Bioinspired Anti Fouling Surfaces for Ship Hull Protection

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bioinspired Antifouling Technology Background and Objectives

Bioinspired antifouling technology represents a revolutionary approach to addressing one of the most persistent challenges in maritime operations. Marine biofouling—the accumulation of microorganisms, plants, algae, and animals on submerged structures—has plagued naval architecture since the dawn of seafaring. This phenomenon increases drag on vessel hulls by up to 60%, resulting in significant fuel consumption increases, reduced maneuverability, and accelerated corrosion rates, collectively costing the global shipping industry an estimated $30 billion annually.

Traditional antifouling solutions have primarily relied on toxic coatings containing biocides such as tributyltin (TBT) and copper compounds. While effective, these approaches have caused substantial environmental damage, including marine ecosystem disruption and bioaccumulation of toxins throughout food chains. Regulatory restrictions, including the International Maritime Organization's global ban on TBT in 2008, have necessitated the development of environmentally sustainable alternatives.

Nature, through millions of years of evolutionary refinement, has developed remarkable antifouling strategies across various marine organisms. Species such as sharks, dolphins, mussels, and certain seaweeds maintain remarkably clean surfaces despite constant exposure to fouling organisms. These natural models offer invaluable inspiration for developing next-generation antifouling technologies that are both effective and environmentally benign.

The primary objective of bioinspired antifouling research is to understand and replicate the multifaceted defense mechanisms employed by marine organisms. These mechanisms typically combine physical surface topography (micro and nanostructures), chemical deterrents (natural compounds with antifouling properties), and behavioral adaptations. By mimicking these strategies, researchers aim to develop synthetic surfaces that can resist biofouling without relying on toxic compounds.

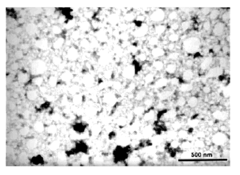

The technological evolution in this field has accelerated significantly over the past decade, driven by advances in materials science, nanotechnology, and surface engineering. Early approaches focused primarily on understanding the physical aspects of natural antifouling surfaces, particularly the microscale topography of shark skin. Recent developments have expanded to incorporate chemical and biological mechanisms, leading to more sophisticated hybrid solutions.

Current research objectives center on developing commercially viable antifouling technologies that combine durability, cost-effectiveness, and environmental sustainability. The ideal solution would provide long-term fouling protection (5+ years), minimize maintenance requirements, reduce fuel consumption, and eliminate ecological impact—all while being economically competitive with existing technologies.

As global environmental regulations continue to tighten and shipping efficiency becomes increasingly critical for reducing carbon emissions, the development of effective bioinspired antifouling technologies represents not just an environmental imperative but also a significant commercial opportunity in the maritime industry's pursuit of sustainability.

Traditional antifouling solutions have primarily relied on toxic coatings containing biocides such as tributyltin (TBT) and copper compounds. While effective, these approaches have caused substantial environmental damage, including marine ecosystem disruption and bioaccumulation of toxins throughout food chains. Regulatory restrictions, including the International Maritime Organization's global ban on TBT in 2008, have necessitated the development of environmentally sustainable alternatives.

Nature, through millions of years of evolutionary refinement, has developed remarkable antifouling strategies across various marine organisms. Species such as sharks, dolphins, mussels, and certain seaweeds maintain remarkably clean surfaces despite constant exposure to fouling organisms. These natural models offer invaluable inspiration for developing next-generation antifouling technologies that are both effective and environmentally benign.

The primary objective of bioinspired antifouling research is to understand and replicate the multifaceted defense mechanisms employed by marine organisms. These mechanisms typically combine physical surface topography (micro and nanostructures), chemical deterrents (natural compounds with antifouling properties), and behavioral adaptations. By mimicking these strategies, researchers aim to develop synthetic surfaces that can resist biofouling without relying on toxic compounds.

