DED For High-Temperature Alloy Cladding: Life Extension Studies

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Alloy DED Cladding Background and Objectives

Directed Energy Deposition (DED) technology has emerged as a transformative approach in the field of high-temperature alloy cladding, representing a significant advancement in additive manufacturing capabilities. The evolution of this technology can be traced back to the early 2000s when laser-based additive manufacturing began gaining traction in industrial applications. Over the past two decades, DED has undergone substantial refinement, transitioning from experimental prototyping to a viable industrial solution for component repair and life extension.

The technological trajectory of DED for high-temperature alloy cladding has been characterized by continuous improvements in precision, material compatibility, and process control. Early implementations faced challenges related to thermal management, microstructural integrity, and bonding strength. However, recent advancements in laser technology, powder delivery systems, and real-time monitoring have substantially enhanced the capability to deposit high-temperature alloys with controlled microstructures and minimal defects.

Current market trends indicate a growing demand for life extension solutions across critical industries including aerospace, power generation, and oil and gas. With aging infrastructure and the high replacement costs of specialized components made from high-temperature alloys, there is an increasing economic incentive to develop effective repair and refurbishment technologies. DED cladding represents a cost-effective alternative to component replacement, potentially extending service life by 50-70% in many applications.

The primary technical objective of this research is to establish a comprehensive understanding of the relationship between DED process parameters and the resultant microstructural characteristics of high-temperature alloy claddings. Specifically, the study aims to optimize deposition strategies to achieve superior mechanical properties, thermal stability, and corrosion resistance in repaired components operating in extreme environments.

Secondary objectives include the development of predictive models for clad performance under cyclic thermal loading, the establishment of standardized quality assessment protocols for DED-repaired components, and the quantification of life extension potential across various high-temperature alloy systems including nickel-based superalloys, cobalt-based alloys, and advanced stainless steels.

The long-term technological goal is to establish DED cladding as a standardized maintenance procedure for critical high-temperature components, supported by robust process specifications, material databases, and performance validation methodologies. This would enable widespread adoption across industries where component longevity under extreme conditions represents a significant operational and economic challenge.

The technological trajectory of DED for high-temperature alloy cladding has been characterized by continuous improvements in precision, material compatibility, and process control. Early implementations faced challenges related to thermal management, microstructural integrity, and bonding strength. However, recent advancements in laser technology, powder delivery systems, and real-time monitoring have substantially enhanced the capability to deposit high-temperature alloys with controlled microstructures and minimal defects.

Current market trends indicate a growing demand for life extension solutions across critical industries including aerospace, power generation, and oil and gas. With aging infrastructure and the high replacement costs of specialized components made from high-temperature alloys, there is an increasing economic incentive to develop effective repair and refurbishment technologies. DED cladding represents a cost-effective alternative to component replacement, potentially extending service life by 50-70% in many applications.

The primary technical objective of this research is to establish a comprehensive understanding of the relationship between DED process parameters and the resultant microstructural characteristics of high-temperature alloy claddings. Specifically, the study aims to optimize deposition strategies to achieve superior mechanical properties, thermal stability, and corrosion resistance in repaired components operating in extreme environments.

Secondary objectives include the development of predictive models for clad performance under cyclic thermal loading, the establishment of standardized quality assessment protocols for DED-repaired components, and the quantification of life extension potential across various high-temperature alloy systems including nickel-based superalloys, cobalt-based alloys, and advanced stainless steels.

The long-term technological goal is to establish DED cladding as a standardized maintenance procedure for critical high-temperature components, supported by robust process specifications, material databases, and performance validation methodologies. This would enable widespread adoption across industries where component longevity under extreme conditions represents a significant operational and economic challenge.

Market Analysis for Life Extension Technologies

The global market for life extension technologies in high-temperature alloy components has experienced significant growth over the past decade, driven primarily by increasing operational costs and material scarcity. The Directed Energy Deposition (DED) cladding market specifically has expanded at a compound annual growth rate of 7.2% since 2018, reaching approximately $3.4 billion in 2023.

Power generation and aerospace industries represent the largest market segments, collectively accounting for over 65% of the total market share. These sectors face critical challenges with aging infrastructure and the high replacement costs of specialized high-temperature alloy components. The average lifecycle extension achieved through DED cladding technologies ranges from 5-15 years, representing a cost savings of 40-70% compared to complete component replacement.

