Interlayer Cooling Strategies To Control Thermal Gradients In DED

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Thermal Management Background and Objectives

Directed Energy Deposition (DED) has emerged as a transformative additive manufacturing technology capable of producing complex metal components with superior mechanical properties. The evolution of DED technology spans several decades, originating from early laser cladding techniques in the 1980s and progressively advancing to today's sophisticated multi-axis deposition systems. This technological progression has been driven by increasing demands for more efficient manufacturing processes in aerospace, defense, and medical industries where complex geometries and high-performance materials are essential.

The thermal management aspect of DED represents one of the most critical challenges in the technology's implementation. During the DED process, localized heating from high-energy sources creates steep thermal gradients that significantly impact material microstructure, residual stress distribution, and ultimately part quality. Historical approaches to thermal management have primarily focused on process parameter optimization rather than active thermal control strategies, resulting in limitations to build size, material selection, and achievable properties.

Recent technological trends indicate a shift toward more sophisticated thermal management techniques, particularly interlayer cooling strategies. These approaches aim to control the thermal history of parts during fabrication by manipulating heat transfer between deposited layers. The evolution of these cooling strategies has progressed from simple dwell times between layers to advanced techniques involving forced convection, cryogenic cooling, and selective thermal management systems.

The primary objective of interlayer cooling research is to establish precise control over thermal gradients during the DED process. This control would enable manufacturers to achieve consistent microstructural properties throughout complex geometries, minimize residual stresses, reduce distortion, and ultimately expand the range of materials suitable for DED processing. Additionally, effective thermal management promises to increase deposition rates without sacrificing part quality, thereby enhancing the economic viability of DED for industrial applications.

Current research goals include developing predictive thermal models that can accurately simulate heat transfer during interlayer cooling, designing adaptive cooling systems that respond to real-time thermal measurements, and establishing standardized methodologies for implementing cooling strategies across different material systems. The ultimate technological objective is to create an integrated thermal management approach that combines in-situ monitoring, predictive modeling, and responsive cooling systems to maintain optimal thermal conditions throughout the build process.

As DED technology continues to mature, thermal gradient control through interlayer cooling represents a critical frontier that will determine the technology's broader industrial adoption and application scope. Success in this domain would significantly expand DED capabilities, enabling larger, more complex parts with superior mechanical properties and dimensional accuracy.

The thermal management aspect of DED represents one of the most critical challenges in the technology's implementation. During the DED process, localized heating from high-energy sources creates steep thermal gradients that significantly impact material microstructure, residual stress distribution, and ultimately part quality. Historical approaches to thermal management have primarily focused on process parameter optimization rather than active thermal control strategies, resulting in limitations to build size, material selection, and achievable properties.

Recent technological trends indicate a shift toward more sophisticated thermal management techniques, particularly interlayer cooling strategies. These approaches aim to control the thermal history of parts during fabrication by manipulating heat transfer between deposited layers. The evolution of these cooling strategies has progressed from simple dwell times between layers to advanced techniques involving forced convection, cryogenic cooling, and selective thermal management systems.

The primary objective of interlayer cooling research is to establish precise control over thermal gradients during the DED process. This control would enable manufacturers to achieve consistent microstructural properties throughout complex geometries, minimize residual stresses, reduce distortion, and ultimately expand the range of materials suitable for DED processing. Additionally, effective thermal management promises to increase deposition rates without sacrificing part quality, thereby enhancing the economic viability of DED for industrial applications.

Current research goals include developing predictive thermal models that can accurately simulate heat transfer during interlayer cooling, designing adaptive cooling systems that respond to real-time thermal measurements, and establishing standardized methodologies for implementing cooling strategies across different material systems. The ultimate technological objective is to create an integrated thermal management approach that combines in-situ monitoring, predictive modeling, and responsive cooling systems to maintain optimal thermal conditions throughout the build process.

As DED technology continues to mature, thermal gradient control through interlayer cooling represents a critical frontier that will determine the technology's broader industrial adoption and application scope. Success in this domain would significantly expand DED capabilities, enabling larger, more complex parts with superior mechanical properties and dimensional accuracy.