The technological evolution in this field has accelerated significantly over the past decade, driven by advances in materials science, nanotechnology, and surface engineering. Early approaches focused primarily on understanding the physical aspects of natural antifouling surfaces, particularly the microscale topography of shark skin. Recent developments have expanded to incorporate chemical and biological mechanisms, leading to more sophisticated hybrid solutions.

Current research objectives center on developing commercially viable antifouling technologies that combine durability, cost-effectiveness, and environmental sustainability. The ideal solution would provide long-term fouling protection (5+ years), minimize maintenance requirements, reduce fuel consumption, and eliminate ecological impact—all while being economically competitive with existing technologies.

As global environmental regulations continue to tighten and shipping efficiency becomes increasingly critical for reducing carbon emissions, the development of effective bioinspired antifouling technologies represents not just an environmental imperative but also a significant commercial opportunity in the maritime industry's pursuit of sustainability.

Marine Industry Demand Analysis for Antifouling Solutions

The global marine industry faces significant challenges from biofouling, with approximately 40% of vessel maintenance costs attributed to fouling-related issues. Ship hull fouling increases drag by up to 60%, resulting in fuel consumption increases of 20-30% and corresponding rises in greenhouse gas emissions. This creates an estimated annual economic burden of $30 billion for the shipping industry worldwide, highlighting the critical need for effective antifouling solutions.

Market research indicates that the global marine coatings market, valued at $3.93 billion in 2022, is projected to reach $5.5 billion by 2028, with antifouling coatings representing the largest segment. This growth is driven by expanding international maritime trade, which has seen container shipping volumes increase by 4.3% annually over the past decade despite recent pandemic-related disruptions.

Environmental regulations have dramatically reshaped market demands, particularly following the International Maritime Organization's ban on tributyltin (TBT) compounds in 2008. The EU's Biocidal Products Regulation and similar frameworks in other regions have accelerated the shift toward environmentally sustainable solutions. This regulatory landscape has created a significant market gap for non-toxic alternatives, with bioinspired technologies emerging as a promising frontier.

Naval forces worldwide represent a premium segment of this market, allocating substantial budgets for advanced hull protection systems that optimize vessel performance and operational readiness. Commercial shipping companies increasingly recognize antifouling as a critical factor in their environmental, social, and governance (ESG) strategies, with major carriers investing in research partnerships to develop next-generation solutions.

Regional analysis reveals varying demand patterns, with Asia-Pacific dominating market growth due to extensive shipbuilding activities in China, South Korea, and Japan. European markets show stronger preference for eco-friendly solutions, while North American buyers emphasize long-term performance and reduced maintenance intervals.

Customer surveys indicate evolving priorities among end-users, with durability and environmental compliance now ranking alongside cost-effectiveness as primary selection criteria. The expected service life of antifouling systems has become a critical factor, with ship operators seeking solutions that align with increasingly extended dry-docking intervals of 5-7 years for commercial vessels.

The emergence of autonomous and unmanned vessels presents new challenges and opportunities, as these platforms require exceptionally reliable, low-maintenance hull protection systems capable of extended deployment periods without human intervention.

Market research indicates that the global marine coatings market, valued at $3.93 billion in 2022, is projected to reach $5.5 billion by 2028, with antifouling coatings representing the largest segment. This growth is driven by expanding international maritime trade, which has seen container shipping volumes increase by 4.3% annually over the past decade despite recent pandemic-related disruptions.

Environmental regulations have dramatically reshaped market demands, particularly following the International Maritime Organization's ban on tributyltin (TBT) compounds in 2008. The EU's Biocidal Products Regulation and similar frameworks in other regions have accelerated the shift toward environmentally sustainable solutions. This regulatory landscape has created a significant market gap for non-toxic alternatives, with bioinspired technologies emerging as a promising frontier.

Naval forces worldwide represent a premium segment of this market, allocating substantial budgets for advanced hull protection systems that optimize vessel performance and operational readiness. Commercial shipping companies increasingly recognize antifouling as a critical factor in their environmental, social, and governance (ESG) strategies, with major carriers investing in research partnerships to develop next-generation solutions.