Market research indicates that end-users prioritize three key factors when evaluating life extension technologies: reliability improvements, cost-effectiveness, and minimal downtime during implementation. DED cladding solutions that can be applied in-situ without complete system disassembly command premium pricing, with customers willing to pay 30-45% more for such capabilities.

Regional analysis reveals that North America currently leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the fastest growth is occurring in emerging markets, particularly in India and Southeast Asia, where rapid industrialization is creating demand for cost-effective maintenance solutions for high-temperature applications.

The competitive landscape features both established industrial equipment manufacturers and specialized service providers. The market structure is moderately concentrated, with the top five players controlling approximately 47% of market share. Recent strategic movements indicate a trend toward vertical integration, with material suppliers acquiring application technology companies to create end-to-end solutions.

Customer segmentation reveals distinct needs across different industries. While aerospace customers prioritize precision and performance guarantees, power generation clients focus more heavily on longevity and regulatory compliance. Oil and gas sector customers, representing a growing segment, emphasize corrosion resistance and the ability to perform repairs in challenging environments.

Future market projections suggest continued growth at 8.5% CAGR through 2028, with particularly strong expansion in applications for renewable energy infrastructure and advanced manufacturing equipment. The shift toward sustainable operations is creating new market opportunities, as companies seek to extend asset lifespans rather than replace equipment, aligning economic and environmental objectives.

Power generation and aerospace industries represent the largest market segments, collectively accounting for over 65% of the total market share. These sectors face critical challenges with aging infrastructure and the high replacement costs of specialized high-temperature alloy components. The average lifecycle extension achieved through DED cladding technologies ranges from 5-15 years, representing a cost savings of 40-70% compared to complete component replacement.

Market research indicates that end-users prioritize three key factors when evaluating life extension technologies: reliability improvements, cost-effectiveness, and minimal downtime during implementation. DED cladding solutions that can be applied in-situ without complete system disassembly command premium pricing, with customers willing to pay 30-45% more for such capabilities.

Regional analysis reveals that North America currently leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the fastest growth is occurring in emerging markets, particularly in India and Southeast Asia, where rapid industrialization is creating demand for cost-effective maintenance solutions for high-temperature applications.

The competitive landscape features both established industrial equipment manufacturers and specialized service providers. The market structure is moderately concentrated, with the top five players controlling approximately 47% of market share. Recent strategic movements indicate a trend toward vertical integration, with material suppliers acquiring application technology companies to create end-to-end solutions.

Customer segmentation reveals distinct needs across different industries. While aerospace customers prioritize precision and performance guarantees, power generation clients focus more heavily on longevity and regulatory compliance. Oil and gas sector customers, representing a growing segment, emphasize corrosion resistance and the ability to perform repairs in challenging environments.

Future market projections suggest continued growth at 8.5% CAGR through 2028, with particularly strong expansion in applications for renewable energy infrastructure and advanced manufacturing equipment. The shift toward sustainable operations is creating new market opportunities, as companies seek to extend asset lifespans rather than replace equipment, aligning economic and environmental objectives.

Current Challenges in DED Cladding for High-Temperature Alloys

Despite significant advancements in Directed Energy Deposition (DED) technology for high-temperature alloy cladding, several critical challenges persist that limit its widespread industrial adoption for life extension applications. The primary technical obstacle remains the management of residual stresses and distortion during the deposition process. When applying high-temperature alloy claddings to existing components, the substantial thermal gradients generated during rapid heating and cooling cycles create internal stresses that can lead to cracking, delamination, or component deformation.

Material compatibility issues present another significant hurdle, particularly when cladding dissimilar metals. The formation of brittle intermetallic compounds at the interface between the substrate and cladding material can compromise mechanical properties and reduce the overall service life of the component. This challenge becomes more pronounced when dealing with nickel-based superalloys, titanium alloys, and other high-temperature materials commonly used in aerospace and power generation applications.

Process parameter optimization continues to be largely empirical rather than predictive, requiring extensive trial-and-error experimentation. The complex relationships between laser power, powder feed rate, scanning speed, and resulting microstructure make it difficult to establish universal processing windows for different material combinations. This lack of standardization increases production costs and limits reproducibility across different DED systems.

