Surface Topography Effects on Anti Fouling Performance

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Surface Topography and Anti-Fouling Technology Background

Surface fouling, the unwanted accumulation of materials on surfaces, represents a significant challenge across numerous industries including maritime, healthcare, food processing, and water treatment. The phenomenon has been studied extensively since the mid-20th century, with research intensifying in the 1970s as environmental regulations began restricting the use of toxic anti-fouling compounds. This technological evolution has shifted focus toward physical surface properties as a means of fouling prevention.

Surface topography—the physical configuration of a surface at micro and nanoscales—has emerged as a critical factor in anti-fouling performance. Nature provides compelling examples through the self-cleaning lotus leaf effect (superhydrophobicity) and shark skin's ability to prevent biofouling. These biological models demonstrate how specific surface patterns can disrupt the attachment mechanisms of fouling organisms and materials.

The relationship between surface topography and anti-fouling capability operates through several mechanisms. First, topographical features can alter surface energy and wettability, creating hydrophobic or hydrophilic conditions that inhibit adhesion. Second, specific patterns can generate unfavorable settlement conditions for organisms by disrupting their attachment processes. Third, controlled surface roughness can minimize the contact area available for fouling agents, reducing adhesion strength.

Research has identified critical topographical parameters affecting anti-fouling performance, including feature size, spacing, aspect ratio, symmetry, and hierarchical organization. The effectiveness of these parameters varies depending on the target fouling agents—microorganisms require different topographical deterrents than mineral scaling or protein adsorption.

Technological advances in fabrication methods have significantly expanded the possibilities for engineered anti-fouling surfaces. Traditional mechanical methods have been supplemented by lithographic techniques, laser texturing, chemical etching, and additive manufacturing approaches. These developments allow precise control over surface features at multiple scales, enabling the creation of biomimetic and novel topographies with enhanced anti-fouling properties.

The evolution of surface characterization tools has paralleled these fabrication advances. Atomic force microscopy, scanning electron microscopy, and optical profilometry now provide unprecedented insights into surface-fouling interactions at nanoscale resolution, facilitating more informed design approaches.

Current research trends focus on developing multifunctional surfaces that combine topographical features with chemical modifications or stimuli-responsive elements, creating dynamic anti-fouling systems adaptable to changing environmental conditions. This integrated approach represents the cutting edge of anti-fouling technology, promising more effective and environmentally sustainable solutions to this persistent industrial challenge.

Surface topography—the physical configuration of a surface at micro and nanoscales—has emerged as a critical factor in anti-fouling performance. Nature provides compelling examples through the self-cleaning lotus leaf effect (superhydrophobicity) and shark skin's ability to prevent biofouling. These biological models demonstrate how specific surface patterns can disrupt the attachment mechanisms of fouling organisms and materials.

The relationship between surface topography and anti-fouling capability operates through several mechanisms. First, topographical features can alter surface energy and wettability, creating hydrophobic or hydrophilic conditions that inhibit adhesion. Second, specific patterns can generate unfavorable settlement conditions for organisms by disrupting their attachment processes. Third, controlled surface roughness can minimize the contact area available for fouling agents, reducing adhesion strength.

Research has identified critical topographical parameters affecting anti-fouling performance, including feature size, spacing, aspect ratio, symmetry, and hierarchical organization. The effectiveness of these parameters varies depending on the target fouling agents—microorganisms require different topographical deterrents than mineral scaling or protein adsorption.

Technological advances in fabrication methods have significantly expanded the possibilities for engineered anti-fouling surfaces. Traditional mechanical methods have been supplemented by lithographic techniques, laser texturing, chemical etching, and additive manufacturing approaches. These developments allow precise control over surface features at multiple scales, enabling the creation of biomimetic and novel topographies with enhanced anti-fouling properties.

The evolution of surface characterization tools has paralleled these fabrication advances. Atomic force microscopy, scanning electron microscopy, and optical profilometry now provide unprecedented insights into surface-fouling interactions at nanoscale resolution, facilitating more informed design approaches.

Current research trends focus on developing multifunctional surfaces that combine topographical features with chemical modifications or stimuli-responsive elements, creating dynamic anti-fouling systems adaptable to changing environmental conditions. This integrated approach represents the cutting edge of anti-fouling technology, promising more effective and environmentally sustainable solutions to this persistent industrial challenge.