Regional analysis reveals varying demand patterns, with Asia-Pacific dominating market growth due to extensive shipbuilding activities in China, South Korea, and Japan. European markets show stronger preference for eco-friendly solutions, while North American buyers emphasize long-term performance and reduced maintenance intervals.

Customer surveys indicate evolving priorities among end-users, with durability and environmental compliance now ranking alongside cost-effectiveness as primary selection criteria. The expected service life of antifouling systems has become a critical factor, with ship operators seeking solutions that align with increasingly extended dry-docking intervals of 5-7 years for commercial vessels.

The emergence of autonomous and unmanned vessels presents new challenges and opportunities, as these platforms require exceptionally reliable, low-maintenance hull protection systems capable of extended deployment periods without human intervention.

Current Antifouling Technologies and Challenges

The maritime industry currently employs several antifouling technologies to combat biofouling on ship hulls, with varying degrees of effectiveness and environmental impact. Traditional antifouling paints containing tributyltin (TBT) were highly effective but have been globally banned since 2008 due to severe environmental toxicity, causing endocrine disruption in marine organisms and bioaccumulation throughout food chains.

Copper-based antifouling coatings have emerged as the primary alternative, utilizing copper oxide as the active biocide. These coatings function through controlled release mechanisms where the biocidal compounds gradually leach into the surrounding water, creating a toxic microenvironment that prevents organism attachment. However, increasing evidence suggests copper accumulation in harbor sediments and potential toxicity to non-target species, raising regulatory concerns.

Self-polishing copolymer (SPC) systems represent an advancement in controlled-release technology, where the coating surface gradually erodes in seawater, continuously exposing fresh biocides. While more efficient than earlier systems, these still rely on toxic compounds and face increasing regulatory scrutiny worldwide.

Foul-release coatings (FRCs) based on silicone or fluoropolymer technologies present a non-biocidal approach, utilizing low surface energy to prevent strong adhesion of marine organisms. These coatings don't kill organisms but make attachment difficult, allowing organisms to be removed by hydrodynamic forces when vessels are in motion. Their primary limitations include high cost, mechanical vulnerability, and reduced effectiveness at low speeds or during extended stationary periods.

Hard, durable coatings incorporating natural biocides derived from marine organisms show promise but face challenges in consistent extraction, stability, and scalable production. These biomimetic approaches often struggle with regulatory approval pathways designed for synthetic compounds.

The fundamental challenge across all current technologies is the trade-off between effectiveness and environmental impact. Highly effective solutions typically involve toxic compounds that harm marine ecosystems, while environmentally benign options often deliver insufficient protection or durability.

Additional technical challenges include achieving uniform performance across diverse marine environments, from tropical to arctic waters, and maintaining effectiveness throughout a vessel's operational profile, including varying speeds and idle periods. The economic challenge of developing solutions that remain effective for 3-5 years while keeping application and maintenance costs reasonable further complicates technology development.

Regulatory frameworks continue to evolve globally, with increasing restrictions on biocidal compounds, creating uncertainty for technology developers and shipowners regarding long-term compliance of current solutions.

Copper-based antifouling coatings have emerged as the primary alternative, utilizing copper oxide as the active biocide. These coatings function through controlled release mechanisms where the biocidal compounds gradually leach into the surrounding water, creating a toxic microenvironment that prevents organism attachment. However, increasing evidence suggests copper accumulation in harbor sediments and potential toxicity to non-target species, raising regulatory concerns.

Self-polishing copolymer (SPC) systems represent an advancement in controlled-release technology, where the coating surface gradually erodes in seawater, continuously exposing fresh biocides. While more efficient than earlier systems, these still rely on toxic compounds and face increasing regulatory scrutiny worldwide.