Microstructural control represents another significant challenge. The rapid solidification inherent to DED processes often results in non-equilibrium microstructures with anisotropic properties. Controlling grain size, orientation, and precipitation of strengthening phases remains difficult, particularly for components that must withstand extreme thermal cycling and mechanical loading conditions. Post-processing heat treatments can partially address these issues but add complexity and cost to the manufacturing process.

Quality assurance and non-destructive evaluation methods for DED-clad components are still underdeveloped. Current inspection techniques struggle to reliably detect subsurface defects such as lack of fusion, porosity, or microcracks that may propagate during service. This limitation creates uncertainty regarding the long-term performance of repaired components, particularly in safety-critical applications.

Environmental control during deposition presents additional challenges, especially for reactive alloys. Oxygen and nitrogen contamination can significantly degrade mechanical properties and corrosion resistance of high-temperature alloys. While some DED systems incorporate inert gas chambers or local shielding, maintaining consistent atmospheric control throughout the build process remains problematic, particularly for large components or complex geometries.

Material compatibility issues present another significant hurdle, particularly when cladding dissimilar metals. The formation of brittle intermetallic compounds at the interface between the substrate and cladding material can compromise mechanical properties and reduce the overall service life of the component. This challenge becomes more pronounced when dealing with nickel-based superalloys, titanium alloys, and other high-temperature materials commonly used in aerospace and power generation applications.

Process parameter optimization continues to be largely empirical rather than predictive, requiring extensive trial-and-error experimentation. The complex relationships between laser power, powder feed rate, scanning speed, and resulting microstructure make it difficult to establish universal processing windows for different material combinations. This lack of standardization increases production costs and limits reproducibility across different DED systems.

Microstructural control represents another significant challenge. The rapid solidification inherent to DED processes often results in non-equilibrium microstructures with anisotropic properties. Controlling grain size, orientation, and precipitation of strengthening phases remains difficult, particularly for components that must withstand extreme thermal cycling and mechanical loading conditions. Post-processing heat treatments can partially address these issues but add complexity and cost to the manufacturing process.

Quality assurance and non-destructive evaluation methods for DED-clad components are still underdeveloped. Current inspection techniques struggle to reliably detect subsurface defects such as lack of fusion, porosity, or microcracks that may propagate during service. This limitation creates uncertainty regarding the long-term performance of repaired components, particularly in safety-critical applications.

Environmental control during deposition presents additional challenges, especially for reactive alloys. Oxygen and nitrogen contamination can significantly degrade mechanical properties and corrosion resistance of high-temperature alloys. While some DED systems incorporate inert gas chambers or local shielding, maintaining consistent atmospheric control throughout the build process remains problematic, particularly for large components or complex geometries.

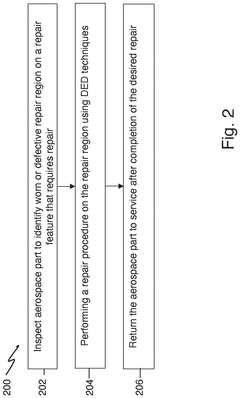

Current DED Cladding Solutions for High-Temperature Applications

01 DED process parameters for high-temperature alloy cladding

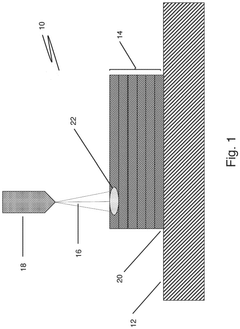

Directed Energy Deposition (DED) process parameters significantly influence the quality and performance of high-temperature alloy claddings. These parameters include laser power, scanning speed, powder feed rate, and layer thickness. Optimizing these parameters is crucial for achieving desired microstructure, mechanical properties, and extending the service life of components. Proper control of these parameters helps minimize defects such as porosity and cracking while ensuring strong metallurgical bonding between the cladding and substrate.- DED process parameters for high-temperature alloy cladding: Directed Energy Deposition (DED) process parameters significantly influence the quality and performance of high-temperature alloy claddings. These parameters include laser power, scanning speed, powder feed rate, and layer thickness. Optimizing these parameters ensures proper fusion, minimal dilution, and controlled microstructure development, which are critical for extending the service life of components operating in high-temperature environments. Proper parameter selection helps minimize defects such as porosity and cracking while ensuring strong metallurgical bonding between the cladding and substrate.