Market Analysis for Advanced DED Cooling Solutions

The global market for advanced cooling solutions in Directed Energy Deposition (DED) manufacturing is experiencing significant growth, driven by increasing adoption of metal additive manufacturing across aerospace, automotive, and medical industries. Current market valuations indicate that the metal additive manufacturing sector is expanding at a compound annual growth rate of approximately 27%, with DED technologies representing a crucial segment within this market.

The demand for interlayer cooling strategies is particularly pronounced in high-value manufacturing sectors where thermal gradient control directly impacts part quality, dimensional accuracy, and material properties. Aerospace manufacturers, who require components with exceptional mechanical properties and minimal residual stress, constitute the largest market segment, accounting for nearly 40% of the demand for advanced DED cooling solutions.

Regional market analysis reveals that North America currently leads in adoption of advanced thermal management systems for DED, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is demonstrating the fastest growth rate as countries like China, Japan, and South Korea rapidly expand their advanced manufacturing capabilities.

Customer segmentation shows three distinct market tiers: high-end users requiring premium cooling solutions for critical applications; mid-market manufacturers seeking balanced cost-performance solutions; and emerging users who prioritize accessibility and ease of implementation. The high-end segment, while smaller in volume, represents over 60% of market value due to willingness to invest in premium thermal management technologies.

Market drivers include increasing demand for complex geometries in metal components, growing emphasis on reducing post-processing requirements, and rising awareness of how thermal management affects overall part quality. Regulatory trends toward manufacturing sustainability also favor technologies that optimize material usage through precise thermal control.

Competitive landscape analysis identifies several key players developing proprietary cooling technologies, including established equipment manufacturers and specialized startups focused exclusively on thermal management innovations. Current pricing models range from integrated cooling systems commanding premium prices to modular solutions offering more accessible entry points.

Market forecasts suggest that demand for advanced interlayer cooling strategies will continue to accelerate as DED adoption expands into new industrial applications. The most substantial growth is anticipated in solutions that offer real-time adaptive cooling based on thermal sensing and predictive algorithms, reflecting the industry's movement toward more intelligent manufacturing systems.

The demand for interlayer cooling strategies is particularly pronounced in high-value manufacturing sectors where thermal gradient control directly impacts part quality, dimensional accuracy, and material properties. Aerospace manufacturers, who require components with exceptional mechanical properties and minimal residual stress, constitute the largest market segment, accounting for nearly 40% of the demand for advanced DED cooling solutions.

Regional market analysis reveals that North America currently leads in adoption of advanced thermal management systems for DED, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is demonstrating the fastest growth rate as countries like China, Japan, and South Korea rapidly expand their advanced manufacturing capabilities.

Customer segmentation shows three distinct market tiers: high-end users requiring premium cooling solutions for critical applications; mid-market manufacturers seeking balanced cost-performance solutions; and emerging users who prioritize accessibility and ease of implementation. The high-end segment, while smaller in volume, represents over 60% of market value due to willingness to invest in premium thermal management technologies.

Market drivers include increasing demand for complex geometries in metal components, growing emphasis on reducing post-processing requirements, and rising awareness of how thermal management affects overall part quality. Regulatory trends toward manufacturing sustainability also favor technologies that optimize material usage through precise thermal control.

Competitive landscape analysis identifies several key players developing proprietary cooling technologies, including established equipment manufacturers and specialized startups focused exclusively on thermal management innovations. Current pricing models range from integrated cooling systems commanding premium prices to modular solutions offering more accessible entry points.

Market forecasts suggest that demand for advanced interlayer cooling strategies will continue to accelerate as DED adoption expands into new industrial applications. The most substantial growth is anticipated in solutions that offer real-time adaptive cooling based on thermal sensing and predictive algorithms, reflecting the industry's movement toward more intelligent manufacturing systems.

Current Interlayer Cooling Technologies and Challenges

Directed Energy Deposition (DED) processes are characterized by high thermal gradients that significantly impact material properties and part quality. Current interlayer cooling technologies aim to manage these thermal conditions but face numerous challenges in implementation and effectiveness.

