Marine Growth Prevention Using Smart Coating Systems

OCT 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Marine Biofouling Background and Prevention Goals

Marine biofouling represents one of the most persistent challenges in maritime industries, dating back to ancient seafaring civilizations. This phenomenon occurs when marine organisms such as barnacles, algae, mollusks, and microorganisms attach and grow on submerged surfaces, including ship hulls, offshore structures, and aquaculture equipment. Historical records indicate that early solutions involved copper sheathing on wooden vessels, demonstrating that this problem has been recognized for millennia.

The evolution of anti-fouling technologies has progressed through several distinct phases. Traditional methods relied heavily on toxic biocides, particularly tributyltin (TBT) compounds, which proved highly effective but caused severe environmental damage, leading to their global ban in the early 2000s. This regulatory shift catalyzed research into alternative solutions, including copper-based coatings and non-toxic approaches, marking a significant turning point in marine protection strategies.

Current market demands are driving the development of smart coating systems that can prevent biofouling while meeting increasingly stringent environmental regulations. These advanced solutions aim to address the estimated $15 billion annual global cost of marine biofouling, which manifests through increased fuel consumption, maintenance expenses, and reduced operational efficiency across maritime sectors.

The primary technical goals for modern marine growth prevention systems include developing coatings that provide long-term protection (5+ years), minimize environmental impact, reduce maintenance requirements, and maintain effectiveness across diverse marine environments. Smart coating technologies represent a promising frontier, incorporating responsive materials that can adapt to changing environmental conditions or trigger controlled release of anti-fouling agents only when needed.

Biomimetic approaches have emerged as a particularly innovative direction, drawing inspiration from natural anti-fouling mechanisms found in marine organisms like sharks, whose unique skin texture naturally deters biofouling. Similarly, enzyme-based systems and surface topography modifications offer potential for environmentally benign solutions that physically prevent organism attachment rather than relying on toxic effects.

The ultimate objective of current research efforts is to develop a new generation of smart coating systems that balance effective biofouling prevention with environmental sustainability, durability, and cost-effectiveness. This represents a significant shift from historical approaches that prioritized effectiveness regardless of environmental consequences, reflecting broader changes in industrial priorities and regulatory frameworks.

The evolution of anti-fouling technologies has progressed through several distinct phases. Traditional methods relied heavily on toxic biocides, particularly tributyltin (TBT) compounds, which proved highly effective but caused severe environmental damage, leading to their global ban in the early 2000s. This regulatory shift catalyzed research into alternative solutions, including copper-based coatings and non-toxic approaches, marking a significant turning point in marine protection strategies.

Current market demands are driving the development of smart coating systems that can prevent biofouling while meeting increasingly stringent environmental regulations. These advanced solutions aim to address the estimated $15 billion annual global cost of marine biofouling, which manifests through increased fuel consumption, maintenance expenses, and reduced operational efficiency across maritime sectors.

The primary technical goals for modern marine growth prevention systems include developing coatings that provide long-term protection (5+ years), minimize environmental impact, reduce maintenance requirements, and maintain effectiveness across diverse marine environments. Smart coating technologies represent a promising frontier, incorporating responsive materials that can adapt to changing environmental conditions or trigger controlled release of anti-fouling agents only when needed.

Biomimetic approaches have emerged as a particularly innovative direction, drawing inspiration from natural anti-fouling mechanisms found in marine organisms like sharks, whose unique skin texture naturally deters biofouling. Similarly, enzyme-based systems and surface topography modifications offer potential for environmentally benign solutions that physically prevent organism attachment rather than relying on toxic effects.

The ultimate objective of current research efforts is to develop a new generation of smart coating systems that balance effective biofouling prevention with environmental sustainability, durability, and cost-effectiveness. This represents a significant shift from historical approaches that prioritized effectiveness regardless of environmental consequences, reflecting broader changes in industrial priorities and regulatory frameworks.

Market Analysis for Smart Anti-fouling Solutions

The global market for smart anti-fouling solutions has experienced significant growth in recent years, driven primarily by increasing maritime activities and stricter environmental regulations. The marine coatings market, valued at approximately 3.3 billion USD in 2022, is projected to reach 5.1 billion USD by 2028, with smart anti-fouling solutions representing the fastest-growing segment at a compound annual growth rate of 8.7%.

Shipping industry demands constitute the largest market share, accounting for nearly 60% of total consumption. This dominance stems from the critical need to reduce fuel consumption and maintenance costs associated with biofouling on vessel hulls. Studies indicate that heavy marine growth can increase fuel consumption by up to 40%, translating to substantial operational expenses for shipping companies.

Offshore structures represent the second-largest market segment, with particular growth in offshore wind installations driving demand for long-lasting anti-fouling solutions. The global offshore wind capacity has tripled over the past decade, creating new application opportunities for advanced coating technologies.

Regionally, Asia-Pacific leads the market with approximately 45% share, attributed to extensive shipbuilding activities in China, South Korea, and Japan. Europe follows at 30%, driven by stringent environmental regulations and substantial investments in marine renewable energy. North America accounts for 20% of the market, with remaining regions constituting the balance.