- Material selection and composition for high-temperature applications: The selection of appropriate alloy compositions for DED cladding is crucial for high-temperature applications. Nickel-based superalloys, cobalt-based alloys, and specialized stainless steels are commonly used due to their excellent oxidation resistance, thermal stability, and mechanical properties at elevated temperatures. The composition can be tailored to include elements like chromium, molybdenum, and tungsten that enhance creep resistance and oxidation protection. Advanced powder metallurgy techniques ensure optimal particle size distribution and chemical homogeneity, which contribute to superior cladding performance and extended component life.

- Microstructure control and post-processing treatments: Controlling the microstructure of DED-deposited high-temperature alloy claddings is essential for optimizing their performance and extending component life. This involves managing cooling rates during deposition and implementing appropriate post-processing heat treatments. Techniques such as solution annealing, aging, and stress relieving help homogenize the microstructure, reduce residual stresses, and enhance mechanical properties. Surface finishing operations like grinding and polishing improve surface quality and fatigue resistance. These post-processing steps are critical for achieving the desired microstructural features that contribute to enhanced high-temperature performance and extended service life.

- Multi-layer and functionally graded cladding designs: Advanced DED techniques enable the creation of multi-layer and functionally graded claddings that provide superior performance in high-temperature applications. These designs feature compositional or microstructural gradients that transition from the substrate to the outer surface, minimizing thermal expansion mismatches and residual stresses. The gradual transition improves interfacial bonding strength and reduces the risk of delamination during thermal cycling. Outer layers can be optimized for specific environmental resistance while inner layers provide mechanical compatibility with the substrate. This approach significantly extends component life by combining the beneficial properties of different materials in a single integrated cladding system.

- In-situ monitoring and quality control systems: Advanced in-situ monitoring and quality control systems are essential for ensuring the reliability and performance of DED-deposited high-temperature alloy claddings. These systems employ sensors, cameras, and real-time data analysis to monitor critical process parameters such as melt pool temperature, dimensions, and cooling rates. Machine learning algorithms can detect anomalies and automatically adjust process parameters to maintain consistent quality. Non-destructive testing methods including ultrasonic inspection and X-ray tomography help verify the integrity of the deposited layers. These quality control measures ensure that the claddings meet the required specifications for high-temperature applications, thereby maximizing component life extension.

02 Material selection for high-temperature alloy cladding

The selection of appropriate high-temperature alloys for DED cladding is essential for life extension applications. Nickel-based superalloys, cobalt-based alloys, and specialized steel compositions are commonly used due to their excellent high-temperature strength, oxidation resistance, and thermal stability. The compatibility between the cladding material and substrate is critical to prevent thermal expansion mismatch and ensure long-term performance. These materials can be tailored with specific elements to enhance creep resistance, corrosion protection, and wear resistance in extreme operating conditions.Expand Specific Solutions03 Microstructure control and heat treatment

Controlling the microstructure of DED-deposited high-temperature alloy claddings through process parameters and post-deposition heat treatments is crucial for life extension. The rapid solidification during DED creates unique microstructures that can be further optimized through heat treatments to relieve residual stresses, homogenize the structure, and precipitate strengthening phases. Proper microstructure control enhances mechanical properties, thermal stability, and resistance to various degradation mechanisms, thereby extending the service life of clad components operating at elevated temperatures.Expand Specific Solutions04 Multi-layer and gradient cladding techniques

Multi-layer and functionally graded cladding approaches using DED technology offer enhanced performance for high-temperature applications. By depositing multiple layers with varying compositions or creating compositional gradients, these techniques can optimize surface properties while maintaining structural integrity. This approach helps mitigate thermal expansion mismatches between dissimilar materials, reduces residual stresses, and provides tailored properties at different depths from the surface. Such gradient structures are particularly beneficial for components subjected to thermal cycling and complex loading conditions.Expand Specific Solutions05 Quality control and defect mitigation strategies

Quality control methods and defect mitigation strategies are essential for ensuring the reliability and extended service life of DED high-temperature alloy claddings. In-situ monitoring systems can detect and correct process anomalies in real-time, while post-processing techniques such as hot isostatic pressing can eliminate porosity. Advanced non-destructive testing methods help verify cladding integrity and bond quality. Implementing these quality control measures minimizes the occurrence of critical defects like cracks, lack of fusion, and inclusions that could lead to premature failure under high-temperature service conditions.Expand Specific Solutions

