Microstructure Evolution During DED: Grain Structure Control

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Microstructure Evolution Background and Objectives

Directed Energy Deposition (DED) has emerged as a transformative additive manufacturing technology over the past three decades, evolving from its origins in laser cladding to a sophisticated process capable of producing complex metallic components. The technology's development trajectory has been characterized by significant advancements in process control, material compatibility, and microstructural engineering. Initially focused on repair applications, DED has expanded into a versatile manufacturing method for aerospace, defense, medical, and energy sectors due to its ability to create fully dense parts with excellent mechanical properties.

The microstructural evolution during DED represents a critical aspect of the technology's capabilities and limitations. The process involves complex thermal cycles where material undergoes rapid heating, melting, and solidification, creating unique microstructural features that directly influence mechanical properties. Historical developments in DED have progressively shifted from merely achieving geometric accuracy to precisely controlling the internal microstructure of fabricated components.

Recent technological trends indicate a growing emphasis on in-situ monitoring and real-time control of microstructural development during deposition. This evolution has been driven by increasing demands for components with tailored mechanical properties, particularly in high-performance applications where specific grain structures are required to withstand extreme operating conditions.

The primary technical objective of microstructural control in DED focuses on achieving predictable and repeatable grain structures across complex geometries. This includes the ability to manipulate grain size, orientation, and morphology to enhance specific mechanical properties such as strength, ductility, creep resistance, and fatigue performance. Additionally, controlling texture development and minimizing defects such as porosity and cracking represent critical goals in advancing DED technology.

Another significant objective involves developing comprehensive process-structure-property relationships that enable precise prediction of microstructural outcomes based on processing parameters. This includes understanding the influence of laser power, scan speed, powder feed rate, and build strategy on solidification dynamics and subsequent grain evolution.

The ultimate technological goal is to establish closed-loop control systems capable of real-time adjustment of process parameters to maintain desired microstructural characteristics throughout the build process. This requires integration of advanced sensing technologies, computational modeling, and machine learning algorithms to predict and control the complex thermal history experienced during deposition.

As DED technology continues to mature, the focus has increasingly shifted toward controlling anisotropy in mechanical properties, managing residual stress development, and enabling site-specific microstructural tailoring within a single component. These objectives align with the broader industry trend toward digital manufacturing and materials by design paradigms.

The microstructural evolution during DED represents a critical aspect of the technology's capabilities and limitations. The process involves complex thermal cycles where material undergoes rapid heating, melting, and solidification, creating unique microstructural features that directly influence mechanical properties. Historical developments in DED have progressively shifted from merely achieving geometric accuracy to precisely controlling the internal microstructure of fabricated components.

Recent technological trends indicate a growing emphasis on in-situ monitoring and real-time control of microstructural development during deposition. This evolution has been driven by increasing demands for components with tailored mechanical properties, particularly in high-performance applications where specific grain structures are required to withstand extreme operating conditions.

The primary technical objective of microstructural control in DED focuses on achieving predictable and repeatable grain structures across complex geometries. This includes the ability to manipulate grain size, orientation, and morphology to enhance specific mechanical properties such as strength, ductility, creep resistance, and fatigue performance. Additionally, controlling texture development and minimizing defects such as porosity and cracking represent critical goals in advancing DED technology.

Another significant objective involves developing comprehensive process-structure-property relationships that enable precise prediction of microstructural outcomes based on processing parameters. This includes understanding the influence of laser power, scan speed, powder feed rate, and build strategy on solidification dynamics and subsequent grain evolution.

The ultimate technological goal is to establish closed-loop control systems capable of real-time adjustment of process parameters to maintain desired microstructural characteristics throughout the build process. This requires integration of advanced sensing technologies, computational modeling, and machine learning algorithms to predict and control the complex thermal history experienced during deposition.

As DED technology continues to mature, the focus has increasingly shifted toward controlling anisotropy in mechanical properties, managing residual stress development, and enabling site-specific microstructural tailoring within a single component. These objectives align with the broader industry trend toward digital manufacturing and materials by design paradigms.

