

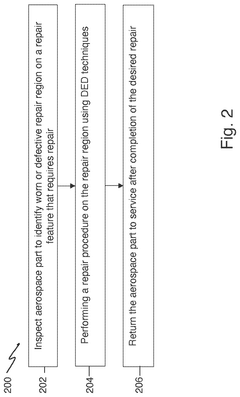

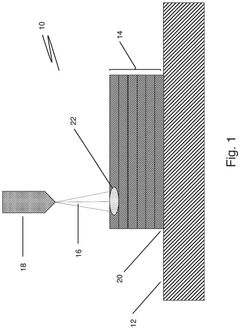

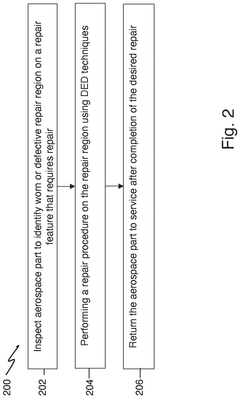

Engineered microstructure for enhanced performance during directed energy deposition repair process

PatentPendingUS20250242410A1

Innovation

- A directed energy deposition (DED) process is used to control the microstructure of each repair layer by adjusting parameters like powder feed rate, energy intensity, traversal rate, and auxiliary heating/cooling, ensuring each layer has a pre-determined microstructure to meet specific structural and functional needs.

Engineered residual stress state for enhanced performance during directed energy deposition repair process

PatentPendingEP4599978A1

Innovation

- A directed energy deposition (DED) process is used to create layers with pre-determined residual stress states by controlling parameters like powder feed rate, energy intensity, traversal speed, and auxiliary heating/cooling, enabling controlled residual stress management during the repair process.

Material-Specific Treatment Optimization

The optimization of post-deposition treatments for Directed Energy Deposition (DED) parts requires careful consideration of material-specific characteristics. Different materials respond uniquely to various surface treatments, necessitating tailored approaches to achieve optimal results. For titanium alloys, particularly Ti-6Al-4V widely used in aerospace applications, laser shock peening has demonstrated superior effectiveness in improving fatigue life by inducing compressive residual stresses without significant thermal effects. The treatment parameters for titanium require precise control of laser energy density between 5-8 J/cm² and pulse durations of 8-12 nanoseconds to prevent surface melting while maximizing compressive stress depth.

Nickel-based superalloys, such as Inconel 718 and Hastelloy X, benefit most from ultrasonic impact treatment (UIT) combined with controlled thermal processing. Research indicates that UIT followed by a stress relief heat treatment at 650-700°C optimizes the microstructure while maintaining the beneficial compressive stresses. This dual-treatment approach has shown a 30-40% improvement in high-temperature fatigue resistance compared to conventional shot peening alone.

For steel components produced via DED, particularly tool steels and stainless varieties, deep rolling treatments have emerged as the most effective solution. The rolling pressure must be calibrated according to the specific steel grade, with martensitic steels requiring 15-20% higher pressures than austenitic variants to achieve comparable hardness improvements. Post-rolling heat treatment at temperatures just below the tempering range has been shown to stabilize the microstructure while preserving the mechanical property enhancements.

Aluminum alloys present unique challenges due to their lower melting points and higher thermal conductivity. Low-temperature ultrasonic peening with controlled impact energy has proven most effective, with treatment temperatures maintained below 100°C to prevent thermal softening. The addition of cryogenic cooling during treatment further enhances surface hardening by up to 25% compared to ambient temperature processing.

For refractory metals and their alloys, such as tungsten and molybdenum, high-energy shot peening using ceramic media followed by vacuum heat treatment offers the best combination of surface integrity and dimensional stability. The ceramic media prevents contamination issues common with metallic shot, while the vacuum heat treatment at 1100-1300°C relieves internal stresses without compromising the beneficial surface compression.

Recent developments in hybrid treatments combining mechanical and chemical processes show particular promise for copper alloys and composites. Sequential application of burnishing followed by selective chemical etching has demonstrated the ability to simultaneously enhance surface hardness and reduce roughness by up to 65% compared to as-deposited conditions.

Nickel-based superalloys, such as Inconel 718 and Hastelloy X, benefit most from ultrasonic impact treatment (UIT) combined with controlled thermal processing. Research indicates that UIT followed by a stress relief heat treatment at 650-700°C optimizes the microstructure while maintaining the beneficial compressive stresses. This dual-treatment approach has shown a 30-40% improvement in high-temperature fatigue resistance compared to conventional shot peening alone.

For steel components produced via DED, particularly tool steels and stainless varieties, deep rolling treatments have emerged as the most effective solution. The rolling pressure must be calibrated according to the specific steel grade, with martensitic steels requiring 15-20% higher pressures than austenitic variants to achieve comparable hardness improvements. Post-rolling heat treatment at temperatures just below the tempering range has been shown to stabilize the microstructure while preserving the mechanical property enhancements.