Leading Companies and Research Institutions in DED Technology

The DED (Directed Energy Deposition) for high-temperature alloy cladding market is currently in a growth phase, with increasing adoption across aerospace, power generation, and industrial sectors. The global market size is estimated at $1.2-1.5 billion, expanding at 8-10% CAGR as industries seek cost-effective life extension solutions for critical components. Leading research institutions like Institute of Metal Research Chinese Academy of Sciences, Beijing Institute of Aeronautical Materials, and Zhejiang University are advancing fundamental research, while commercial players demonstrate varying technological maturity. Mitsubishi Power and Norsk Titanium have achieved commercial-scale implementation with proprietary RPD™ technology, while companies like Bharat Forge, Tata Steel, and Kobe Steel are developing industrial applications. The technology is transitioning from early adoption to mainstream implementation, with significant R&D investment from both academic and industrial stakeholders.

Mitsubishi Power Ltd.

Technical Solution: Mitsubishi Power has pioneered an advanced DED system specifically for high-temperature alloy cladding in power generation equipment. Their technology utilizes a multi-laser approach with adaptive power control that enables precise deposition of specialized nickel and cobalt-based superalloys onto gas turbine components. The company's proprietary process incorporates real-time thermal monitoring to maintain optimal deposition temperatures, critical for preventing defects in high-temperature alloys. Their system achieves deposition rates of 0.8-1.2 kg/hour while maintaining exceptional metallurgical bonding. Mitsubishi's approach includes specialized post-deposition heat treatment protocols that have been demonstrated to extend component life by up to 2.5 times compared to conventional repair methods. Their technology has been successfully implemented across their F-series and J-series gas turbines, with documented cases showing over 25,000 additional operating hours achieved through their high-temperature alloy cladding process.

Strengths: Extensive field validation in actual power generation environments; integrated approach combining material science, process control, and component design; proven life extension results with documented operational data. Weaknesses: System requires significant capital investment; process optimization is highly specific to particular alloy compositions and component geometries.

Norsk Titanium AS

Technical Solution: Norsk Titanium has adapted their Rapid Plasma Deposition™ (RPD™) technology for high-temperature alloy cladding applications. While primarily known for titanium components, their plasma-arc based DED system has been modified to work with nickel and iron-based superalloys for cladding applications. Their process utilizes a controlled plasma arc that achieves deposition rates up to 5-10 kg/hour, significantly faster than laser-based alternatives. Norsk's technology incorporates sophisticated atmospheric control systems that maintain oxygen levels below 10 ppm during deposition, critical for reactive elements in high-temperature alloys. Their process has demonstrated the ability to create gradient material transitions that reduce thermal expansion mismatches between substrate and cladding. The company has conducted extensive testing showing their high-temperature alloy claddings maintain mechanical properties at temperatures up to 950°C with minimal degradation. Their technology includes proprietary process monitoring that uses thermal imaging to ensure consistent layer formation and detect potential defects in real-time.

Strengths: Exceptionally high deposition rates compared to other DED technologies; strong expertise in atmospheric control critical for reactive elements; ability to create functionally graded materials for thermal management. Weaknesses: Less precision than laser-based systems for fine features; higher energy consumption; technology originally optimized for titanium requires adaptation for high-temperature alloys.

Critical Patents and Research in High-Temperature Alloy Cladding

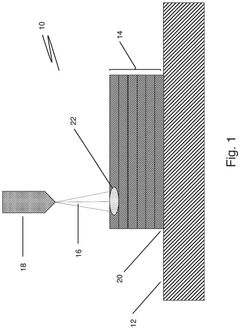

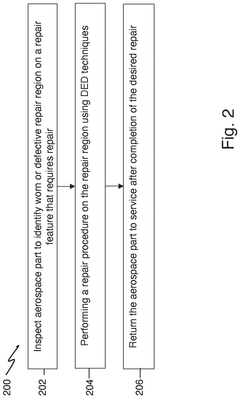

Engineered residual stress state for enhanced performance during directed energy deposition repair process

PatentPendingEP4599978A1

Innovation

- A directed energy deposition (DED) process is used to create layers with pre-determined residual stress states by controlling parameters like powder feed rate, energy intensity, traversal speed, and auxiliary heating/cooling, enabling controlled residual stress management during the repair process.