Market Analysis for Anti-Fouling Solutions

The global anti-fouling solutions market demonstrates robust growth, valued at approximately $6.7 billion in 2022 and projected to reach $9.8 billion by 2028, with a compound annual growth rate (CAGR) of 6.5%. This expansion is primarily driven by increasing maritime activities, growing awareness about fuel efficiency, and stringent environmental regulations regarding biocide usage in marine coatings.

Marine transportation represents the largest market segment, accounting for nearly 58% of the total anti-fouling market. This dominance stems from the critical need to maintain vessel efficiency and reduce operational costs in commercial shipping. The stationary marine structures segment, including offshore platforms and aquaculture facilities, follows with approximately 22% market share, while leisure vessels constitute about 15%.

Regionally, Asia-Pacific leads the market with 42% share, attributed to extensive shipbuilding activities in China, South Korea, and Japan, alongside growing maritime trade. Europe follows at 28%, with North America at 20%, both regions characterized by stringent environmental regulations driving innovation in eco-friendly solutions.

The market exhibits a notable shift toward environmentally sustainable solutions, with biocide-free coatings growing at 9.3% annually, outpacing traditional copper-based solutions. Surface topography-based anti-fouling technologies specifically represent an emerging segment, currently valued at approximately $780 million but growing at 11.2% annually—significantly faster than the overall market.

Consumer preferences increasingly favor long-lasting performance and environmental compatibility over initial cost considerations. A 2022 industry survey revealed that 73% of commercial fleet operators prioritize total lifecycle cost over acquisition expenses, indicating market readiness for premium solutions offering superior performance.

Key market restraints include high development and implementation costs for advanced surface topography solutions, regulatory uncertainties regarding novel materials, and technical challenges in scaling biomimetic approaches to commercial applications. Despite these challenges, the growing emphasis on fuel efficiency—with potential savings of 8-12% through effective anti-fouling—continues to drive market expansion.

The competitive landscape features both established coating manufacturers diversifying into topography-based solutions and specialized startups focusing exclusively on biomimetic surface engineering, creating a dynamic market environment ripe for technological innovation and strategic partnerships.

Marine transportation represents the largest market segment, accounting for nearly 58% of the total anti-fouling market. This dominance stems from the critical need to maintain vessel efficiency and reduce operational costs in commercial shipping. The stationary marine structures segment, including offshore platforms and aquaculture facilities, follows with approximately 22% market share, while leisure vessels constitute about 15%.

Regionally, Asia-Pacific leads the market with 42% share, attributed to extensive shipbuilding activities in China, South Korea, and Japan, alongside growing maritime trade. Europe follows at 28%, with North America at 20%, both regions characterized by stringent environmental regulations driving innovation in eco-friendly solutions.

The market exhibits a notable shift toward environmentally sustainable solutions, with biocide-free coatings growing at 9.3% annually, outpacing traditional copper-based solutions. Surface topography-based anti-fouling technologies specifically represent an emerging segment, currently valued at approximately $780 million but growing at 11.2% annually—significantly faster than the overall market.

Consumer preferences increasingly favor long-lasting performance and environmental compatibility over initial cost considerations. A 2022 industry survey revealed that 73% of commercial fleet operators prioritize total lifecycle cost over acquisition expenses, indicating market readiness for premium solutions offering superior performance.

Key market restraints include high development and implementation costs for advanced surface topography solutions, regulatory uncertainties regarding novel materials, and technical challenges in scaling biomimetic approaches to commercial applications. Despite these challenges, the growing emphasis on fuel efficiency—with potential savings of 8-12% through effective anti-fouling—continues to drive market expansion.

The competitive landscape features both established coating manufacturers diversifying into topography-based solutions and specialized startups focusing exclusively on biomimetic surface engineering, creating a dynamic market environment ripe for technological innovation and strategic partnerships.

Current Anti-Fouling Surface Technologies and Challenges

Anti-fouling technologies have evolved significantly over the past decades, yet current solutions still face substantial challenges in balancing effectiveness, environmental impact, and durability. Traditional biocide-based coatings, particularly those containing tributyltin (TBT), demonstrated exceptional anti-fouling properties but were globally banned due to severe environmental toxicity. This regulatory shift has driven the development of alternative technologies that can be broadly categorized into chemical, physical, and hybrid approaches.