Environmental regulations have significantly reshaped market dynamics. The International Maritime Organization's ban on tributyltin compounds and increasing restrictions on copper-based solutions have accelerated the shift toward environmentally friendly alternatives. This regulatory landscape has created substantial market opportunities for innovative, non-toxic smart coating systems.

Customer preferences are increasingly favoring solutions that offer extended service life and reduced maintenance requirements. Market research indicates willingness to pay premium prices for coatings that can demonstrate tangible operational cost reductions through decreased fuel consumption and extended dry-docking intervals.

Emerging market trends include integration of nanotechnology, biomimetic approaches, and self-healing capabilities. Solutions incorporating real-time monitoring and adaptive response mechanisms are gaining traction, particularly in high-value maritime assets. The market is also witnessing increased collaboration between coating manufacturers, marine engineering firms, and technology providers to develop comprehensive anti-fouling systems.

Future market growth is expected to be driven by expanding aquaculture operations, increasing deployment of ocean monitoring systems, and growing investments in marine renewable energy infrastructure. These emerging application areas present significant opportunities for specialized smart coating solutions tailored to specific operational environments and performance requirements.

Shipping industry demands constitute the largest market share, accounting for nearly 60% of total consumption. This dominance stems from the critical need to reduce fuel consumption and maintenance costs associated with biofouling on vessel hulls. Studies indicate that heavy marine growth can increase fuel consumption by up to 40%, translating to substantial operational expenses for shipping companies.

Offshore structures represent the second-largest market segment, with particular growth in offshore wind installations driving demand for long-lasting anti-fouling solutions. The global offshore wind capacity has tripled over the past decade, creating new application opportunities for advanced coating technologies.

Regionally, Asia-Pacific leads the market with approximately 45% share, attributed to extensive shipbuilding activities in China, South Korea, and Japan. Europe follows at 30%, driven by stringent environmental regulations and substantial investments in marine renewable energy. North America accounts for 20% of the market, with remaining regions constituting the balance.

Environmental regulations have significantly reshaped market dynamics. The International Maritime Organization's ban on tributyltin compounds and increasing restrictions on copper-based solutions have accelerated the shift toward environmentally friendly alternatives. This regulatory landscape has created substantial market opportunities for innovative, non-toxic smart coating systems.

Customer preferences are increasingly favoring solutions that offer extended service life and reduced maintenance requirements. Market research indicates willingness to pay premium prices for coatings that can demonstrate tangible operational cost reductions through decreased fuel consumption and extended dry-docking intervals.

Emerging market trends include integration of nanotechnology, biomimetic approaches, and self-healing capabilities. Solutions incorporating real-time monitoring and adaptive response mechanisms are gaining traction, particularly in high-value maritime assets. The market is also witnessing increased collaboration between coating manufacturers, marine engineering firms, and technology providers to develop comprehensive anti-fouling systems.

Future market growth is expected to be driven by expanding aquaculture operations, increasing deployment of ocean monitoring systems, and growing investments in marine renewable energy infrastructure. These emerging application areas present significant opportunities for specialized smart coating solutions tailored to specific operational environments and performance requirements.

Current Smart Coating Technologies and Challenges

Smart coating technologies for marine growth prevention have evolved significantly in recent years, with several innovative approaches emerging to address biofouling challenges. Currently, the market offers various categories of smart coating systems, each with distinct mechanisms and applications. Self-polishing copolymer (SPC) coatings represent one of the most widely adopted technologies, gradually releasing biocides through hydrolysis when exposed to seawater. These coatings provide effective protection for 3-5 years but face increasing regulatory scrutiny due to environmental concerns regarding biocide leaching.

Fouling release coatings (FRCs) based on silicone or fluoropolymer technologies have gained prominence as environmentally friendly alternatives. These coatings create ultra-smooth, low surface energy interfaces that prevent strong adhesion of marine organisms. While effective at higher vessel speeds (typically above 15 knots), their performance diminishes significantly at lower speeds or during static conditions, limiting their application range.

Biomimetic coatings represent an emerging frontier, drawing inspiration from natural antifouling mechanisms found in marine organisms like sharks, mussels, and certain seaweeds. These coatings replicate micro-textured surfaces or incorporate naturally-derived compounds to deter settlement of marine organisms without relying on toxic biocides. Though promising, many biomimetic solutions remain in developmental stages, facing challenges in durability and scalable manufacturing.

Smart responsive coatings that can adapt to environmental stimuli constitute another innovative approach. These include coatings that change properties in response to pH, temperature, light, or electrical stimulation. For instance, some systems can alter surface characteristics when triggered, releasing accumulated fouling organisms without manual intervention. However, the complexity of these systems often results in higher costs and reliability concerns in harsh marine environments.

Despite these advancements, significant challenges persist in smart coating development. Durability remains a primary concern, as marine environments subject coatings to extreme conditions including UV radiation, temperature fluctuations, mechanical abrasion, and aggressive chemical exposure. Most current solutions struggle to maintain performance beyond 5 years without maintenance, falling short of the ideal 10+ year service life desired by the industry.