Active cooling methods represent the most direct approach to thermal gradient control in DED. Forced air cooling systems utilize compressed air jets directed at the deposition area, offering simplicity and cost-effectiveness but limited cooling capacity for high-energy processes. Cryogenic cooling employs liquid nitrogen or CO2 to rapidly extract heat, achieving dramatic temperature reductions but requiring complex delivery systems and raising concerns about material embrittlement from excessive cooling rates.

Water-based cooling solutions provide an intermediate option with substantial heat extraction capabilities through mist cooling or closed-loop water circulation systems. These methods offer good thermal control but introduce complexity regarding water containment and potential part contamination, particularly in metal-based DED processes where oxidation is a concern.

Passive cooling strategies focus on controlled interruptions in the build process. Dwell time insertion between layers allows natural cooling through radiation and convection, requiring no additional equipment but significantly extending build times. Adaptive layer sequencing techniques strategically alternate deposition locations to maximize cooling time for previously deposited regions, optimizing thermal management without additional hardware but demanding sophisticated path planning algorithms.

The primary challenges in current interlayer cooling technologies center around process integration and control precision. Most cooling systems require retrofitting existing DED equipment, creating compatibility issues and workspace constraints. Real-time temperature monitoring remains difficult, with infrared thermography and embedded thermocouples providing only partial solutions due to accessibility limitations and response time delays.

Energy efficiency presents another significant challenge, as active cooling systems substantially increase the overall energy consumption of DED processes, contradicting sustainability goals in advanced manufacturing. Material-specific cooling requirements further complicate implementation, as optimal cooling rates vary dramatically between different alloys and composites, necessitating adaptive cooling strategies.

Scale-up challenges emerge when transitioning from laboratory demonstrations to production environments, where cooling uniformity becomes increasingly difficult to maintain across larger build volumes. Additionally, the lack of standardized approaches to thermal management in DED processes hampers widespread adoption, with most solutions remaining proprietary or highly customized to specific equipment configurations.

Active cooling methods represent the most direct approach to thermal gradient control in DED. Forced air cooling systems utilize compressed air jets directed at the deposition area, offering simplicity and cost-effectiveness but limited cooling capacity for high-energy processes. Cryogenic cooling employs liquid nitrogen or CO2 to rapidly extract heat, achieving dramatic temperature reductions but requiring complex delivery systems and raising concerns about material embrittlement from excessive cooling rates.

Water-based cooling solutions provide an intermediate option with substantial heat extraction capabilities through mist cooling or closed-loop water circulation systems. These methods offer good thermal control but introduce complexity regarding water containment and potential part contamination, particularly in metal-based DED processes where oxidation is a concern.

Passive cooling strategies focus on controlled interruptions in the build process. Dwell time insertion between layers allows natural cooling through radiation and convection, requiring no additional equipment but significantly extending build times. Adaptive layer sequencing techniques strategically alternate deposition locations to maximize cooling time for previously deposited regions, optimizing thermal management without additional hardware but demanding sophisticated path planning algorithms.

The primary challenges in current interlayer cooling technologies center around process integration and control precision. Most cooling systems require retrofitting existing DED equipment, creating compatibility issues and workspace constraints. Real-time temperature monitoring remains difficult, with infrared thermography and embedded thermocouples providing only partial solutions due to accessibility limitations and response time delays.

Energy efficiency presents another significant challenge, as active cooling systems substantially increase the overall energy consumption of DED processes, contradicting sustainability goals in advanced manufacturing. Material-specific cooling requirements further complicate implementation, as optimal cooling rates vary dramatically between different alloys and composites, necessitating adaptive cooling strategies.

Scale-up challenges emerge when transitioning from laboratory demonstrations to production environments, where cooling uniformity becomes increasingly difficult to maintain across larger build volumes. Additionally, the lack of standardized approaches to thermal management in DED processes hampers widespread adoption, with most solutions remaining proprietary or highly customized to specific equipment configurations.

Existing Interlayer Cooling Implementation Methods

01 Interlayer cooling channels and fluid flow systems

Implementing cooling channels between layers of electronic or structural components allows for efficient heat dissipation. These channels facilitate the flow of cooling fluids (liquid or gas) that absorb and transport heat away from critical areas. The strategic placement and design of these channels help maintain optimal operating temperatures and reduce thermal gradients across the structure, preventing thermal stress and potential failures.- Liquid cooling systems for interlayer thermal management: Liquid cooling systems are effective for managing thermal gradients between layers in electronic devices. These systems utilize coolant circulation through channels or microchannels positioned between layers to absorb and dissipate heat. The liquid coolants provide superior heat transfer capabilities compared to air cooling, allowing for more efficient temperature control and reduction of thermal gradients across different layers of integrated circuits or other multilayered structures.