Foul-release coatings (FRCs) based on silicone or fluoropolymer technologies present a non-biocidal approach, utilizing low surface energy to prevent strong adhesion of marine organisms. These coatings don't kill organisms but make attachment difficult, allowing organisms to be removed by hydrodynamic forces when vessels are in motion. Their primary limitations include high cost, mechanical vulnerability, and reduced effectiveness at low speeds or during extended stationary periods.

Hard, durable coatings incorporating natural biocides derived from marine organisms show promise but face challenges in consistent extraction, stability, and scalable production. These biomimetic approaches often struggle with regulatory approval pathways designed for synthetic compounds.

The fundamental challenge across all current technologies is the trade-off between effectiveness and environmental impact. Highly effective solutions typically involve toxic compounds that harm marine ecosystems, while environmentally benign options often deliver insufficient protection or durability.

Additional technical challenges include achieving uniform performance across diverse marine environments, from tropical to arctic waters, and maintaining effectiveness throughout a vessel's operational profile, including varying speeds and idle periods. The economic challenge of developing solutions that remain effective for 3-5 years while keeping application and maintenance costs reasonable further complicates technology development.

Regulatory frameworks continue to evolve globally, with increasing restrictions on biocidal compounds, creating uncertainty for technology developers and shipowners regarding long-term compliance of current solutions.

Current Bioinspired Antifouling Surface Solutions

01 Biomimetic surface structures for anti-fouling

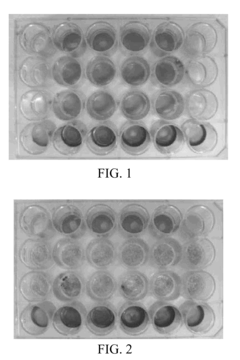

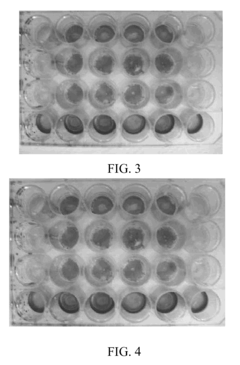

Bioinspired anti-fouling surfaces mimic natural structures found in organisms that resist fouling, such as shark skin, lotus leaves, or marine organisms. These surfaces typically feature micro or nano-scale patterns that prevent the adhesion of fouling organisms or contaminants. The specific topography disrupts the ability of organisms to attach, creating a physical barrier against biofouling without relying solely on chemical treatments.- Biomimetic surface structures for anti-fouling: Surfaces inspired by natural organisms like shark skin, lotus leaves, and marine creatures that have evolved anti-fouling properties. These biomimetic surfaces typically feature micro and nano-scale patterns that prevent organisms from adhering. The structures may include ridges, bumps, or specific topographical features that disrupt the settlement of fouling organisms by creating unfavorable surface conditions for attachment.

- Anti-fouling coatings with natural compounds: Coatings that incorporate biologically-derived compounds or extracts from marine organisms that naturally repel fouling. These formulations may include enzymes, peptides, or other bioactive compounds that interfere with the biological mechanisms of fouling organisms. The natural compounds can inhibit bacterial communication, prevent biofilm formation, or disrupt the adhesion process of marine organisms without causing environmental harm.

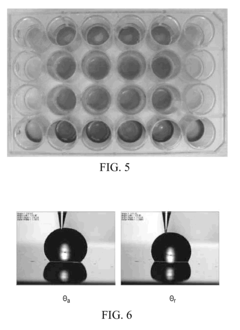

- Self-cleaning surface technologies: Surfaces designed with properties that enable automatic cleaning through environmental factors such as water flow, air movement, or light exposure. These technologies often combine hydrophobic or hydrophilic properties with specific surface textures to create self-cleaning effects. The surfaces may utilize photocatalytic materials that break down organic matter when exposed to light or incorporate materials that change properties in response to environmental stimuli.

- Marine vessel anti-fouling solutions: Specialized anti-fouling technologies specifically designed for ships, submarines, and other marine vessels. These solutions address the unique challenges of preventing biological growth on moving vessels in various marine environments. They may include specialized hull coatings, physical surface modifications, or dynamic systems that create unfavorable conditions for marine organism attachment while minimizing drag and maintaining vessel performance.