Market Analysis for DED Grain Structure Control Applications

The global market for Directed Energy Deposition (DED) technologies with advanced grain structure control capabilities is experiencing robust growth, driven by increasing demand for high-performance components in aerospace, defense, and medical industries. Current market valuations indicate that the metal additive manufacturing sector, which includes DED technologies, has reached approximately 2.7 billion USD in 2023, with DED-specific applications accounting for roughly 15% of this market.

The aerospace sector represents the largest application area for DED grain structure control technologies, constituting nearly 40% of the total market share. This dominance stems from the critical need for components with precisely controlled microstructures that can withstand extreme operating conditions. The medical implant industry follows closely, representing about 25% of market demand, where controlled grain structures significantly enhance biocompatibility and mechanical performance of implants.

Market analysis reveals a compound annual growth rate (CAGR) of 23% for DED technologies with advanced grain structure control capabilities, outpacing the broader additive manufacturing market's growth rate of 18%. This accelerated growth trajectory is attributed to increasing adoption in critical applications where microstructural integrity directly impacts component performance and reliability.

Regional market distribution shows North America leading with 38% market share, followed by Europe at 32% and Asia-Pacific at 24%. However, the Asia-Pacific region demonstrates the fastest growth rate at 27% annually, primarily driven by substantial investments in advanced manufacturing capabilities in China, Japan, and South Korea.

Customer segmentation analysis indicates that tier-one aerospace manufacturers and medical device companies are the primary early adopters, willing to pay premium prices for the enhanced material properties achieved through controlled grain structures. The automotive sector represents an emerging market segment, currently accounting for only 8% of applications but projected to reach 15% by 2027 as high-volume production capabilities improve.

Price sensitivity varies significantly across application sectors. Defense and aerospace customers demonstrate low price sensitivity due to performance-critical requirements, while industrial equipment manufacturers show higher price sensitivity, primarily adopting the technology for specialized high-value components. Current market pricing structures indicate a premium of 30-40% for components with controlled grain structures compared to conventional DED processes, though this premium is expected to decrease to 15-20% as the technology matures and competition intensifies.

The aerospace sector represents the largest application area for DED grain structure control technologies, constituting nearly 40% of the total market share. This dominance stems from the critical need for components with precisely controlled microstructures that can withstand extreme operating conditions. The medical implant industry follows closely, representing about 25% of market demand, where controlled grain structures significantly enhance biocompatibility and mechanical performance of implants.

Market analysis reveals a compound annual growth rate (CAGR) of 23% for DED technologies with advanced grain structure control capabilities, outpacing the broader additive manufacturing market's growth rate of 18%. This accelerated growth trajectory is attributed to increasing adoption in critical applications where microstructural integrity directly impacts component performance and reliability.

Regional market distribution shows North America leading with 38% market share, followed by Europe at 32% and Asia-Pacific at 24%. However, the Asia-Pacific region demonstrates the fastest growth rate at 27% annually, primarily driven by substantial investments in advanced manufacturing capabilities in China, Japan, and South Korea.

Customer segmentation analysis indicates that tier-one aerospace manufacturers and medical device companies are the primary early adopters, willing to pay premium prices for the enhanced material properties achieved through controlled grain structures. The automotive sector represents an emerging market segment, currently accounting for only 8% of applications but projected to reach 15% by 2027 as high-volume production capabilities improve.

Price sensitivity varies significantly across application sectors. Defense and aerospace customers demonstrate low price sensitivity due to performance-critical requirements, while industrial equipment manufacturers show higher price sensitivity, primarily adopting the technology for specialized high-value components. Current market pricing structures indicate a premium of 30-40% for components with controlled grain structures compared to conventional DED processes, though this premium is expected to decrease to 15-20% as the technology matures and competition intensifies.

Current Technical Challenges in DED Microstructure Control

Despite significant advancements in Directed Energy Deposition (DED) technology, controlling microstructure evolution during the process remains a formidable challenge. The rapid heating and cooling cycles inherent to DED create complex thermal histories that significantly influence grain formation and growth. Current DED processes struggle to achieve consistent grain size distribution throughout the built structure, often resulting in heterogeneous mechanical properties that compromise component performance.