Aluminum alloys present unique challenges due to their lower melting points and higher thermal conductivity. Low-temperature ultrasonic peening with controlled impact energy has proven most effective, with treatment temperatures maintained below 100°C to prevent thermal softening. The addition of cryogenic cooling during treatment further enhances surface hardening by up to 25% compared to ambient temperature processing.

For refractory metals and their alloys, such as tungsten and molybdenum, high-energy shot peening using ceramic media followed by vacuum heat treatment offers the best combination of surface integrity and dimensional stability. The ceramic media prevents contamination issues common with metallic shot, while the vacuum heat treatment at 1100-1300°C relieves internal stresses without compromising the beneficial surface compression.

Recent developments in hybrid treatments combining mechanical and chemical processes show particular promise for copper alloys and composites. Sequential application of burnishing followed by selective chemical etching has demonstrated the ability to simultaneously enhance surface hardness and reduce roughness by up to 65% compared to as-deposited conditions.

Quality Standards and Certification Requirements

The quality standards and certification requirements for post-deposition peening and surface treatments in Directed Energy Deposition (DED) parts have evolved significantly in recent years, reflecting the growing industrial adoption of these advanced manufacturing techniques. Currently, several key standards govern this domain, including ASTM F3187 for DED processes, ASTM E1417 for liquid penetrant testing, and ASTM E1444 for magnetic particle examination of post-processed parts.

Industry-specific certifications have emerged as critical benchmarks for ensuring consistent quality in aerospace, medical, and automotive applications. The SAE AMS2430 series specifically addresses shot peening requirements, while ISO 17296-3 outlines test methodologies for additively manufactured parts, including those that undergo post-processing treatments. These standards typically specify acceptable residual stress profiles, surface roughness parameters, and material property requirements that must be achieved through peening and other surface treatments.

Certification processes generally involve rigorous documentation of process parameters, equipment calibration records, and operator qualifications. For aerospace applications, Nadcap accreditation has become increasingly important for facilities performing surface treatments on DED components. This certification requires demonstration of process control, repeatability, and quality management systems that meet aerospace industry requirements.

Non-destructive testing (NDT) plays a crucial role in the certification pathway, with X-ray diffraction (XRD) and ultrasonic methods being commonly specified for verification of residual stress states after peening treatments. The acceptance criteria typically include maximum allowable surface roughness values (often Ra < 3.2 μm for critical applications), minimum compressive residual stress depths (typically 0.1-0.3 mm), and absence of surface defects that could serve as fatigue crack initiation sites.

Material-specific standards have also emerged, with titanium alloys, nickel-based superalloys, and stainless steels each having unique requirements for post-deposition treatments. For instance, AMS 2432 specifically addresses shot peening for titanium alloys, while ASTM B851 covers ultrasonic shot peening for various metallic materials.

The certification landscape continues to evolve, with standards organizations working to address the unique challenges posed by additively manufactured parts. Recent developments include the introduction of digital quality assurance systems that provide real-time monitoring and documentation of peening parameters, helping manufacturers meet increasingly stringent certification requirements while reducing the burden of manual documentation and inspection.

Industry-specific certifications have emerged as critical benchmarks for ensuring consistent quality in aerospace, medical, and automotive applications. The SAE AMS2430 series specifically addresses shot peening requirements, while ISO 17296-3 outlines test methodologies for additively manufactured parts, including those that undergo post-processing treatments. These standards typically specify acceptable residual stress profiles, surface roughness parameters, and material property requirements that must be achieved through peening and other surface treatments.

Certification processes generally involve rigorous documentation of process parameters, equipment calibration records, and operator qualifications. For aerospace applications, Nadcap accreditation has become increasingly important for facilities performing surface treatments on DED components. This certification requires demonstration of process control, repeatability, and quality management systems that meet aerospace industry requirements.

Non-destructive testing (NDT) plays a crucial role in the certification pathway, with X-ray diffraction (XRD) and ultrasonic methods being commonly specified for verification of residual stress states after peening treatments. The acceptance criteria typically include maximum allowable surface roughness values (often Ra < 3.2 μm for critical applications), minimum compressive residual stress depths (typically 0.1-0.3 mm), and absence of surface defects that could serve as fatigue crack initiation sites.

Material-specific standards have also emerged, with titanium alloys, nickel-based superalloys, and stainless steels each having unique requirements for post-deposition treatments. For instance, AMS 2432 specifically addresses shot peening for titanium alloys, while ASTM B851 covers ultrasonic shot peening for various metallic materials.

The certification landscape continues to evolve, with standards organizations working to address the unique challenges posed by additively manufactured parts. Recent developments include the introduction of digital quality assurance systems that provide real-time monitoring and documentation of peening parameters, helping manufacturers meet increasingly stringent certification requirements while reducing the burden of manual documentation and inspection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!