- Smart responsive anti-fouling materials: Advanced materials that can change their properties in response to environmental triggers to prevent fouling. These materials may alter their surface chemistry, texture, or release anti-fouling agents when specific conditions are detected. The responsive nature allows for targeted anti-fouling action only when needed, which can increase effectiveness while reducing environmental impact and extending the functional lifespan of the anti-fouling properties.

02 Chemical coatings with anti-fouling properties

These anti-fouling solutions involve the application of specialized chemical coatings that create surfaces hostile to fouling organisms. The coatings may incorporate biocides, enzymes, or compounds that interfere with the biological mechanisms of attachment. Some formulations create low surface energy interfaces that reduce the ability of organisms to adhere. These chemical approaches can be combined with physical surface modifications for enhanced performance.Expand Specific Solutions03 Self-cleaning surface technologies

Self-cleaning anti-fouling surfaces utilize mechanisms that actively remove contaminants without external intervention. These may include superhydrophobic or superhydrophilic properties that cause water to either bead up and roll off surfaces carrying contaminants away, or create a thin water layer that prevents direct contact with fouling agents. Some designs incorporate responsive materials that change properties in response to environmental triggers to dislodge accumulated fouling.Expand Specific Solutions04 Marine vessel and underwater structure protection

Specialized anti-fouling technologies designed specifically for marine applications, including ship hulls, underwater structures, and offshore installations. These solutions address the unique challenges of continuous water exposure and marine organism attachment. The technologies may incorporate flow-dynamic principles, specialized materials resistant to saltwater degradation, or systems that create unfavorable conditions for marine organism settlement and growth.Expand Specific Solutions05 Environmentally friendly anti-fouling solutions

Sustainable anti-fouling approaches that minimize environmental impact while maintaining effectiveness against fouling. These solutions avoid toxic compounds traditionally used in anti-fouling applications and instead rely on biodegradable materials, natural compounds derived from marine organisms, or physical deterrence mechanisms. The technologies aim to provide effective fouling protection while reducing ecological harm to aquatic ecosystems and complying with increasingly strict environmental regulations.Expand Specific Solutions

Leading Companies in Marine Antifouling Industry

The bioinspired anti-fouling surfaces for ship hull protection market is currently in a growth phase, with increasing environmental regulations driving innovation. The global marine coatings market, valued at approximately $3.5 billion, is expected to expand significantly as shipping industries seek eco-friendly solutions. Leading players include established marine coating specialists like Chugoku Marine Paints and Hempel A/S, who possess mature commercial technologies. Research institutions such as NDSU Research Foundation, Battelle Memorial Institute, and China Shipbuilding Industry Corp. No. 725 Research Institute are advancing the technological frontier through biomimetic approaches. Chemical companies including Evonik, RESONAC, and Nitto Denko are developing specialized materials, while universities like Dalian Maritime University and Hong Kong University of Science & Technology contribute fundamental research, creating a competitive landscape balancing commercial applications with scientific innovation.

Battelle Memorial Institute

Technical Solution: Battelle Memorial Institute has developed a comprehensive bioinspired antifouling technology platform called BioGuard™ that draws inspiration from multiple natural antifouling mechanisms. Their approach combines micro-engineered surface topographies mimicking shark skin denticles with novel polymer chemistry inspired by the mucous secretions of fish and echinoderms[1]. The institute's researchers have created hierarchical surface structures at multiple length scales (nano to micro) that physically disrupt the settlement patterns of fouling organisms while maintaining hydrodynamic efficiency. Battelle's technology incorporates environmentally benign natural compounds extracted from marine organisms known for their fouling resistance, encapsulated in controlled-release matrices that provide sustained protection[2]. Their interdisciplinary approach integrates materials science, marine biology, and computational modeling to optimize surface properties for specific vessel operating profiles and marine environments. The institute has conducted extensive field testing demonstrating significant reductions in fouling accumulation and associated drag reduction of up to 8% compared to conventional antifouling coatings[3].

