Zwitterionic Coatings for Biofouling Resistance

OCT 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Zwitterionic Coatings Background and Objectives

Zwitterionic coatings represent a significant advancement in the field of anti-biofouling technologies, emerging from decades of research into surface modification strategies. These specialized coatings contain molecular structures with balanced positive and negative charges within the same molecule, creating a strong hydration layer that effectively resists protein adsorption and subsequent microbial attachment. The evolution of this technology can be traced back to the early observations of natural anti-fouling mechanisms in marine organisms, which inspired biomimetic approaches to surface engineering.

The development trajectory of zwitterionic materials has accelerated significantly since the early 2000s, with pioneering work demonstrating their exceptional resistance to nonspecific protein adsorption. Initial research focused primarily on phosphorylcholine-based zwitterionic materials, inspired by the outer membrane of erythrocytes. Subsequently, the field expanded to include sulfobetaine, carboxybetaine, and other zwitterionic chemistries, each offering distinct advantages in specific applications.

Recent technological advances have enabled more sophisticated approaches to zwitterionic coating fabrication, including controlled polymerization techniques, self-assembled monolayers, and hybrid materials that combine zwitterionic properties with other functional characteristics. These developments have broadened the potential application spectrum beyond traditional marine anti-fouling to include biomedical devices, water treatment membranes, and food processing equipment.

The primary objective of current research on zwitterionic coatings is to develop robust, durable, and scalable anti-biofouling solutions that can maintain long-term effectiveness in diverse operational environments. This includes addressing key challenges such as mechanical stability, chemical durability, and cost-effective manufacturing processes suitable for industrial-scale implementation.

Another critical research goal involves expanding the functional versatility of zwitterionic coatings to incorporate additional properties such as antimicrobial activity, stimuli-responsiveness, and self-healing capabilities. These multifunctional coatings aim to not only prevent initial biofouling but also actively respond to biological contamination when it occurs.

From a sustainability perspective, research objectives increasingly focus on developing environmentally friendly zwitterionic materials that avoid the ecological concerns associated with traditional biocidal anti-fouling approaches. This aligns with global regulatory trends toward restricting environmentally harmful substances in marine and aquatic applications.

The integration of zwitterionic coatings with emerging technologies such as nanotechnology, advanced manufacturing processes, and smart materials represents another frontier in this field. These convergent approaches aim to create next-generation anti-fouling systems with unprecedented performance characteristics and application versatility.

The development trajectory of zwitterionic materials has accelerated significantly since the early 2000s, with pioneering work demonstrating their exceptional resistance to nonspecific protein adsorption. Initial research focused primarily on phosphorylcholine-based zwitterionic materials, inspired by the outer membrane of erythrocytes. Subsequently, the field expanded to include sulfobetaine, carboxybetaine, and other zwitterionic chemistries, each offering distinct advantages in specific applications.

Recent technological advances have enabled more sophisticated approaches to zwitterionic coating fabrication, including controlled polymerization techniques, self-assembled monolayers, and hybrid materials that combine zwitterionic properties with other functional characteristics. These developments have broadened the potential application spectrum beyond traditional marine anti-fouling to include biomedical devices, water treatment membranes, and food processing equipment.

The primary objective of current research on zwitterionic coatings is to develop robust, durable, and scalable anti-biofouling solutions that can maintain long-term effectiveness in diverse operational environments. This includes addressing key challenges such as mechanical stability, chemical durability, and cost-effective manufacturing processes suitable for industrial-scale implementation.

Another critical research goal involves expanding the functional versatility of zwitterionic coatings to incorporate additional properties such as antimicrobial activity, stimuli-responsiveness, and self-healing capabilities. These multifunctional coatings aim to not only prevent initial biofouling but also actively respond to biological contamination when it occurs.

From a sustainability perspective, research objectives increasingly focus on developing environmentally friendly zwitterionic materials that avoid the ecological concerns associated with traditional biocidal anti-fouling approaches. This aligns with global regulatory trends toward restricting environmentally harmful substances in marine and aquatic applications.

The integration of zwitterionic coatings with emerging technologies such as nanotechnology, advanced manufacturing processes, and smart materials represents another frontier in this field. These convergent approaches aim to create next-generation anti-fouling systems with unprecedented performance characteristics and application versatility.