Environmental compliance presents another major challenge, with increasingly stringent regulations restricting the use of biocides and other potentially harmful compounds. The International Maritime Organization (IMO) and regional authorities continue to implement stricter controls on coating compositions, driving the need for more sustainable alternatives.

Cost-effectiveness also remains problematic, as advanced smart coating systems typically command premium prices that can be 3-5 times higher than conventional antifouling paints. This economic barrier limits widespread adoption, particularly in cost-sensitive shipping segments and developing markets.

Fouling release coatings (FRCs) based on silicone or fluoropolymer technologies have gained prominence as environmentally friendly alternatives. These coatings create ultra-smooth, low surface energy interfaces that prevent strong adhesion of marine organisms. While effective at higher vessel speeds (typically above 15 knots), their performance diminishes significantly at lower speeds or during static conditions, limiting their application range.

Biomimetic coatings represent an emerging frontier, drawing inspiration from natural antifouling mechanisms found in marine organisms like sharks, mussels, and certain seaweeds. These coatings replicate micro-textured surfaces or incorporate naturally-derived compounds to deter settlement of marine organisms without relying on toxic biocides. Though promising, many biomimetic solutions remain in developmental stages, facing challenges in durability and scalable manufacturing.

Smart responsive coatings that can adapt to environmental stimuli constitute another innovative approach. These include coatings that change properties in response to pH, temperature, light, or electrical stimulation. For instance, some systems can alter surface characteristics when triggered, releasing accumulated fouling organisms without manual intervention. However, the complexity of these systems often results in higher costs and reliability concerns in harsh marine environments.

Despite these advancements, significant challenges persist in smart coating development. Durability remains a primary concern, as marine environments subject coatings to extreme conditions including UV radiation, temperature fluctuations, mechanical abrasion, and aggressive chemical exposure. Most current solutions struggle to maintain performance beyond 5 years without maintenance, falling short of the ideal 10+ year service life desired by the industry.

Environmental compliance presents another major challenge, with increasingly stringent regulations restricting the use of biocides and other potentially harmful compounds. The International Maritime Organization (IMO) and regional authorities continue to implement stricter controls on coating compositions, driving the need for more sustainable alternatives.

Cost-effectiveness also remains problematic, as advanced smart coating systems typically command premium prices that can be 3-5 times higher than conventional antifouling paints. This economic barrier limits widespread adoption, particularly in cost-sensitive shipping segments and developing markets.

Existing Smart Coating System Solutions

01 Anti-fouling coatings with biocidal agents

Smart coating systems for marine growth prevention often incorporate biocidal agents that actively prevent the attachment and growth of marine organisms. These coatings release controlled amounts of biocides that deter or eliminate fouling organisms such as barnacles, algae, and mollusks. The formulations typically include copper compounds, zinc pyrithione, or other environmentally acceptable biocides that provide long-term protection against marine growth while minimizing environmental impact.- Anti-fouling coatings with biocidal agents: Smart coating systems for marine growth prevention often incorporate biocidal agents that actively inhibit the attachment and growth of marine organisms on submerged surfaces. These coatings typically contain compounds that are released at a controlled rate to create an environment hostile to barnacles, algae, and other fouling organisms. The formulations may include copper compounds, zinc pyrithione, or other environmentally acceptable biocides that provide long-term protection against marine biofouling.

- Self-polishing copolymer coatings: Self-polishing copolymer coatings represent an advanced approach to marine growth prevention. These smart coating systems gradually wear away through controlled hydrolysis when exposed to seawater, continuously revealing fresh biocidal layers. This self-renewing mechanism ensures consistent anti-fouling performance throughout the coating's service life. The hydrolysis rate can be engineered to match specific operational conditions, providing optimal protection for various marine applications while minimizing environmental impact.

- Silicone-based foul-release coatings: Silicone-based foul-release coatings prevent marine growth through physical rather than chemical means. These smart coating systems create an ultra-smooth, low surface energy interface that makes it difficult for marine organisms to establish strong attachment. When vessels move through water, even weakly attached organisms are easily washed away by hydrodynamic forces. These environmentally friendly coatings do not rely on biocides but instead on their unique surface properties to maintain clean hulls and underwater structures.

- Nanostructured and hybrid coating systems: Nanostructured and hybrid coating systems combine multiple technologies to prevent marine growth. These advanced formulations may incorporate nanomaterials that modify surface topography at the microscopic level, creating patterns that discourage organism settlement. Hybrid systems often integrate conventional biocides with novel delivery mechanisms or combine foul-release properties with active compounds. This multi-functional approach provides enhanced protection against diverse marine fouling organisms under various environmental conditions.

- Electroactive and stimuli-responsive coatings: Electroactive and stimuli-responsive coatings represent cutting-edge smart systems for marine growth prevention. These innovative coatings can change their properties in response to external stimuli such as electrical current, pH changes, or mechanical stress. Some systems generate oxidizing species on demand or alter surface characteristics to deter organism attachment. Others may incorporate conductive polymers that, when activated, create an environment inhospitable to marine growth, providing an environmentally sustainable alternative to traditional biocidal approaches.