The layer-by-layer nature of DED introduces thermal gradients that vary spatially and temporally, leading to anisotropic grain structures. This anisotropy manifests as columnar grains growing epitaxially along the build direction, which can result in direction-dependent mechanical properties. While beneficial in certain applications, this directional grain growth often creates challenges for components requiring isotropic behavior.

Residual stress accumulation during DED processing represents another significant technical hurdle. These stresses can induce unwanted microstructural transformations, grain boundary migration, and in severe cases, part distortion or cracking. Current in-process monitoring systems lack the resolution and response time necessary to detect and mitigate these microstructural changes in real-time.

The relationship between process parameters and resultant microstructure remains incompletely understood. While correlations between laser power, scan speed, and general microstructural features have been established, predictive models that can accurately forecast grain morphology, size distribution, and texture based on process parameters are still in their infancy. This knowledge gap hinders the development of robust process control strategies.

Material-specific challenges further complicate microstructure control. Different alloy systems respond uniquely to DED processing conditions, with some materials exhibiting phase transformations, segregation, or precipitation phenomena that are difficult to predict and control. For instance, high-strength aluminum alloys and nickel superalloys present particular difficulties due to their complex solidification behavior and sensitivity to thermal conditions.

Current post-processing techniques to modify DED microstructures, such as heat treatment, often cannot fully remediate undesirable as-built microstructural features. The effectiveness of these treatments is limited by the initial grain structure established during deposition, highlighting the critical importance of in-process microstructure control.

The integration of real-time feedback control systems for microstructure management remains technically challenging. While sensors can monitor thermal conditions, translating this data into actionable adjustments that predictably influence microstructure evolution requires sophisticated algorithms and processing capabilities that exceed current industrial implementations.

The layer-by-layer nature of DED introduces thermal gradients that vary spatially and temporally, leading to anisotropic grain structures. This anisotropy manifests as columnar grains growing epitaxially along the build direction, which can result in direction-dependent mechanical properties. While beneficial in certain applications, this directional grain growth often creates challenges for components requiring isotropic behavior.

Residual stress accumulation during DED processing represents another significant technical hurdle. These stresses can induce unwanted microstructural transformations, grain boundary migration, and in severe cases, part distortion or cracking. Current in-process monitoring systems lack the resolution and response time necessary to detect and mitigate these microstructural changes in real-time.

The relationship between process parameters and resultant microstructure remains incompletely understood. While correlations between laser power, scan speed, and general microstructural features have been established, predictive models that can accurately forecast grain morphology, size distribution, and texture based on process parameters are still in their infancy. This knowledge gap hinders the development of robust process control strategies.

Material-specific challenges further complicate microstructure control. Different alloy systems respond uniquely to DED processing conditions, with some materials exhibiting phase transformations, segregation, or precipitation phenomena that are difficult to predict and control. For instance, high-strength aluminum alloys and nickel superalloys present particular difficulties due to their complex solidification behavior and sensitivity to thermal conditions.

Current post-processing techniques to modify DED microstructures, such as heat treatment, often cannot fully remediate undesirable as-built microstructural features. The effectiveness of these treatments is limited by the initial grain structure established during deposition, highlighting the critical importance of in-process microstructure control.

The integration of real-time feedback control systems for microstructure management remains technically challenging. While sensors can monitor thermal conditions, translating this data into actionable adjustments that predictably influence microstructure evolution requires sophisticated algorithms and processing capabilities that exceed current industrial implementations.

State-of-the-Art DED Grain Control Methodologies

01 Control of grain structure in DED processes

Directed Energy Deposition (DED) processes can be controlled to achieve specific grain structures in the deposited material. Various process parameters such as laser power, scanning speed, and deposition strategy influence the solidification rate and thermal gradients, which directly affect the resulting grain structure. By manipulating these parameters, manufacturers can produce fine-grained, columnar, or equiaxed microstructures depending on the desired mechanical properties of the final component.- Control of grain structure in DED processes: Directed Energy Deposition (DED) processes can be controlled to achieve specific grain structures in the fabricated components. Various parameters such as laser power, deposition rate, and scanning strategy influence the resulting microstructure. By carefully manipulating these parameters, it is possible to control grain size, orientation, and morphology, which directly impacts the mechanical properties of the final part. This control is essential for applications requiring specific structural characteristics.

