DED Process Simulation: Coupling Thermal, Metallurgical, And Stress Models

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Background and Objectives

Directed Energy Deposition (DED) has emerged as a transformative additive manufacturing technology over the past two decades, evolving from experimental processes to industrially viable manufacturing methods. This metal-based additive manufacturing technique utilizes focused thermal energy to fuse materials as they are deposited, enabling the creation of complex geometries and functionally graded materials that were previously unattainable through conventional manufacturing methods.

The evolution of DED technology has been marked by significant advancements in process control, material compatibility, and equipment sophistication. Initially developed in the 1990s as laser cladding technology, DED has since expanded to incorporate various energy sources including electron beams, plasma arcs, and high-powered lasers, each offering distinct advantages for specific applications and materials.

Current technological trends in DED are focused on enhancing process stability, improving deposition accuracy, and expanding the range of compatible materials. Particularly noteworthy is the growing emphasis on multi-material deposition capabilities, which allow for the creation of components with spatially varying compositions and properties, opening new possibilities for aerospace, defense, and medical applications.

The simulation of DED processes represents a critical frontier in advancing this technology. Accurate modeling of the complex physical phenomena occurring during deposition—including heat transfer, phase transformations, and residual stress development—is essential for predicting and controlling the final properties of manufactured components. The coupling of thermal, metallurgical, and stress models presents a particularly challenging but necessary objective for comprehensive process simulation.

The primary technical objectives in DED process simulation include developing integrated computational frameworks that can accurately predict temperature distributions, microstructural evolution, and residual stress states throughout the build process. These simulations must account for the dynamic nature of the process, including the continuous addition of material, changing boundary conditions, and complex material behavior under extreme thermal gradients.

Achieving these objectives would enable significant advancements in process optimization, defect prediction, and part qualification. By providing insights into the relationships between process parameters and resultant material properties, coupled simulations can facilitate the development of optimized deposition strategies, reduce the need for costly experimental iterations, and accelerate the certification of DED-manufactured components for critical applications.

The ultimate goal is to establish a robust, validated simulation capability that can serve as a virtual testbed for DED process development, enabling manufacturers to confidently produce components with predictable properties and performance characteristics while minimizing material waste and energy consumption.

The evolution of DED technology has been marked by significant advancements in process control, material compatibility, and equipment sophistication. Initially developed in the 1990s as laser cladding technology, DED has since expanded to incorporate various energy sources including electron beams, plasma arcs, and high-powered lasers, each offering distinct advantages for specific applications and materials.

Current technological trends in DED are focused on enhancing process stability, improving deposition accuracy, and expanding the range of compatible materials. Particularly noteworthy is the growing emphasis on multi-material deposition capabilities, which allow for the creation of components with spatially varying compositions and properties, opening new possibilities for aerospace, defense, and medical applications.

The simulation of DED processes represents a critical frontier in advancing this technology. Accurate modeling of the complex physical phenomena occurring during deposition—including heat transfer, phase transformations, and residual stress development—is essential for predicting and controlling the final properties of manufactured components. The coupling of thermal, metallurgical, and stress models presents a particularly challenging but necessary objective for comprehensive process simulation.

The primary technical objectives in DED process simulation include developing integrated computational frameworks that can accurately predict temperature distributions, microstructural evolution, and residual stress states throughout the build process. These simulations must account for the dynamic nature of the process, including the continuous addition of material, changing boundary conditions, and complex material behavior under extreme thermal gradients.

Achieving these objectives would enable significant advancements in process optimization, defect prediction, and part qualification. By providing insights into the relationships between process parameters and resultant material properties, coupled simulations can facilitate the development of optimized deposition strategies, reduce the need for costly experimental iterations, and accelerate the certification of DED-manufactured components for critical applications.

The ultimate goal is to establish a robust, validated simulation capability that can serve as a virtual testbed for DED process development, enabling manufacturers to confidently produce components with predictable properties and performance characteristics while minimizing material waste and energy consumption.