Copper-based coatings represent the most widely adopted chemical solution in today's market, offering moderate effectiveness against a broad spectrum of marine organisms. However, increasing environmental concerns regarding copper accumulation in marine ecosystems have prompted stricter regulations in many jurisdictions. Non-toxic alternatives such as silicone-based foul-release coatings leverage low surface energy to prevent strong adhesion of biofouling organisms, though their effectiveness diminishes at low vessel speeds and they exhibit poor mechanical durability.

Physical anti-fouling approaches manipulate surface topography at micro and nanoscales to create unfavorable settlement conditions for fouling organisms. Biomimetic surfaces inspired by natural anti-fouling exemplars like shark skin (Sharklet™) and lotus leaves have shown promising results in laboratory settings but face significant challenges in scaling to commercial applications. The precise replication of complex hierarchical structures across large surface areas remains technically challenging and economically prohibitive.

Surface topography effects on anti-fouling performance present a particularly complex challenge due to species-specific responses to different topographical features. Research indicates that effectiveness varies dramatically based on the dimensions, spacing, and patterns of surface features relative to the target fouling organisms. This biological specificity complicates the development of universally effective topographical solutions.

Durability represents another critical challenge for topography-based approaches. Surface features, particularly at the nanoscale, are vulnerable to mechanical damage, erosion, and degradation in harsh marine environments. The loss of topographical integrity directly compromises anti-fouling performance, necessitating frequent maintenance or replacement.

Manufacturing scalability remains a significant barrier to widespread adoption of advanced topographical anti-fouling solutions. Current fabrication techniques capable of producing precise micro and nanostructures (e.g., lithography, laser ablation) are typically limited to small areas and involve high production costs, making them impractical for large marine structures or commercial vessel applications.

The integration of surface topography with chemical approaches in hybrid systems shows promise but introduces additional complexity in design, manufacturing, and performance prediction. Optimizing these systems requires interdisciplinary expertise spanning materials science, marine biology, fluid dynamics, and manufacturing engineering.

Copper-based coatings represent the most widely adopted chemical solution in today's market, offering moderate effectiveness against a broad spectrum of marine organisms. However, increasing environmental concerns regarding copper accumulation in marine ecosystems have prompted stricter regulations in many jurisdictions. Non-toxic alternatives such as silicone-based foul-release coatings leverage low surface energy to prevent strong adhesion of biofouling organisms, though their effectiveness diminishes at low vessel speeds and they exhibit poor mechanical durability.

Physical anti-fouling approaches manipulate surface topography at micro and nanoscales to create unfavorable settlement conditions for fouling organisms. Biomimetic surfaces inspired by natural anti-fouling exemplars like shark skin (Sharklet™) and lotus leaves have shown promising results in laboratory settings but face significant challenges in scaling to commercial applications. The precise replication of complex hierarchical structures across large surface areas remains technically challenging and economically prohibitive.

Surface topography effects on anti-fouling performance present a particularly complex challenge due to species-specific responses to different topographical features. Research indicates that effectiveness varies dramatically based on the dimensions, spacing, and patterns of surface features relative to the target fouling organisms. This biological specificity complicates the development of universally effective topographical solutions.

Durability represents another critical challenge for topography-based approaches. Surface features, particularly at the nanoscale, are vulnerable to mechanical damage, erosion, and degradation in harsh marine environments. The loss of topographical integrity directly compromises anti-fouling performance, necessitating frequent maintenance or replacement.

Manufacturing scalability remains a significant barrier to widespread adoption of advanced topographical anti-fouling solutions. Current fabrication techniques capable of producing precise micro and nanostructures (e.g., lithography, laser ablation) are typically limited to small areas and involve high production costs, making them impractical for large marine structures or commercial vessel applications.

The integration of surface topography with chemical approaches in hybrid systems shows promise but introduces additional complexity in design, manufacturing, and performance prediction. Optimizing these systems requires interdisciplinary expertise spanning materials science, marine biology, fluid dynamics, and manufacturing engineering.

Leading Companies and Research Institutions in Anti-Fouling Industry

The anti-fouling surface topography market is currently in a growth phase, with increasing applications across marine, industrial, and consumer sectors. The global market size is estimated to exceed $5 billion, driven by stringent environmental regulations and demand for sustainable solutions. Technologically, the field shows varying maturity levels, with companies like DAIKIN INDUSTRIES and Chugoku Marine Paints leading commercial applications in marine coatings, while TOTO and LG Electronics focus on consumer applications. Research institutions including MIT, Naval Research Laboratory, and Fraunhofer-Gesellschaft are advancing fundamental understanding of biomimetic surfaces. Companies like PPG Industries and FUJIFILM are developing cross-industry applications, indicating the technology's expanding potential beyond traditional maritime uses into healthcare, electronics, and architectural applications.