- Columnar to equiaxed grain transition in DED: The transition from columnar to equiaxed grain structures is a critical aspect of DED processes. This transition can be influenced by thermal gradients and solidification rates during deposition. By adjusting process parameters such as cooling rates and heat input, manufacturers can promote either columnar grains (preferred for directional properties) or equiaxed grains (preferred for isotropic properties). Understanding and controlling this transition is essential for tailoring material properties to specific applications.

- Heat treatment effects on DED grain structure: Post-process heat treatments significantly influence the final grain structure of DED-fabricated components. Heat treatments can be used to refine grain size, relieve residual stresses, and promote phase transformations. Different heat treatment protocols, including annealing, normalizing, and aging, can be applied to modify the as-deposited microstructure and achieve desired mechanical properties. The selection of appropriate heat treatment parameters depends on the material composition and intended application.

- Multi-material DED grain boundary engineering: Multi-material deposition in DED processes presents unique challenges and opportunities for grain boundary engineering. The interface between different materials can be controlled to achieve specific properties, such as enhanced strength or corrosion resistance. By managing the thermal history and deposition parameters at material interfaces, it is possible to control grain boundary characteristics, including orientation, density, and composition. This approach enables the fabrication of functionally graded materials with tailored properties.

- In-situ monitoring and control of grain formation: Advanced monitoring systems can be integrated into DED processes to observe and control grain formation in real-time. These systems use various sensing technologies, including thermal imaging, acoustic monitoring, and spectroscopy, to provide feedback on the solidification process. The collected data can be used in closed-loop control systems to make real-time adjustments to process parameters, ensuring consistent grain structure throughout the build. This approach significantly improves the reliability and reproducibility of DED-fabricated components.

02 Heat treatment effects on DED grain structure

Post-deposition heat treatments significantly influence the grain structure of components produced via Directed Energy Deposition. Techniques such as annealing, solution treatment, and aging can be applied to modify the as-deposited microstructure, relieve residual stresses, and homogenize the material. These thermal processes can transform columnar grains into equiaxed structures, refine grain size, and dissolve unwanted precipitates, ultimately enhancing the mechanical properties and performance of DED-manufactured parts.Expand Specific Solutions03 Multi-material DED grain boundary engineering

Multi-material deposition using DED technology enables sophisticated grain boundary engineering. By carefully controlling the interface between different materials during deposition, it's possible to create functionally graded materials with tailored grain structures. This approach allows for the manipulation of grain boundaries to enhance specific properties such as corrosion resistance, fatigue strength, or high-temperature performance. The controlled transition between materials can minimize thermal stresses and prevent the formation of brittle intermetallic compounds at the interfaces.Expand Specific Solutions04 In-situ monitoring and control of grain formation

Advanced in-situ monitoring systems can be integrated with DED equipment to observe and control grain formation during the deposition process. These systems use various sensing technologies such as thermal imaging, optical monitoring, and acoustic emission to provide real-time data on melt pool dynamics and solidification behavior. This information can be fed back to the control system to make immediate adjustments to process parameters, ensuring consistent grain structure throughout the build and enabling closed-loop control for improved microstructural consistency.Expand Specific Solutions05 Grain refinement techniques for DED processes

Various grain refinement techniques can be applied in DED processes to achieve finer microstructures with enhanced mechanical properties. These include the addition of inoculants or nucleating agents to the feedstock material, ultrasonic vibration during deposition, electromagnetic stirring of the melt pool, and controlled cooling strategies. Finer grain structures typically result in improved strength, hardness, and fatigue resistance while maintaining good ductility. These refinement methods are particularly valuable for applications requiring high performance under demanding conditions.Expand Specific Solutions

Leading Organizations in DED Microstructure Research

Directed Energy Deposition (DED) technology for microstructure evolution and grain structure control is currently in a growth phase, with the market expected to reach significant expansion due to increasing applications in aerospace, defense, and manufacturing sectors. Companies like RTX Corp., Rolls-Royce Corp., and Safran Aircraft Engines are leading industrial implementation, while research institutions such as The Regents of the University of California and Huazhong University of Science & Technology are advancing fundamental understanding. Velo3D represents emerging specialized players developing proprietary DED solutions. The technology is approaching maturity in aerospace applications but remains in development for broader industrial adoption, with significant research focusing on controlling microstructural properties to enhance material performance and reliability.