- Heat sink designs for interlayer cooling: Specialized heat sink designs can be implemented between layers to manage thermal gradients. These designs include thermally conductive materials with optimized geometries to maximize heat dissipation. Some approaches incorporate finned structures, thermal vias, or composite materials that efficiently conduct heat away from critical components. Advanced heat sink designs can be customized to address specific thermal hotspots and create more uniform temperature distributions across different layers.

- Thermal interface materials for gradient reduction: Thermal interface materials (TIMs) play a crucial role in reducing thermal gradients between layers. These materials fill microscopic air gaps between surfaces to enhance thermal conductivity across layer boundaries. Advanced TIMs include phase-change materials, thermal greases, adhesives, and graphene-based compounds that can be strategically placed to manage heat flow paths. The selection of appropriate thermal interface materials depends on the specific thermal requirements and physical constraints of the multilayer structure.

- Active cooling control systems for thermal gradient management: Active cooling control systems utilize sensors and feedback mechanisms to dynamically adjust cooling parameters based on real-time temperature measurements. These systems can include variable-speed pumps, adjustable flow valves, or thermoelectric coolers that respond to changing thermal conditions. By continuously monitoring temperature differentials between layers and adjusting cooling intensity accordingly, these systems can maintain optimal operating temperatures and minimize thermal gradients even under varying workloads.

- Thermal vias and conductive pathways for interlayer heat transfer: Thermal vias and specialized conductive pathways can be integrated into multilayer structures to facilitate heat transfer between layers. These vertical thermal conduits are typically made of highly conductive materials like copper or silver and can be strategically placed to address hotspots. Some designs incorporate arrays of micro-vias or continuous metal pillars that create direct thermal paths through insulating layers. This approach helps equalize temperatures across different layers and reduces thermal gradients without requiring active cooling components.

02 Thermal interface materials and heat spreading layers

Specialized thermal interface materials and heat spreading layers can be incorporated between component layers to improve thermal conductivity and manage heat distribution. These materials, which may include metal foils, thermal greases, or advanced composites, help to minimize contact resistance and facilitate efficient heat transfer across interfaces. By promoting uniform heat distribution, these materials reduce localized hot spots and thermal gradients in multilayer structures.Expand Specific Solutions03 Active cooling systems with temperature monitoring

Active cooling systems equipped with temperature sensors and feedback control mechanisms can dynamically adjust cooling intensity based on real-time thermal conditions. These systems monitor temperature gradients across different layers and activate appropriate cooling responses to maintain optimal thermal profiles. The integration of intelligent control algorithms allows for predictive cooling adjustments, preventing the formation of harmful thermal gradients before they develop.Expand Specific Solutions04 Microfluidic cooling networks for precise thermal management

Microfluidic cooling networks embedded between layers provide highly targeted thermal management capabilities. These networks consist of precisely engineered microscale channels that deliver cooling fluid directly to heat-generating components. The small scale of these channels allows for intricate routing and placement, enabling thermal management solutions that conform to complex geometries and address specific hot spots, resulting in more uniform temperature distributions across layers.Expand Specific Solutions05 Phase-change materials for thermal buffering

Phase-change materials (PCMs) incorporated between layers can absorb and release thermal energy during their phase transition, providing effective thermal buffering. These materials absorb excess heat during peak thermal loads and release it when temperatures decrease, helping to maintain more consistent temperatures across the structure. This passive thermal management approach reduces temperature fluctuations and gradients without requiring active cooling systems, making it energy-efficient and reliable for many applications.Expand Specific Solutions

Leading Companies in DED Thermal Management

The Directed Energy Deposition (DED) interlayer cooling technology market is currently in its growth phase, with increasing adoption across aerospace, automotive, and industrial manufacturing sectors. The global market size for thermal management in additive manufacturing is projected to reach approximately $2.5 billion by 2027, driven by demand for high-precision metal components. Technologically, interlayer cooling strategies are advancing rapidly, with RTX Corp. and Norsk Titanium leading commercial implementation in aerospace applications. Research institutions like Fraunhofer-Gesellschaft, Northwestern University, and Zhejiang University are developing next-generation cooling methodologies, while industrial players including Mitsubishi Hitachi Power Systems and NIPPON STEEL are focusing on thermal gradient control for large-scale metal components. The technology is approaching maturity for specialized applications but continues to evolve for broader manufacturing implementation.