02 Self-polishing copolymer coatings

Self-polishing copolymer coatings represent an advanced approach to marine growth prevention. These smart coating systems gradually wear away through controlled hydrolysis when exposed to seawater, continuously revealing fresh biocidal layers. This self-renewing mechanism ensures consistent anti-fouling performance throughout the coating's lifespan. The controlled erosion rate helps maintain an optimal release of active ingredients while reducing the accumulation of depleted coating layers, extending the effective service life of marine structures.Expand Specific Solutions03 Silicone-based foul-release coatings

Silicone-based foul-release coatings provide a non-toxic alternative for marine growth prevention. These smart coating systems create an ultra-smooth, low surface energy interface that makes it difficult for marine organisms to establish strong attachments. Rather than killing marine life, these coatings work by creating a surface from which fouling organisms can be easily removed by water flow or minimal mechanical cleaning. The silicone polymers maintain flexibility and non-stick properties over extended periods, making them particularly suitable for vessels that maintain regular movement through water.Expand Specific Solutions04 Nanostructured and hybrid coating systems

Nanostructured and hybrid coating systems combine multiple technologies to enhance marine growth prevention. These smart coatings incorporate nanomaterials such as carbon nanotubes, graphene, or metal oxide nanoparticles to create surfaces with unique physical and chemical properties. The nanostructured surfaces can disrupt biofilm formation through altered surface topography while simultaneously releasing anti-fouling compounds. Hybrid systems may combine conventional biocides with novel release mechanisms or physical deterrents, providing synergistic protection against diverse marine organisms in various environmental conditions.Expand Specific Solutions05 Electro-active and stimuli-responsive coatings

Electro-active and stimuli-responsive coatings represent cutting-edge smart systems for marine growth prevention. These coatings can change their properties in response to external stimuli such as electrical current, pH changes, or mechanical stress. Some systems use low-voltage electrical fields to prevent organism attachment, while others may alter surface characteristics in response to environmental triggers. These dynamic coating systems can adapt to changing conditions, activating anti-fouling mechanisms only when needed, which improves efficiency and reduces environmental impact compared to continuously active traditional coatings.Expand Specific Solutions

Leading Companies in Smart Coating Industry

Marine Growth Prevention Using Smart Coating Systems is currently in a growth phase, with the market expanding due to increasing maritime activities and environmental regulations. The global smart marine coatings market is estimated to reach $10-12 billion by 2027, growing at 5-7% CAGR. Technologically, the field is advancing rapidly with varying maturity levels across solutions. Industry leaders like Jotun AS, Hempel A/S, and Chugoku Marine Paints have established commercial antifouling systems, while companies such as Shell, ABB Group, and Elkem Silicones are developing next-generation smart coatings with self-healing and responsive properties. Research institutions including the Naval Research Laboratory, National University of Singapore, and Agency for Science, Technology & Research are driving innovation in environmentally friendly biocide-free solutions, indicating a shift toward sustainable technologies in this competitive landscape.

Chugoku Marine Paints, Ltd.

Technical Solution: Chugoku Marine Paints has developed advanced self-polishing copolymer (SPC) technology for marine growth prevention. Their SEAFLO NEO series incorporates hydrolysis technology that creates a constantly renewing surface through controlled polymer degradation when exposed to seawater. This mechanism ensures consistent biocide release rates throughout the coating's lifetime, maintaining antifouling performance for up to 90 months. Their latest innovation includes silyl acrylate polymer technology that optimizes hydrolysis rates based on vessel operating conditions and water temperature. The company has also introduced copper-free alternatives using novel zinc-based biocides combined with organic co-biocides that reduce environmental impact while maintaining effectiveness against barnacles, algae, and other marine organisms.

Strengths: Industry-leading longevity with 90-month effectiveness; precise control of biocide release rates; adaptable to various vessel operating profiles. Weaknesses: Still relies on biocide release which faces increasing regulatory scrutiny; higher initial cost compared to conventional coatings; performance may vary in extreme temperature conditions.

Elkem Silicones France SASU

Technical Solution: Elkem Silicones has developed advanced fouling release coating systems based on their proprietary silicone elastomer technology. Their SILOFLEX marine coating platform utilizes modified polydimethylsiloxane (PDMS) polymers with engineered surface topography at the microscale to create ultra-low surface energy interfaces that prevent marine organism adhesion. The company's smart coating systems incorporate amphiphilic copolymers that create a dynamic surface chemistry, adapting to different marine environments and organism settlement strategies. Elkem's latest innovation includes self-healing silicone matrices that can repair microscopic damage through reversible crosslinking mechanisms, extending coating longevity. Their coatings also feature embedded fluorescent markers that change color patterns when coating effectiveness diminishes, providing visual indicators for maintenance timing without requiring sophisticated monitoring equipment.

Strengths: Non-biocidal approach meets stringent environmental regulations; excellent longevity with self-healing capabilities; simple visual monitoring system. Weaknesses: Higher initial application costs; requires specialized application techniques; less effective in static or slow-moving vessel applications.