The Regents of the University of California

Technical Solution: The University of California has developed several innovative approaches to microstructure control in DED processes through their advanced manufacturing research centers. Their technology combines high-resolution in-situ monitoring with multi-scale computational models to predict and control grain evolution during deposition. UC researchers have pioneered the use of ultrasonic vibration during deposition to influence nucleation behavior and grain refinement. Their approach incorporates controlled substrate heating and cooling strategies to manipulate thermal gradients and solidification rates. Particularly significant is their development of machine learning algorithms that correlate process parameters with resulting microstructures across different alloy systems, enabling rapid process optimization. UC has also developed novel beam shaping technologies that modify energy distribution within the melt pool, allowing for precise control over solidification conditions and resulting grain structures. Their research has demonstrated the ability to produce gradient microstructures with spatially varying grain sizes and orientations to optimize local mechanical properties.

Strengths: Cutting-edge fundamental research on solidification phenomena; broad material expertise across multiple alloy systems; innovative approaches to microstructure manipulation. Weaknesses: Some technologies remain at laboratory scale; commercialization pathways still developing; complex control systems require further refinement for industrial implementation.

Huazhong University of Science & Technology

Technical Solution: Huazhong University has developed significant innovations in DED microstructure control through their Advanced Manufacturing Technology Center. Their approach focuses on multi-scale modeling of solidification phenomena coupled with advanced process monitoring techniques. The university has pioneered the use of electromagnetic fields during deposition to influence melt pool dynamics and solidification behavior, enabling control over grain nucleation and growth directions. Their technology incorporates pulsed laser strategies with precisely controlled duty cycles to manipulate cooling rates and thermal gradients during solidification. Particularly notable is their development of heterogeneous nucleation agents that can be selectively introduced into the feedstock to promote grain refinement in specific regions. Huazhong researchers have also developed novel scan strategies that create controlled oscillations in the thermal history, enabling the formation of refined, equiaxed grain structures even in materials that typically exhibit strong columnar growth tendencies. Their approach has been successfully demonstrated across multiple alloy systems, including titanium, nickel, and aluminum-based materials.

Strengths: Strong fundamental understanding of solidification science; innovative approaches to microstructure manipulation; excellent integration of simulation and experimental validation. Weaknesses: Some technologies require specialized equipment modifications; industrial scale implementation still developing; complex control systems add process complexity.

Critical Patents and Research in DED Microstructure Manipulation

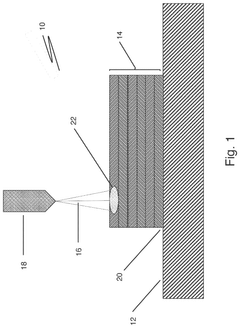

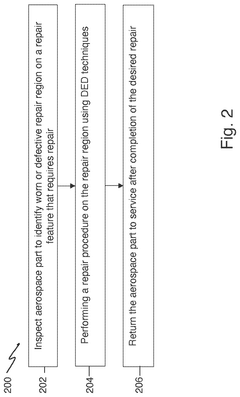

Engineered microstructure for enhanced performance during directed energy deposition repair process

PatentPendingUS20250242410A1

Innovation

- A directed energy deposition (DED) process is used to control the microstructure of each repair layer by adjusting parameters like powder feed rate, energy intensity, traversal rate, and auxiliary heating/cooling, ensuring each layer has a pre-determined microstructure to meet specific structural and functional needs.