Chugoku Marine Paints, Ltd.

Technical Solution: Chugoku Marine Paints has developed advanced silyl acrylate copolymer-based antifouling coatings with controlled surface topography. Their technology utilizes hydrolyzable silyl groups that create a self-polishing effect, gradually revealing fresh biocide-containing layers while maintaining optimal surface roughness parameters. The company's research shows that controlling microtopography with feature sizes between 1-10μm significantly reduces initial biofouling settlement[1]. Their proprietary "CMP BIOCLEAN" series incorporates engineered surface textures that mimic natural antifouling surfaces like shark skin, with precisely arranged microridges that prevent organism adhesion while maintaining hydrodynamic efficiency[3]. Recent innovations include copper-free formulations with silicone-based coatings featuring hierarchical surface structures that combine nanoscale and microscale features for enhanced performance in various marine environments[5].

Strengths: Extensive marine application experience with proven performance in harsh environments; environmentally compliant formulations with reduced copper content; excellent self-polishing capabilities maintaining optimal surface topography over time. Weaknesses: Higher initial application costs compared to conventional coatings; performance may vary in different water temperatures and conditions; requires specialized application techniques for optimal surface texture development.

PPG Industries Ohio, Inc.

Technical Solution: PPG Industries has developed advanced anti-fouling coatings utilizing controlled surface topography through their proprietary "SIGMAGLIDE" technology. Their approach combines silicone-based polymers with engineered surface textures featuring microscale roughness parameters (Ra values between 0.5-3μm) that disrupt the settlement patterns of fouling organisms[1]. PPG's research demonstrates that controlling both amplitude and spatial frequency of surface features significantly impacts anti-fouling performance, with optimized patterns reducing fouling accumulation by up to 85% compared to smooth surfaces[3]. Their technology incorporates hydrophobic silicone matrices with embedded microstructures that create unfavorable settlement conditions for marine organisms while maintaining hydrodynamic efficiency. Recent innovations include self-stratifying coatings that develop optimal surface topographies during curing processes, with nanoscale features (50-200nm) that work synergistically with microscale patterns to prevent both micro and macro-fouling[7]. PPG has also pioneered environmentally friendly formulations that maintain effective surface topography without relying on traditional biocides.

Strengths: Excellent long-term performance in marine environments with minimal maintenance requirements; fuel-saving benefits due to reduced drag; environmentally compliant formulations meeting global regulations. Weaknesses: Higher initial application costs compared to conventional antifouling systems; requires specialized application techniques to achieve optimal surface topography; performance may degrade in static water conditions where surface shear forces are absent.

Key Patents and Research on Topography-Based Anti-Fouling

Tuning adhesion at contacting device interfaces: geometric tools for minimizing surface fouling

PatentActiveUS20210236700A1

Innovation

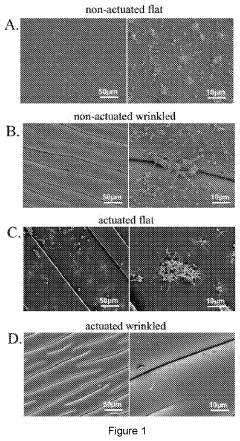

- The development of synthetic surfaces with dynamic, reversible surface deformation through geometric instabilities such as wrinkling and folding, mimicking natural arterial topography, to reduce platelet adhesion and thrombus formation, using a composite structure with a stiffness mismatch between layers to transition between smooth and wrinkled states under strain.