Market Applications and Industry Demand for DED Simulation

The Directed Energy Deposition (DED) process simulation market is experiencing significant growth driven by the expanding adoption of additive manufacturing technologies across multiple industries. Aerospace and defense sectors represent the largest market segments, where DED simulations enable the production of complex components with reduced material waste and enhanced performance characteristics. These industries particularly value the ability to predict residual stresses and microstructural properties in critical components subject to extreme operating conditions.

The automotive industry has emerged as another major consumer of DED simulation technologies, particularly as manufacturers transition toward lightweight materials and complex geometries to improve fuel efficiency and performance. The ability to accurately predict material behavior during the DED process allows for optimized design and manufacturing parameters, reducing the need for costly physical prototyping and testing cycles.

Medical device manufacturing represents a rapidly growing application area, with an increasing demand for patient-specific implants and prosthetics. DED simulation tools that can accurately model the interaction between thermal, metallurgical, and stress factors are essential for ensuring biocompatibility and mechanical integrity of these critical components.

Energy sector applications, particularly in oil and gas and power generation, demonstrate growing interest in DED simulation for repair and maintenance operations of high-value components. The ability to predict how repaired sections will perform under operational conditions provides significant cost savings and improved reliability.

Market research indicates that the global demand for coupled multi-physics DED simulation tools is growing at approximately twice the rate of the overall additive manufacturing software market. This accelerated growth reflects the increasing recognition that accurate process simulation is essential for reducing the trial-and-error approach traditionally associated with additive manufacturing implementation.

Industry surveys reveal that manufacturers are particularly seeking simulation capabilities that can predict defect formation, residual stress distributions, and final part properties with greater accuracy. The ability to couple thermal, metallurgical, and stress models represents a significant competitive advantage for simulation software providers, as it addresses the fundamental challenge of predicting complex material behavior during the DED process.

Academic and industrial research partnerships focused on DED simulation have increased substantially over the past five years, indicating strong market interest in advancing the state-of-the-art in this field. These collaborations frequently cite the need for validated simulation tools that can accurately predict microstructural evolution and mechanical properties across a wider range of materials and process conditions.

The automotive industry has emerged as another major consumer of DED simulation technologies, particularly as manufacturers transition toward lightweight materials and complex geometries to improve fuel efficiency and performance. The ability to accurately predict material behavior during the DED process allows for optimized design and manufacturing parameters, reducing the need for costly physical prototyping and testing cycles.

Medical device manufacturing represents a rapidly growing application area, with an increasing demand for patient-specific implants and prosthetics. DED simulation tools that can accurately model the interaction between thermal, metallurgical, and stress factors are essential for ensuring biocompatibility and mechanical integrity of these critical components.

Energy sector applications, particularly in oil and gas and power generation, demonstrate growing interest in DED simulation for repair and maintenance operations of high-value components. The ability to predict how repaired sections will perform under operational conditions provides significant cost savings and improved reliability.

Market research indicates that the global demand for coupled multi-physics DED simulation tools is growing at approximately twice the rate of the overall additive manufacturing software market. This accelerated growth reflects the increasing recognition that accurate process simulation is essential for reducing the trial-and-error approach traditionally associated with additive manufacturing implementation.

Industry surveys reveal that manufacturers are particularly seeking simulation capabilities that can predict defect formation, residual stress distributions, and final part properties with greater accuracy. The ability to couple thermal, metallurgical, and stress models represents a significant competitive advantage for simulation software providers, as it addresses the fundamental challenge of predicting complex material behavior during the DED process.

Academic and industrial research partnerships focused on DED simulation have increased substantially over the past five years, indicating strong market interest in advancing the state-of-the-art in this field. These collaborations frequently cite the need for validated simulation tools that can accurately predict microstructural evolution and mechanical properties across a wider range of materials and process conditions.

Current Challenges in Multi-Physics DED Modeling

Despite significant advancements in Directed Energy Deposition (DED) simulation technologies, researchers and engineers continue to face substantial challenges in developing fully integrated multi-physics models. The fundamental difficulty lies in the complex interplay between thermal, metallurgical, and mechanical phenomena occurring simultaneously during the DED process at vastly different time and length scales.

One of the primary challenges is computational efficiency. Current coupled models require enormous computational resources, often taking days or weeks to simulate even relatively simple geometries. This computational burden severely limits their practical application in industrial settings where rapid design iterations are necessary. The multi-scale nature of the process—ranging from microscopic solidification dynamics to macroscopic part distortion—further compounds this challenge.