Key Innovations in Anti-fouling Technology

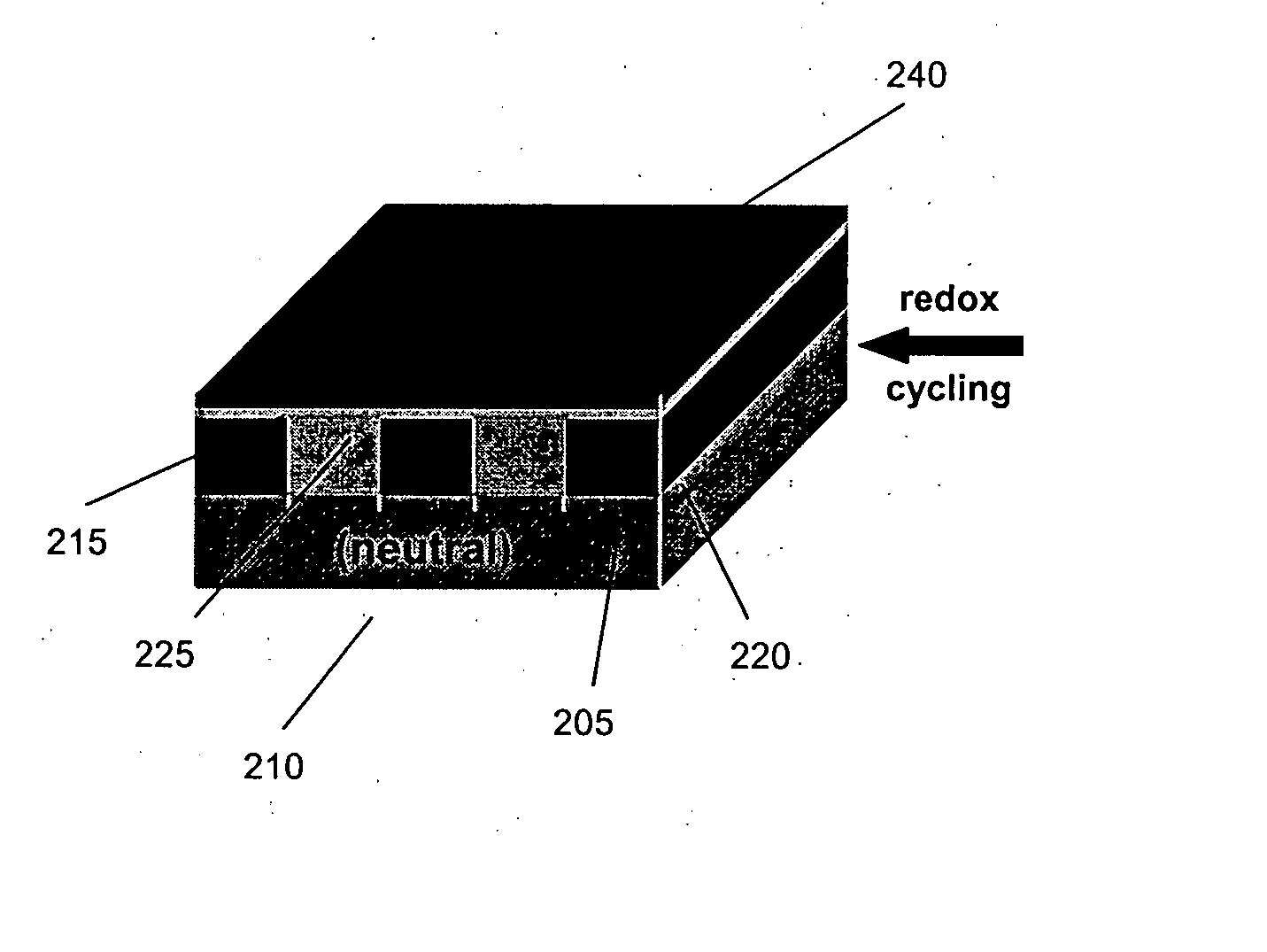

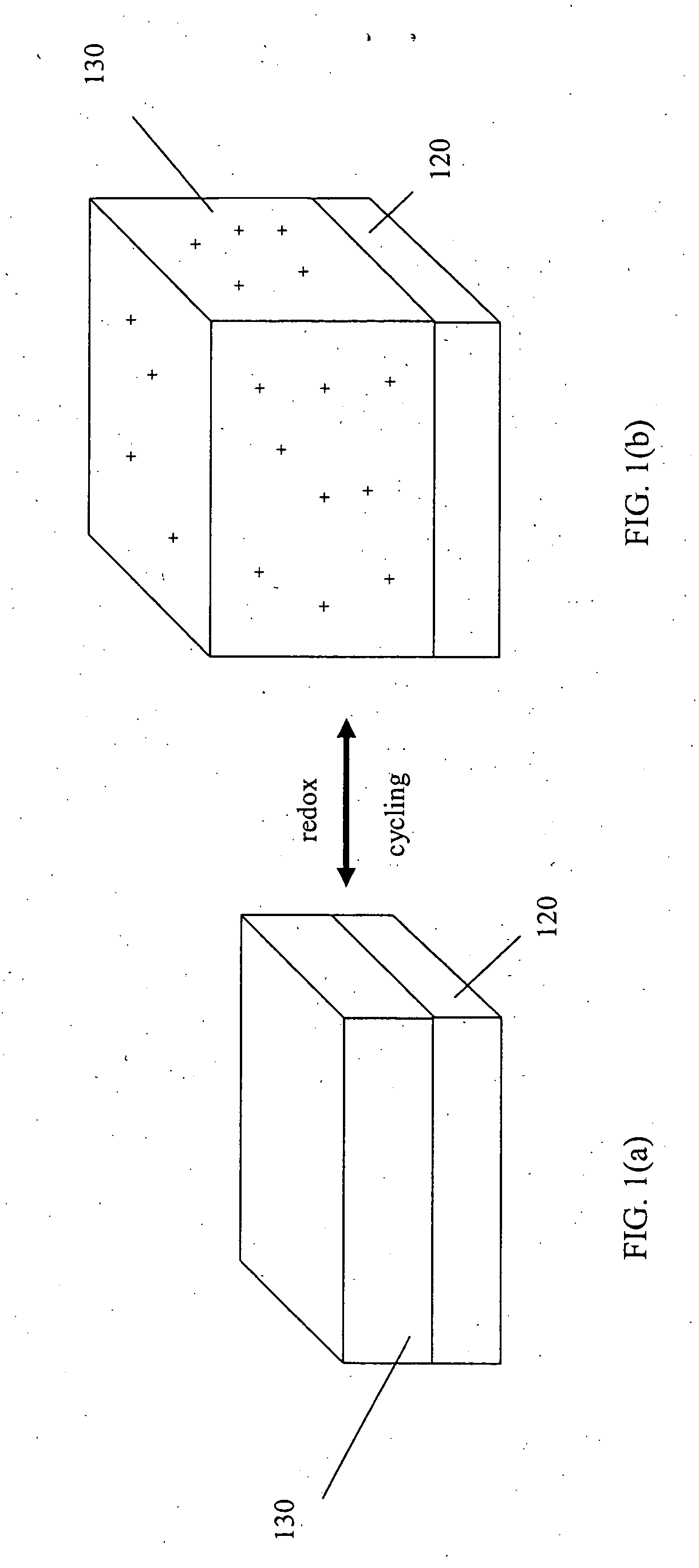

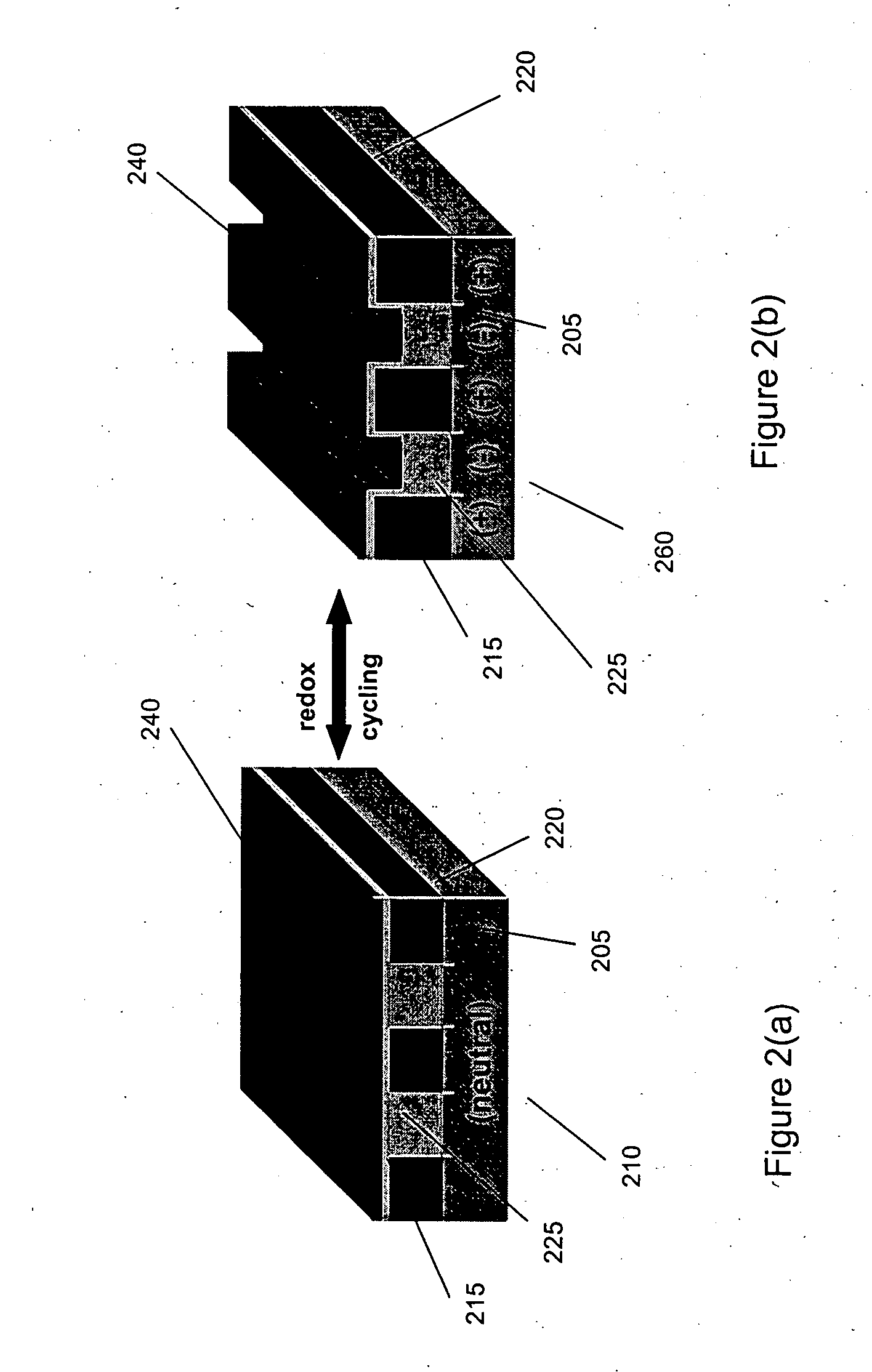

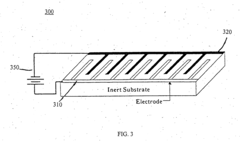

Dynamically modifiable polymer coatings and devices

PatentInactiveUS20050178286A1

Innovation

- A dynamic polymer-based coating with an electrically conducting polymer layer that changes contact angle and surface roughness in response to oxidation and reduction, providing a non-toxic, long-lasting biofouling prevention system by dynamically altering surface energy and topography.

Marine antifoulant coating

PatentInactiveUS20120094032A1

Innovation

- A protective coating comprising a polymer, a marine biocide, a preservative, and an antimicrobial agent, chemically bonded to prevent leaching and enhance longevity, applied using a process involving heating and electric field alignment to maximize bonding, followed by plasma treatment for adherence.

Environmental Impact Assessment

The environmental impact of marine growth prevention systems, particularly smart coating technologies, requires comprehensive assessment to ensure sustainable maritime operations. Traditional antifouling methods have historically relied on toxic compounds that leach into marine environments, causing significant ecological damage. Smart coating systems represent a paradigm shift toward more environmentally responsible solutions, but their impacts must be thoroughly evaluated.