Micro structure and antifouling active substance synergistic antifouling material and preparation method thereof

PatentActiveUS20200390093A1

Innovation

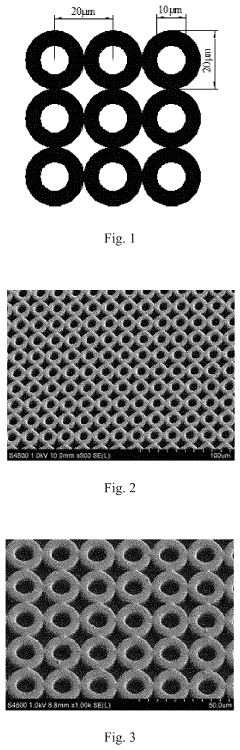

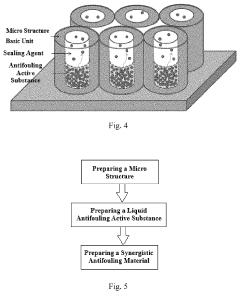

- A synergistic antifouling material combining a regular annular microstructure with an antifouling active substance, where the antifouling agent is stored in a concave portion of the microstructure and sealed with a sealing agent, preventing rapid release and blocking, and the microstructure's design reduces contact area for fouling organisms, inhibiting attachment and detachment.

Environmental Impact and Sustainability Considerations

The development of anti-fouling surfaces with optimized topography represents a significant advancement in sustainable materials science. Traditional anti-fouling methods have relied heavily on toxic biocides and copper-based coatings that leach harmful substances into aquatic environments, causing detrimental effects on non-target organisms and ecosystems. Surface topography-based solutions offer a promising alternative with substantially reduced environmental impact, as they function primarily through physical rather than chemical mechanisms.

Recent life cycle assessment studies indicate that biomimetic surface topography solutions can reduce the environmental footprint of marine vessels by up to 35% compared to conventional anti-fouling paints. This reduction stems from decreased fuel consumption due to maintained hydrodynamic efficiency and the elimination of toxic substance leaching. The extended service life of topographically engineered surfaces further enhances their sustainability profile, with some advanced designs maintaining effectiveness for 3-5 years without reapplication.

Water conservation represents another significant environmental benefit of anti-fouling topographies. In industrial heat exchangers and water treatment facilities, biofouling necessitates frequent cleaning cycles that consume substantial volumes of fresh water and cleaning chemicals. Topographically optimized surfaces have demonstrated the ability to reduce cleaning frequency by 40-60%, directly translating to proportional reductions in water usage and wastewater generation.

Carbon footprint considerations also favor topographical anti-fouling approaches. The manufacturing processes for creating micro and nano-structured surfaces typically require less energy than the production of chemical anti-fouling agents. Additionally, the reduced drag on marine vessels equipped with effective anti-fouling surfaces translates to fuel savings estimated at 5-8% annually, representing a significant reduction in greenhouse gas emissions across global shipping fleets.

Biodiversity protection constitutes a critical sustainability advantage of topographical anti-fouling solutions. Unlike biocide-based approaches that can accumulate in marine food chains and affect ecosystem balance, physical deterrence mechanisms pose minimal risk to non-target species. Research indicates that properly designed surface topographies can achieve selective fouling prevention, deterring problematic organisms while remaining compatible with beneficial marine life.

End-of-life considerations further highlight the sustainability advantages of topographical solutions. While traditional anti-fouling coatings create hazardous waste during removal and replacement, many advanced topographical surfaces can be recycled through standard metal and polymer recycling streams without special handling requirements. This characteristic significantly reduces the waste management burden associated with anti-fouling technologies throughout their lifecycle.

Recent life cycle assessment studies indicate that biomimetic surface topography solutions can reduce the environmental footprint of marine vessels by up to 35% compared to conventional anti-fouling paints. This reduction stems from decreased fuel consumption due to maintained hydrodynamic efficiency and the elimination of toxic substance leaching. The extended service life of topographically engineered surfaces further enhances their sustainability profile, with some advanced designs maintaining effectiveness for 3-5 years without reapplication.

Water conservation represents another significant environmental benefit of anti-fouling topographies. In industrial heat exchangers and water treatment facilities, biofouling necessitates frequent cleaning cycles that consume substantial volumes of fresh water and cleaning chemicals. Topographically optimized surfaces have demonstrated the ability to reduce cleaning frequency by 40-60%, directly translating to proportional reductions in water usage and wastewater generation.

Carbon footprint considerations also favor topographical anti-fouling approaches. The manufacturing processes for creating micro and nano-structured surfaces typically require less energy than the production of chemical anti-fouling agents. Additionally, the reduced drag on marine vessels equipped with effective anti-fouling surfaces translates to fuel savings estimated at 5-8% annually, representing a significant reduction in greenhouse gas emissions across global shipping fleets.