Material characterization presents another significant obstacle. Temperature-dependent material properties are essential inputs for accurate simulations, yet comprehensive data sets are only available for a limited range of materials. Properties such as thermal conductivity, specific heat, and yield strength change dramatically during the extreme thermal cycles of DED, and capturing these variations accurately remains problematic, especially for novel alloys and composites increasingly used in additive manufacturing.

The modeling of phase transformations and microstructure evolution continues to be particularly challenging. Current models struggle to accurately predict grain structure, texture development, and precipitation phenomena that directly influence mechanical properties. The rapid solidification rates in DED create non-equilibrium conditions that conventional phase transformation models fail to capture adequately.

Interface physics between layers and passes represents another frontier challenge. The complex thermal history creates varying degrees of remelting, diffusion, and potential defect formation at these interfaces. Current models typically employ simplifications that fail to capture the full complexity of these interactions, leading to discrepancies between simulated and actual mechanical properties.

Residual stress prediction remains perhaps the most elusive aspect of DED simulation. The complex thermal cycling, phase transformations, and plastic deformation mechanisms interact in ways that are difficult to model comprehensively. Current approaches often fail to accurately predict distortion patterns and residual stress distributions, particularly for complex geometries with varying wall thicknesses or overhanging features.

Validation methodologies constitute a cross-cutting challenge. The lack of standardized experimental techniques for measuring in-situ temperatures, stresses, and microstructural evolution during the DED process makes it difficult to validate simulation results and improve model accuracy through iterative refinement.

One of the primary challenges is computational efficiency. Current coupled models require enormous computational resources, often taking days or weeks to simulate even relatively simple geometries. This computational burden severely limits their practical application in industrial settings where rapid design iterations are necessary. The multi-scale nature of the process—ranging from microscopic solidification dynamics to macroscopic part distortion—further compounds this challenge.

Material characterization presents another significant obstacle. Temperature-dependent material properties are essential inputs for accurate simulations, yet comprehensive data sets are only available for a limited range of materials. Properties such as thermal conductivity, specific heat, and yield strength change dramatically during the extreme thermal cycles of DED, and capturing these variations accurately remains problematic, especially for novel alloys and composites increasingly used in additive manufacturing.

The modeling of phase transformations and microstructure evolution continues to be particularly challenging. Current models struggle to accurately predict grain structure, texture development, and precipitation phenomena that directly influence mechanical properties. The rapid solidification rates in DED create non-equilibrium conditions that conventional phase transformation models fail to capture adequately.

Interface physics between layers and passes represents another frontier challenge. The complex thermal history creates varying degrees of remelting, diffusion, and potential defect formation at these interfaces. Current models typically employ simplifications that fail to capture the full complexity of these interactions, leading to discrepancies between simulated and actual mechanical properties.

Residual stress prediction remains perhaps the most elusive aspect of DED simulation. The complex thermal cycling, phase transformations, and plastic deformation mechanisms interact in ways that are difficult to model comprehensively. Current approaches often fail to accurately predict distortion patterns and residual stress distributions, particularly for complex geometries with varying wall thicknesses or overhanging features.

Validation methodologies constitute a cross-cutting challenge. The lack of standardized experimental techniques for measuring in-situ temperatures, stresses, and microstructural evolution during the DED process makes it difficult to validate simulation results and improve model accuracy through iterative refinement.

State-of-the-Art Coupled Simulation Approaches for DED

01 Coupling of thermal and mechanical simulations in DED processes

Direct Energy Deposition (DED) processes involve complex thermal and mechanical interactions. Simulation approaches that couple thermal and mechanical analyses enable more accurate prediction of residual stresses, distortions, and material properties in the final part. These coupled simulations account for how heat transfer affects mechanical behavior and vice versa, providing a more comprehensive understanding of the DED manufacturing process.- Coupled multi-physics simulation for DED processes: Directed Energy Deposition (DED) processes involve complex physical phenomena that require coupled multi-physics simulation approaches. These simulations integrate thermal, mechanical, and microstructural models to accurately predict material behavior during deposition. By coupling different physical domains, these simulations can predict temperature distributions, residual stresses, and microstructural evolution simultaneously, leading to more accurate process optimization and part quality prediction.