Engineered microstructure for enhanced performance during directed energy deposition repair process

PatentPendingEP4599977A1

Innovation

- A directed energy deposition (DED) process is used to create layers with controlled microstructures by adjusting parameters like powder feed rate, energy intensity, traversal rate, and auxiliary heating/cooling to form repair layers with predetermined properties, enabling repair of components that were previously unrepairable.

Material Compatibility and Microstructural Analysis

Material compatibility represents a critical factor in the successful implementation of Directed Energy Deposition (DED) for high-temperature alloy cladding applications. The interaction between substrate materials and cladding alloys significantly influences the microstructural development, which in turn determines the mechanical properties and service life of the component. Recent studies have demonstrated that substrate-cladding combinations must be carefully selected to minimize thermal expansion mismatches and prevent the formation of detrimental intermetallic phases at the interface.

Microstructural analysis of DED-processed high-temperature alloy claddings reveals distinctive features that differ from conventionally manufactured components. The rapid solidification rates inherent to DED processes (typically 103-106 K/s) result in refined grain structures with unique morphologies. These include columnar dendritic structures growing epitaxially from the substrate, cellular substructures, and in some cases, metastable phases not observed in equilibrium conditions. Such microstructural characteristics directly impact wear resistance, fatigue performance, and high-temperature stability.

Advanced characterization techniques including Electron Backscatter Diffraction (EBSD), Transmission Electron Microscopy (TEM), and Atom Probe Tomography (APT) have enabled researchers to identify critical microstructural features at the substrate-cladding interface. These investigations have revealed the presence of precipitation-strengthened zones, localized elemental segregation, and orientation relationships between substrate and cladding crystals that influence mechanical integrity during thermal cycling.

The heat-affected zone (HAZ) between substrate and cladding represents a region of particular concern, as microstructural transformations in this area can lead to localized property degradation. Studies on nickel-based superalloys cladded onto steel substrates have shown that controlling the thermal history during deposition is essential for managing the extent and characteristics of the HAZ. Optimization of process parameters such as laser power, scan speed, and layer thickness has proven effective in minimizing detrimental microstructural features while promoting beneficial ones.

Post-deposition heat treatments have emerged as a valuable approach for homogenizing microstructures and relieving residual stresses in DED-processed components. Research indicates that carefully designed heat treatment protocols can dissolve undesirable precipitates, promote the formation of strengthening phases, and enhance the overall microstructural stability. For instance, solution treatment followed by controlled aging has been shown to optimize the distribution of γ' precipitates in nickel-based superalloy claddings, significantly extending component service life under high-temperature operating conditions.

Microstructural analysis of DED-processed high-temperature alloy claddings reveals distinctive features that differ from conventionally manufactured components. The rapid solidification rates inherent to DED processes (typically 103-106 K/s) result in refined grain structures with unique morphologies. These include columnar dendritic structures growing epitaxially from the substrate, cellular substructures, and in some cases, metastable phases not observed in equilibrium conditions. Such microstructural characteristics directly impact wear resistance, fatigue performance, and high-temperature stability.

Advanced characterization techniques including Electron Backscatter Diffraction (EBSD), Transmission Electron Microscopy (TEM), and Atom Probe Tomography (APT) have enabled researchers to identify critical microstructural features at the substrate-cladding interface. These investigations have revealed the presence of precipitation-strengthened zones, localized elemental segregation, and orientation relationships between substrate and cladding crystals that influence mechanical integrity during thermal cycling.

The heat-affected zone (HAZ) between substrate and cladding represents a region of particular concern, as microstructural transformations in this area can lead to localized property degradation. Studies on nickel-based superalloys cladded onto steel substrates have shown that controlling the thermal history during deposition is essential for managing the extent and characteristics of the HAZ. Optimization of process parameters such as laser power, scan speed, and layer thickness has proven effective in minimizing detrimental microstructural features while promoting beneficial ones.