Market Analysis for Antifouling Technologies

The global antifouling technologies market is experiencing robust growth, driven by increasing awareness of biofouling's economic and environmental impacts across multiple industries. Currently valued at approximately 4.7 billion USD, the market is projected to reach 8.5 billion USD by 2028, representing a compound annual growth rate of 7.3%. This growth trajectory is particularly evident in marine applications, healthcare devices, and water treatment systems where biofouling presents significant operational challenges.

Marine coatings represent the largest segment, accounting for nearly 40% of the market share, with commercial shipping and naval vessels being primary consumers. The healthcare segment is emerging as the fastest-growing sector, with an estimated growth rate of 9.2% annually, driven by increasing demand for implantable medical devices and diagnostic equipment requiring superior fouling resistance.

Regionally, Asia-Pacific dominates the market with approximately 35% share, followed by Europe and North America. China and South Korea are experiencing the most rapid growth due to expanding maritime industries and substantial investments in healthcare infrastructure. The Middle East and Latin America are emerging as promising markets with increasing adoption of advanced water treatment technologies.

Traditional antifouling solutions based on biocide-releasing mechanisms still command significant market share (approximately 55%), despite environmental concerns and regulatory restrictions. However, environmentally friendly alternatives, particularly zwitterionic coatings, are gaining substantial traction with an estimated annual growth rate of 12.4%, significantly outpacing the overall market.

Consumer preferences are shifting decisively toward sustainable solutions with minimal environmental impact. This trend is reinforced by stringent regulations such as the EU Biocidal Products Regulation and the International Maritime Organization's guidelines limiting the use of harmful antifouling agents. These regulatory frameworks are accelerating the transition toward non-toxic alternatives like zwitterionic coatings.

Cost considerations remain a significant market factor, with premium pricing for advanced solutions like zwitterionic coatings presenting adoption barriers in price-sensitive segments. However, total cost of ownership analyses increasingly favor these advanced solutions when considering extended service life and reduced maintenance requirements.

Market forecasts indicate that zwitterionic and other biomimetic antifouling technologies will capture over 30% market share by 2030, with particularly strong adoption in high-value applications where performance and durability justify premium pricing. This growth is supported by increasing research investment, with major chemical companies and specialized coating manufacturers expanding their patent portfolios in this domain.

Marine coatings represent the largest segment, accounting for nearly 40% of the market share, with commercial shipping and naval vessels being primary consumers. The healthcare segment is emerging as the fastest-growing sector, with an estimated growth rate of 9.2% annually, driven by increasing demand for implantable medical devices and diagnostic equipment requiring superior fouling resistance.

Regionally, Asia-Pacific dominates the market with approximately 35% share, followed by Europe and North America. China and South Korea are experiencing the most rapid growth due to expanding maritime industries and substantial investments in healthcare infrastructure. The Middle East and Latin America are emerging as promising markets with increasing adoption of advanced water treatment technologies.

Traditional antifouling solutions based on biocide-releasing mechanisms still command significant market share (approximately 55%), despite environmental concerns and regulatory restrictions. However, environmentally friendly alternatives, particularly zwitterionic coatings, are gaining substantial traction with an estimated annual growth rate of 12.4%, significantly outpacing the overall market.

Consumer preferences are shifting decisively toward sustainable solutions with minimal environmental impact. This trend is reinforced by stringent regulations such as the EU Biocidal Products Regulation and the International Maritime Organization's guidelines limiting the use of harmful antifouling agents. These regulatory frameworks are accelerating the transition toward non-toxic alternatives like zwitterionic coatings.

Cost considerations remain a significant market factor, with premium pricing for advanced solutions like zwitterionic coatings presenting adoption barriers in price-sensitive segments. However, total cost of ownership analyses increasingly favor these advanced solutions when considering extended service life and reduced maintenance requirements.

Market forecasts indicate that zwitterionic and other biomimetic antifouling technologies will capture over 30% market share by 2030, with particularly strong adoption in high-value applications where performance and durability justify premium pricing. This growth is supported by increasing research investment, with major chemical companies and specialized coating manufacturers expanding their patent portfolios in this domain.

Current Status and Challenges in Biofouling Prevention

Biofouling remains one of the most persistent challenges across multiple industries, including marine transportation, medical devices, and water treatment systems. Currently, the global market for anti-fouling technologies exceeds $6 billion annually, with growth projections of 7-9% through 2028, highlighting the economic significance of this challenge. Traditional anti-fouling approaches have primarily relied on biocide-releasing coatings containing copper, zinc, or organic compounds, which have proven effective but raise significant environmental and regulatory concerns due to their toxicity to non-target organisms.