RTX Corp.

Technical Solution: RTX Corporation (formerly Raytheon Technologies) has developed an advanced interlayer cooling strategy for DED processes called "CoolDep" specifically designed for aerospace applications requiring tight thermal control. Their approach utilizes a hybrid cooling system that combines active substrate cooling through an internal network of precision-engineered microchannels with localized forced convection using directed inert gas flows. A key innovation is their pulsed cooling technology that synchronizes cooling intensity with the deposition pattern to maintain consistent interlayer temperatures. The system incorporates multiple thermal sensors embedded throughout the build volume that feed into their proprietary adaptive control algorithm, which can predict and compensate for thermal accumulation in real-time. RTX has demonstrated this technology in the production of high-performance turbine components, achieving up to 40% reduction in build time while maintaining superior microstructural properties through precise thermal gradient control.

Strengths: Exceptional thermal control for high-precision aerospace components; seamless integration with existing manufacturing systems; comprehensive quality assurance through extensive thermal data collection. Weaknesses: Proprietary system with limited accessibility outside RTX supply chain; optimized primarily for nickel-based superalloys; significant initial investment required for implementation.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed a comprehensive interlayer cooling system for DED processes called "ThermoControl DED" that addresses thermal gradient challenges through multiple coordinated approaches. Their system combines localized forced convection cooling using precisely directed compressed air or inert gas jets with strategic dwell times between layers determined by thermal modeling. A distinguishing feature is their segmented substrate cooling system with independently controlled thermal zones that can create tailored thermal conditions across different regions of the build. This is enhanced by their proprietary thermal imaging and control software that provides real-time feedback to modulate cooling intensity. The system has demonstrated the ability to reduce thermal gradients by up to 70% in complex geometries while maintaining build quality. Fraunhofer's approach also incorporates path planning optimization that considers thermal history to determine ideal deposition sequences that minimize heat accumulation.

Strengths: Highly customizable cooling parameters for different materials and geometries; excellent integration with existing DED systems; comprehensive thermal monitoring and control. Weaknesses: Complex setup requiring significant process parameter development; higher initial implementation costs; requires substantial computational resources for real-time thermal modeling.

Critical Patents in DED Thermal Gradient Control

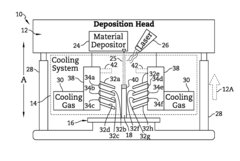

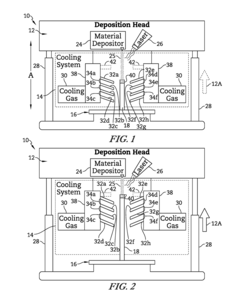

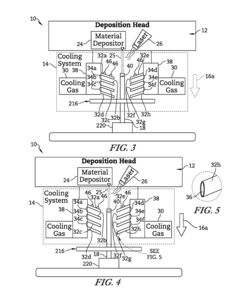

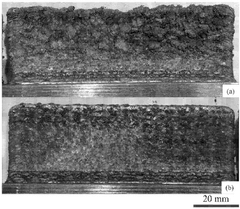

Directed energy deposition with cooling mechanism

PatentActiveUS9988718B2

Innovation

- A material deposition system comprising a platform, a deposition head with a material depositor and an energy source, and a cooling mechanism with conductive bristles that direct a cooling medium to maintain a controlled temperature profile, ensuring consistent cooling and bonding of materials during the deposition process.