- Real-time monitoring and simulation feedback loops: Advanced DED process simulation incorporates real-time monitoring data to create feedback loops between the physical process and digital simulation. This approach allows for dynamic adjustment of process parameters based on simulation predictions and actual measurements. Sensors capture thermal, geometric, and other process data that are fed into simulation models, enabling adaptive control strategies and improving deposition quality through continuous optimization during the build process.

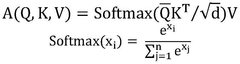

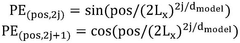

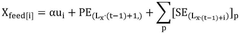

- Machine learning integration with DED process simulation: Machine learning algorithms are increasingly being integrated with DED process simulations to enhance predictive capabilities and reduce computational costs. These approaches use training data from both simulations and experimental results to develop models that can quickly predict process outcomes. Neural networks and other AI techniques help identify complex relationships between process parameters and part quality, enabling rapid optimization and reducing the need for extensive physical testing.

- Microstructure evolution and material property prediction: Specialized simulation approaches for DED processes focus on predicting microstructure evolution and resulting material properties. These simulations couple thermal history with phase transformation models to predict grain structure, phase composition, and mechanical properties of deposited materials. By understanding how process parameters affect microstructure formation, these simulations help optimize DED processes for specific material performance requirements and part applications.

- Multi-scale modeling approaches for DED simulation: Multi-scale modeling techniques address the challenge of simulating DED processes across different length and time scales. These approaches combine macro-scale process models with meso-scale and micro-scale simulations to capture phenomena ranging from overall part distortion to individual grain formation. By bridging these scales through appropriate coupling methods, these simulations provide comprehensive insights into process-structure-property relationships in DED-manufactured components.

02 Multi-physics simulation frameworks for DED process optimization

Advanced multi-physics simulation frameworks integrate various physical phenomena occurring during DED processes, including heat transfer, fluid dynamics, phase transformations, and mechanical responses. These comprehensive simulation approaches enable optimization of process parameters, prediction of microstructure evolution, and identification of potential defects before physical manufacturing, thereby improving part quality and reducing development time.Expand Specific Solutions03 Real-time monitoring and simulation coupling for DED process control

Integration of real-time monitoring data with simulation models creates a feedback loop for adaptive control of DED processes. Sensor data from the manufacturing process is fed into simulation models to update predictions and adjust process parameters dynamically. This approach enables in-process quality control, defect prevention, and adaptive manufacturing strategies that respond to variations in material properties or environmental conditions.Expand Specific Solutions04 Material behavior modeling in DED process simulations

Accurate modeling of material behavior is crucial for DED process simulations. Advanced models incorporate phase transformations, microstructure evolution, and temperature-dependent material properties to predict how materials respond during the deposition process. These simulations account for phenomena such as grain growth, solidification dynamics, and thermal cycling effects, enabling better prediction of final part properties and performance.Expand Specific Solutions05 Machine learning integration with DED process simulation

Machine learning techniques are being integrated with traditional simulation approaches to enhance the accuracy and efficiency of DED process modeling. These hybrid approaches use data-driven models to capture complex relationships between process parameters and outcomes, reduce computational requirements, and enable rapid prediction of process results. Machine learning also facilitates parameter optimization and can identify non-intuitive relationships in the manufacturing process.Expand Specific Solutions

Leading Research Institutions and Industrial Players in DED Simulation

The DED Process Simulation market is currently in a growth phase, characterized by increasing adoption across aerospace, automotive, and manufacturing sectors. The market size is estimated to be expanding at a CAGR of 15-20%, driven by demand for more efficient metal additive manufacturing solutions. Technologically, the field is advancing rapidly but remains moderately mature, with companies at varying development stages. Leading players like Norsk Titanium AS and Seurat Technologies are pioneering commercial applications with proprietary plasma arc technologies, while RTX Corp, GE Avio, and Safran are integrating these solutions into aerospace applications. Academic institutions such as Northwestern Polytechnical University and University of Science & Technology Beijing are contributing significant research advancements in coupling thermal, metallurgical, and stress models, creating a competitive ecosystem of both specialized additive manufacturing firms and established industrial giants.