Smart coating technologies demonstrate significantly reduced ecotoxicity compared to conventional copper and tributyltin (TBT) based coatings. Laboratory studies indicate that advanced silicone-based foul-release coatings show minimal bioaccumulation in marine organisms and substantially lower toxicity to non-target species. Field monitoring at various deployment sites confirms reduced chemical leaching rates, with some next-generation coatings showing up to 90% less biocide release than traditional alternatives.

Lifecycle assessment (LCA) data reveals that smart coating systems generally exhibit lower environmental footprints across production, application, use, and disposal phases. The extended service life of these coatings—typically 5-7 years compared to 2-3 years for conventional systems—reduces the frequency of reapplication and associated environmental disruptions. However, certain polymer-based components in some smart coatings present end-of-life disposal challenges that require further innovation.

Biodiversity impact studies conducted in various marine ecosystems demonstrate that vessels utilizing smart coating technologies show reduced "biological pollution" effects when traveling between different biogeographical regions. The decreased transport of invasive species represents a significant ecological benefit that extends beyond the immediate chemical impact considerations.

Energy efficiency improvements resulting from smart coating applications contribute to reduced carbon emissions across maritime operations. Vessels with optimized hull surfaces experience decreased drag, leading to fuel consumption reductions of 5-15% depending on vessel type and operational profile. This translates to meaningful reductions in greenhouse gas emissions from the global shipping fleet.