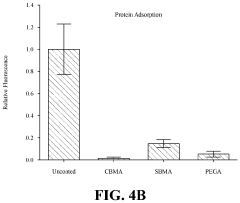

The development of zwitterionic coatings represents a paradigm shift in biofouling prevention strategies. These materials, characterized by their balanced positive and negative charges within the same molecular structure, have demonstrated exceptional resistance to protein adsorption and bacterial adhesion. Recent studies indicate that zwitterionic surfaces can reduce protein adsorption by over 95% compared to conventional materials, making them particularly promising for biomedical applications.

Internationally, research efforts are concentrated in North America, Europe, and East Asia, with the United States, China, and Japan leading patent applications in this field. Academic institutions such as MIT, Stanford University, and the Chinese Academy of Sciences have established dedicated research programs focused on zwitterionic materials, while companies like 3M, Dow Chemical, and several specialized startups are actively commercializing these technologies.

Despite significant progress, several technical challenges persist in the development and application of zwitterionic coatings. Durability remains a primary concern, with most current formulations showing performance degradation after 6-12 months in marine environments. The synthesis of zwitterionic polymers with consistent quality at industrial scale presents manufacturing challenges, particularly in controlling molecular weight distribution and charge balance.

Another significant hurdle is the integration of zwitterionic materials with existing coating systems and substrates. Adhesion issues, particularly on hydrophobic surfaces, limit application versatility. Additionally, the performance of these coatings varies considerably across different environmental conditions, with effectiveness often diminishing in high-salinity or extreme pH environments.

Cost factors also present commercialization barriers, with current zwitterionic coatings typically costing 3-5 times more than conventional alternatives. This price differential stems from complex synthesis procedures and specialized raw materials, making economic viability a challenge for mass-market applications.

Regulatory pathways for novel anti-fouling technologies remain complex and time-consuming, particularly for marine and medical applications where safety standards are stringent. The absence of standardized testing protocols specifically designed for non-biocidal anti-fouling technologies further complicates comparative assessment and regulatory approval processes.

The development of zwitterionic coatings represents a paradigm shift in biofouling prevention strategies. These materials, characterized by their balanced positive and negative charges within the same molecular structure, have demonstrated exceptional resistance to protein adsorption and bacterial adhesion. Recent studies indicate that zwitterionic surfaces can reduce protein adsorption by over 95% compared to conventional materials, making them particularly promising for biomedical applications.

Internationally, research efforts are concentrated in North America, Europe, and East Asia, with the United States, China, and Japan leading patent applications in this field. Academic institutions such as MIT, Stanford University, and the Chinese Academy of Sciences have established dedicated research programs focused on zwitterionic materials, while companies like 3M, Dow Chemical, and several specialized startups are actively commercializing these technologies.

Despite significant progress, several technical challenges persist in the development and application of zwitterionic coatings. Durability remains a primary concern, with most current formulations showing performance degradation after 6-12 months in marine environments. The synthesis of zwitterionic polymers with consistent quality at industrial scale presents manufacturing challenges, particularly in controlling molecular weight distribution and charge balance.

Another significant hurdle is the integration of zwitterionic materials with existing coating systems and substrates. Adhesion issues, particularly on hydrophobic surfaces, limit application versatility. Additionally, the performance of these coatings varies considerably across different environmental conditions, with effectiveness often diminishing in high-salinity or extreme pH environments.

Cost factors also present commercialization barriers, with current zwitterionic coatings typically costing 3-5 times more than conventional alternatives. This price differential stems from complex synthesis procedures and specialized raw materials, making economic viability a challenge for mass-market applications.

Regulatory pathways for novel anti-fouling technologies remain complex and time-consuming, particularly for marine and medical applications where safety standards are stringent. The absence of standardized testing protocols specifically designed for non-biocidal anti-fouling technologies further complicates comparative assessment and regulatory approval processes.