Norsk Titanium AS

Technical Solution: Norsk Titanium has developed a proprietary Rapid Plasma Deposition™ (RPD™) process for DED simulation that integrates thermal, metallurgical, and stress models. Their approach uses plasma arc technology to deposit titanium wire in a controlled atmosphere, creating near-net-shape components. The simulation framework incorporates real-time thermal monitoring with infrared cameras to validate their thermal models, which predict temperature gradients and cooling rates during deposition. Their metallurgical models account for phase transformations specific to titanium alloys, predicting microstructure evolution based on thermal history. The stress models calculate residual stresses and distortions by considering thermal expansion/contraction and phase transformation effects. Norsk's simulation platform enables parameter optimization before physical builds, reducing development time and material waste while ensuring consistent mechanical properties across complex geometries.

Strengths: Specialized expertise in titanium processing with validated models for aerospace applications; simulation results closely match physical builds, reducing iteration cycles. Weaknesses: Models are primarily optimized for titanium alloys, limiting applicability to other materials; high computational requirements for complex geometries can slow design iterations.

Caterpillar, Inc.

Technical Solution: Caterpillar has developed an integrated multi-physics simulation platform for Directed Energy Deposition (DED) processes that couples thermal, metallurgical, and stress models specifically designed for heavy equipment applications. Their approach uses finite element analysis with adaptive meshing techniques to accurately capture the moving heat source and material addition characteristics of DED. The thermal model incorporates laser-material interaction physics, accounting for absorption, reflection, and heat transfer mechanisms during deposition. Their metallurgical component predicts grain structure evolution, phase transformations, and precipitation kinetics based on thermal history and cooling rates. The mechanical model calculates transient and residual stresses, accounting for elasto-plastic material behavior and phase transformation strains. Caterpillar's simulation framework includes material models calibrated specifically for wear-resistant alloys and structural steels commonly used in heavy machinery components, enabling accurate prediction of final part properties and performance.

Strengths: Robust validation against physical parts used in demanding applications; models optimized for large-scale industrial components with complex geometries. Weaknesses: Simulation framework is computationally intensive, requiring significant hardware resources; primarily focused on ferrous alloys and wear-resistant materials rather than lightweight metals.

Critical Technologies in Thermal-Metallurgical-Stress Model Integration

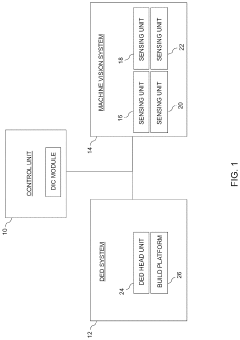

Direct energy deposition (DED) process neural network online monitoring system and method based on time sequence data set

PatentPendingCN119442861A

Innovation

- A direct energy deposition DED process neural network online monitoring system based on a time series data set is adopted, which includes obtaining time series data, predicting temperature trends, determining defect prediction results, and optimizing process parameters.

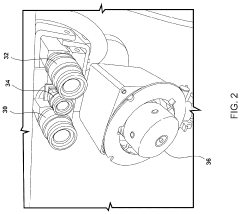

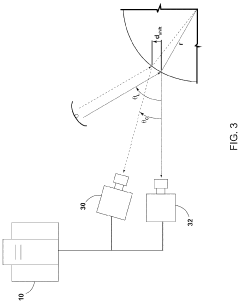

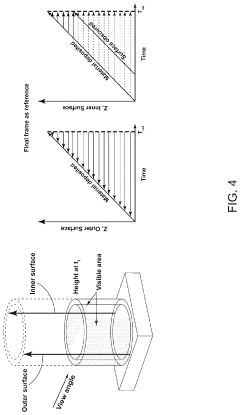

In-situ digital image correlation and thermal monitoring in directed energy deposition

PatentActiveUS11890808B2

Innovation

- A method and system for digital image correlation and thermal monitoring using global off-axis 3D mapping with natural surface roughness, infrared thermography, and a machine vision system comprising stereo imaging cameras and an infrared camera, allowing for strain and temperature data acquisition without a speckle pattern and enabling synthetic reference frames for inner surface features.