Post-deposition heat treatments have emerged as a valuable approach for homogenizing microstructures and relieving residual stresses in DED-processed components. Research indicates that carefully designed heat treatment protocols can dissolve undesirable precipitates, promote the formation of strengthening phases, and enhance the overall microstructural stability. For instance, solution treatment followed by controlled aging has been shown to optimize the distribution of γ' precipitates in nickel-based superalloy claddings, significantly extending component service life under high-temperature operating conditions.

Sustainability and Cost-Benefit Assessment of DED Life Extension

The sustainability of Directed Energy Deposition (DED) for high-temperature alloy cladding in life extension applications represents a critical consideration for industries seeking to balance economic viability with environmental responsibility. When evaluating the sustainability profile of DED-based life extension strategies, several key environmental metrics demonstrate significant advantages over traditional component replacement approaches.

Life cycle assessment (LCA) studies indicate that DED repair and refurbishment processes can reduce carbon footprint by 60-85% compared to manufacturing new components, primarily due to substantial reductions in raw material consumption. This material efficiency translates directly to conservation of critical elements such as nickel, cobalt, and chromium that are essential in high-temperature alloys but face increasing supply constraints and extraction-related environmental impacts.

Energy consumption analysis reveals that DED processes typically require 30-50% less energy than conventional manufacturing when considering the complete production cycle. The localized nature of material deposition minimizes waste generation, with material utilization rates exceeding 90% in optimized DED systems compared to 60-70% in traditional manufacturing processes.

From a cost-benefit perspective, DED-based life extension demonstrates compelling economic advantages. Initial implementation costs for DED systems range from $500,000 to $2 million depending on scale and capabilities, representing a significant capital investment. However, return on investment calculations indicate payback periods of 1.5-3 years for organizations regularly maintaining high-value components.

Component-specific cost analyses show that DED repair of high-temperature alloy components typically costs 30-60% of replacement value, with greater savings realized for geometrically complex parts or those containing expensive alloying elements. For power generation turbine components, this can translate to savings of $50,000-200,000 per component, with additional value derived from reduced downtime.

Long-term financial modeling demonstrates that organizations implementing systematic DED-based life extension programs can achieve 15-25% reduction in maintenance budgets over a 10-year operational period. These savings compound when considering the avoided costs of unplanned outages and emergency replacements, which can exceed $100,000 per day in critical industrial applications.

The sustainability equation is further enhanced by the potential for DED to enable circular economy principles, where components undergo multiple repair-reuse cycles. Advanced high-temperature alloy components can potentially experience 2-4 repair cycles before retirement, effectively doubling or tripling functional lifespan and distributing initial manufacturing impacts across an extended service period.

Life cycle assessment (LCA) studies indicate that DED repair and refurbishment processes can reduce carbon footprint by 60-85% compared to manufacturing new components, primarily due to substantial reductions in raw material consumption. This material efficiency translates directly to conservation of critical elements such as nickel, cobalt, and chromium that are essential in high-temperature alloys but face increasing supply constraints and extraction-related environmental impacts.

Energy consumption analysis reveals that DED processes typically require 30-50% less energy than conventional manufacturing when considering the complete production cycle. The localized nature of material deposition minimizes waste generation, with material utilization rates exceeding 90% in optimized DED systems compared to 60-70% in traditional manufacturing processes.

From a cost-benefit perspective, DED-based life extension demonstrates compelling economic advantages. Initial implementation costs for DED systems range from $500,000 to $2 million depending on scale and capabilities, representing a significant capital investment. However, return on investment calculations indicate payback periods of 1.5-3 years for organizations regularly maintaining high-value components.

Component-specific cost analyses show that DED repair of high-temperature alloy components typically costs 30-60% of replacement value, with greater savings realized for geometrically complex parts or those containing expensive alloying elements. For power generation turbine components, this can translate to savings of $50,000-200,000 per component, with additional value derived from reduced downtime.

Long-term financial modeling demonstrates that organizations implementing systematic DED-based life extension programs can achieve 15-25% reduction in maintenance budgets over a 10-year operational period. These savings compound when considering the avoided costs of unplanned outages and emergency replacements, which can exceed $100,000 per day in critical industrial applications.

The sustainability equation is further enhanced by the potential for DED to enable circular economy principles, where components undergo multiple repair-reuse cycles. Advanced high-temperature alloy components can potentially experience 2-4 repair cycles before retirement, effectively doubling or tripling functional lifespan and distributing initial manufacturing impacts across an extended service period.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!