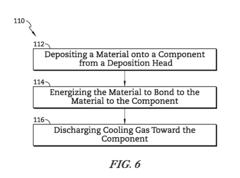

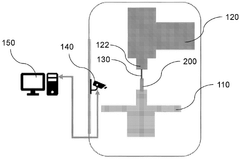

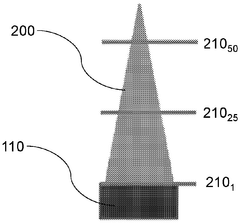

Directed energy deposition apparatus and method

PatentWO2024242628A1

Innovation

- A method and apparatus that incorporate a temperature-based cooling time feedback loop, where each layer is cooled to a predefined temperature before adding the next, using a thermal device to measure and control the cooling process, thereby minimizing overheating and oxidation.

Material Science Implications for Interlayer Cooling

The material science implications of interlayer cooling in Directed Energy Deposition (DED) processes are profound and multifaceted. When thermal gradients are controlled through strategic cooling between layers, the microstructural development of the deposited material undergoes significant alterations. Primarily, controlled cooling rates influence grain size, morphology, and orientation, which directly impact the mechanical properties of the final component.

Rapid cooling typically promotes the formation of finer grain structures, enhancing strength and hardness but potentially reducing ductility. Conversely, slower cooling rates facilitate larger grain growth, which may improve fracture toughness while sacrificing some strength. The ability to manipulate these microstructural characteristics through interlayer cooling strategies provides unprecedented control over material performance tailored to specific applications.

Phase transformation kinetics are equally affected by cooling strategies. In materials susceptible to multiple phase formations, such as titanium alloys or tool steels, the cooling rate determines which phases predominate in the final structure. For instance, in Ti-6Al-4V, rapid cooling promotes the formation of martensitic α' phase, while controlled slower cooling allows for the development of the preferred α+β microstructure with improved mechanical balance.

Residual stress development, a critical concern in additive manufacturing, is directly influenced by thermal management between layers. Excessive thermal gradients generate high residual stresses that can lead to distortion, cracking, or premature failure. Interlayer cooling strategies that homogenize temperature distribution throughout the build minimize these detrimental effects, resulting in components with enhanced structural integrity and dimensional accuracy.

The precipitation behavior of secondary phases and intermetallic compounds is another material science aspect governed by cooling rates. Controlled cooling can be leveraged to either promote or suppress precipitation phenomena, depending on the desired material properties. This becomes particularly relevant in precipitation-hardenable alloys where strength is derived from the controlled formation of fine precipitates.

Furthermore, texture development—the preferred crystallographic orientation of grains—is significantly influenced by thermal history during deposition. Interlayer cooling strategies can be designed to promote specific textures that enhance directional properties, such as creep resistance or fatigue performance, particularly valuable in high-performance applications like aerospace components or power generation equipment.

Rapid cooling typically promotes the formation of finer grain structures, enhancing strength and hardness but potentially reducing ductility. Conversely, slower cooling rates facilitate larger grain growth, which may improve fracture toughness while sacrificing some strength. The ability to manipulate these microstructural characteristics through interlayer cooling strategies provides unprecedented control over material performance tailored to specific applications.

Phase transformation kinetics are equally affected by cooling strategies. In materials susceptible to multiple phase formations, such as titanium alloys or tool steels, the cooling rate determines which phases predominate in the final structure. For instance, in Ti-6Al-4V, rapid cooling promotes the formation of martensitic α' phase, while controlled slower cooling allows for the development of the preferred α+β microstructure with improved mechanical balance.

Residual stress development, a critical concern in additive manufacturing, is directly influenced by thermal management between layers. Excessive thermal gradients generate high residual stresses that can lead to distortion, cracking, or premature failure. Interlayer cooling strategies that homogenize temperature distribution throughout the build minimize these detrimental effects, resulting in components with enhanced structural integrity and dimensional accuracy.

The precipitation behavior of secondary phases and intermetallic compounds is another material science aspect governed by cooling rates. Controlled cooling can be leveraged to either promote or suppress precipitation phenomena, depending on the desired material properties. This becomes particularly relevant in precipitation-hardenable alloys where strength is derived from the controlled formation of fine precipitates.

Furthermore, texture development—the preferred crystallographic orientation of grains—is significantly influenced by thermal history during deposition. Interlayer cooling strategies can be designed to promote specific textures that enhance directional properties, such as creep resistance or fatigue performance, particularly valuable in high-performance applications like aerospace components or power generation equipment.