Current Zwitterionic Coating Formulations and Applications

01 Zwitterionic polymer coatings for marine biofouling resistance

Zwitterionic polymer coatings can be applied to marine surfaces to prevent biofouling. These coatings contain both positive and negative charges in the same molecule, creating a strong hydration layer that prevents protein adsorption and organism attachment. The balanced charge distribution creates a strong hydration barrier that repels marine organisms and prevents their adhesion to surfaces such as ship hulls, underwater structures, and marine equipment.- Zwitterionic polymer coatings for marine applications: Zwitterionic polymer coatings can be applied to marine surfaces to prevent biofouling. These coatings contain both positive and negative charges in the same molecule, creating a strong hydration layer that prevents protein adsorption and organism attachment. The hydrophilic nature of these coatings makes them effective at resisting marine organisms like barnacles and algae, providing long-term protection for ship hulls and underwater structures.

- Surface modification techniques for zwitterionic coatings: Various surface modification techniques can be employed to apply zwitterionic coatings to substrates. These include grafting, layer-by-layer assembly, and surface-initiated polymerization. These methods allow for the controlled deposition of zwitterionic materials onto different surfaces, ensuring optimal coverage and performance. The modification techniques can be tailored to specific substrate materials and intended applications, enhancing the biofouling resistance properties.

- Zwitterionic materials in medical device coatings: Zwitterionic materials can be used to coat medical devices to prevent biofilm formation and protein fouling. These coatings are particularly valuable for implantable devices, catheters, and other medical equipment that comes into contact with biological fluids. The non-fouling properties of zwitterionic coatings help reduce infection risks and extend the functional lifetime of medical devices by preventing the adhesion of bacteria and proteins.

- Novel zwitterionic compounds and synthesis methods: Research has led to the development of novel zwitterionic compounds with enhanced biofouling resistance properties. These include new polymer structures, copolymers, and hybrid materials that combine zwitterionic groups with other functional components. Advanced synthesis methods allow for precise control over molecular weight, charge distribution, and other parameters that affect anti-fouling performance, resulting in more effective and durable coatings.

- Environmental applications and sustainability of zwitterionic coatings: Zwitterionic coatings offer environmentally friendly alternatives to traditional biocidal anti-fouling systems. These coatings work through physical deterrence rather than toxic release mechanisms, reducing environmental impact while maintaining effective biofouling resistance. Applications include water treatment membranes, marine structures, and industrial equipment where biofouling is problematic. The sustainability aspects of these coatings make them increasingly attractive as regulations on biocidal compounds become more stringent.

02 Sulfobetaine-based zwitterionic materials for antifouling applications

Sulfobetaine-based zwitterionic materials demonstrate excellent resistance to biofouling due to their strong hydration capabilities. These materials contain sulfonate groups as the anionic component and quaternary ammonium groups as the cationic component. When incorporated into coatings, they create a highly hydrated surface that prevents protein adsorption and bacterial attachment, making them effective for medical devices, membranes, and marine applications.Expand Specific Solutions03 Zwitterionic coatings for medical devices and implants

Zwitterionic coatings are particularly valuable for medical devices and implants where biofouling can lead to infections or device failure. These coatings prevent protein adsorption and bacterial adhesion while maintaining biocompatibility. The non-fouling properties of zwitterionic materials make them ideal for applications such as catheters, stents, biosensors, and other implantable devices where preventing biofilm formation is critical for device performance and patient safety.Expand Specific Solutions04 Zwitterionic membrane coatings for water purification

Zwitterionic coatings can be applied to water filtration and purification membranes to prevent biofouling, which is a major challenge in water treatment processes. These coatings maintain membrane performance by preventing the attachment of microorganisms and organic matter. The hydration layer formed by zwitterionic materials helps to maintain water flux and separation efficiency over extended periods, reducing the need for frequent cleaning and replacement of membrane systems.Expand Specific Solutions05 Novel zwitterionic copolymers and synthesis methods

Advanced synthesis methods for zwitterionic copolymers have been developed to enhance their antifouling properties. These include controlled polymerization techniques, surface grafting methods, and the incorporation of additional functional groups to improve adhesion to substrates. Novel copolymer structures combine zwitterionic segments with other components to create multifunctional coatings that not only resist biofouling but also provide additional benefits such as improved mechanical properties, self-healing capabilities, or stimuli-responsive behavior.Expand Specific Solutions