Strengths: Comprehensive research capabilities spanning fundamental science to applied engineering; strong intellectual property portfolio covering multiple aspects of bioinspired antifouling; established relationships with naval and commercial maritime sectors facilitating technology transition. Weaknesses: Some technologies remain at prototype or limited deployment stage; complex manufacturing processes for hierarchical surface structures may increase production costs; performance longevity in extreme conditions requires further validation.

Chugoku Marine Paints, Ltd.

Technical Solution: Chugoku Marine Paints has developed advanced bioinspired antifouling coatings that mimic natural defense mechanisms found in marine organisms. Their flagship technology incorporates hydrogel-based surfaces inspired by fish mucus that create a slippery, hydrated barrier preventing organism attachment. The company has pioneered self-polishing copolymer (SPC) technology that gradually releases biocides while maintaining a smooth hull surface through controlled hydrolysis[1]. Their latest innovation combines silicone-based foul-release coatings with micro-textured surfaces mimicking shark skin denticles, creating physical deterrents to settlement while minimizing surface energy[2]. Chugoku has also developed environmentally compliant copper-free formulations that utilize natural compounds extracted from marine organisms as biodegradable antifoulants, addressing increasing regulatory restrictions on traditional biocides[3].

Strengths: Industry-leading expertise in marine coatings with global market presence; extensive field testing capabilities across diverse marine environments; strong R&D pipeline integrating biomimetic principles with advanced polymer chemistry. Weaknesses: Higher initial application costs compared to conventional antifouling paints; performance variability in different operating conditions; some formulations still rely partially on controlled-release biocides requiring regulatory approval.

Key Biomimetic Innovations for Marine Applications

Polysiloxanes with anti-fouling activity

PatentInactiveUS20090018276A1

Innovation

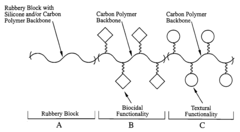

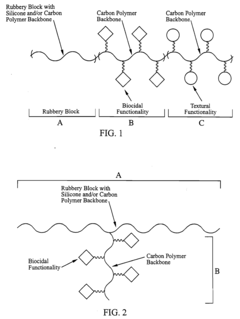

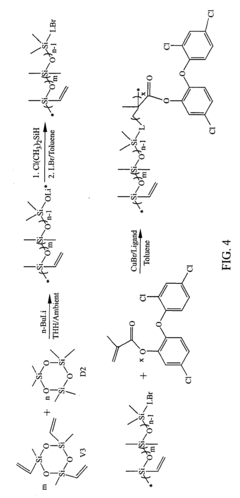

- Development of a copolymer-based anti-fouling material comprising a polysiloxane backbone with biocidal, fouling release, and texturizing groups, which can be used alone or in combination with other materials to inhibit the settlement and growth of aquatic organisms, while being environmentally sensitive.

Polymeric materials with Anti-fouling activity

PatentInactiveUS20070021529A1

Innovation

- Development of copolymers with biocidal and fouling release properties, comprising rubbery polymer sequences with carbon or silicone backbones, combined with biocidal and fouling release groups, which can be cross-linked to enhance their effectiveness and reduce environmental impact.

Environmental Impact and Regulatory Compliance

The environmental impact of biofouling and its control methods represents a critical consideration in maritime operations. Traditional antifouling solutions, particularly those containing tributyltin (TBT) compounds, have demonstrated severe ecological consequences, including endocrine disruption in marine organisms and bioaccumulation throughout food chains. These impacts led to the International Maritime Organization's (IMO) global ban on TBT-based coatings in 2008, marking a significant regulatory milestone in the industry.

Current copper-based alternatives, while less harmful than TBT, still pose substantial environmental concerns. Studies indicate that copper accumulation in harbor sediments can reach toxic levels, affecting benthic communities and potentially disrupting marine ecosystems. This has prompted increasingly stringent regulations in various jurisdictions, with the European Union's Biocidal Products Regulation (BPR) and the U.S. Environmental Protection Agency's Vessel General Permit program imposing progressively tighter restrictions on copper release rates.