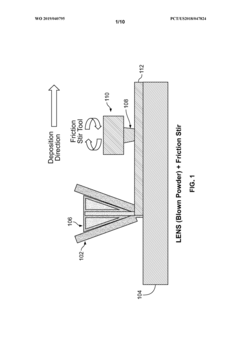

Additively manufactured parts having varied grain microstructures and related methods of making the same

PatentWO2019040795A1

Innovation

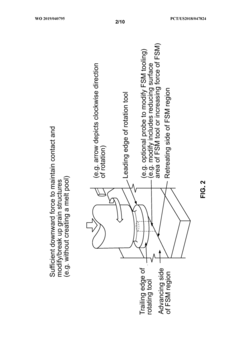

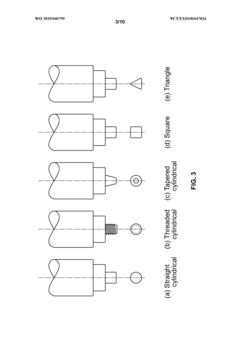

- The method involves using a friction stir modification (FSM) tool to transform the columnar grain structure of AM builds into an equiaxed structure by applying compressive stresses and mechanical stirring forces during the additive manufacturing process, specifically targeting the grain microstructure transformation across layers.

Process-Property Relationships in DED Manufacturing

The relationship between process parameters and resulting material properties in Directed Energy Deposition (DED) manufacturing represents a critical area of understanding for industrial implementation. Process variables such as laser power, scan speed, powder feed rate, and layer thickness directly influence the thermal history experienced by the material, which in turn determines the microstructural evolution and final mechanical properties.

Thermal gradients and cooling rates during DED processing significantly impact grain morphology and size distribution. Higher cooling rates typically result in finer grain structures with enhanced mechanical properties, while slower cooling promotes larger columnar grains that may exhibit anisotropic behavior. The thermal cycling inherent to layer-by-layer deposition creates complex temperature histories that can induce phase transformations, precipitation reactions, and residual stress development.

Material selection interacts substantially with process parameters to determine final properties. For instance, titanium alloys processed via DED exhibit different α/β phase distributions depending on cooling rates, while nickel-based superalloys show varying γ' precipitate morphologies based on thermal history. These microstructural features directly correlate with tensile strength, fatigue resistance, and creep behavior.

Empirical studies have established several key process-property relationships in DED manufacturing. Increased energy density generally leads to reduced porosity but may promote excessive grain growth. Conversely, insufficient energy input results in lack-of-fusion defects that severely compromise mechanical integrity. The balance between these extremes represents an optimal processing window that varies by material system.

Post-processing treatments, including heat treatment and hot isostatic pressing (HIP), can modify the as-deposited microstructure to achieve desired property profiles. These secondary processes can homogenize composition, relieve residual stresses, and refine grain structures, thereby enhancing overall performance characteristics.

Computational modeling approaches, particularly finite element analysis and phase-field modeling, have emerged as valuable tools for predicting process-property relationships in DED. These models can simulate thermal histories, solidification behavior, and resulting microstructures, enabling more efficient process parameter optimization without extensive experimental campaigns.

Thermal gradients and cooling rates during DED processing significantly impact grain morphology and size distribution. Higher cooling rates typically result in finer grain structures with enhanced mechanical properties, while slower cooling promotes larger columnar grains that may exhibit anisotropic behavior. The thermal cycling inherent to layer-by-layer deposition creates complex temperature histories that can induce phase transformations, precipitation reactions, and residual stress development.

Material selection interacts substantially with process parameters to determine final properties. For instance, titanium alloys processed via DED exhibit different α/β phase distributions depending on cooling rates, while nickel-based superalloys show varying γ' precipitate morphologies based on thermal history. These microstructural features directly correlate with tensile strength, fatigue resistance, and creep behavior.

Empirical studies have established several key process-property relationships in DED manufacturing. Increased energy density generally leads to reduced porosity but may promote excessive grain growth. Conversely, insufficient energy input results in lack-of-fusion defects that severely compromise mechanical integrity. The balance between these extremes represents an optimal processing window that varies by material system.

Post-processing treatments, including heat treatment and hot isostatic pressing (HIP), can modify the as-deposited microstructure to achieve desired property profiles. These secondary processes can homogenize composition, relieve residual stresses, and refine grain structures, thereby enhancing overall performance characteristics.

Computational modeling approaches, particularly finite element analysis and phase-field modeling, have emerged as valuable tools for predicting process-property relationships in DED. These models can simulate thermal histories, solidification behavior, and resulting microstructures, enabling more efficient process parameter optimization without extensive experimental campaigns.