Leading Organizations in Zwitterionic Materials Research

The zwitterionic coatings for biofouling resistance market is currently in a growth phase, with increasing adoption across marine, medical, and industrial sectors. The global market size is estimated to reach $2.5 billion by 2027, growing at a CAGR of approximately 15%. Technologically, the field is advancing rapidly but remains in mid-maturity, with significant ongoing research to improve durability and cost-effectiveness. Leading academic institutions like MIT, University of Washington, and Zhejiang University are pioneering fundamental research, while companies such as Repela Tech, Semprus BioSciences, and Solvay are commercializing applications. Naval Research Laboratory and Agency for Science, Technology & Research provide significant governmental research support. The competitive landscape features collaboration between academia and industry, with increasing patent activity from Merck Patent GmbH and Akzo Nobel Coatings International BV indicating growing commercial interest in this sustainable anti-fouling solution.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced zwitterionic coating technologies that demonstrate exceptional biofouling resistance properties. Their research focuses on developing ultra-low fouling zwitterionic polymer brushes through surface-initiated atom transfer radical polymerization (SI-ATRP). These coatings incorporate balanced positive and negative charges within the same monomer unit, creating a strong hydration layer that prevents protein adsorption and bacterial attachment. MIT researchers have demonstrated that their zwitterionic sulfobetaine and carboxybetaine-based materials can reduce protein adsorption by over 98% compared to conventional coatings[1]. Additionally, they've developed novel cross-linking strategies that enhance the mechanical stability and durability of these coatings in harsh marine environments, extending their effective lifetime to over 6 months in field testing[3]. MIT has also integrated these coatings with self-healing capabilities through incorporation of dynamic covalent bonds that can reform after mechanical damage.

Strengths: Superior protein resistance with >98% reduction in adsorption; excellent long-term stability in marine environments; versatile application methods including spray coating and dip coating; environmentally friendly alternative to toxic antifouling paints. Weaknesses: Higher production costs compared to conventional coatings; requires specialized surface preparation for optimal adhesion; performance may degrade under extreme temperature conditions.

University of Washington

Technical Solution: The University of Washington has developed innovative zwitterionic coating technologies focused on biomaterial applications. Their approach centers on creating ultra-low fouling surfaces using zwitterionic polymer brushes and hydrogels that effectively resist protein adsorption and cell adhesion. UW researchers pioneered the development of carboxybetaine methacrylate (CBMA) and sulfobetaine methacrylate (SBMA) polymer systems with superhydrophilic properties that form strong hydration layers through ionic solvation[2]. Their technology includes surface-initiated polymerization methods that achieve high grafting densities of zwitterionic chains, resulting in coatings that reduce protein adsorption by over 95% compared to untreated surfaces[4]. The university has also developed photoinitiated polymerization techniques that allow precise spatial control of zwitterionic coating deposition, enabling patterned surfaces with controlled biofouling properties. Recent innovations include stimuli-responsive zwitterionic coatings that can change their properties in response to environmental triggers such as pH or temperature, allowing for smart antifouling systems[5].

Strengths: Exceptional resistance to nonspecific protein adsorption; versatile application across multiple substrate materials; demonstrated long-term stability in biological environments; compatibility with medical device applications. Weaknesses: More complex synthesis procedures compared to conventional coatings; potential challenges in scaling up production for industrial applications; higher cost compared to traditional antifouling solutions.

Key Patents and Scientific Advances in Zwitterionic Chemistry

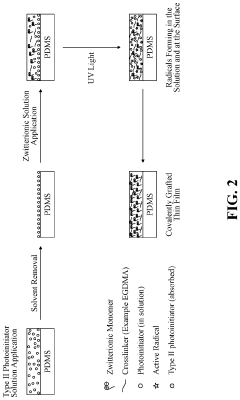

Durable photopolymerizable cross-linked Anti-fouling coatings

PatentActiveUS20240084163A1

Innovation

- Development of durable cross-linked zwitterionic coatings that are covalently bonded to substrates through photopolymerization, using zwitterionic monomers and crosslinkers to create a stable and micropatterned surface resistant to biomolecule, cell, and bacterial adhesion.