Regulatory frameworks worldwide are increasingly recognizing the environmental advantages of smart coating technologies. The International Maritime Organization's (IMO) biofouling guidelines and regional regulations like the European Union's Biocidal Products Regulation are evolving to incentivize adoption of environmentally preferable solutions while establishing monitoring protocols to verify environmental performance claims.

Future environmental assessment priorities should focus on long-term ecological monitoring, standardization of testing methodologies, and development of comprehensive end-of-life management strategies for advanced coating materials to ensure their full environmental benefits are realized throughout the complete product lifecycle.

Smart coating technologies demonstrate significantly reduced ecotoxicity compared to conventional copper and tributyltin (TBT) based coatings. Laboratory studies indicate that advanced silicone-based foul-release coatings show minimal bioaccumulation in marine organisms and substantially lower toxicity to non-target species. Field monitoring at various deployment sites confirms reduced chemical leaching rates, with some next-generation coatings showing up to 90% less biocide release than traditional alternatives.

Lifecycle assessment (LCA) data reveals that smart coating systems generally exhibit lower environmental footprints across production, application, use, and disposal phases. The extended service life of these coatings—typically 5-7 years compared to 2-3 years for conventional systems—reduces the frequency of reapplication and associated environmental disruptions. However, certain polymer-based components in some smart coatings present end-of-life disposal challenges that require further innovation.