Bioinspired antifouling surfaces offer promising environmental advantages through their non-toxic mechanisms. These solutions typically function through physical deterrence rather than chemical toxicity, aligning with the "green chemistry" principles increasingly favored by regulatory frameworks worldwide. The reduced environmental footprint of biomimetic approaches potentially provides shipping companies with compliance advantages as regulations continue to evolve toward zero-discharge policies.

Regulatory compliance frameworks for ship hull coatings vary significantly across global jurisdictions, creating complex operational challenges for international shipping. The IMO's International Convention on the Control of Harmful Anti-fouling Systems on Ships provides baseline standards, but regional and national regulations often impose additional requirements. For instance, California and Washington state maintain stricter copper leaching limits than federal U.S. standards, while Australia's NICNAS (National Industrial Chemicals Notification and Assessment Scheme) requires comprehensive ecotoxicological data for new coating technologies.

Life cycle assessment (LCA) studies comparing traditional and bioinspired antifouling solutions demonstrate that while manufacturing processes for biomimetic surfaces may initially require more energy, their extended service life and elimination of toxic releases result in superior overall environmental performance. This holistic evaluation approach is increasingly being incorporated into regulatory frameworks, potentially favoring bioinspired solutions in future compliance requirements.

The development of standardized testing protocols specifically for non-toxic antifouling mechanisms remains a regulatory gap that affects market adoption of bioinspired solutions. Current testing frameworks were largely designed for chemical biocides, creating certification challenges for physical deterrence mechanisms. Industry stakeholders and regulatory bodies are working to establish appropriate performance metrics that can accurately assess the effectiveness of biomimetic approaches while ensuring environmental protection.

Current copper-based alternatives, while less harmful than TBT, still pose substantial environmental concerns. Studies indicate that copper accumulation in harbor sediments can reach toxic levels, affecting benthic communities and potentially disrupting marine ecosystems. This has prompted increasingly stringent regulations in various jurisdictions, with the European Union's Biocidal Products Regulation (BPR) and the U.S. Environmental Protection Agency's Vessel General Permit program imposing progressively tighter restrictions on copper release rates.

Bioinspired antifouling surfaces offer promising environmental advantages through their non-toxic mechanisms. These solutions typically function through physical deterrence rather than chemical toxicity, aligning with the "green chemistry" principles increasingly favored by regulatory frameworks worldwide. The reduced environmental footprint of biomimetic approaches potentially provides shipping companies with compliance advantages as regulations continue to evolve toward zero-discharge policies.

Regulatory compliance frameworks for ship hull coatings vary significantly across global jurisdictions, creating complex operational challenges for international shipping. The IMO's International Convention on the Control of Harmful Anti-fouling Systems on Ships provides baseline standards, but regional and national regulations often impose additional requirements. For instance, California and Washington state maintain stricter copper leaching limits than federal U.S. standards, while Australia's NICNAS (National Industrial Chemicals Notification and Assessment Scheme) requires comprehensive ecotoxicological data for new coating technologies.

Life cycle assessment (LCA) studies comparing traditional and bioinspired antifouling solutions demonstrate that while manufacturing processes for biomimetic surfaces may initially require more energy, their extended service life and elimination of toxic releases result in superior overall environmental performance. This holistic evaluation approach is increasingly being incorporated into regulatory frameworks, potentially favoring bioinspired solutions in future compliance requirements.

The development of standardized testing protocols specifically for non-toxic antifouling mechanisms remains a regulatory gap that affects market adoption of bioinspired solutions. Current testing frameworks were largely designed for chemical biocides, creating certification challenges for physical deterrence mechanisms. Industry stakeholders and regulatory bodies are working to establish appropriate performance metrics that can accurately assess the effectiveness of biomimetic approaches while ensuring environmental protection.