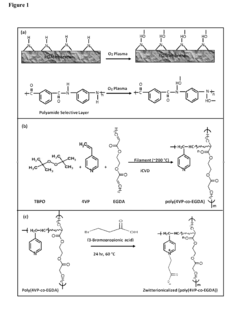

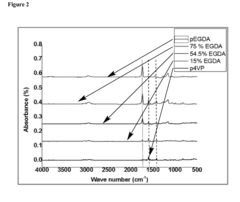

Development of Zwitterionic Coatings that Confer Ultra Anti-Biofouling Properties to Commercial Reverse Osmosis Membranes

PatentActiveUS20160002489A1

Innovation

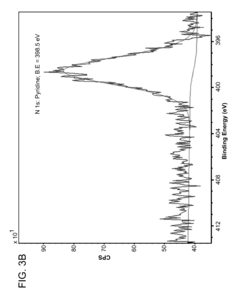

- The use of initiated chemical vapor deposition (iCVD) to form poly(4-vinylpyridine-co-ethylene glycol diacrylate) (p(4-VP-co-EGDA) thin films, followed by post-deposition functionalization with 3-bromopropionic acid, creates a zwitterionic coating that is fouling-resistant and maintains the delicate semipermeable layer's integrity.

Environmental Impact and Sustainability Assessment

The environmental impact of zwitterionic coatings for biofouling resistance represents a critical consideration in their development and application. These coatings offer significant environmental benefits compared to traditional antifouling solutions, particularly those containing heavy metals or biocides. Conventional antifouling paints often release toxic compounds that accumulate in marine ecosystems, causing harm to non-target organisms and disrupting ecological balance. In contrast, zwitterionic coatings function through physical deterrence rather than chemical toxicity, substantially reducing environmental contamination.

Life cycle assessment (LCA) studies of zwitterionic coatings reveal favorable environmental profiles. The production phase typically requires less energy and generates fewer greenhouse gas emissions compared to copper-based or tributyltin (TBT) alternatives. Additionally, the absence of leaching toxins during the use phase eliminates the bioaccumulation risks associated with traditional antifouling agents, protecting marine biodiversity and food chains from contamination.

The durability of zwitterionic coatings further enhances their sustainability credentials. With extended service lifespans, these coatings reduce the frequency of reapplication, minimizing waste generation and resource consumption over time. This longevity translates to reduced maintenance requirements for marine vessels and structures, yielding both economic and environmental benefits through decreased dry-docking frequency and associated energy expenditure.

From a regulatory perspective, zwitterionic coatings align well with increasingly stringent environmental legislation worldwide. As international maritime organizations and environmental protection agencies continue to restrict the use of biocidal antifouling systems, these non-toxic alternatives position industries for long-term compliance and reduced regulatory risk.

The end-of-life considerations for zwitterionic coatings also demonstrate environmental advantages. Their non-toxic nature simplifies disposal processes and reduces hazardous waste management requirements. Research into biodegradable zwitterionic polymers shows promise for creating fully sustainable coating systems that decompose harmlessly after their useful life, further minimizing environmental footprint.

Water conservation represents another significant benefit of these advanced coatings. By maintaining clean surfaces that require less aggressive cleaning, zwitterionic technologies reduce water consumption and wastewater generation associated with maintenance operations. This aspect is particularly valuable in water-stressed regions and applications where cleaning resources are limited or costly.

Life cycle assessment (LCA) studies of zwitterionic coatings reveal favorable environmental profiles. The production phase typically requires less energy and generates fewer greenhouse gas emissions compared to copper-based or tributyltin (TBT) alternatives. Additionally, the absence of leaching toxins during the use phase eliminates the bioaccumulation risks associated with traditional antifouling agents, protecting marine biodiversity and food chains from contamination.

The durability of zwitterionic coatings further enhances their sustainability credentials. With extended service lifespans, these coatings reduce the frequency of reapplication, minimizing waste generation and resource consumption over time. This longevity translates to reduced maintenance requirements for marine vessels and structures, yielding both economic and environmental benefits through decreased dry-docking frequency and associated energy expenditure.

From a regulatory perspective, zwitterionic coatings align well with increasingly stringent environmental legislation worldwide. As international maritime organizations and environmental protection agencies continue to restrict the use of biocidal antifouling systems, these non-toxic alternatives position industries for long-term compliance and reduced regulatory risk.

The end-of-life considerations for zwitterionic coatings also demonstrate environmental advantages. Their non-toxic nature simplifies disposal processes and reduces hazardous waste management requirements. Research into biodegradable zwitterionic polymers shows promise for creating fully sustainable coating systems that decompose harmlessly after their useful life, further minimizing environmental footprint.