Biodiversity impact studies conducted in various marine ecosystems demonstrate that vessels utilizing smart coating technologies show reduced "biological pollution" effects when traveling between different biogeographical regions. The decreased transport of invasive species represents a significant ecological benefit that extends beyond the immediate chemical impact considerations.

Energy efficiency improvements resulting from smart coating applications contribute to reduced carbon emissions across maritime operations. Vessels with optimized hull surfaces experience decreased drag, leading to fuel consumption reductions of 5-15% depending on vessel type and operational profile. This translates to meaningful reductions in greenhouse gas emissions from the global shipping fleet.

Regulatory frameworks worldwide are increasingly recognizing the environmental advantages of smart coating technologies. The International Maritime Organization's (IMO) biofouling guidelines and regional regulations like the European Union's Biocidal Products Regulation are evolving to incentivize adoption of environmentally preferable solutions while establishing monitoring protocols to verify environmental performance claims.

Future environmental assessment priorities should focus on long-term ecological monitoring, standardization of testing methodologies, and development of comprehensive end-of-life management strategies for advanced coating materials to ensure their full environmental benefits are realized throughout the complete product lifecycle.

Regulatory Compliance Framework

The regulatory landscape for marine coatings has evolved significantly in response to growing environmental concerns about traditional antifouling systems. The International Maritime Organization (IMO) established a pivotal framework through the International Convention on the Control of Harmful Anti-fouling Systems on Ships (AFS Convention), which came into force in 2008. This convention specifically prohibits the use of harmful organotins in anti-fouling paints and establishes a mechanism to prevent the future use of other harmful substances in anti-fouling systems.

Smart coating systems must comply with additional regulations including the European Union's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which controls the use of chemical substances that may have adverse effects on human health or the environment. The EU Biocidal Products Regulation (BPR) further regulates substances designed to control harmful organisms, directly impacting the development and deployment of biocide-releasing smart coatings.

In the United States, the Environmental Protection Agency (EPA) regulates antifouling coatings under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring registration of biocidal components. Additionally, the Vessel General Permit (VGP) program establishes discharge requirements for commercial vessels, including limitations on leaching from hull coatings.

Regional variations in regulatory frameworks present significant challenges for global deployment of smart coating technologies. Asian markets, particularly China, Japan, and South Korea, have implemented their own chemical management systems that may require separate certification processes. Australia and New Zealand maintain particularly stringent biosecurity regulations due to their unique marine ecosystems.

Compliance certification for smart coating systems typically involves a multi-phase testing protocol including laboratory leaching studies, ecotoxicological assessments, and field trials to demonstrate efficacy without environmental harm. Documentation requirements include comprehensive chemical composition disclosure, environmental impact assessments, and ongoing monitoring plans.

Future regulatory trends indicate movement toward more harmonized international standards while simultaneously increasing restrictions on biocidal components. The development of "green chemistry" standards specifically for marine applications is gaining momentum, with potential certification schemes for environmentally preferable coating technologies. Companies developing smart coating systems must therefore implement robust regulatory monitoring systems and engage proactively with regulatory bodies during product development phases.

Successful navigation of this complex regulatory landscape requires cross-functional expertise spanning marine engineering, environmental science, and legal compliance. Organizations must establish dedicated compliance teams that can interpret evolving regulations across multiple jurisdictions and translate requirements into practical product development guidelines.

Smart coating systems must comply with additional regulations including the European Union's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which controls the use of chemical substances that may have adverse effects on human health or the environment. The EU Biocidal Products Regulation (BPR) further regulates substances designed to control harmful organisms, directly impacting the development and deployment of biocide-releasing smart coatings.

In the United States, the Environmental Protection Agency (EPA) regulates antifouling coatings under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring registration of biocidal components. Additionally, the Vessel General Permit (VGP) program establishes discharge requirements for commercial vessels, including limitations on leaching from hull coatings.

Regional variations in regulatory frameworks present significant challenges for global deployment of smart coating technologies. Asian markets, particularly China, Japan, and South Korea, have implemented their own chemical management systems that may require separate certification processes. Australia and New Zealand maintain particularly stringent biosecurity regulations due to their unique marine ecosystems.

Compliance certification for smart coating systems typically involves a multi-phase testing protocol including laboratory leaching studies, ecotoxicological assessments, and field trials to demonstrate efficacy without environmental harm. Documentation requirements include comprehensive chemical composition disclosure, environmental impact assessments, and ongoing monitoring plans.

Future regulatory trends indicate movement toward more harmonized international standards while simultaneously increasing restrictions on biocidal components. The development of "green chemistry" standards specifically for marine applications is gaining momentum, with potential certification schemes for environmentally preferable coating technologies. Companies developing smart coating systems must therefore implement robust regulatory monitoring systems and engage proactively with regulatory bodies during product development phases.

Successful navigation of this complex regulatory landscape requires cross-functional expertise spanning marine engineering, environmental science, and legal compliance. Organizations must establish dedicated compliance teams that can interpret evolving regulations across multiple jurisdictions and translate requirements into practical product development guidelines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!