Economic Analysis of Bioinspired Antifouling Implementation

The implementation of bioinspired antifouling solutions for ship hulls presents a complex economic equation that shipping companies, naval architects, and maritime stakeholders must carefully evaluate. Initial investment costs for bioinspired antifouling technologies typically exceed those of conventional toxic coating systems by 30-45%, representing a significant capital expenditure barrier for fleet operators. This premium primarily stems from specialized manufacturing processes, advanced material requirements, and the relatively limited scale of production compared to established antifouling products.

However, lifecycle cost analysis reveals compelling long-term economic advantages. Vessels utilizing bioinspired antifouling surfaces demonstrate fuel consumption reductions of 5-9% compared to ships with conventional coatings experiencing moderate fouling. For a medium-sized commercial vessel, this translates to approximately $180,000-$320,000 in annual fuel savings, depending on operational profiles and fuel prices.

Maintenance economics further strengthen the value proposition, as bioinspired solutions typically extend dry-docking intervals by 20-30%. The extended service life reduces operational disruptions and maintenance costs, with estimated savings of $50,000-$150,000 per maintenance cycle for medium to large vessels. Additionally, the elimination of toxic biocide leaching avoids potential regulatory compliance costs and environmental penalties, which have been increasing globally at an average rate of 15% annually.

Return on investment calculations indicate that despite higher upfront costs, the break-even point for bioinspired antifouling implementation typically occurs within 18-36 months of operation, depending on vessel type, operational profile, and fuel prices. Sensitivity analysis shows that the economic viability is most influenced by fuel price fluctuations, with higher fuel costs accelerating ROI timelines.

Market adoption models predict that as production scales increase and manufacturing processes mature, initial implementation costs will decrease by approximately 5-8% annually over the next decade. This cost reduction trajectory, combined with increasingly stringent environmental regulations on conventional antifouling compounds, is expected to significantly improve the economic proposition for bioinspired solutions.

For fleet operators, a phased implementation strategy often presents the most economically viable approach, allowing for capital expenditure distribution while gathering operational data to optimize future deployments. Economic modeling suggests that prioritizing implementation on vessels with high operational profiles or those operating in warm waters where fouling pressures are greatest maximizes economic returns.

However, lifecycle cost analysis reveals compelling long-term economic advantages. Vessels utilizing bioinspired antifouling surfaces demonstrate fuel consumption reductions of 5-9% compared to ships with conventional coatings experiencing moderate fouling. For a medium-sized commercial vessel, this translates to approximately $180,000-$320,000 in annual fuel savings, depending on operational profiles and fuel prices.

Maintenance economics further strengthen the value proposition, as bioinspired solutions typically extend dry-docking intervals by 20-30%. The extended service life reduces operational disruptions and maintenance costs, with estimated savings of $50,000-$150,000 per maintenance cycle for medium to large vessels. Additionally, the elimination of toxic biocide leaching avoids potential regulatory compliance costs and environmental penalties, which have been increasing globally at an average rate of 15% annually.

Return on investment calculations indicate that despite higher upfront costs, the break-even point for bioinspired antifouling implementation typically occurs within 18-36 months of operation, depending on vessel type, operational profile, and fuel prices. Sensitivity analysis shows that the economic viability is most influenced by fuel price fluctuations, with higher fuel costs accelerating ROI timelines.

Market adoption models predict that as production scales increase and manufacturing processes mature, initial implementation costs will decrease by approximately 5-8% annually over the next decade. This cost reduction trajectory, combined with increasingly stringent environmental regulations on conventional antifouling compounds, is expected to significantly improve the economic proposition for bioinspired solutions.

For fleet operators, a phased implementation strategy often presents the most economically viable approach, allowing for capital expenditure distribution while gathering operational data to optimize future deployments. Economic modeling suggests that prioritizing implementation on vessels with high operational profiles or those operating in warm waters where fouling pressures are greatest maximizes economic returns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!