Standardization and Quality Assurance for DED Microstructures

Standardization of microstructure control in Directed Energy Deposition (DED) processes represents a critical challenge for industry-wide adoption. Current quality assurance frameworks remain fragmented, with different manufacturers employing proprietary methodologies for evaluating grain structure characteristics. This inconsistency creates significant barriers to certification, particularly in high-consequence industries such as aerospace and medical implants.

The development of unified testing protocols specifically designed for DED microstructures has gained momentum in recent years. Organizations including ASTM International and ISO have established working groups focused on developing standards that address the unique characteristics of additively manufactured materials. Standard F3303, for instance, provides guidelines for evaluating microstructure in metal additive manufacturing but requires further refinement for DED-specific applications.

Real-time monitoring systems have emerged as essential tools for quality assurance in DED processes. Advanced systems incorporating thermal imaging, high-speed cameras, and spectroscopic analysis can detect microstructural anomalies during deposition. These technologies enable correlation between process parameters and resulting grain structures, facilitating closed-loop control systems that maintain consistent microstructural properties throughout builds.

Post-process verification techniques have also evolved significantly. Non-destructive testing methods including ultrasonic testing, X-ray computed tomography, and neutron diffraction provide comprehensive data on internal grain structures without compromising part integrity. These techniques are increasingly being standardized to ensure consistent evaluation across different manufacturing facilities.

Digital certification frameworks represent the next frontier in DED quality assurance. These systems integrate process monitoring data, material certification, and post-build verification into comprehensive digital threads that document the complete manufacturing history of components. Such frameworks enable traceability of microstructural properties from powder characteristics through final heat treatment.

Statistical process control methodologies tailored specifically for DED microstructures have demonstrated significant improvements in consistency. These approaches establish control limits for key microstructural parameters including grain size distribution, texture, and phase composition. Implementation of these methodologies has reduced microstructural variability by up to 40% in industrial applications.

International collaboration between research institutions, standards organizations, and industrial partners has accelerated the development of harmonized quality assurance protocols. The formation of consortia dedicated to DED standardization has facilitated knowledge sharing and best practice development. These collaborative efforts are essential for establishing globally recognized certification pathways for DED-manufactured components with controlled microstructures.

The development of unified testing protocols specifically designed for DED microstructures has gained momentum in recent years. Organizations including ASTM International and ISO have established working groups focused on developing standards that address the unique characteristics of additively manufactured materials. Standard F3303, for instance, provides guidelines for evaluating microstructure in metal additive manufacturing but requires further refinement for DED-specific applications.

Real-time monitoring systems have emerged as essential tools for quality assurance in DED processes. Advanced systems incorporating thermal imaging, high-speed cameras, and spectroscopic analysis can detect microstructural anomalies during deposition. These technologies enable correlation between process parameters and resulting grain structures, facilitating closed-loop control systems that maintain consistent microstructural properties throughout builds.

Post-process verification techniques have also evolved significantly. Non-destructive testing methods including ultrasonic testing, X-ray computed tomography, and neutron diffraction provide comprehensive data on internal grain structures without compromising part integrity. These techniques are increasingly being standardized to ensure consistent evaluation across different manufacturing facilities.

Digital certification frameworks represent the next frontier in DED quality assurance. These systems integrate process monitoring data, material certification, and post-build verification into comprehensive digital threads that document the complete manufacturing history of components. Such frameworks enable traceability of microstructural properties from powder characteristics through final heat treatment.

Statistical process control methodologies tailored specifically for DED microstructures have demonstrated significant improvements in consistency. These approaches establish control limits for key microstructural parameters including grain size distribution, texture, and phase composition. Implementation of these methodologies has reduced microstructural variability by up to 40% in industrial applications.

International collaboration between research institutions, standards organizations, and industrial partners has accelerated the development of harmonized quality assurance protocols. The formation of consortia dedicated to DED standardization has facilitated knowledge sharing and best practice development. These collaborative efforts are essential for establishing globally recognized certification pathways for DED-manufactured components with controlled microstructures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!