Validation Methodologies and Experimental Benchmarking

Validation of coupled thermal, metallurgical, and stress models in DED process simulation requires rigorous methodologies to ensure accuracy and reliability. The validation process typically follows a multi-level approach, starting with individual model validation before progressing to integrated system validation. Temperature measurements using thermocouples and infrared cameras serve as primary validation tools for thermal models, providing real-time temperature distribution data during deposition processes.

For metallurgical model validation, microstructural characterization techniques including optical microscopy, SEM, EBSD, and XRD are employed to analyze grain structure, phase composition, and texture. These experimental results are compared with model predictions to verify the accuracy of phase transformation kinetics and microstructure evolution simulations. The correlation between cooling rates and resulting microstructures provides critical validation points.

Residual stress validation employs both destructive and non-destructive techniques. Neutron diffraction and X-ray diffraction offer non-destructive measurement of internal stresses, while contour method and hole-drilling techniques provide destructive but highly accurate stress measurements. Displacement measurements using digital image correlation (DIC) during and after deposition provide additional validation data for mechanical models.

Benchmark experiments designed specifically for validation purposes typically involve simplified geometries with well-controlled process parameters. Standard test cases such as single-track depositions, multi-layer walls, and simple 3D structures allow for systematic comparison between simulation predictions and experimental measurements. Round-robin testing across multiple research institutions helps establish reproducibility and reliability of both experimental and simulation approaches.

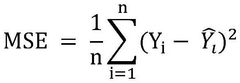

Quantitative validation metrics must be established to objectively assess model accuracy. These include statistical measures such as root mean square error (RMSE), mean absolute error (MAE), and correlation coefficients between predicted and measured values. Sensitivity analysis is conducted to identify the most influential parameters affecting model accuracy and to establish confidence intervals for predictions.

The validation process must also address multi-physics coupling effects. Sequential validation of thermal-metallurgical coupling followed by thermal-mechanical coupling helps isolate and verify specific interaction mechanisms. Time-resolved in-situ measurements during deposition provide particularly valuable validation data for transient phenomena that occur during the DED process.

Ultimately, successful validation requires establishing clear acceptance criteria based on application requirements. For structural components, stress prediction accuracy within 10-15% may be acceptable, while applications requiring precise microstructure control may demand higher fidelity in metallurgical predictions. Documentation of validation procedures, including experimental uncertainties and model limitations, ensures transparency and facilitates continuous improvement of simulation capabilities.

For metallurgical model validation, microstructural characterization techniques including optical microscopy, SEM, EBSD, and XRD are employed to analyze grain structure, phase composition, and texture. These experimental results are compared with model predictions to verify the accuracy of phase transformation kinetics and microstructure evolution simulations. The correlation between cooling rates and resulting microstructures provides critical validation points.

Residual stress validation employs both destructive and non-destructive techniques. Neutron diffraction and X-ray diffraction offer non-destructive measurement of internal stresses, while contour method and hole-drilling techniques provide destructive but highly accurate stress measurements. Displacement measurements using digital image correlation (DIC) during and after deposition provide additional validation data for mechanical models.

Benchmark experiments designed specifically for validation purposes typically involve simplified geometries with well-controlled process parameters. Standard test cases such as single-track depositions, multi-layer walls, and simple 3D structures allow for systematic comparison between simulation predictions and experimental measurements. Round-robin testing across multiple research institutions helps establish reproducibility and reliability of both experimental and simulation approaches.

Quantitative validation metrics must be established to objectively assess model accuracy. These include statistical measures such as root mean square error (RMSE), mean absolute error (MAE), and correlation coefficients between predicted and measured values. Sensitivity analysis is conducted to identify the most influential parameters affecting model accuracy and to establish confidence intervals for predictions.

The validation process must also address multi-physics coupling effects. Sequential validation of thermal-metallurgical coupling followed by thermal-mechanical coupling helps isolate and verify specific interaction mechanisms. Time-resolved in-situ measurements during deposition provide particularly valuable validation data for transient phenomena that occur during the DED process.