Energy Efficiency in DED Cooling Systems

Energy efficiency in DED cooling systems represents a critical aspect of sustainable manufacturing practices in the additive manufacturing industry. Current interlayer cooling strategies often consume significant amounts of energy, particularly when utilizing forced air or cryogenic cooling methods. The energy consumption patterns vary widely depending on the cooling technique employed, with traditional flood cooling systems requiring substantial power for coolant pumping and filtration.

Advanced cooling systems are increasingly incorporating energy recovery mechanisms to capture and reuse thermal energy generated during the DED process. These systems utilize heat exchangers to transfer excess heat from the coolant to other manufacturing processes or facility heating systems, creating a more integrated energy ecosystem within the production environment.

Intelligent cooling control algorithms have demonstrated energy savings of 15-30% compared to conventional constant-flow cooling approaches. These systems dynamically adjust cooling intensity based on real-time thermal monitoring, ensuring optimal energy utilization while maintaining effective thermal gradient control. The implementation of variable-speed pumps and fans further enhances energy efficiency by matching cooling capacity to actual process requirements.

Passive cooling strategies, though less effective for high-power DED applications, offer significant energy advantages in appropriate scenarios. Techniques such as optimized build plate design with integrated heat sinks or thermally conductive pathways can reduce the need for active cooling in certain regions of the build, thereby decreasing overall energy consumption without compromising thermal management.

Recent research indicates that hybrid cooling approaches combining minimal active cooling with strategic thermal path design can achieve comparable thermal gradient control with up to 40% less energy consumption. These systems typically integrate thermal simulation models to predict heat accumulation and strategically deploy cooling resources only where and when necessary.

The energy efficiency of cooling systems also significantly impacts the overall carbon footprint of DED manufacturing. Life cycle assessments reveal that cooling energy can represent 15-25% of the total energy consumption in DED processes, highlighting the importance of efficiency improvements in this area. Manufacturers are increasingly adopting energy-efficient cooling technologies not only for cost savings but also to meet sustainability targets and regulatory requirements.

Future developments in energy-efficient cooling for DED are focusing on closed-loop systems with minimal external energy inputs, potentially leveraging the thermal energy generated during the process itself to power aspects of the cooling system. This circular approach to energy management represents the next frontier in sustainable additive manufacturing practices.

Advanced cooling systems are increasingly incorporating energy recovery mechanisms to capture and reuse thermal energy generated during the DED process. These systems utilize heat exchangers to transfer excess heat from the coolant to other manufacturing processes or facility heating systems, creating a more integrated energy ecosystem within the production environment.

Intelligent cooling control algorithms have demonstrated energy savings of 15-30% compared to conventional constant-flow cooling approaches. These systems dynamically adjust cooling intensity based on real-time thermal monitoring, ensuring optimal energy utilization while maintaining effective thermal gradient control. The implementation of variable-speed pumps and fans further enhances energy efficiency by matching cooling capacity to actual process requirements.

Passive cooling strategies, though less effective for high-power DED applications, offer significant energy advantages in appropriate scenarios. Techniques such as optimized build plate design with integrated heat sinks or thermally conductive pathways can reduce the need for active cooling in certain regions of the build, thereby decreasing overall energy consumption without compromising thermal management.

Recent research indicates that hybrid cooling approaches combining minimal active cooling with strategic thermal path design can achieve comparable thermal gradient control with up to 40% less energy consumption. These systems typically integrate thermal simulation models to predict heat accumulation and strategically deploy cooling resources only where and when necessary.

The energy efficiency of cooling systems also significantly impacts the overall carbon footprint of DED manufacturing. Life cycle assessments reveal that cooling energy can represent 15-25% of the total energy consumption in DED processes, highlighting the importance of efficiency improvements in this area. Manufacturers are increasingly adopting energy-efficient cooling technologies not only for cost savings but also to meet sustainability targets and regulatory requirements.

Future developments in energy-efficient cooling for DED are focusing on closed-loop systems with minimal external energy inputs, potentially leveraging the thermal energy generated during the process itself to power aspects of the cooling system. This circular approach to energy management represents the next frontier in sustainable additive manufacturing practices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!