Biodiversity protection constitutes a critical sustainability advantage of topographical anti-fouling solutions. Unlike biocide-based approaches that can accumulate in marine food chains and affect ecosystem balance, physical deterrence mechanisms pose minimal risk to non-target species. Research indicates that properly designed surface topographies can achieve selective fouling prevention, deterring problematic organisms while remaining compatible with beneficial marine life.

End-of-life considerations further highlight the sustainability advantages of topographical solutions. While traditional anti-fouling coatings create hazardous waste during removal and replacement, many advanced topographical surfaces can be recycled through standard metal and polymer recycling streams without special handling requirements. This characteristic significantly reduces the waste management burden associated with anti-fouling technologies throughout their lifecycle.

Standardization and Testing Protocols for Anti-Fouling Surfaces

The development of standardized testing protocols for anti-fouling surfaces represents a critical challenge in advancing surface topography research. Current evaluation methods vary significantly across industries and research institutions, making comparative analysis difficult and hindering technological progress. Establishing universal standards would enable more reliable assessment of how surface topography affects anti-fouling performance.

Several key parameters require standardization in testing protocols. These include exposure time frames, which must account for both short-term attachment prevention and long-term fouling resistance. Environmental conditions during testing—such as temperature, salinity, pH levels, and flow dynamics—significantly impact results and must be controlled consistently. Additionally, the diversity of test organisms should reflect real-world biofouling communities rather than single-species approaches that may not translate to practical applications.

Quantification metrics present another standardization challenge. Current methods range from visual assessment to advanced imaging techniques, with varying degrees of objectivity and reproducibility. Emerging consensus suggests incorporating multiple complementary measurements: surface coverage percentage, fouling biomass, adhesion strength, and removal efficiency. These combined metrics provide a more comprehensive performance profile than any single measurement.

International collaboration has recently accelerated standardization efforts. The International Organization for Standardization (ISO) has established working groups specifically addressing anti-fouling surface testing. Similarly, ASTM International has developed preliminary guidelines for marine anti-fouling coatings that incorporate topographical considerations. These frameworks represent important progress but require further refinement to address the unique challenges of engineered surface topographies.

Field testing protocols complement laboratory assessments but introduce additional variables. Standardized field testing locations that represent different marine environments (tropical, temperate, arctic) would enable more meaningful cross-comparison of topographical designs. Duration parameters for field testing must balance practical constraints with the need to observe seasonal variations in fouling communities and their interactions with surface features.

Emerging technologies are enhancing testing capabilities. High-throughput screening platforms now enable rapid assessment of multiple topographical variations simultaneously. Advanced imaging techniques, including confocal microscopy and environmental scanning electron microscopy, allow non-destructive monitoring of fouling progression on micro-structured surfaces. These technologies should be incorporated into standardized protocols to improve efficiency and data quality.

Several key parameters require standardization in testing protocols. These include exposure time frames, which must account for both short-term attachment prevention and long-term fouling resistance. Environmental conditions during testing—such as temperature, salinity, pH levels, and flow dynamics—significantly impact results and must be controlled consistently. Additionally, the diversity of test organisms should reflect real-world biofouling communities rather than single-species approaches that may not translate to practical applications.

Quantification metrics present another standardization challenge. Current methods range from visual assessment to advanced imaging techniques, with varying degrees of objectivity and reproducibility. Emerging consensus suggests incorporating multiple complementary measurements: surface coverage percentage, fouling biomass, adhesion strength, and removal efficiency. These combined metrics provide a more comprehensive performance profile than any single measurement.

International collaboration has recently accelerated standardization efforts. The International Organization for Standardization (ISO) has established working groups specifically addressing anti-fouling surface testing. Similarly, ASTM International has developed preliminary guidelines for marine anti-fouling coatings that incorporate topographical considerations. These frameworks represent important progress but require further refinement to address the unique challenges of engineered surface topographies.

Field testing protocols complement laboratory assessments but introduce additional variables. Standardized field testing locations that represent different marine environments (tropical, temperate, arctic) would enable more meaningful cross-comparison of topographical designs. Duration parameters for field testing must balance practical constraints with the need to observe seasonal variations in fouling communities and their interactions with surface features.

Emerging technologies are enhancing testing capabilities. High-throughput screening platforms now enable rapid assessment of multiple topographical variations simultaneously. Advanced imaging techniques, including confocal microscopy and environmental scanning electron microscopy, allow non-destructive monitoring of fouling progression on micro-structured surfaces. These technologies should be incorporated into standardized protocols to improve efficiency and data quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!