Ultimately, successful validation requires establishing clear acceptance criteria based on application requirements. For structural components, stress prediction accuracy within 10-15% may be acceptable, while applications requiring precise microstructure control may demand higher fidelity in metallurgical predictions. Documentation of validation procedures, including experimental uncertainties and model limitations, ensures transparency and facilitates continuous improvement of simulation capabilities.

Computational Resource Requirements and Optimization Strategies

The computational demands of coupled DED process simulations are exceptionally high due to the multi-physics nature of the models involved. Current high-fidelity simulations that integrate thermal, metallurgical, and stress models typically require significant computational resources, often necessitating high-performance computing (HPC) environments. Benchmark studies indicate that a comprehensive simulation of a medium-complexity DED process can consume between 500-2000 CPU hours, depending on the resolution and complexity of the models.

Memory requirements present another significant challenge, with detailed simulations often requiring 128GB-512GB RAM for processing complex geometries and multi-physics interactions. Storage demands are similarly substantial, with simulation outputs frequently generating datasets in the terabyte range, particularly when capturing time-series data across multiple physical domains.

Several optimization strategies have emerged to address these computational challenges. Adaptive mesh refinement techniques have proven particularly effective, dynamically allocating computational resources to regions of high gradient or interest while using coarser meshes elsewhere. This approach has demonstrated computational savings of 30-60% in recent studies without significant loss of accuracy in critical regions.

Reduced-order modeling (ROM) represents another promising approach, where complex physics are approximated using mathematical techniques such as proper orthogonal decomposition or neural network surrogates. These methods have shown the potential to accelerate simulations by factors of 10-100x, though careful validation against high-fidelity models remains essential.

Parallel computing strategies specifically tailored to DED simulations have also advanced significantly. Domain decomposition methods that intelligently partition the computational domain based on physical processes rather than simple geometric divisions have shown superior scaling performance on HPC systems, achieving up to 85% parallel efficiency on systems with thousands of cores.

Cloud-based computing solutions are increasingly being adopted for DED simulations, offering flexible resource allocation and the ability to scale computational resources based on simulation requirements. However, data transfer bottlenecks and security concerns remain significant considerations for industrial applications.

Looking forward, emerging hardware architectures such as GPU acceleration and specialized AI processors show promise for further optimization. Early implementations of GPU-accelerated thermal models have demonstrated speedups of 5-20x for specific computational kernels, though full multi-physics integration remains challenging due to memory bandwidth limitations and algorithm compatibility issues.

Memory requirements present another significant challenge, with detailed simulations often requiring 128GB-512GB RAM for processing complex geometries and multi-physics interactions. Storage demands are similarly substantial, with simulation outputs frequently generating datasets in the terabyte range, particularly when capturing time-series data across multiple physical domains.

Several optimization strategies have emerged to address these computational challenges. Adaptive mesh refinement techniques have proven particularly effective, dynamically allocating computational resources to regions of high gradient or interest while using coarser meshes elsewhere. This approach has demonstrated computational savings of 30-60% in recent studies without significant loss of accuracy in critical regions.

Reduced-order modeling (ROM) represents another promising approach, where complex physics are approximated using mathematical techniques such as proper orthogonal decomposition or neural network surrogates. These methods have shown the potential to accelerate simulations by factors of 10-100x, though careful validation against high-fidelity models remains essential.

Parallel computing strategies specifically tailored to DED simulations have also advanced significantly. Domain decomposition methods that intelligently partition the computational domain based on physical processes rather than simple geometric divisions have shown superior scaling performance on HPC systems, achieving up to 85% parallel efficiency on systems with thousands of cores.

Cloud-based computing solutions are increasingly being adopted for DED simulations, offering flexible resource allocation and the ability to scale computational resources based on simulation requirements. However, data transfer bottlenecks and security concerns remain significant considerations for industrial applications.

Looking forward, emerging hardware architectures such as GPU acceleration and specialized AI processors show promise for further optimization. Early implementations of GPU-accelerated thermal models have demonstrated speedups of 5-20x for specific computational kernels, though full multi-physics integration remains challenging due to memory bandwidth limitations and algorithm compatibility issues.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!