Water conservation represents another significant benefit of these advanced coatings. By maintaining clean surfaces that require less aggressive cleaning, zwitterionic technologies reduce water consumption and wastewater generation associated with maintenance operations. This aspect is particularly valuable in water-stressed regions and applications where cleaning resources are limited or costly.

Regulatory Framework for Marine and Medical Coatings

The regulatory landscape governing zwitterionic coatings spans multiple jurisdictions and varies significantly between marine and medical applications. In the marine sector, the International Maritime Organization (IMO) has established the International Convention on the Control of Harmful Anti-fouling Systems on Ships (AFS Convention), which came into force in 2008. This convention specifically prohibits the use of harmful organotin compounds in anti-fouling paints and establishes a mechanism to prevent the potential future use of other harmful substances in anti-fouling systems.

The European Union has implemented the AFS Convention through Regulation (EC) No 782/2003, which restricts the application of organotin compounds on EU-flagged vessels. Additionally, the EU's Biocidal Products Regulation (BPR, Regulation (EU) 528/2012) governs the approval of active substances and authorization of biocidal products, including anti-fouling paints, requiring extensive environmental and toxicological data.

In the United States, the Environmental Protection Agency (EPA) regulates anti-fouling coatings under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) and the Toxic Substances Control Act (TSCA). The EPA's Vessel General Permit program also addresses discharges from anti-fouling coatings under the Clean Water Act.

For medical applications, zwitterionic coatings must comply with stringent biocompatibility and safety standards. In the US, the Food and Drug Administration (FDA) regulates medical devices with coatings under the Medical Device Regulation framework, requiring manufacturers to demonstrate safety and efficacy through premarket approval (PMA) or 510(k) clearance processes.

The EU Medical Device Regulation (MDR 2017/745) and In Vitro Diagnostic Regulation (IVDR 2017/746) impose comprehensive requirements for medical devices, including those with specialized coatings. These regulations mandate risk management, clinical evaluation, and post-market surveillance for coated medical devices.

ISO 10993 series standards for biological evaluation of medical devices are globally recognized benchmarks for testing biocompatibility of materials, including surface coatings. Specifically, ISO 10993-1 outlines the framework for biological evaluation, while other parts address specific aspects such as cytotoxicity, sensitization, and hemocompatibility.

Emerging regulations increasingly focus on sustainability aspects, with restrictions on persistent, bioaccumulative, and toxic substances. The development of zwitterionic coatings must therefore balance performance requirements with evolving regulatory constraints, particularly as these environmentally friendly alternatives gain prominence in replacing traditional biocide-based solutions.

The European Union has implemented the AFS Convention through Regulation (EC) No 782/2003, which restricts the application of organotin compounds on EU-flagged vessels. Additionally, the EU's Biocidal Products Regulation (BPR, Regulation (EU) 528/2012) governs the approval of active substances and authorization of biocidal products, including anti-fouling paints, requiring extensive environmental and toxicological data.

In the United States, the Environmental Protection Agency (EPA) regulates anti-fouling coatings under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) and the Toxic Substances Control Act (TSCA). The EPA's Vessel General Permit program also addresses discharges from anti-fouling coatings under the Clean Water Act.

For medical applications, zwitterionic coatings must comply with stringent biocompatibility and safety standards. In the US, the Food and Drug Administration (FDA) regulates medical devices with coatings under the Medical Device Regulation framework, requiring manufacturers to demonstrate safety and efficacy through premarket approval (PMA) or 510(k) clearance processes.

The EU Medical Device Regulation (MDR 2017/745) and In Vitro Diagnostic Regulation (IVDR 2017/746) impose comprehensive requirements for medical devices, including those with specialized coatings. These regulations mandate risk management, clinical evaluation, and post-market surveillance for coated medical devices.

ISO 10993 series standards for biological evaluation of medical devices are globally recognized benchmarks for testing biocompatibility of materials, including surface coatings. Specifically, ISO 10993-1 outlines the framework for biological evaluation, while other parts address specific aspects such as cytotoxicity, sensitization, and hemocompatibility.

Emerging regulations increasingly focus on sustainability aspects, with restrictions on persistent, bioaccumulative, and toxic substances. The development of zwitterionic coatings must therefore balance performance requirements with evolving regulatory constraints, particularly as these environmentally friendly alternatives gain prominence in replacing traditional biocide-based solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!